How to start a motorcultivator in winter. What they do with gasoline in the winter period?

Motoblock does not start in winter the reason

A mini-tractor is considered a functional device. It is indispensable for housekeeping. Hanging special equipment makes it possible to process the territory, mowing of grass, snow removal, transportation of goods, landing and harvesting. Often a situation appears when a motoblock does not start. The owner must establish the reason for the refusal and eliminate the damage.

Start of gasoline and diesel unit

Equipment is equipped with gasoline or diesel engines. Starting diesel motor block and gasoline apparatus has differences. For this reason, analyze the factors because of which the unit is not started, follows for each specific type of motor.

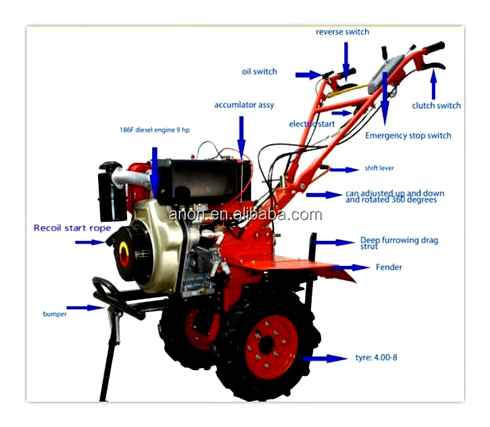

Before purchasing a motorcycle block, special equipment is prepared. It is necessary to make sure of the presence of absolutely all elements, make sure of the strength of the mounting of the mechanisms.

Mechanisms often refuse to work after winter. A long break becomes a prerequisite for the occurrence of problems in the systems of the walk.Behind tractor. Preservation in a cool and wet room leads to the following faults:

Before starting the new walk.Behind tractor, absolutely all compounds, clutch, reverse and gas cable are controlled. You can not turn on the device if there are clamps and twisting of the thread threads.

During the first launch, the level of oil in the crankcase is certainly checked. Lack of lubrication will spoil the piston group. The crankshaft spin up to 1,400 turns per minute at idle. Enough a couple of seconds for creating a bunker on the plane of the cylinder.

Old oil can be the cause of a non.Working engine. At the same time, the walk.Behind tractor smokes white gases. Absolute oil change suggests itself.

It should be taken into account that a mini-tractor is poorly started with a missing oil volume. Follow this parameter before starting a carburetor and diesel motoblock

In certain modifications, defense is determined by low level. The device blocks the launch and the unit freezes.

Do not forget that any type of motor requires gasoline of a particular brand. For a two.Stroke engine, fuel is prepared separately. The fuel mixture consists of fuel and oil. The number of ingredients is maintained in strict balance.

Repair of mechanisms

The launch of a diesel engine after acquisition may be difficult. The problem is that air enters the fuel supply system. If you cannot start with prolonged scrolling (starter), it is necessary to release air traffic jams. To do this, open the feed valve and unwind the connections along the channels. Nozzles are considered the final point of purging.

In order for the internal combustion motor to start, several conditions should be fulfilled. We list them in order:

The fulfillment of the mentioned conditions ensures the launch of any engine.

Difficulties in launch

Difficulties in starting are shown for a malfunction of nodes and elements. The success of repair work depends on the accuracy of the diagnosis. If disadvantages are found, they are repairing diesel motoblock. Service and small repair can be carried out on their own. You need a set of keys, a locksmith mechanism and skillful hands.

At the stage of fuel preparation, the following incidents are likely:

- A light filter does not let in air;

- The hole of the tank cover is boarded up;

- The channel of fuel is littered;

- The carburetor broke.

After a series of unsuccessful launches, it is advisable to unscrew the candle. The working part can be filled with fuel. In this case, dry the element, then pump the cylinder through the hole. We twist the candle and let it down again.

If the candle is dry, then the fuel does not enter the burning chamber. We will perform several operations alternately to renew the feed system:

- Drain the old gasoline;

- Wash the tank;

- Clean the special filter from dirt;

- Clean the fuel supply hose;

- Clean the jacklers of the carburetor;

- Season the tank with clean fuel;

- Open the tap;

- Clean the breathing channel in the tire.

