How to sharpen a knife with a grinder correctly. Sharpening methods

How to properly sharpen knives for meat grinders at home

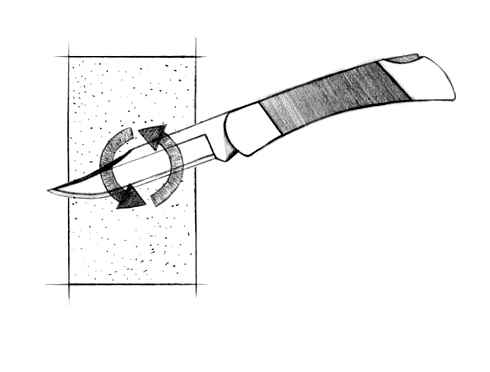

Every housewife in the kitchen has an indispensable assistant. A meat grinder. This can be either a mechanical and an electric device, but the principle of operation in both cases is the same: grinding meat into minced meat with with with with with with with with with a wire knives. And the more often you use a meat grinder for its intended purpose, the faster the knives will need sharpening. Let’s talk about how to sharpen knives for a meat grinder at home.

- Current correctly

- How can I sharpen knives for meat grinders at home

How often it is necessary to hide

Knives can be sharpened once a month or once a week. Everything will depend on how the blade is often blurred. But remember that some tools cannot be sharpened:

Steel knives will often require sharpening.

How to Get an Extremely Sharp Knife Using Angle Grinder

Arguments for”

- Speed of execution. There is no need to give the tool to the repair workshop, because you can sharpen yourself.

- Small costs. Bulgarian It is cheap, well, you can use it for a long time for many purposes.

- Absolutely suitable for sharpening kitchen knives.

- One of the usual sharpening methods.

How to sharpen a metal drill with different tools

Sharpening of iron tools allows one percent to return their performance. The operation can be performed using different auxiliary devices.

How to correctly sharpen the drill on metal and not spoil the cutting surface of the product, will be told in the publication.

How to sharpen with a nozzle for a drill

It is necessary to act in this case in the subsequent order:

- Fix the nozzle;

- We turn on the electric drill;

- We insert the drill into the hole on the device and pull the cutting part on one side;

- Then we take out the pulled tool from the hole, unfold it 180 degrees and sharpen the cutting part on the 2nd side.

In home criteria, returning the work of a blunt drill on metal is most easily using a drill with a special nozzle. After all, this device, unlike the “grinder” and sharpen, will help beginners to avoid mistakes, because of which they will have to throw away a spoiled tool.

Sharpowing with a file or a file

A drill used for metal processing, Silence Ratfil or Nadfille is unrealistic for two reasons:

- The hardness of the material. Even the best ratefil will be erased before the cutting tool corrects.

- When using diamond or abrasive bars, it is unrealistic to manually withstand the appropriate angle.

How to sharpen a metal drill

Correctly selected device will allow to significantly reduce temporary costs and do the work very accurately. Learn below how to sharpen a metal drill on a grind.

Many devices allow debugging cutting products for metal with a diane of 3 to 19 mm. To turn the spiral core, you can use special workers that have an integrated electric motor and a mechanism for serving.

Unlike the use of ordinary sharpener and holder, a professional equipment can cost 10 thousand rubles. Therefore, if sharpening is not a profession, then it is possible to do the use of the above tandem from the tochline circle and the holder or to make an instrument edit manually.

You can make a gail with a rasteril and without experience. The main thing is to choose the right file. Taking into account the fact that even cheap cords are made of high.Quality cutting steel, it will be necessary to choose a file with diamond spraying. Apart from the ratfille, you need to prepare a vice in which the tool should be fixed.

In order not to waste strength and time on the manual method, you can apply a grinder with an abrasive circle.

Crown

When debugging crown tools, a special device is used and you should know at what angle the metal should be removed from the cutting surface. Taking into account all the difficulties and temporary costs for performing the procedure, it is better for sharpening will turn to experienced craftsmen.

