How to Test a Chainsaw Ignition Coil

Gasoline saws are necessarily equipped with an ignition system. It is necessary for the timely ignition of the fuel mixture in the engine cylinder. Therefore, the installation of the ignition on the chainsaw and its periodic adjustment are so necessary, since without a spark the tool simply will not start.

How it works and how the ignition of a chainsaw works

The carburetor engine is independent of the model of tool. Therefore, we can talk about the standard ignition system of a chainsaw. It consists of the following elements:

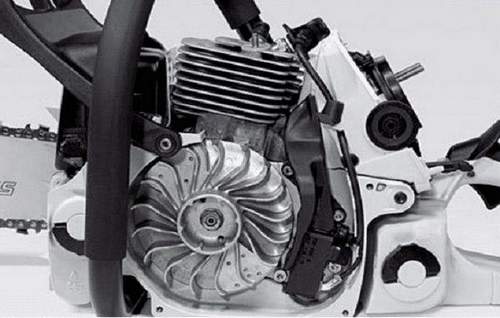

- Magneto. It is an alternator. It is necessary to supply spark plugs with electric current. Externally, this part looks like a stationary winding of an inductor and a permanent magnet, which is fixed on the flywheel. The latter rotates simultaneously with the engine crankshaft.

- Spark plug.

- An electric cable that connects the 2 previous elements.

- Buttons to turn off the device.

The ignition circuit of a chainsaw is simple. After starting the tool, a rotating magnetic field is formed due to the movement of the flywheel and crankshaft. It in the existing winding creates a moving force that transforms into voltage. This potential is enough to create a spark.

The differences between different chainsaw models can only be in the fact that contact or non-contact magneto is used. In the first case, one output of the winding goes to the candle, and the second. first to the disconnect button, and then through it to the ground. In the second case, the device has a capacitor that generates current when discharged.

Major malfunctions and their elimination

If you cannot start the saw the first time, there may be several reasons. Most often, the problem is with the spark plug:

- electrode wear or damage to the ceramic insulator;

- loose fit of the removable cap (if any);

- walking sparks along the ceramic winding, a sign of which is a brown residue on the outer shell;

- cracks in the cap of the candle (a saw with such a problem will continue to work, but can hurt the user when touched).

If there are no problems with the candle, it is recommended to inspect the wires coming from the coil. They may be torn off or have other mechanical damage. There may be wire breaks inside the insulation, so sometimes these violations can not be detected during visual inspection.

Video: How to Test a Chainsaw Ignition Coil

The cause of the breakdown may lie in the toggle switches. Checking them is easy. To do this, disconnect the wires from the module, and then check the ignition. If a spark appears after tripping, the switch must be replaced.

Check ignition coil on chainsaw

If the preliminary steps did not help in identifying the cause of the malfunction of the chainsaw, it is necessary to check the ignition coil of the saw. Diagnostics is carried out in several stages:

- Measure coil resistance using a multimeter. To do this, you should know the optimal parameters that are indicated in the instruction manual. However, due to the use of semiconductor elements in the system, when trying to “ring” the coil, the result will be the indication “Open circuit”. This is normal. A sign of malfunction is a positive test result. That is, if it was possible to determine the resistance of the coil using a special tool, then it is definitely faulty.

- Check for sparks with a special device. This device should be installed in an open circuit located between the spark plug and the high voltage terminal of the saw ignition coil. The indicators will be visible on the display. This method of verification is more often used in service centers, since the device necessary for this is expensive, and the costs will not be comparable with the provided benefits.

- Testing the coil with a candle, i.e., make homemade ignition. To do this, it must be unscrewed, and then attached to the cylinder body. Now you need to pull the starter and watch the spark. But this method gives only an approximate result, since the flywheel spins faster due to the unnatural position of the candle.

If none of these methods yields a result or, if necessary, perform field tests, you can do the following:

- Remove the cap from the candle, insert a nail without a hat into the core at a distance of 6-7 mm from the cylinder. This should be done as carefully as possible so as not to damage the part.

- Follow the steps to be taken when starting the tool. Now you need to look at the presence of a spark and its color. If there is no malfunction, then the spark will be strong, and the color will be bright blue.

This method can be used as a last resort and only if there are no electronic nodes, it is important to follow the rules:

- you can not completely unscrew the candle, as this can lead to faster rotation of the flywheel, which is not the correct mode of operation of the engine;

- it is necessary to place it at a distance that corresponds to the compression model and the dielectric properties of the fuel mixture, therefore this parameter can be viewed in the instructions (a value of 6-7 mm is averaged).

How to set the ignition on a chainsaw

Periodically adjust the ignition of the chainsaw. This action involves setting the correct clearance of the spark plug between the coil and the flywheel. The parameter depends on the model of the chainsaw. It is indicated in the instruction manual. The average value is a parameter of 0.2-0.4 mm. The presence of the correct clearance is important so that the spark appears at the right time, i.e., not earlier and not much later than the fuel supply.

Special templates will help to adjust the ignition on the chainsaw, however, it is not always advisable to purchase them for one-time use. Therefore, they can be replaced with homemade. To make it, you need to cut a strip from a plastic bottle. The part of the container where there is no embossing is suitable. After that, you can install the ignition, acting in the following sequence:

- Remove the ignition bolts slightly to loosen.

- The magnets located on the flywheel must be connected to the ignition coil.

- Clamp the plastic plate between the flywheel and the coil, and then tighten the screws again.

- Take out the strip.

- Scroll the flywheel a full turn several times in a row, while making sure that it does not cling anywhere.

If during the diagnosis any malfunctions of the coil were detected and it did not work out, then the part must be replaced, since the repair is impractical.