How to get a motor block in winter. Advice to beginners

The advantages of modern motoblock are its multifunctionality and high performance. Subject to the availability of appropriate attachment equipment available in the farm, the unit can be actively used in winter. To clear a large amount of snow and solve other household problems.

At the same time, the improper operation of the walk.Behind tractor in winter, and especially its incorrect launch, significantly reduces the working resource of the main mechanisms of the unit. What to do to prevent typical errors when starting a “cold” walk.Behind?

First of all, you will need to deal with the type of cooling system provided for in its design. Units equipped with an air system are more simple when storing and starting in the winter. They do not need a rapidly freezing antifreeze and a constant check of the radiator. At the same time, the air cooling system has its drawback. The engine heats up faster with it, which means it cools faster, which will not allow long breaks when working in winter.

Many motoblocks need preliminary insulation of their engines to operate in winter. For this purpose, both branded covers and various improvised means. Blankets, blankets and other fabric products can be used

It is especially important to provide high.Quality insulation in conditions of severe frosts, up to.20 ⁰C. If the temperature does not drop below 5-10 ⁰C, then this step can be skipped

An important role is also played by the place in which the motorcycle block is stored. If the unit is planned to be actively used in winter, then it is best to choose a heated room for this. A garage or another household building.

With intensive use of the walk.Behind tractor in winter, it is extremely important to take care of the oil poured into the gearbox. Synthetic oils are best for use in winter, since they, at subsequent temperatures, retain their most important properties longer

In any case, it is best to use more liquid oils that do not thicken so quickly in the cold.

Following all these rules, the owner of the walk.Behind tractor can easily start his unit. The launch of an agricultural machine in winter is carried out in the same sequence as at any other time of the year. The only difference is to allow the walk.Behind tractor to work at least 15 minutes on idle. During this time its engine will warm up and will be completely ready to work. In more detail about starting a walk.Behind tractor in winter, you can find a video.

Whether it is necessary to drain gasoline from a walk.Behind tractor for the winter?

The operating instructions clearly say that the fuel from the walk.Behind tractor before winter storage must be drained. But the opinions of the owners on this subject diverge. Some say that it is best to drain gasoline and let the tank dry thoroughly. Others advise filling the tank to the top to avoid corrosion.

Corrosion of the tank will not be in the first or second case. But following the fire safety technique to leave a walk.Behind tractor with a full tank of gasoline. Also, gasoline during prowe can be circled.

Our advice. Before winter storage, be sure to drain gasoline, develop the remaining fuel in the system and let the tank dry out. After such actions, there will be no problems with the fuel system of the motoblock in the spring.

Plows

The plow is the main working body that is used for plowing land plots. In addition to the standard plow, which is usually included in the kit, there are several more types that can be useful for certain types of work:

Frosts require to take the fuel capacity seriously. The opinions of specialists in this case vary. Full fuel drain involves the formation of corrosion. However, with the full tank of the walk.Behind tractor, which is stored, the risk of fire increases sharply, which can lead to irreparable consequences.

So why the motor.Cultivator does not start:

- At the end of work on the site, many owners leave the equipment without work with the old fuel inside. Since after several days the fuel emits condensate and precipitate falls, all this negatively affects the fuel system. The carburetor is even more subjected to this, which will then need to be cleaned. To avoid such problems, always pour the remaining fuel from the tank, or work as a cultivator until the gasoline is over.

- If you left gasoline winter in the unit, then first of all you will need to pour it out of the fuel tank. Next, pour new clean gasoline and leave the unit for a couple of hours. After a combination of time, supplement the tank with a small amount of fuel. If after the operation the motor.Cultivator does not start, then it is worth looking for a problem in electrical firing. And this is already very difficult, so we advise you to contact specialists here.

- The engine of any garden equipment will in no case function in the absence of oil. So check the presence of lubrication in your cultivator.

This we provided the basic recommendations on how to make a cultivator in case of its malfunction. DIY Cultivator repair instructions can be found in the unit maintenance manual. If you do not have technical skills and are poorly versed in the design of motor cultivators, then you should seek help from professionals. Experts in a short time will be able to find out and eliminate the reason why the motor cultivator is not started.

