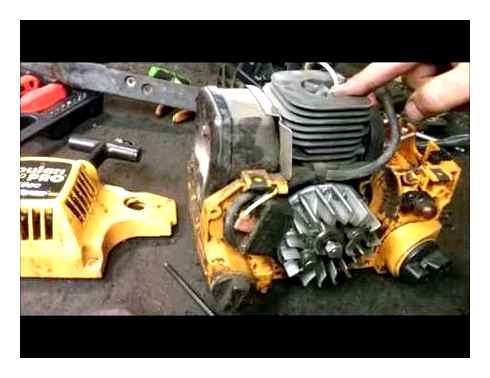

How to tighten clutch on a chainsaw. Removing the flywheel

How to remove and change the clutch on a chainsaw with your own hands

In devices released in the near future, a single.Cylinder two.Stroke carburetor engine is installed. It contains several devices that work harmoniously. The main components of the motor:

Read adjusting the carburetor of the chainsaw Energomash

How to remove

The leading star serves at the same time and the drum. One of the main circumstances of the breakdown of this block is to steal the teeth of the star. In the whole version of the drum, the chain can cut out a star during operation. Such a mechanism asks for substitutions. In the case when there is a replaced crown on the drum, it must be removed and changed during service. After which the drum can continue to work.

Когда появляется потребность в ремонте следует обращаться за помощью в сервисный центр, где работают бывалые спецы. But if this is not close to the question. How to remove the clutch without the help of others? If there is a necessary set of tools, you can easily perform a mystery. Naturally, there are some differences in the models of various companies, but the disassembly scheme remains constant:

- At first, the brake brake cover is removed by turning the lever. Nuts are slightly twisted to loosen the tension of the chain. After weakening, you can completely turn the nuts and remove the lid;

- Disassembling the chain and guide tires, also cleaning the mechanism from pollution;

- The candle of the cylinder head is twisted and the piston is fixed. To do this, the crankshaft should be twisted until the exhaust hole is overlapped, and later a segment of the rope is placed in the cylinder to lock the piston. After the end of the work, the rope is removed from the mechanism;

- The nuts are unscrewed on the clutch with a special key from the kit. In this mechanism, they are made with left thread, and this must be taken into account when dismantling. After which the mechanism is disassembled, and all its details are examined for damage. Worn parts must be removed and changed to new.

After the repair and substitution of parts, it is necessary to assemble in a revolutionary sequence. In more detail, the disassembly process is presented at.

So that without the help of others to repair such chainsaws as STIHL, Husqvarna, Partner, GoodLuck, you should know some features of models. For example, a puck was installed on some varieties of saw (between the cup of the leading star and the engine). During the assembly, it must be installed in its former place.

If the model has a special spring that transfers rotation to the pump drive, then its correct installation is very fundamental after repair. In an unpleasant case, the device may seriously suffer. After preventive and repair work, you need to check whether the mechanisms work properly.

Removing and replacing the coupling with your own hands according to the instructions

Far from how to remove the clutch on a chainsaw is known. The constructive performance of mechanisms on different models of chainsaws differs, but the principle of operation is the same everywhere. The dismantling procedure is also practically identical, so then we will consider how to unscrew the coupling on a chainsaw with an internal location.

Initially, you will need to prepare the necessary tools:

- A special key called a puller. He often comes with a chainsaw

- Screwdriver screwdriver with which the protective casing is attached

- Candle key. Used to unscrew the fastening of the casing and tire (it comes with the tool)

- Rope. In order to lock the crankshaft. It is better to use asbestos, but for this purpose any. The rope is used in case a special stopping key for the piston is not attached to the tool

Easy Flywheel Removal

If dismantling is performed for the purpose of replacement, then accordingly you will need to prepare a new mechanism in advance. When buying a new coupling, you only need to know the exact brand of the chainsaw, since the devices differ in the outer diameter, thread and design of the working mechanism. Instructions on how to remove a clutch clutch on a chainsaw has the following view:

- Initially, it is necessary to unscrew the fasteners of the casing and tires

- Remove the casing with a manual brake, as well as the chain and tire

- After that, go to the removal of the plastic cover to get to the spark plug. For this, the fasteners are unscrewed with a screwdriver, and the lid is dismantled with an air filter

- The spark plug is unscrewed with a candle key

- You need to stick a rope into the candle hole of the cylinder (install a special key if any). This is done in order to lock the crankshaft. If the diameter of the rope is several times smaller than the size of the candle hole, you can make nodes on it

