How to thread an aluminum tube

How to thread a pipe near a wall

Installing pipes often involves creating threads on them. You can cut it yourself. For this, it is not necessary to call professionals, spending money on it. Before starting work, you should read all instructions, videos and photos.

Pipe cutting

It will take

- Klupp for the required pipe diameter.

- Adjustable wrench (gas).

In this case, the Chinese version is presented, quite good.

There is such a thing in the region of 200-500 rubles. It all depends on the diameter and the markup. Running models for diameters 1/2, 3/4 inches and inch as in my version.

You can ask plumbers for a Soviet counterpart, if there is such an opportunity. Then it will be generally free for you.

How to thread a pipe with your own hands

When performing work related to the installation of plumbing or heating, it becomes necessary to thread pipes. To do this, you can take a pipe and head to the metal rolling, where the thread will be cut in a matter of minutes. However, this method has not been relevant for a long time, since there are other options that do not require the transportation of the pipe to production.

Cutting techniques and tool composition

Depending on the type and parameters of the thread, you can cut it at home in several ways:

- use special cutters and threaded combs;

- using dies and special taps;

- the use of flat or round dies;

- cut with cutters.

If you need to cut an external thread, then the best advice would be to get a set of “klupp”. This is a special tapping kit that includes a set of cylindrical dies and a lever handle.

Additional tools and materials that you will need will be. vise, grinder and lubricant.

Attention! The vise should be fixed on a table or a special tabletop and the distance between the jaws in the open state should allow fixing the pipe necessary for cutting.

Idea from an old bearing

I will show you how easy it is for an ordinary home craftsman to cut a thread on a water pipe, without any skills in this matter and with a minimum set of tools. For example, when replacing a central heating battery, as in my case. There is absolutely nothing complicated in this and the method is accessible to almost everyone.

So, you cut the pipe with an angle grinder or other tool, such as a hacksaw. The main thing is that the cut is even and perpendicular.

We cut threads on the pipe

Old paint can be left on. We lubricate the place where the thread will be with solid or liquid lubricant: grease, lithol, engine oil.

We also coat the incisors on the die.

Neither there nor there it is necessary to apply a lot of solid lubricant, since the shavings after cutting will stick to it and will not fall down, which means they will be removed.

We put the klupp guide on the pipe.

In theory, the klupp rotates with a specialized tool. a ratchet, but since we have a one-time job, it will not be profitable to purchase an expensive tool.

We take an adjustable wrench and adjust its size to fit the klupp’s back skirt.

We rotate the tool making several turns around the pipe. The cutters are now engaged.

If the pipe is flimsy and unstable, you need to hold it with another adjustable wrench like this:

And with another adjustable wrench, rotate the nozzle.

The cutting sequence is as follows: 2-3 turns of the chuppa forward, 1 back. This must be done without fail so that the chips break, fall off and do not interfere with further cutting. If this is neglected, shavings can jam the threads.

In total, you need to cut 4-5 full threads.

As a result, the thread on the pipe is cut.

Also note that the incisors in the die have a small taper. This is so that you can easily start and cut threads. As a result, I lead to the fact that the end turns may not be complete and not cut in depth.

Therefore, in order to get 3-4 full threads on the pipe, it is visually better to cut 6-7 threads.

After all work, the thread can be checked by screwing any adapter or fitting onto it.

The thicker the pipe, the more force has to be applied to turn the nozzle. The method is not tricky, proper skills are almost not required, even a beginner can handle it. It is impossible to skew the thread, so you should not be afraid.

Existing threading options

There are five types of pipe threads, but the most popular options are tapered and cylindrical. Households often encounter such options for pipe threads. There are two ways to thread a water pipe:

- Automatic, providing threading on water supply pipes using special machines and power tools.

- Manual. For this, special hand tools are used.

If, on duty, a person needs to cut threads on a large number of pipes, then it is appropriate to purchase a special power tool, which will facilitate manual labor.