How to get a motorcycle block correctly?

Motobobes are quite serious and not cheap gardening technique. If you want it to fully fulfill its functions, serve for a long time and reliably, then you need to carefully take care of it and follow all the recommendations prescribed by the manufacturer.

When you bought a technique, it is important to know how to start a motorcycle block. There is a certain sequence of actions consisting of preparing the technique to launch and its direct launch.

Whether it is necessary to drain gasoline from a walk.Behind tractor for the winter?

The operating instructions clearly say that the fuel from the walk.Behind tractor before winter storage must be drained. But the opinions of the owners on this subject diverge. Some say that it is best to drain gasoline and let the tank dry thoroughly. Others advise filling the tank to the top to avoid corrosion.

Corrosion of the tank will not be in the first or second case. But following the fire safety technique to leave a walk.Behind tractor with a full tank of gasoline. Also, gasoline during prowe can be circled.

Our advice. Before winter storage, be sure to drain gasoline, develop the remaining fuel in the system and let the tank dry out. After such actions, there will be no problems with the fuel system of the motoblock in the spring.

Preparation of the walk.Behind tractor for winter

Before sending a walk.Behind tractor for winter storage, you need to carry out a number of procedures for its successful “wintering” and quality work in the spring. First of all, before the onset of frosts, the motoblock should be washed and thoroughly dried, small breakdowns should be eliminated. All working mechanisms and nodes carefully lubricate. The cutting elements of the attachment equipment also clean, sharpen and lubricate.

Store a walk.Behind tractor should be in a dry ventilated room. There is no need for additional heating.

Basic rules for the conservation of a walk.Behind tractor for the winter:

- Change the oil in the gearbox and engine.

- Clean and pour oil filters with oil (if a bath is provided for them).

- It is recommended to unscrew the spark plug, pour several milliliters of oil into the cylinder and manually scroll through the crankshaft several times.

- If a battery is installed on the walk.Behind tractor, remove it and take it to a warm room. Also several times during the winter, do not forget to recharge it.

- A special anti.Corrosion coating can also be applied to a cleaned and dry walk.Behind tractor, which can be purchased in specialized stores.

We also offer you to get acquainted with the video that shows the process of preparing a walk.Behind tractor for winter:

Preparation of the walk.Behind tractor for work in the winter period. What to do?

Here the people are more interested in the conservation of garden technology. I want to ask, but what needs to be done with the walk.Behind tractor and nozzles to it in order to successfully operate them in winter? Neva-MB2-K Motoblock, nozzles-snowmaker (used 1 year), carts on wheels, iron wheels, dump, water pump The rest I think is not relevant in winter. For he will have to clean the snow and take a bit, and maybe shake the water, well, completely episodically.

It can be recommended to change the oil for winter, with less viscosity. Peel the fuel sedimentation and filter (if any) change. Prepare air, in case of problems with the factory.

Interesting, and clean up a lot of snow? It seems to me that it is more convenient with a shovel. Just as I imagine that the walk.Behind tractor needs to be pulled out, seasoned, it is possible to put on a hinged, and then cleaned from snow, remove the hinged and remove. Fresh snow is easy to remove and shovel. Although the snowman has never worked. It is interesting, but how to clean the platform of 7×7 meters, where it throws snow?

Old Major wrote: I want to ask, but what needs to be done with the walk.Behind tractor and nozzles to it in order to successfully operate them in winter? Motoblock Neva-MB2-K.

There was a thought to pre.Warm the engine crankcase with a building hairdryer. In the instructions, it is written to change the oil for a more winter.

Oil is older. The candles are more playful. And in general. It is advisable to store in a warm garage. The difficulty of starting. In a miserable carburetor. In the Lada, then the carburetor is heated by antifreeze. And here. Icy gas with icy and wet air. Savsham Ne vapor, yes! Abye. If I had such a problem (launch a walk.Behind tractor in the frost), I would buy an electric power and act like this: I would have thrown it on a walk.Behind tractor that would have been thrown out for an hour before work, and just a blanket (insulation). I would warm up a motorcycle block, only then. Launched. Yes, the broadcast (sprayed) into the air filter helps greatly in starting. Even special cans sell.