- Next, proceed to the unscrewing of the clutch itself. To do this, take a special key that should be in the kit. If there is no key, then you can use the tool from Ushm or make an independent puller, which will also not be difficult

- The key slots must be installed in the holes of the coupling, and then proceed to rotate the part. It is necessary to rotate in the direction clockwise. Typically, manufacturers indicate the directions for unscrewing in the form of an arrow

- With the rotation of the coupling, the piston will reach the upper dead point, after which the crankshaft will stoop. Then putting a small effort, tearing the clutch with the subsequent twisting of the mechanism

- The twisted coupling is dismantled from the chainsaw. If necessary, a drum with an asterisk is also extracted

The procedure is not at all difficult, and does not take much time. The assembly is performed in the reverse order of removal. In order to avoid any malfunctions, it is recommended to set a fully identical adhesion on the corresponding model of the tool.

It is interesting!Similarly, the procedure for removing and replacing the clutch for all brands of chainsaws of Khuskvarna, partner and others is performed.

Malfunction of the chainsaw engine

Here are different violations in the operation of the chainsaw motor, which happen more often. The main such malfunctions are reduced to subsequent signs:

The engine does not start (quite generally and the prerequisites can be quite different);

Loosening flywheel and drum clutch removal | Husqvarna 45 chainsaw

Does not develop power, t.E. It works normally at idle, but it stalls or zabliks under load.

3) malfunction of the chainsaw: clutch often “slips”, at times the spring bursts. Prerequisites for a malfunction: Clutch wear of a chainsaw. Cross.Rosopila repair in artisanal criteria: Change the clutch of the chainsaw assembly.

How To Remove a Clutch On a Homelite Chainsaw

Do.It.Yourself Repair and Service of the Chainsaw

Benzopila are reduced and this makes them more popular and affordable not only for professionals, and for ordinary, so to say, lovers. But a common dependence. The lower the price, the less reliable apparatus and malfunctions appear more often, for the chainsaws are also relevant. But for a chainsaw, at least any price range, most of the flaws can be avoided with proper operation, care and timely maintenance of equipment. But from the breakdown of the chainsaw, as well as at least some other technology, no one is safe. Therefore, it is proposed to consider the main types of fabric defects, methods for their diagnosis, elimination and repair.

All the main malfunctions of the chainsaws can be conditionally divided into two main categories:. Malfunctions of the motor and its different nodes: the system of preparation and supply of fuel, ignition, piston group with crankshaft, exhaust system of exhaust gases;. Malfunctions and breakdowns of other nodes: a lubrication system, clutch clutch, chain brake, tire and others.

How to remove clutch on a chainsaw?

In order to remove the clutch from the chainsaw, you should first be careful and careful so as not to damage anything superfluous.

This operation should be performed according to this algorithm:

- Remove the saw and chain. To do this, unscrew the manual brake of the chain, pulling the handle over yourself. Then dismantle the tire, remove the pollution.

- Remove the casing from the air filter and clutch.

- Blok the crankshaft. This is a mandatory procedure to avoid its rotation during operation. To do this, unscrew the spark plug, fix the piston at the lower “dead” point and put the rope into the candle hole.

- Using a special key, remove the clutch. You need to unscrew it clockwise, because it usually has left thread.

- Replace damaged parts. Collect the clutch of the chainsaw should be in the reverse order in which the analysis was carried out.

Quite often, replacing the chain coupling, including Champion 242, is explained by the fact that this part may burst. And the reason is simple.

All modern chainships are equipped with a chain brake device, and in most models it is controlled using a tape located on the tire and a chain surrounding the clutch drum.

If the user does not turn off the chain brake over time, but, on the contrary, continues to press the throttle of the throttle on the trigger, the tire cover and the chain will be melted, forcing the clutch drum burst. In this case, the repair of the chainsaw is inevitable.Consider the replacement of the clutch drum on the example of Champion 242 chainsaw, which is fully executed.The clutch drum is replaced in several stages, we will consider each of them:

- Remove the air filter lid.

- To unscrew the nuts holding the structure of the coupling on the crankshaft, it is necessary to stop the engine. To do this, remove the cover from the candle, turn it and insert the rope into the hole for the candle.

After that, gently pull the starter handle to remove the remaining space in the combustion chamber. It is not recommended to use a metal plug, since the crankshaft can be turned during the unscrewing of the nut.

In this case, the piston will take a rope, and the stopper will break its bottom.