When the need to obtain a threaded connection is a single case, then manual technology is suitable for such purposes. On water pipelines, as well as pipes of heating systems, threading is performed using a die.

A die (another name for a lerk) is the simplest device designed for cutting an external threaded connection on pipes.

The die is a steel disc, and its inner diameter has axial holes in different numbers, depending on the size of the product. The edges of these holes form cutters, with the help of which the threading is performed. To ensure the reliability of such a tool, it is made from alloyed types of steel or hard alloys.

Dies can have different shapes (round, square, hexagonal or prismatic), but most often disc options are used. It is the disc dies that are intended to obtain a threaded connection on water pipes. To make it convenient to work with the die, they are additionally equipped with knobs, as well as fasteners in the form of screws. Dies are also available in solid, split and sliding.

One-piece pipe threading dies have one significant drawback. the rapid wear of the cutters. This is due to the rigidity of the product’s own design. Split or spring-loaded dies have a less rigid structure, which significantly increases the life of the product. Due to the spring-loaded mechanism, such a pipe threading tool allows you to vary the diameter of the resulting threaded connections in the range from 0.1 to 0.3 mm. A device of this type has a high resistance to cutter wear, however, it is not able to provide high accuracy.

Sliding dies are 2 working parts intended for installation in the fastening module. A die with a special fixing module forms a tool called a pipe die. The die in the die is fixed with a cracker and an adjusting screw. It is with the help of the adjusting screw that the thread diameter is adjusted.

Typically, pipe couplings are supplied with dies of various diameters. With such a set, you can always cut threads on pipes of any diameter.

How to thread a pipe with your own hands

When performing work related to the installation of plumbing or heating, it becomes necessary to thread pipes. To do this, you can take a pipe and head to the metal rolling, where the thread will be cut in a matter of minutes. However, this method has not been relevant for a long time, since there are other options that do not require the transportation of the pipe to production.

How to cut a thread on a pipe with your own hands

To make a thread cutting on a pipe with your own hands, you initially need to perform a number of preparatory measures:

- Thoroughly clean the tube in the area where you plan to receive the thread.

- Clean the end of the product with a file.

- Lubricate work area to reduce drag.

Threading Aluminum

In order for the threading process to be convenient, and the end result to meet the requirements, before proceeding, you need to fix the products in a vice. This will fix the part so that you can perform the necessary actions with both hands. After that, the following actions are carried out:

- A wrench with a die of the required diameter is used, with the help of which a rough cut is carried out. In this case, it is important to keep the die strictly perpendicular to the pipe.

- The rough cut is the basis for threading, so take your time and do the steps slowly but efficiently.

- A rough cut allows you to get 2-3 threads of a thread. This is how many threads are needed for the tool to take a secure position.

- The next step is to twist the rough die, and use the finishing one. With its help, the required number of threads is cut on the pipe, which is planned to be installed in the water supply or heating system.

- After each pass, you need to do 0.5 turns back to clear the cut from the chips.

- At the final stage, you should use the third plate, which carries out the control passage.

How to cut Threads on a tube

When threading, it is important that all actions are carried out slowly, and with each subsequent turn, the cut is cleaned of metal chips.

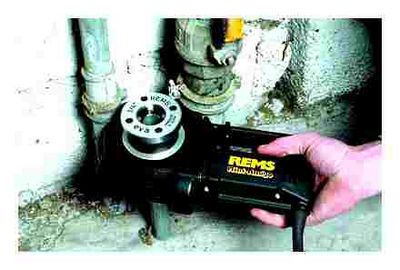

How to thread a pipe near a wall

Often times, threading needs to be done on site, with the piping partly anchored to the water or heating system. In hard-to-reach places, it is impossible to thread a thread on a pipeline installed near the wall with a die with a knob. For such purposes, you will need to use a threading device such as a ratchet die. With its help, the threading process is simplified several times.

The manual threading procedure is carried out as follows:

- A nozzle of the corresponding diameter is fixed in the clamp of the klupp, after which you can proceed to the procedure itself.

- Cleans the surface of the pipe. working area.