I have already described the process of work of the Neva with the snowman. “Snowman. I have Novgorod SMB-1m. It is attached to the pin. Power selection from engine pulley. At temperatures below zero, it is difficult to start. In addition, if you do not take measures to heat the carburetor, then it freezes and stalls and does not start anymore until you heat. At temperatures below zero, I do this:

The most common motives for the breakdown of the walk.Behind tractor

The motoblock is equipped with an internal combustion engine (ICE) and as everyone else breaks over time, its repair and maintenance is carried out as well as for single.Cylinder carburetor ICE on any other equipment. In the article we will analyze in more detail the reasons why the motorcycle block is not started, as well as the methods for their elimination.

- A neutral speed is set to switch. Checked according to the pointer, or by simple rolling of the walk.Behind tractor. On the neutral it rolls easily, without rotation of the engine.

- The air supply flap is placed in a closed position (indicated on the case at the lever of the damper).

- The fuel supply crane opens.

- The “Start” button is pressed or fixed on the handle (from the model).

- The handle of the hand starter is pulled to the hook hook. A smooth jerk (or several) ICE is launched.

- After starting the air supply, the air is opened.

Nuances. If a particular ICE is unstable at idle, the launch is carried out with a squeezed “gas” handle (a ajar throttle, “gas” for a third or half).

Differences between winter & summer blend gas

You can find out in detail how to run a motor block correctly in the video:

When the hot engine is launched, the airblock air filter is not closed at all. Buttons “suction”, manual pumping of fuel on a carburetor in four.Stroke engines. The fuel-air mixture begins to enter (sucked) into the combustion chamber when rotating from the starter without preliminary let-the-up, which is used on almost all two-stroke one piston internal combustion centers.

How to start a cultivator. Methods of repair of malfunctions

If the motor.Cultivator does not start, then the cause of this may be the malfunctions of several main units of the unit. Below we consider the typical breakdown of the main mechanisms of the household cultivator and the methods of their independent elimination in more detail.

Malfunctions in the ignition system

Elements such as magneto, a candle, a pre.Installed cap and a high.Voltage wire are most often oxidized, as a result of which they inevitably fail. If dirt and moisture are found on a high.Voltage wire, then they are the cause of its breakdown.

Ran Out of Gas #gas#gas #cars #fuel #e85

A weak spark or its complete absence most often indicates a lack of efficiency in the spark plug, which is why the motor-cultivator refuses to start. In this case, you should check the condition of the gaps and the distance between them. It is best to do this with a special probe. A normal value for work should be 0.8 mm. If there is such a necessity, then you need to completely remove the resulting carpet from the outer surface of the insulator and the metal parts available in the candle.

The readiness of the engine before launch is affected by the serviceability of the elements of the piston group. Since they constantly work in difficult operating conditions, their surfaces are severely heated, which leads to a breakdown of the ICE cylinder, pistons and rings. If the unit does not start, you will need to check it with the exhaust and inlet valve. It often happens that they do not fit the saddles loosely, and in this case it will be necessary to eliminate the malfunction as soon as possible, and then try to start the cultivator again.

Another detail that often lends itself to breakdowns is a full.Time muffler of the cultivator. On the walls of the element inevitably accumulate combustion products and the remnants of the exhaust gases, which leads to the lack of the opportunity to start a cultivator. With a large number of these substances, the engine will stop starting sooner or later. To eliminate this malfunction, you will need to completely remove the muffler and clean it with compressed air from the cylinder.

All of the listed malfunctions and methods of elimination are suitable if motor cultivators of the production of brands Sungarden, Texas and Neva do not start. Models from these manufacturers have a simple design, so even a beginner can easily cope with their repair.

Breakage of the carburetor and ways to repair it

Often, the motor-cultivator does not start due to clogging inside the nozzles or a carburetor filter. A sign of this will be an absolutely dry and pure unit sparkling candle. Repair is carried out in the following order:

- First remove the carburetor of the unit;

- Disconnect the fuel fitting and blow it with compressed air from the cylinder;

- After that, blow the combustion chamber and fuel tubes;

- Install the carburetor in place and try to start a cultivator.

