How to sharpen a chainsaw chain with a file

Sharpening the chain with a file

This type of sharpening can be used directly in the field. It requires a round file, a holder for it (clamp) and a vise for clamping the tire.

To sharpen with a file, you need to perform the following manipulations:

- Clamp the tire in a vice. If you are in landing and did not take a vise with you, then you can clamp the tire by resting it on the log.

- Place the clip with the file on the chain so that it creates an angle of 30 °.

- With light movements forward (away from yourself), we sharpen the tooth. With a new file, it is enough to make 5. 7 movements. If the file has already been used several times, then more movements will be required.

- After the tooth has been sharpened, remove the file with a clip and scroll the chain to the next tooth. After passing all the right teeth, turn the saw (or change the position of the file) and sharpen the left teeth.

Some file holders have a filed template on which the turning angle is already indicated. So you do not have to “figure out” this angle. But from experience we will say that you need to practice well until it turns out to sharpen the chain perfectly smoothly with a file.

Saw chain sharpening methods

There are three ways to sharpen your saw chain effectively:

- File.

- Angle Grinder.

- Sharpening machine.

Method 2

In this case, it is the angle grinder that needs to be fixed immovably. Can be clamped in a vise or screwed to a workbench with a bracket. Sharpening is done as on a conventional grinding wheel. We hold the chain with our hands and turn it so that the tooth sharpens at an angle of 30 °.

With this method, hands are less tired, since you need to hold the chain, and not the angle grinder. However, the chance of getting injured increases significantly. We recommend using this method infrequently or not at all, since safety is still more important than speed or quality of sharpening.

How to sharpen a chainsaw chain with your own hands: 3 proven methods

The quality of sawing wood with a chainsaw largely depends on the sharpness of the chain. How to sharpen a chainsaw chain with your own hands at home? We will tell you about three good ways.

The speed and quality of sawing wood with a chain saw depends on the sharpness of the chain. It needs to be sharpened from time to time. How can this be done? We will tell you about three reliable ways in which you can sharpen a chain with your own hands. One of them allows you to sharpen the chain right in the field, while the other two require a special tool and electricity.

Method 1

We install the chainsaw on the table, and clamp the tire with a vice so that it does not move during operation. We set low revolutions on the angle grinder (if there is only smooth adjustment, then slightly press the start button). We direct the disc at an angle of 30 ° relative to the plane of the tooth and tilt it slightly (as shown in the photo). Press on the tooth with light, soft movements.

With this method, the main thing is not to overheat the tooth and not to grind off too much metal. Ditching teeth, sharpening in this way, is much easier than with a hand file, but the sharpening speed increases significantly.

Chain design

The saw chain consists of the following elements:

- Left cutting tooth.

- Right cutting tooth.

- Cutting depth stop.

- Leading link.

- Rivet.

In order for the chain to saw well, it is necessary to sharpen each tooth on the left and right sides. However, in order not to spoil the sharpening, it is important to know what shape our teeth on the chain are. There are two common forms of saw teeth:

- Chipper. This is the more common tooth shape and is found in almost all chains. Here the profile is somewhat rounded, so it is much easier to sharpen it with a round file. In practice, however, the chipper dulls a little faster than the chisel.

- Chisel. The cutter profile in this case looks like a seven. Such a cutter has a rather small contact area when it comes into contact with wood, so it encounters less resistance. For this reason, in one cut, he makes a greater depth of cut, which means that the speed of cutting a log will be higher (in comparison with a chipper). But sharpening it without damaging the edge is much more difficult.

Chain sharpening angle grinder

If you have an angle grinder, you can sharpen your chainsaw chain much faster. It is best to use a small, 125-disc angle grinder. Sharpening is done at low speeds. There are two ways to sharpen an angle grinder.

How to sharpen a chain on a chainsaw with your own hands

A person who has a chainsaw in his household should know how to sharpen a chainsaw chain with his own hands. There are several ways:

- Sharpening with a file (the most common method of sharpening, because it allows you to sharpen the tool directly at the cutting site.)

- Sharpening using a special machine (this method is used in service centers, but can also be used on a personal farm)

- Sharpen using an angle grinder. To sharpen in this way, certain skills are required. Uncommon method, because it is quite difficult to sharpen with an angle grinder correctly.

In this video, you can familiarize yourself with the sharpening process, the most popular methods and tools used for this.