How to sharpen a sharpener

This “home»The method has its own characteristics. The manual wrapping regime is available only to experienced locksmiths that own enormous experience that allows “by eye” to restore any blunt tools.

All other home masters will have to purchase or take a special holder from a neighbor. This device must be installed in the next to the emery (about 1 mm.). With all this, you need to make sure that the stamina of the bolt connection, in order to exclude the shift of the lock in the process of execution of work.

Only after which you can run to run specifically to the sharpening of the tool:

- We fix the drill in the holder (the angle of sharpening is set in advance);

- Turn on the sharpener;

- We remove damage from the cutting surface;

- Smooting the cutting surface by short.Term. Less than 2 seconds. Contacts with emery.

Sharpening the drill with a sharpener

Determine the amount of damage to the cutting product and debugging by eye can be after longend practice.

Smout the drill

In other cases, you can install a special holder of the Sovers in a specific proximity to the sandpaper. The fastening should be strong so that during the performance of the work there is no displacement of the latch. If the grinding machine is fixed on the wood base, the installation of the latch should still be carried out using a bolt connection.

To perform sharpening: the tool is reliably fixed in the holding device, the sharpener is cut and the drill is in contact with the time with the sharpened circle at a well.Chosen angle in advance.

- If Zazubrina formed on the surface of the cutting product, then before debugging it, you need to remove damage moderately from both sides.

- Caution should be shown. Products of a huge diameter are heated from contact with an abrasive circle to high temperature, which leads to a decrease in the mechanical strength of the metal.

Bulgarian

The master will be needed, not counting the electric drive himself, a vice in which the gripped product is clamped.

WEIRD KNIFE SHARPENING METHOD. Can you sharpen a knife on a file?

The granularity of the grinder is chosen so that it was unrealistic to consider the microbors left with the grains of glass, which polishes the metal with the naked eye.

To turn the drill with a grinder, make the next:

Do not hold the drill in the turn for a free time for more than 2 seconds. The short sessions consist in removing thin, much less than 1 mm, layers of alloy from the working face. The drill is ready for work again.

Read which grinder is better to grind a tree

Sharpowing with a nozzle for a drill

Without an emery machine, using a special nozzle for a drill, an operation is performed qualitatively no less timely time.

You can purchase a nozzle in any specialized store, but you can use the device of course only for sharpening average products in diameter. Most of these nozzles allow you to effectively finish the tool with a diameter of four to ten mm.

For beginners, the method is the most preferred. Sharpening of the core is performed so.

- Set the nozzle on the drill;

- The drill is inserted into the hole of the appropriate diameter;

- The drill is turned on, the product is not tightened that;

- Turning the drill one hundred and eighty degrees the opposite edge is pulled.

How to Sharpen a Knife with a Japanese Master Sharpener

To use the device effectively, consider the following features:

- Through the nozzle, only slightly dull tools are hidden on the drill. If there are deep damage to the cutting surface not when the drill was overheated, it does not work to restore the product.

- Angle of sharpening in such devices fixed. How fast and just sharpenhacksaw file sharpening sharpeningBulgarianmanual. To restore the Sovers on work with non.Ferrous metals, it will be necessary to purchase an original device, or to finalize the products with a file.

Despite some disadvantages of this design, its use allows us to simplify not to speed up the process of restoring the cutting edges, and low cost explains popularity.

Electric power plants

Progress inexorably goes forward and electricity is increasingly being introduced into our lives. There are even electronically invented electrical devices and tools intended to facilitate the existence of a person, but in this case we are interested in devices for electrical sharpening of ordinary steel knives, but even such devices are incredibly many. In the household, one of the following is usually used:

Table grinder

As they are not called-grinding machines, sharpened, editing, sharpener, sharpening machine, etc.D. Current machines are used mainly for sharpening various kinds of building tools, but for ordinary kitchen knives, such machines are quite suitable. You need to work on such a machine in compliance with all safety measures.

Carpentry machine

The device of some carpentry machines allows you to change the sawing disk to a grinding circle. However, no protective covers and screens are provided for such machines and therefore it is necessary to hide knives on such machines with maximum caution in the goggles.