If even after that the cultivator is not started, then the position of the float placed in the combustion chamber of the unit should be checked. The setting of the part is performed using special screws. Turning them clockwise, you raise the float, and when turning the screws against the course of the watch, the part is lowered.

The cultivator does not start. Engine repair

Another mechanism, the breakdown of which does not allow the cultivator to start, is the engine of the agricultural machine. In the case of the use of poor.Quality fuel or non.Compliance with the proportions of the preparation of the fuel mixture indicated by the manufacturer, the fuel will begin to fill the light of the ignition, which will lead to the absence of a spark.

In this case, it will be necessary to block the fuel supply, disassemble the motor and thoroughly dry the cylinder. After that, it is necessary to turn out the candle and start the cultivator using a hand starter. In most cases, after the following actions, the cultivator starts up. At the end, you need to screw the candle back and continue the operation of the unit.

A motor cultivator does not start. The causes and repair with your own hands

With the onset of spring, the garden technique is exported to the areas, and here some farmers have a problem-a motor cultivator does not start starting. In this case, it is required to quickly identify the cause of the malfunction, and quickly eliminate it.

The technique can be equipped with a gasoline or diesel engine. The start of each of the engines is slightly different, which is why it is necessary to identify the reason that the cultivator does not start, it should be for each individual type of motor.

Before you start a motor.Cultivator, it is necessary to prepare it. To do this, check the presence and integrity of all elements and make sure that the reliability of fasteners. Some nodes refuse to work after long downtime. This is often due to the storage of technology in raw cold rooms. In such cases, the following breakdowns arise:

Before starting the new engine, you need to check all the connections, gas and reverse, the clutch cable. The cables should “walk” smoothly, special efforts should not be made for launch. The motor cannot be launched if the cable is clamped or twisted.

At the first launch, you must definitely check the amount of oil inside the crankcase. If there is no lubricant, then this can damage the engine pistons. And if you consider that the crankshaft is spent to 1,500 about./min., then a few seconds are enough for the deformation of the cylinder.

Features and rules for launching a walk.Behind tractor with step.By.Step instructions

After preparatory measures, making sure that the oil is flooded, gasoline or diesel fuel corresponds to the model of the walk.Behind tractor, all nodes are fixed and are in good condition, we start the unit.

How to run a walk.Behind tractor you can find out by watching the video:

Motoblock with a gasoline engine

- Open a fuel tap tile. In this case, the lever of the fuel leaks must be installed in the start position, and the ignition should be turned off.

- Several times (2-3 will be enough) pull the launch cord.

- Turn on the ignition and pull the starter cable again.

- After the engine has started, you should quickly install the lever lever to the work position.

Motoblock with diesel power plant

If the technique is new, then its entire fuel system is ascended. To blow it and start the engine, you need to perform a certain sequence of actions:

- Unscrew the fuel supply crane, gradually unwinding each connection of the fuel line from it. When the diesel fuel reaches a certain connection, immediately tighten it.

- As soon as the fuel enters the nozzle, you need to open all the available cranes and put the gas lever in the middle position.

- Press your finger and pump a decompressor several times until the fuel reaches the cylinder;

- Release the decompressor and pull it until the moment he stands in the regular place;

- Click on the decompressor again, and without supporting it, sharply pull on yourself a launch cord.

This is a general algorithm that shows how to properly start a walk.Behind tractor of any brand, it is applicable to almost all models, but below we will analyze the step.By.Step launch algorithms for the most popular motor cultivators.

Rules for preparing a walk.Behind tractor for winter conservation

If the technique is used only in the warm season, it is necessary to provide it with the correct storage in winter. Competent conservation preserves the working resource of the motor.

- Oil change. To prepare a walk.Behind tractor for conservation from the engine and gearbox, technical fluids are drained. You can filter the old oil, but it is better to pour new, recommended by the manufacturer of equipment.

- Washing. Clean filters, fasteners, details with visible pollution. If there are filters in the oil bath in the design of the walk.Behind tractor, it is necessary to replace the liquid.