Description of the sharpening process with files

The first thing to start with straightening the saw chain on the saw is placing the tool on a flat surface or table. In forest conditions, a large diameter chock is well suited for this. Next, you need to inspect the saw chain for any defects, it can be cracks, completely broken off teeth. After inspection, you need to set the brake in working condition, thereby blocking its movement on the tire.

The chain must be taut when sharpening with a file.

It is advisable to put a stand under the tire, as it you can use a log, a piece of a branch of a suitable diameter, or the manufacturers of sharpening tools have special clamps to hold the bar in the process of sharpening the chain.

The chain is sharpened by moving the file from the inside of the tooth outward. In this case, the file should be located parallel to the special mark on the chain. This mark is applied by the chain manufacturer to indicate the standard sharpening angle.

The sharpened tooth should be located approximately in the middle of the tire, this is necessary for the convenience of work, during the sharpening process, you need to move the chain along the tire, not forgetting to set the brake to the working position each time.

Work on sharpening the chain on a chainsaw must be carried out using gloves made of coarse material, otherwise it is quite easy to injure yourself, because the working surface of the teeth is very sharp.

Ideally, manufacturers advise to make the same number of file movements for each tooth, but in practice this is not always possible. teeth have different degrees of damage to the working edge.

To facilitate sharpening the saw chain with a file, special holders can be used, with corner markings applied to them. The markings are made not only for the standard cross-cut, but also for the longitudinal.

Tool holders are also handy if you don’t have sufficient sharpening experience. Experienced sharpeners do not use holders for sharpening, but can only use special devices that support the file.

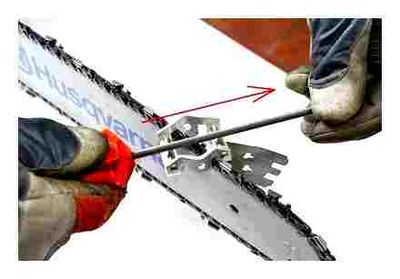

Another sharpening device is a hand-held saw chain straightener. It uses a regular file as a sharpening tool, which can be replaced independently. The machine is mounted directly on the tire, it also has the ability to adjust the angle of sharpening of the tooth and a special stop that holds the sharpened tooth.

Manual sharpening machine, perfect for beginners. Along with electric models of sharpening machines, manual has its undeniable plus in the form of a low price. Depending on the manufacturer of the hand-held machine, their appearance may differ, but the principle of operation is the same for all.

The depth of cut is adjusted with a flat file, so that there is a difference between the upper cutting edge of the tooth and the height stop.

As you can see from the figure, the depth gauge is grinded in such a way as to bring the gap indicator to the factory value. Below is a table that shows the main values of the angles, as well as clearances for the most common types of chains.

As a rule, the size of the gap is corrected using a special die. It is installed on the chain during sharpening, after which the depth gauge is grinded.

Sharpening with a file

The first thing you need to sharpen the chain, or tweak it a little, are special files.

File

For sharpening and straightening saw chains, two types of files are used. The first is a round file with a diameter corresponding to the diameter of the rounding of the working edge of the saw tooth.

For sharpening saw chains of household tools, round files with a diameter of 4, 4.8 mm are used, due to the fact that they have a small tooth. For professional models, more powerful chains with a larger tooth are used, and accordingly files with a diameter of 5.2, 5.5 mm are needed.

In order to sharpen correctly, it is not enough to sharpen only the cutting edges of the tooth, you also need to adjust the cutting depth limiter. If this is not done, the chain will not cut into the material being cut to the required depth, which will noticeably reduce the speed of work and, just like in a situation with a blunt chain, can lead to overheating of the saw motor due to insufficient load on the motor. This work is done with a flat file.

Electric grinding machines

For straightening a large number of chains, as a rule, in service centers or in manufacturing plants, electric sharpening machines are used. Depending on the manufacturer, the design of the machines may vary, but they have the same principle of operation.

The saw chain is installed in a special guide, which is mounted on the basis of the turntable and has a special retainer to hold the sharpened tooth. The latch can be moved horizontally. An electric emery is installed at an adjustable angle to the sharpened tooth, which is turned on by the operator by pressing the start button. The immersion depth of the emery, as well as the angle at which the sharpening is performed, can be adjusted. The dive itself is performed by the operator. The chain is straightened with a special sharpening wheel, which can be changed if necessary.

How to sharpen a chainsaw chain with your own hands

Everyone knows that the saw chain, which is used in chainsaws, needs to be sharpened periodically, but not everyone knows how to do it correctly. Determining that the saw requires sharpening the chain is very simple, for this you need to inspect the sawdust, and if they consist of fine dust, then the tool needs to be sharpened. If it is impossible to sharpen, it is worth replacing it with a new one.