Bulgarian

(angle grinder). Initially, this power tool is not intended for hidden knives, however, it is quite possible to sharpen a knife on a grinding circle, but again it is necessary to observe all safety measures when working with a grinder.

Ribbon electric grinding

This power tool is used mainly not to sharpen knives, but for refinement after sharpening on a machine or grinder.

The disadvantage of the above methods is that these tools are construction, take up a lot of space and therefore it does not make sense to buy them specifically for tightening knives. And if one of the above is already on the farm, then no one prohibits using it. For example, in the country you have to sharpen knives, tramps, scissors and a grinder and a tape electric grinding.

Electric engineer for kitchen knives

There have been more and more such sharpeners recently. They are made specifically for sharpening kitchen knives, have relatively small sizes and sharpen the knives on such sharpeners is safer. There are a lot of models of electric shoes for kitchen knives, from a simple and cheap price of 10-15 (a), to semi-professional, at a price of 100-150 (c) that allowed sharpening in several stages. Electric sharpeners for kitchen knives look something like this:

Photo 1. Electric shoes for kitchen knives, scissors

To sharpen the knife with such an electric grin, you need to insert the knife with the cutting part into the corresponding gap and spend several times with a knife back and forth.

How to sharpen a knife on a wood with a file

To sharpen the blade of a hand saw, you need to clamp between the equipment of the equipment so that the teeth towers one and a half to two centimeters above them. For various types of canvases, the sharpening of a hacksaw on wood is carried out in its own way.

To properly sharpen the transverse hacksaw, the blade should be set under 45 °, the file should be selected with a triangular transverse profile. To ensure the proper quality of sharpening, the following sequence of actions must be observed:

- Sharpen left edges of even (distant from the master) teeth;

- Turn the canvas;

- Sharpen left edges of even teeth;

- Form sharp cutting faces and pointed peaks

To sharpen longitudinal or universal hacksaw, it should be fixed at an angle of 90 °. Here you need a file with a diamond transverse section. The file moves in the plane of the desktop. The sequence of sharpening the teeth is the same as for transverse hacksaws. In the course of work on non.Sharpened faces, there are usually burrs, large or smaller, depending on the thickness of the canvas of the hacksaw. They should be smoothed out by a “velvet” file or abrasive bar minimum granularity. The quality of sharpening can be checked in two ways:

- To the touch. Sharpness should be felt, burrs should not be felt.

- By color. On properly sharpened faces during lighting, there are no x glare.

The quality is also checked by a trial cut. The hacksaw should not be taken to the side, the surface of the saw should be smooth, without soaked wood fibers.

Necessary tool

To quickly and high quality sharpen Khobeska on wood, you should prepare a set of equipment for wiring teeth and sharpening. Would need:

- Workbench;

- Locksmith vice;

- Passatigi;

- Grinding bar;

- Sandpaper;

- Measuring instrument: transporter and caliper;

- Locksmith;

- Equipment that allows you to fix the canvas at angles 90 ° and 45 °.

- A cross section in the form of a triangle;

- A cross section in the form of a rhombus;

- Flat;

- Nadphyli.

A notch is needed a whole and not clogged with metal dust. If on time and right sharpen hacksaw, working with it will be easy and convenient. Such an instrument will last much longer, delighting its owner with an even and accurate relay and high quality of the surface of the cut of wood.

How to sharpen small products

Sometimes, to sharpen a thin drill using mechanized methods, including nozzles for a drill, it will be doubtful. All work to restore the product of small diameter will need to be performed manually.

The first attempt may end unsuccessfully, so first you should choose an inexpensive subtle drill

Needing to restore not to carry out the operation here. You will also need a small diamond file not glasses with a 4-fold increase to perform work.

The process occurs in the following sequence:

The entire operation is performed “by eye”, it is important to use the magnifying glasses during operation is not a powerful lighting device.

If the first attempt was unsuccessful, you should know that any skill can be developed only over a certain period of time. If the passage of failure, do not leave an attempt to learn a useful skill, like sharpening of thin core on your own.