- Writing out candles. Many unit owners recommend unscrewing the spark plugs before winter storage. Then a little butter (about 20 g) is poured into the engine and cranked manually (it is necessary to put it in the upper dead point). Several revolutions are enough for an oil film to form on the details. Switch caps are lubricated with silicone lubricant. The same operation is carried out for all electrical connectors. Silicone film reliably protects from oxidation.

- Cleaning the motor block. The equipment is thoroughly washed. You can do it manually or use a high.Pressure apparatus. Wash not only external surfaces, but also inaccessible places. After cleaning, all metal parts (including the body) are covered with a layer of special polishes to protect against dust and corrosion. You can use oil for these purposes. It is important to apply the product to clean metal, otherwise the protective function will be reduced to zero.

- Removing the battery. If an electric starter is installed on the walk.Behind tractor, then the battery must be removed and placed for storage in a warm room for the winter. Throughout the downtime, the battery is periodically charged.

- Preparation of hitch. All hinged equipment is removed, cutting edges are pulled. The tools also need to be cleaned and dried. Moisture causes corrosion of metal parts.

Through the entire storage period, periodically twitch the starter when the tank is open without turning on the engine. This will prevent rings.

Preparation of the walk.Behind tractor for winter. What to take care of?

The proper conservation of the walk.Behind tractor for the winter is an important topic that allows, if not extended, then at least save the working resource of the unit used in the farm. The preparation of an agricultural machine itself is not a complicated procedure. It is enough to study a number of rules and tips that will help save the walk.Behind tractor and start it without problems after wintering.

By sending an unit for winter storage, you will need:

- Completely replace the oils in the motor and gearbox of the unit. To do this, in the corresponding tanks for the winter, you will need to fill a new lubricant, or, in extreme cases, filter the old, making sure that there is no sediment in it. In any case, with the onset of spring oil, it will be necessary to replace;

- Rinse all the filters available in the design. If the unit is equipped with filters placed in an oil bath, then they need to fill in fresh motor oil;

- Many experienced farmers recommend that the motoblock sparkles with the ignition of the walk.In, then pour not more than 20 ml of motor oil into the working cylinder, and manually scroll through the crankshaft of the unit, performing literally a few revolutions;

- Motoblock for the winter must be washed from dirt, without missing details located in hard.To.Reach places. After washing on the body and spare parts of the unit, it will be necessary to apply a thick layer of oil, which will help eliminate the formation of corrosion;

- If possible, instead of oil, a special polish with a protective function can be applied to the parts of the walk.Behind tractor. It forms a strong film on the metal surface, which will prevent the metal rotting in winter. At the same time, it is very important to apply the product on a clean surface, since otherwise it will not protect the metal parts of the walk.Behind tractor;

- All the caps of candles and electrical connectors of the unit for the winter need to be lubricated with silicone grease in the form of a spray. It will effectively protect their effects of various environmental factors;

- If an electric starter is provided in the design of the walk.Behind tractor, then it is best to remove the battery from the unit during the storage in the winter and transfer it to a dry and warm room. During storage, the battery will need to be completely charged several times;

- In order to exclude the extent of the rings in the cylinders in winter, you will need to open the motor block fuel several times a month and pull the starter handle 3-4 times 3-4 times.

Adhering to these simple rules, the farmer will provide optimal conditions for storing a walk.Behind tractor in winter. With the onset of spring, the unit can be removed from the room, replaced oils, and begin the operation of the unit.

How to get a motor block. In details for beginners and not only

Any branded motoblock consists of many complex mechanisms that are driven by starting a built.In power unit. At the time of turning on the engine, the agricultural nodes amenable to an increased load, therefore, the working resource of each of the factory motor block systems directly depends on the correct launch of the standard motor. To reduce the load and extend the timing of their operation, the user must study the correct procedure for starting the motor, taking into account different weather and operational conditions.

Reasons why the motorcycle block and ways to eliminate them are not started

The reasons why motor equipment does not start when starting, there are several. These include:

- Damage to the carburetor (in walk.In with a gasoline engine);

- Malfunction of ignition/incandescent devices;

- Low lubrication.