The use of a chain that is not sharpened can lead to overheating of the engine and the formation of scoring on the cylinder.

Technical Tips- How To Sharpen Chainsaw Chain

We will analyze the main ways with which you can, without problems, sharpen the chain on a chainsaw.

- How to sharpen a chain on a chainsaw with your own hands

- Sharpening with a file

- File

- Description of the sharpening process with files

- Electric grinding machines

- How to sharpen with an angle grinder (angle grinder)

How to sharpen with an angle grinder (angle grinder)

The method of sharpening the saw chain using an angle grinder, the least common due to its insecurity. In order to straighten the teeth of the chain using an angle grinder as a sharpening tool, it is necessary to install it in a vice and clamp it securely. Then the tool is switched on and the sharpened edge of the tooth is placed on the rotating surface of the disc. A tooth sharpened in this way can differ significantly from that sharpened with a file, because in the process of dressing using an angle grinder, it is rather difficult to control the sharpening angle.

A big disadvantage can be considered the possibility of a notch with an angle grinder with an angle grinder of the eyelet for attaching the connecting link of the chain, which in the future will lead to rupture during work. If, in the process of carrying out work using a chainsaw, the need arose for sharpening, it is better to use a special tool than to come up with various tricks that can result not only in financial losses, but cause serious injuries during their implementation.

Sharpening the chain is not as difficult as it seems at first glance. Any person, after studying the process of straightening chains, is able to sharpen the cutting set of his tool on his own. Even if the first time you manage to do it not very well, you should not despair, because with every next try, the result will be better and better.

How to understand that the chain is dull?

There are several signs by which you can understand that the chain is currently not suitable for work:

- You need to put in more physical effort for the same action.

- Chain stretch.

- Feeling of vibration when using the tool.

- Unevenness of sawdust, which, moreover, becomes more like dust.

The chain can also become dull for several reasons:

- Improper handling.

- Contact with objects that are too hard, such as stones.

- Overly voluminous and long-term work.

We sharpen the chainsaw chain with our own hands. All possible and available ways

“The lumberjack working with a blunt ax was advised:. Sharpen the ax.

He replied:. There is no time. It is necessary to cut down the forest. “

Greetings to all readers!

Today I decided to tell you about the tool, without which, as it seems to me, today it is simply impossible. A good tool should work well, and this largely depends on its owner.

Cleaning the autumn garden, preparing firewood for winter, building a bathhouse, repairing a wooden fence will require not only time and desire, but also the readiness of the “cutting” tool. If it is a chainsaw, then it must be properly sharpened.

Of course, there are paid specialists, and you, for example, have extra money. But we know that such a procedure is performed periodically and therefore a natural question arises: how to sharpen a chainsaw chain at home? I’ll tell you about that. Go!

How to sharpen a chain on a chainsaw with your own hands

A person who has a chainsaw in his household should know how to sharpen a chainsaw chain with his own hands. There are several ways:

- Sharpening with a file (the most common method of sharpening, because it allows you to sharpen the tool directly at the cutting site.)

- Sharpening using a special machine (this method is used in service centers, but can also be used on a personal farm)

- Sharpen using an angle grinder. To sharpen in this way, certain skills are required. Uncommon method, because it is quite difficult to sharpen with an angle grinder correctly.

In this video, you can familiarize yourself with the sharpening process, the most popular methods and tools used for this.

How to sharpen with an angle grinder (angle grinder)

The method of sharpening the saw chain using an angle grinder, the least common due to its insecurity. In order to straighten the teeth of the chain using an angle grinder as a sharpening tool, it is necessary to install it in a vice and clamp it securely. Then the tool is switched on and the sharpened edge of the tooth is placed on the rotating surface of the disc. A tooth sharpened in this way can differ significantly from that sharpened with a file, because in the process of dressing using an angle grinder, it is rather difficult to control the sharpening angle.

A big disadvantage can be considered the possibility of a notch with an angle grinder with an angle grinder of the eyelet for attaching the connecting link of the chain, which in the future will lead to rupture during work. If, in the process of carrying out work using a chainsaw, the need arose for sharpening, it is better to use a special tool than to come up with various tricks that can result not only in financial losses, but cause serious injuries during their implementation.