- The area to be cut must be cleaned until a metallic sheen appears.

- A chamfer is made at an angle of 45-60 degrees.

- The material is lubricated with Litol or Solidol.

- A wrench is put on the working area of the pipe.

- Moderate reciprocating tool rotations are performed.

As with a die, and when working with a die, you need to make a half turn back after each new thread to remove the metal edge. To facilitate the process of threading, you can use an electric die cutter, however, it is rational to purchase such a tool only if you need to use it every day.

On pipes, you can cut not only external, but also internal threads, for which taps are used. However, the need to obtain a thread on the inside of the pipeline arises only in rare cases. Knowing the features of self-threading, there will never be problems with the installation of water supply and heating systems.

If you use a die, as opposed to the paragraph above, do not remove the chamfer.

Since the klupp has a tapered approach, it is easier for them to catch on a flat cut of the pipe.

10 Tips for Tapping Pipe:

Treat each of them with attention, all of the following: a guarantee of trouble-free crimping, achieving the best result and simplifying work. In order not to take a lot of your time, I will add, only short explanations.

If you use a stick (die) in a stick holder, on the cut, remove the chamfer at 30-45 degrees, along the entire circumference

This will provide an easy entry for the first turn, it is removed using an angle grinder with a sharpening disc.

Hold the pipe with a gas wrench if necessary

In order to avoid breaking, crushing. Relevant for “loose” pipe, or “loose”. the same place of tie.

Make a cut at right angles to the pipe axis

Otherwise, the threading will not carry out the proper hook on the entire plane. The tool will break.

Do not be lazy to periodically “dump” the chips

Threading is done clockwise. After passing one or two turns, discard the chips by rotating counterclockwise. Non-observance is fraught, as a maximum, with crushing of already cut turns, but at least with an increase in the labor intensity.

Apply lubricant to pipe and cutting tool before cutting

Use engine oil, special lubricant, or a piece of bacon for this. It will be easier to cut and less wear on the threading tool.

Cut as close to the riser as possible

Clean the inside of the plaque, often there is a hole for the passage of water as thick as a match. Clean carefully, so as not to tamp the rust inside.

How to properly thread a pipe with a die

If you are repairing plumbing, changing the water supply, then you need to know how to properly cut the threads on the pipe with a die in order to screw on the tap, coupling, and the safety of repairing your apartment, as well as the neighbors below, depends on the correct threading.

I have already described the threading process itself in the article “How to connect a heating radiator”, but according to questions from readers of my blog by mail, I decided to describe in more detail how to do this.

In order to cut a thread, you will need the following tool:

- die holder, lerka

- rough thread cutting die

- fine threading die

- grease, machine oil or lard

- angle grinder or file

Also called dies. first pass and finish.

For which I advise you to use two dies:

Firstly, it is easier to cut, and secondly, tool wear decreases, and with the current quality, this is very important, since now you will cut 3-4 threads, and the die can be thrown out.

If you cut a thread on a water or heating riser, or a tie-in for an apartment, be sure to make sure that it is in good condition, otherwise you risk breaking the pipe.

How to thread a pipe

When the pipe was cut to size, on the side where you will cut the thread, be sure to remove the chamfer, you can also clean the very place where the thread will be a little, if there is paint on the pipe, then it is better to clean it, it will be easier to cut the thread.

Lubricate with grease or lard the place of the thread, and the teeth of the die.

Take a die holder with a 1-pass die, or a threading tool for a rough thread. A clerk (pictured) and pressing it with your hand with force (so that the die catches on the pipe and starts cutting), start cutting clockwise, approximately 5 turns. After about the 2nd turn, when it goes tight, turn back half a turn, this will break off the chips, and it will be easier to cut, and turn clockwise again.

When the rough cut was cut, we take the 2nd die, again grease the thread, the die for the fine thread, and repeat the same steps.

And now some tips and nuances.

Do not buy taps in which the internal thread is 3.5 turns, even if they are thick-walled, such valves can be screwed onto fittings with brass threads, for a water supply, iron pipe, they are not suitable.