When strange changes appear in the motor.Cultivator and its work becomes not stable, the carburetor is first checked. In this important node, the fuel mixture (TVS) and dosing it for supply to the internal combustion engine (ICE) are formed in this important node. And if the jackets are clogged, the obstruction of the fuel system occurs, as a result of which the carburetor loses the ability to ensure the launch of the motor. To eliminate the malfunction, repairs of the fuel supply, which involves a partial analysis of the carburetor, washing the pump, blowing out nozzles through the fittings for fuel.

Sometimes the reason that the motoblock does not start, lies in the malfunction of the spark plugs (the spark has disappeared), which play an important role in the start of the carburetor ICE, or the glow candles ensuring the launch of the diesel engine. If the devices of the fuse become wet, which happens due to throwing their TVS, then the spark begins to disappear on them. In the absence of sparking, there is no ignition of the fuel mixture, which means that the engine does not start. You can solve such a problem in different ways:

Motorized technique is not started due to the fact that damage to the glow of incandescent occurs. In the diesel engine, fuel ignition comes from contact with red.Hot air, which warms up in the cylinder by compressing the piston. This happens without problems when the diesel has already warmed up and the working temperature in it is maintained by the heated walls of the cylinder. But in cold weather, and especially in winter, heating the engine is carried out using incandescent devices and if they fail, it will not be possible to start a walk.Behind tractor.

If, when examining the carburetor engine or diesel, there were no defective candles, but the problems remained, and they are also accompanied by cotton into the silencer, the performance of all devices responsible for fuel ignition should be checked. The malfunction in them can also be the reason that the motoblock does not start. Diagnostics is best done in the service center, where professionals will find the cause of the damage and competently carry out repairs.

Motics is not started and with insufficient lubricant fluid levels in the motor. Some models are equipped with special control sensors, which, in case of lack of lubrication, prevent the engine. Particular attention should be paid to those options for cars that do not have such sensors. Sooner or later, the level of lubricant mixture will reach a critical value and if it is not replenished to the norm, this will soon lead to wear of the parts and, as a result, to the overhaul of the engine.

We start correctly

Launch rules for gasoline and diesel models are different. At the factory of the first you need to immediately switch the handle of the suction. Need to put up in the “Launch” position. Only then can you open a gasoline faucet and pull the starter a couple of times. When correctly performing all operations, the motorcycle block should start. If it is equipped with an electric starter, then it is enough to turn it on and start the engine.

Diesel types of machines require a different approach. First of all, the air from the fuel hoses should be. To fulfill this task, the tap opens, after which the connection is unscrewed to feed the DT to the nozzle itself. It is necessary to wait for diesel fuel to flow. Then the taps open, the gas handle is transferred to the middle position. It is necessary to squeeze the lever 3-4 times and shake the decompressor (holding your finger). Then it must be returned to the initial position. After performing these manipulations, press and pull the starter once. When fulfilling all these stages, the motoblock should start.

Preparation of the walk.Behind tractor for launch

Problems with the start of the motor can arise not only the motor block and the cultivator who were in use, but also new, just bought in the store. Therefore, before the first time to start a motorcycle block, whether it is a cascade, a mole, a bison, a centaur, a hoper, a tarn, an eye, a salute must read the guide to its operation, then carefully examine all the connections and, of course, check the oil level in the internal combustion engine.

To study the instructions compiled by the manufacturer, it is necessary to find out what kind of working cycle the engine has: four.Stroke (like forte, centaur, lifan, bison) or two.Stroke. This is important to know, since for models with a two.Stroke engine (like a mole cultivator) you need a special combustible mixture, consisting of a certain proportion of gasoline and oil. Due to the discrepancy between the fuel, the technique will stall, and the candles of the fuse and the fuel pipeline can also suffer, which is fraught with the refusal of the gasoline pump-and this is the direct path to expensive repair in one hundred. Determine whether the fuel is suitable for motor vehicles by smoke. With poor quality of gasoline, it will have white color, as is the case with a strong slope of the machine. If you have bad gasoline, then replace it to prevent breakdown.

Fuel quality is also important for a diesel walk.Behind engineer. It does not start in the winter, or starts up, but soon stalls if the summer diesel fuel is flooded into its engine, since at low temperatures it begins to thicken and clog the fuel stove. In such cases, the risk of breakdown increases. In cold weather, select the corresponding fuel.