Tips: how to remove an asterisk from a chainsaw

Many tools need constant substitution of consumables. It applies and saw. 3 independent adjustment of the carburetor carburetor on the chainsaw Partner 350. How to remove a clutch to remove the clutch on a chainsaw, with my Chinese.

That is why the question of how to remove the star from the chainsaw, which is often called the clutch disk or centrifugal mechanism, very lively among home masters.

In this regard, you need to see what is called an asterisk and for what purposes it is needed.

The clutch drum called an asterisk is an integral part of the chainsaw.

The drum located in the clutch base of the mechanism is an integral part of the circuit drive system. How to remove clutch on a chainsaw? With your own hands, replacing the coupling and how to collect a clutch back. Read all this on our website! This part recalls the star with its own form, due to which it received its title. How to remove clutch on a chainsaw: STIHL, Husqvarna.

Depending on the type of chainsaw, the part can be professional or household. Because the profile saw is used more often than the household, then the leading star asks for constant substitution. At the chainsaws of Husqvarna how to remove the clutch to remove the clutch on the chainsaw.

If you read about household tools, then everything is depending on the volume of work performed and the load that is on the device chain.

In most cases, a star, a crown and a saw bearing requires substitution.

Usually, in order to remove the star from the chainsaw, many people contact the special service centers, but if there is a need to save the home budget, this work can be done without the help of others. This event does not look complicated, but at the same time it is necessary to have all the necessary details and tools. The process of replacing the sprocket is similar to any device model.

How to tighten clutch on a chainsaw

Clutch is a connecting link located between the power unit and the cutting organs of the chainsaw. Its main function is the transfer of a rotational force created by the engine to the saw set. Most modern household and professional chainsaws are equipped with reliable metallic clutch details, but they eventually completely fail. You can eliminate the breakdown of the node at home, however, for this it is necessary to carefully study the order of disassembly and features of replacing the adhesion elements with your own hands.

Most high.Quality chainsaws of well.Known brands are originally equipped with centrifugal clutch. It is distinguished by high reliability, an increased working resource and works in automatic mode, that is, it independently works when the power unit reaches the necessary speed of rotation.

The device of the factory centrifugal mechanism constructively includes durable friction linings, a clutch drum for a chainsaw and return steel springs. The friction pads of the mechanism can move radially. They are pulled up to the crankshaft springs when the internal combustion engine is at low speed. At the same time, a standard metal drum is acted, which is initially connected to the star of the cutting circuit. When typing a fairly high motor speed, the force of built.In springs in relation to the created centrifugal force decreases. This makes the springs press against the inner surface of the drum and put it into effect. At the same time, an asterisk starting to rotate, responsible for the work of a saw chain. In different types of clutch chainsaws, it can be located behind the clutch mechanism or in front of it.

This principle of centrifugal adhesion has one important advantage. The mechanism automatically slips when jaming the cutting circuit. Thanks to this, the power unit does not stall, but continues to work further.

Design features and clutch work scheme

Most high.Quality chainsaws of well.Known brands are originally equipped with centrifugal clutch. It is distinguished by high reliability, an increased working resource and works in automatic mode, that is, it independently works when the power unit reaches the necessary speed of rotation.

The device of the factory centrifugal mechanism constructively includes durable friction linings, a clutch drum for a chainsaw and return steel springs. The friction pads of the mechanism can move radially. They are pulled up to the crankshaft springs when the internal combustion engine is at low speed. At the same time, a standard metal drum is acted, which is initially connected to the star of the cutting circuit. When typing a fairly high motor speed, the force of built.In springs in relation to the created centrifugal force decreases. This makes the springs press against the inner surface of the drum and put it into effect. At the same time, an asterisk starting to rotate, responsible for the work of a saw chain. In different types of clutch chainsaws, it can be located behind the clutch mechanism or in front of it.

This principle of centrifugal adhesion has one important advantage. The mechanism automatically slips when jaming the cutting circuit. Thanks to this, the power unit does not stall, but continues to work further.

Replacement and repair of clutch on a chainsaw

Malfunction of the clutch clutch of chainsaws is one of the most common breakdowns of this technique. On the question of how to remove the clutch on a chainsaw at home correctly and not harm the instrument, not only inexperienced techniques, but specialists who have repeatedly repaired its repair. This is due to the fact that the clutch is an important key element of the power of power and the brand, on which their serviceable, prolonged and successful operation depends.

In cases where gasoline carriers begin to start poorly, slip instead of launching a traffic check on a malfunction is required, the recommendations will be presented further.