Sharpening the chain is not as difficult as it seems at first glance. Any person, after studying the process of straightening chains, is able to sharpen the cutting set of his tool on his own. Even if the first time you manage to do it not very well, you should not despair, because with every next try, the result will be better and better.

File

This type of sharpening is the simplest. This set includes round and flat files, special holders, gauge, chip removal hook and more. And if the file sharpening tools may differ slightly, nevertheless they have approximately the same logic and the same functionality.

The diameter of a round file is directly related to the size of the chain:

- Chains with a diameter of 1.3. require a file of ø 4 mm (used much more often).

- Chains with a diameter of 1.6. require a file of ø 5.2 mm.

How to sharpen?

The sharpening process is divided into several stages:

- Make sure the chain brake is engaged on the saw. Then you should firmly grip the tool in a vice.

- The tooth from which sharpening was started should be marked with something so that you do not accidentally start sharpening the teeth again.

- Before sharpening, pay attention to the special mark, with which the manufacturer indicated the maximum possible sharpening angle. Sharpening itself should be in the direction of the direction arrows.

- In addition to the teeth, the stop is also sharpened. This may become necessary over time as the sharpening reduces the height of the teeth. As a rule, the stop is sharpened after two or three sharpening of the teeth. If this is not done, then problems may arise while working with the tool.

Tips from experts

- In the absence of experience, it is better not to start with expensive chains.

- Movements should be made only in one direction “away from yourself”. over, for each of the teeth, the same number of movements should be performed with approximately equal application of efforts.

- For sharpening a vertical plane, the file must be located strictly at a right angle, and for sharpening a horizontal plane. at an angle of 20-30 degrees.

- If, before sharpening, it was found that not all teeth are of the same height, then the lowest of them becomes the guideline.

Pros:

- One of the most striking advantages is the low cost of this method, since not every owner can afford to give the saw for sharpening every time. In addition, sharpening tools are also relatively inexpensive.

- Convenience and the ability not to postpone work the next day. Especially when you are in a remote place (village, village, etc.).

Minuses:

- The need for the presence of some physical strength.

- Sometimes file sharpening takes a long time.

- When sharpening a saw with a file, the first one pretty soon becomes unusable, so it is better to take a more expensive tool so that it lasts for a longer time.

How to sharpen a chainsaw chain with your own hands

Everyone knows that the saw chain, which is used in chainsaws, needs to be sharpened periodically, but not everyone knows how to do it correctly. Determining that the saw requires sharpening the chain is very simple, for this you need to inspect the sawdust, and if they consist of fine dust, then the tool needs to be sharpened. If it is impossible to sharpen, it is worth replacing it with a new one.

The use of a chain that is not sharpened can lead to overheating of the engine and the formation of scoring on the cylinder.

We will analyze the main ways with which you can, without problems, sharpen the chain on a chainsaw.

Topics. some expert advice:

- Before starting work. run in the chain. To do this, run the chain at a low speed for ≈ 1 minute. During this period, the lubricant will fall on every necessary part, and the chain and the sprocket will warm up and “rub” together. If necessary, adjust the tension (after the chain has cooled down);

“Announcement in the newspaper: I am changing the chainsaw for a prosthesis”.

I hope the information was moderately useful. If yes, then subscribe to the blog for updates and share the article with your friends. All the best to you. Good luck!

Quote of wisdom: It’s not about the word, but the tone in which this word is pronounced (Belinsky).

Description of the sharpening process with files

The first thing to start with straightening the saw chain on the saw is placing the tool on a flat surface or table. In forest conditions, a large diameter chock is well suited for this. Next, you need to inspect the saw chain for any defects, it can be cracks, completely broken off teeth. After inspection, you need to set the brake in working condition, thereby blocking its movement on the tire.

The chain must be taut when sharpening with a file.

It is advisable to put a stand under the tire, as it you can use a log, a piece of a branch of a suitable diameter, or the manufacturers of sharpening tools have special clamps to hold the bar in the process of sharpening the chain.

How to sharpen a chainsaw

The chain is sharpened by moving the file from the inside of the tooth outward. In this case, the file should be located parallel to the special mark on the chain. This mark is applied by the chain manufacturer to indicate the standard sharpening angle.

The sharpened tooth should be located approximately in the middle of the tire, this is necessary for the convenience of work, during the sharpening process, you need to move the chain along the tire, not forgetting to set the brake to the working position each time.

Work on sharpening the chain on a chainsaw must be carried out using gloves made of coarse material, otherwise it is quite easy to injure yourself, because the working surface of the teeth is very sharp.