Be sure to cut the first through thread with a guide, so that the thread does not go into distortion.

If you cut the finishing thread without a guide, carefully watch that the die winds 1-1.5 turns evenly, without skewing.

Tip: cut at least 5 turns, and be sure to screw the tap on the bare thread, and count the number of turns, it should be 5, when installing the ball valve on an iron pipe with flax, you must wind at least 4.5 turns. So do not be lazy, if the tap is screwed in fewer turns, be sure to cut the thread.

If you screw it by 2-3, then after a short time 1-2 turns will rot away, and the tap will fall off, and there will be a flood. How to properly wind flax on a thread, read here.

Here is such a process and tips on how to properly cut a thread on a pipe with a die with your own hands, you can watch the video.

How to properly thread a pipe?

- Features of the

- Tools

- How to cut?

- The ways

- Advice

To connect parts in systems of different types, cutting or threading is often used. It provides reliability and strength of structures. Fasteners with threads are universal, because they can be used to easily mount and dismantle pipes of various systems.

The ways

A thread is a type of connection, for the implementation of which the elements and the angle of the profile (cross-section of the turn), as well as the diameter along the outer, middle and inner edges, are taken into account. By the profile, the thread is divided into triangular, trapezoidal, rectangular and other types.

For cutting gas and water pipes, cylindrical pipe threads are used. The last two turns are incomplete. This is the escape required for a hermetically sealed pipe connection. The run is performed with special types of dies. Pipe diameter is measured in millimeters and threads in inches.

Slicing is divided into internal and external, left- and right-sided. In the left-hand version, the nuts are tightened to the left, and in the right-hand version, to the right. The types of threads are determined by the methods of operation and are fastening, running and fastening and sealing. The latter option is used for pipe threading at home.

There is a so-called cutting step. this is the distance between the turns, as well as the size of the thread depth. Their configurations are different, but they all operate according to the same rule: the deeper, the stronger.

There are many ways to cut a thread: using a die cutter, an automatic electric cutter, and also a threading machine. The external thread is manually made with dies installed in the die frame. One-piece and sliding die designs are used. With the help of split (split) structures, the diameter of the cut is corrected.

Sliding dies are set according to the number values, round ones are installed with special screws on the knob. Then the dies are fixed. In the sliding dies between them and the screw, a gasket is installed. a cracker.

Internal threads are made with taps. With the help of their device, holes are drilled in a metal pipe, strictly adhering to special calculations. For high-quality cutting, you have to make at least three turns.

The internal thread is applied in the same way as the external one. in reciprocating movements: two steps forward. one back. The first approach is carried out with a rough tap. He only has one risk. Then the procedure is repeated with a middle tap with two risks. Cutting ends with a finishing tool with three risks at the end.

When threading deep surfaces, the tool must be removed and cleaned periodically. In blind holes, long taps are used with the obligatory use of a lubricating emulsion.

Automatic electric die cutters greatly simplify pipe threading. They consist of modified gearboxes and a set of dies of various calibers. They are distinguished by high performance, they work from the mains. With all the advantages, the tool has its negative features. For example, an electric clamp with all its power of 1 kW has a very significant return, therefore, a clamp is used to secure the electric clamp.

The threading machine is usually used on an industrial scale and in large workshops. The machine has its advantages over manual and electric tools, which include high productivity, precision in threading, as well as minimal human factor.

Pipe threading machines are divided into manual, electrical and automatic versions. Manual is used at home. it is compact, transportable, weighs no more than 50 kg, but is not suitable for pipes of large diameters. Electric machines are good for small workshops, automatic versions, due to their large dimensions and high productivity, are widely used on a production scale.

Some types of pipes can only be cut in an industrial environment. For example, on a carbon pipe with a diameter of 32 mm, you can make cutting only after processing its surface with a special compound.

After the work is carried out, the material is rejected. If the product has defects in the thread, then it cannot be used, therefore, cutting must be carried out with basic skills and knowledge in this matter.

