How to Sharpen a Hacksaw Tree Video

It seems to be a simple tool, but no, if you make the wrong choice, at best we won’t get the expected pleasure from work. At worst. as the author has a comment on the forum: “It seemed to me that the saws were selling ready to use, that is, already imprisoned and divorced. " So how to choose a hacksaw for wood? What to look for: brand, length or price? We will try to answer this question in this article.

Main characteristics

Of primary importance in this tool is the canvas. Convenience of using the product and its service life will depend on the steel grade, the correct hardening procedure and successful sharpening. The choice of a hacksaw for wood is based on four basic characteristics:

- web length;

- tooth size;

- type of steel;

- handle type.

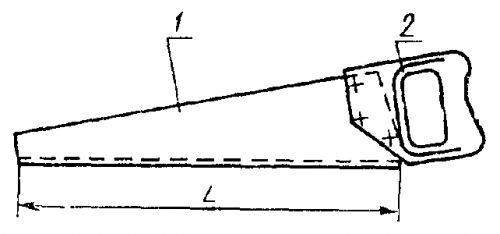

The first criterion is the length of the canvas. It depends on the needs of the buyer, so for small bars, boards, etc. quite enough 280. 300 mm hacksaws. For construction or summer cottage, a canvas of 450. 500 mm is more appropriate. There are more. When choosing a model, you must clearly know what size wood you are going to saw. The rule is as follows: the length of the hacksaw should be twice as large as the largest workpiece for which it is intended. Less is possible, but usability will be lost. There are several reasons for this:

- this ratio allows all the hacksaw teeth to completely exit the log during cutting, and this is an effective removal of sawdust (it will not clog);

- hands easier, with more sweeping movements the hand is not so tired.

A.

The size of the teeth and their sharpening. The accuracy of the cut and its speed will depend on this characteristic. The pattern is as follows: a small tooth. a clean and accurate cut, but less speed; a larger. coarse cut at a significantly higher speed and less fatigue. This feature on hacksaws is referred to as “TPI,” which means the number of teeth per inch (almost 30 mm). The larger the TPI value, the more “delicate” the cut will be. For example, for work with chipboard and fiberboard, this value should be at least 7. 9. The cut surface will be smoother without a “torn” edge.

For gardening, the cleanliness of the cut is not so critical, especially for trimming or sawing logs. A more important characteristic in such work is the cutting speed and the effort to be spent. For this we need a hacksaw with a TPI value of 3-6, the distance between the teeth from 4 to 8 mm.

The classic shape of a tooth is a triangle. As a rule, such saws belong to the sharpened type. The latest generation of hacksaw with red-hot teeth has a trapezoidal shape. They are initially designed with increased strength and durability. When dull, go, buy a new hacksaw or change the blade. With all the desire to sharpen it will not work: it is extremely difficult to repeat the sharpening angles, and even such steel does not lend itself to file. Provided that the production technology is observed.

Steel type. The standard hardness of metal for a hacksaw is 45 HRC. For teeth, steel with a hardness of 55-60 HRC is used. This type of hacksaw combines the flexibility of the blade with a high resistance to tooth wear. They are easy to recognize by their characteristic appearance. the teeth have a darker shade than the rest of the blade surface. These hacksaws are not sharpened type. If the teeth are not red-hot. they can be edited and sharpened.

Lever. The quantity of corns on the hands depends on its ergonomics. There are two options for the handle: cross over or classic. The first option allows you to change the blade, for example, in the model of a hacksaw for wood Bahco Superior EX-19-XT9-C.

Video: How to Sharpen a Hacksaw Tree Video

How to choose?

First of all, it is necessary to determine what type of tool is needed: carpentry or carpentry. The carpentry has a more accurate and clean cut, mainly used for dry wood. Cutting speed for this type of tool is not the main characteristic.

When choosing a length, focus on your needs, i.e. what sizes of timber or log you are going to saw. If the tool will not be used often, for example, in a summer cottage, choose with red-hot teeth. The service life of such a saw is large. In addition, the right to grind and breed teeth. its own science, and to master it for seasonal gardening may not be advisable.

The quality of the canvas can be checked upon purchase. To do this, take a hacksaw and see how smooth the blade is. Next, bend the canvas to tangible resistance and release. Fold zeal should be slight, do not break. After that, look at the evenness of the blade at the bend, if the deviation is more than 2 mm, the steel is not very high quality.

Hacksaw teeth have a dual role:

- cut wood;

- take away sawdust.

The smaller the number of teeth per inch. the greater the cutting speed and less clogged with sawdust. Hacksaws with a number of teeth up to 7 provide high performance at low cost of user effort. True, accuracy will suffer from this. But here it is necessary to look for a middle ground, because the greater the distance between the teeth, the smaller the cutting surface. Accordingly, performance will drop. The best rule is the following rule: the minimum thickness of the bar should be greater than the step of three teeth. Otherwise, it will be flour, not cut.

One of the determining criteria for choosing a hacksaw for wood is price. As in everything else, high-quality products of leading brands will cost more than Chinese brands. This overpayment is, in fact, a guarantee of the durability and wear resistance of such a tool. And with red-hot teeth, this is very important, the total resource of operation of such a tool will depend on this. He does not give in to sharpening. Leading manufacturers exercise tighter control when choosing steel grades and hardening technologies. And as we discussed above, even the shape and pitch of the teeth of such a tool will affect a lot. Starting with convenience and effort, ending with precision and evenness of cut.

Models to which you should definitely look

Wood Hacksaw Bison Expert, It has a very comfortable plastic handle. Teeth red-hot, triangular in shape with two cutting edges. Suitable for both longitudinal and transverse sawing. The length of the blade, as well as the number of teeth per inch, the user selects on his own, the variations of this model are different. It cuts well any kind of wood. This tool is suitable for carpentry, as controllability and accuracy of cutting at height. For the garden, you can choose a model with a lower TPI value. Cost from 12 to 15 cu

Wood Hacksaw Gross Piranha also presented in several versions. Cloths Available in different lengths (from 400 to 550 mm) and a different number of teeth. The saw is made of hard steel 52 HRc, teeth, hardened 66 HRc with trihedral laser sharpening. Saws evenly and cleanly. The hacksaw for wood Piranha has a Teflon coating, which significantly improves the sliding of the blade and allows you to get clean edges of the cut. The cost of this tool is 12. 15

Wood Hacksaw Stanley General Purpose. This tool is produced by a French company, has good quality and not a high price (about 12 cu). Designed for both longitudinal and transverse sawing. Length 500 mm with TPI 8. Teeth red-hot. Cut light, without extra effort. Great purchase for a summer cottage.

Hacksaw Irwin Xpert. A very good tool at a reasonable cost, from 20 Washed down light, cut even and smooth. When sawing hardwood, the effort on the arm does not increase significantly. Good grip ergonomics. Length 500 mm, teeth, red-hot with signature geometry, TPI 8.

Sandvik Wood Hacksaws (in the past), and now it is a well-known instrument under the Bahco brand. Bahco saws with proprietary XT geometry are almost unrivaled, this is the category of professional tools. A noteworthy model is Bahco ProfCut PC-19-File-U7. This is one of the few saws that can be sharpened. Convenient, 475 mm long hacksaw. Saws evenly and easily. Cost from 20 cu

By the way, you can get the quality of Bahco, and at the same time save, you can buy a hacksaw under the brand name "Mother-in-law". This instrument comes to Russia from two countries. If purchased with the mark “made in Sweden”. you will have in your hands a tool from the Bahco factory, with its level of quality.