Ideally, manufacturers advise to make the same number of file movements for each tooth, but in practice this is not always possible. teeth have different degrees of damage to the working edge.

To facilitate sharpening the saw chain with a file, special holders can be used, with corner markings applied to them. The markings are made not only for the standard cross-cut, but also for the longitudinal.

Tool holders are also handy if you don’t have sufficient sharpening experience. Experienced sharpeners do not use holders for sharpening, but can only use special devices that support the file.

Another sharpening device is a hand-held saw chain straightener. It uses a regular file as a sharpening tool, which can be replaced independently. The machine is mounted directly on the tire, it also has the ability to adjust the angle of sharpening of the tooth and a special stop that holds the sharpened tooth.

Manual sharpening machine, perfect for beginners. Along with electric models of sharpening machines, manual has its undeniable plus in the form of a low price. Depending on the manufacturer of the hand-held machine, their appearance may differ, but the principle of operation is the same for all.

The depth of cut is adjusted with a flat file, so that there is a difference between the upper cutting edge of the tooth and the height stop.

As you can see from the figure, the depth gauge is grinded in such a way as to bring the gap indicator to the factory value. Below is a table that shows the main values of the angles, as well as clearances for the most common types of chains.

As a rule, the size of the gap is corrected using a special die. It is installed on the chain during sharpening, after which the depth gauge is grinded.

How to sharpen a chainsaw chain. instructions for action

Do you want to use sawing equipment for a long time? Then take care of its timely prevention. It is necessary to sharpen the tool as needed.

File and chainsaw. a successful tandem!

To correct the inconvenience that has arisen, it is advisable to stock up on round and flat files, as well as a template and a vice. The latter device will greatly facilitate your work, freeing both hands.

Remember to pay attention to each link in the chain. The rule should also be taken into account that the efficiency of the saw is determined by the difference in heights: we are talking about the distance between the cutting teeth and the limiter itself. Differences in height parameters allow the teeth to cut into the tree (usually a stop tooth should be about 0.7 mm lower than the cutting tooth in terms of its characteristics).

How to sharpen a chainsaw chain correctly. we will tell you the tool yourself!

A chainsaw without a normal chain belt is like a machine without a motor. This time-proven postulate will be confirmed by any tech-savvy person. The chain must always be well sharpened if you want to always use your chainsaw. Otherwise, she will not forgive you for miscalculations. This means that you will not see accuracy, efficiency and safety of work.

Any professional will confirm that the final result of such a laborious activity as working with a chainsaw will depend on sharpening the teeth of your tool, even more than on the motor itself. Experienced lumberjacks give the following good advice. sharpening is necessary as the sharpening sharpness deteriorates. If you have to put in a lot more effort than before, the saw starts to cut as it pleases, and changes the angle, slowing down your work, in which case you have no choice. start sharpening.

Pay attention to the sharpness of the chain and escaping chips. If everything is in order with sharpness and sharpening, then your chips will be almost uniform, and the resulting sawdust will be square in shape. If the need for sharpening is ripe, then this will be visible by the dust in the shavings and sawdust in the form of needles.

The chain sharpening process is more difficult than sawing!

Don’t think that everything will turn out so easy the first time. But if you get the hang of it, you will achieve success. The cutting teeth must be sharpened first. For this, a special template is imposed. When sharpening along it, the arrows will indicate the direction of movement. Do not use physical force in such cases, but try to carry out uniform pressing at an angle directly to the saw bar with smooth and precise movements.

Experts remind that the angle of the slope itself in practice can be different and depends on the pitch of the chain. The main thing in such a jewelry and laborious work is not to rush and, as an option, remember how many movements you made. This practice of counting will allow you not to overdo it in one place and remember to perform the same amount of load in another.

Sharpened cutting teeth, it’s too early to rejoice. grinding of the stop tooth is ahead. A template is also used here (it is better to use a flat file in this place). As practice shows, if you sharpen without a template, then you can accidentally go beyond the mark, and then your chainsaw will “bite” into the tree and increase vibration when working with the material, which means you can simply forget about such an important characteristic as accuracy.

Things to consider:

If you are already ready to start sharpening, then it is better to do it right away, without postponing until later. And remember: the frequency of sharpening can vary significantly depending on the bark of the trees. If the bark from the logs is ripped off, then you can not sharpen the chain so often and, accordingly, cut longer. And don’t be afraid to use a chainsaw. If your trees and branches are small, then you can always use different types of tools for pruning trees. So good luck!