Tools

To carry out the work, you need to prepare all the necessary tools and devices for cutting. In each case, the pipe threaded set will differ in composition, but for manual use it consists of dies, a die and a ratchet holder. The set also includes a pipe cutter, a gas wrench, a file, a hacksaw, an angle grinder, lubricants and other tools. For those who do not want to work in the old-fashioned way with the classical method, there is an alternative. a power tool.

The main requirements are for the quality of the tool used and preparation for work.

The cutting itself is carried out using dies. Some are cut on one side only, others on both.

For the implementation of internal threads, the kit can also include several taps with different indices of the depth of the slot. Some are designed for roughing the inner surface of the pipe, others for finishing. This equipment is in the form of a flute screw. It is attached to the cranks with the help of the tail.

With the help of a tap, internal cutting is performed in several passes. Their number depends on the material with which they work. For example, for threading in titanium alloys, special sets of several taps are designed.

A die, run or die is used to make threads of various shapes on pipes. It is a steel nut with a cutting base inside, in which there are special holes. grooves for waste. Dies are tubular, hexagonal, round and square. Modification of their body is one-piece, split and sliding.

Sliding (prismatic) models are also called half-dies, they are attached to the clamp with screws and a special gasket. a biscuit. This is necessary to evenly distribute the pressure on the screw. Dies are used to cut cylindrical, conical, round or metric threads. Die accessories. special wrenches and chucks, with which it is attached to the frame body.

Klupp consists of a frame in which the cutting elements are fixed. dies. Each mandrel is fitted with four steel dies. The klupp is also equipped with a special ratchet handle. Only one die can be inserted into the die holder, several into the die holder. The purlin cutter is capable of cutting two types of threads: 0.5. 1 ¼, 1 ½. 2 inches.

A manual die cutter, as a rule, cuts small diameter pipes. They are equipped with a special handle. holder. They can also be used with a suitable pipe wrench. It is small in size, simple and convenient to use.

The holder and ratchet clamp is a modification of the gear mechanism designed to accommodate threads larger than one inch. The ratchet is an irreplaceable mechanism. The left- and right-hand ratchets are convenient for working in hard-to-reach places, such as near walls. Using the ratchet lever, the die is quickly removed from the thread by turning in the opposite direction, providing a reciprocating method of threading.

In practice, they use ordinary, oblique and Mayevsky kluppas.

The oblique clamp is called because it adjusts the distance between the sliding dies. This tells the diameter of the cut. Constructions of this kind are the easiest to use.

Klupps of Mayevsky of a more complex design are used for the implementation of pipe threads. They contain three sets of interchangeable dies, specializing in thread diameters up to 2 inches. Structures of this type are used for threading on pipes with a small diameter.

Cutting on large diameter pipes is carried out on an industrial scale. For example, to cut a seamless pipe with a diameter of 219 mm, you need a special auto-stop. Casing pipes (columns) are cut only on special machines under special conditions, subject to all safety measures.

How to cut?

When all the tools are ready, you can thread a pipe, for example, a heating system. It should be noted that it is not necessary to have any special skills to perform this type of work. you can do everything yourself.

First of all, you need to study the process itself, guided by the following rule: threading on pipes must be carried out in a certain sequence, otherwise the consumption of sources and equipment breakdown cannot be avoided.

Before cutting, the pipe must be inspected for old paint, the presence of corrosion and plaque, and then processed by thoroughly cleaning the surface using special means and tools, for example, a grinder. From the end, the pipe must be pre-processed by removing the chamfer for better thread lead. If the cut is made with a pipe cutter, then the cut edges will be smooth, without serifs. If this is done with a hacksaw or an angle grinder, then it is necessary to clean them up to metal with a file. this will significantly improve the joining. Before and after threading, it is necessary to lubricate the cutters and the surface of the pipe with a special liquid.

The dies of the required caliber are inserted into the die frame using the clamping screws. Then the clamp is put on the prepared surface of the pipe and a couple of starting turns are made in the direction of cutting. The thread is made only after such fastening.

After that, the ratchet switch is adjusted and rotation begins clockwise to the right (in the direction of the thread). You do not need to apply special efforts. For good chip removal, you need to work with the following rotation range: two turns forward, half a turn back. To avoid skewing, the correct position of the die relative to the pipe must be strictly observed.

You can check the quality of the thread with a nut screwing it onto the pipe.

After completing the work, you should prepare the thread before installation with a sealant, fum tape or linen thread.

Features of the

The thread was invented two centuries ago: then the screw-lathe first appeared in Britain. The inventor G. Maudsley discovered a way to apply precise threads and invented a device for measuring it (micrometer) with an accuracy of 0.0001 inches.

Around the same time, mechanical engineer D. Whitworth created the first screw thread profile and proposed a system of its standards. Since then, the invention bears his name. Whitworth carving. She formed the basis for all kinds of national standards.

No one remembers the exact date of the appearance of the thread, however, the date of its application can well be considered the beginning of industrial production.

The main feature of threading is that the tool for its implementation must be made of a material of greater hardness than the element being cut, and for the manufacture of this tool, in turn, structures with even harder elements in composition must be used.

Most piping systems are now made of plastic. It is often necessary to fasten structures using plastic and metal connecting elements. In the domestic sphere, such fasteners are a fairly common solution, they are called combined. In modern communication systems, one of the types of plastic or metal pipes is traditionally used. However, in some cases, it is advisable to use precisely combined structures.

To install systems when combining elements of HDPE and metal, several connection methods are used, including threaded and flange threads.

Pipes with a diameter of up to 40 mm are threaded. Flanged connections are used for larger pipe diameters where it is impossible to tighten the thread.

The connection of a polypropylene pipe with a metal pipe is carried out using fittings that are specially created for this. They are connections, one side of which has a thread for metal, and the other. a sleeve for plastic. Multiple combined connections are made with special complex fittings.

Advice

It will be useful to know some of the subtleties of operation and choice of tools, as well as how to use them.

Some tips will help in this matter.

- Before buying a klup, you need to make sure of the quality of the materials of its body and components, for which you should study the annotation and familiarize yourself with the technical conditions for the operation of the device. Choose the best licensed models from reliable manufacturers.

- A die with replaceable cutters will last longer and better than a regular die. Cutters are best chosen from alloy steel.

- Before threading water pipes, make sure that the system is intact, otherwise pipe breakage may occur during work.

- If elements of rust are found in the pipe, it is better to remove them using a pipe cutter. An electric model is suitable for this. It can handle large diameter items. The manual die is only intended for thin pipe steel surfaces.

- To make cutting easier and better, you need to use a special liquid for the cutters during work, which will simultaneously cool and lubricate the cutting surface. this will reduce the friction force, which will protect the cutters from heating and deformation. Working surfaces, tools and sources are usually lubricated with special lubricants: machine oil or grease. If they are not at hand, then you can use a proven remedy. a piece of bacon.

- For manual cutting from the inside, it is better to use a pipe cutter and a wrench. With the help of a gas wrench, the pipe is fixed and cut. Due to the length of its handles, it is lightweight and easy to use. A vise may not be needed, however, this safety material is sometimes necessary as a reliable fixture of the pipe structure.

- It is better to cut in such a way that the diameter of the outer turns is slightly larger than the diameter of the pipe. this guarantees a high-quality connection.

- For the reliability of the connection in the cut, it is better to make a larger number of turns, for example, five. Finishing the thread, you need to walk over the surface again for guaranteed cutting quality.

- To set the grommets correctly, you need to follow the number values at risk.

- For a good long-term work of the klupp, it is necessary to replace the failed components in time. It is better to purchase new teeth instead of worn ones from the same manufacturer.

- It is necessary to combine the structural elements of the tool strictly according to the parameters. non-observance of the values \ u200b \ u200bof the dimensions of the dies and chuppa will lead to breakage of the cutters.

You can watch how to thread a pipe in this video.