Device and principle of operation of the clutch clutch of chainsaws

Modern chainsaws are equipped with centrifugal clutch couplings. This means that their work entirely depends on the torque of the motor, which at a particular moment in time gives out a saw.

Its main constructive elements are:

The principle of operation is as follows. When the saw is launched, the elements that are freely move in the radial direction, with the springs are tightened to the axis of the shaft. In this case, the torque does not enter the drum, which means to the asterisk and the guide. At the moment when the centrifugal force prevails over the power potential of the springs, the adhesion elements are weakened and compressed at the inside of the drum, initiating it. Together with him, the rotational cycle passes to the asterisk and the tire-like headset itself.

The main advantage of the clutch of this type is its slippage when the cutting part is suddenly inhibition, which does not stop the engine. As a result, the “heart” drank. The engines remain intact and preservation.

How to remove clutch from a chainsaw: detailed report

The process of repairing the clutch coupling is composed of such operations:

- Dismantle the chain headset, the airfilter shutters and the clutch itself;

- Stop the crankshaft. For this it is enough just to unscrew the spark plug;

- Unscrew the clutch with a special key with strong movements of software or counterclockwise (different models of saw can have either the left and right threads). Usually, a tool in order to remove the coupling is included in the completeness of chainsaws;

- Proceed to the disconnection of the drum and stars;

- If during the inspection of the clutch coupling one or more cracked springs was found (there may be several, for example, the Huskvarn chainsaws. 3.). We need to replace the spring that failed, with a new one;

- Collect clutch on a chainsaw, put it in place and screw it up. Do not forget that the crankshaft should still be motionless;

- Aggregate the removed parts in the sequence, reverse disassembly;

- Fix the coupling. Send the handle of additional braking forward, start the device and carefully remove from the inertial brake.

Clutch repair: process nuances

With independent maintenance of clutch couplings, you need to know that:

- Several saws have a puck that is located between an asterisk and a clutch, and an asterisk and a motor. Consider this when repairing;

- The special firing of the oil pump drive should not be damaged during disassembly, and is also subject to return to the original position. Otherwise, the chain will not receive a lubricant or even cease to be lubricated.

The tool that has visited the repair must undergo a check for the reliability of bolted screeds, the supply of lubrication to the circuit and the serviceability of the motor (it should smoothly turn on and work smoothly). Only after that can it be operated.

Clutch repair: process nuances

With independent maintenance of clutch couplings, you need to know that:

- Several saws have a puck that is located between an asterisk and a clutch, and an asterisk and a motor. Consider this when repairing;

- The special firing of the oil pump drive should not be damaged during disassembly, and is also subject to return to the original position. Otherwise, the chain will not receive a lubricant or even cease to be lubricated.

The tool that has visited the repair must undergo a check for the reliability of bolted screeds, the supply of lubrication to the circuit and the serviceability of the motor (it should smoothly turn on and work smoothly). Only after that can it be operated.

Removing and replacing the coupling with your own hands according to the instructions

Far from how to remove the clutch on a chainsaw is known. The constructive performance of mechanisms on different models of chainsaws differs, but the principle of operation is the same everywhere. The dismantling procedure is also practically identical, so then we will consider how to unscrew the coupling on a chainsaw with an internal location.

Initially, you will need to prepare the necessary tools:

How to tighten flywheel and drum clutch nuts | Hussqvarna 45 chainsaw

- A special key called a puller. He often comes with a chainsaw

- Screwdriver screwdriver with which the protective casing is attached

- Candle key. Used to unscrew the fastening of the casing and tire (it comes with the tool)

- Rope. In order to lock the crankshaft. It is better to use asbestos, but for this purpose any. The rope is used in case a special stopping key for the piston is not attached to the tool

If dismantling is performed for the purpose of replacement, then accordingly you will need to prepare a new mechanism in advance. When buying a new coupling, you only need to know the exact brand of the chainsaw, since the devices differ in the outer diameter, thread and design of the working mechanism. Instructions on how to remove a clutch clutch on a chainsaw has the following view:

- Initially, it is necessary to unscrew the fasteners of the casing and tires

- Remove the casing with a manual brake, as well as the chain and tire

- After that, go to the removal of the plastic cover to get to the spark plug. For this, the fasteners are unscrewed with a screwdriver, and the lid is dismantled with an air filter

- The spark plug is unscrewed with a candle key

- You need to stick a rope into the candle hole of the cylinder (install a special key if any). This is done in order to lock the crankshaft. If the diameter of the rope is several times smaller than the size of the candle hole, you can make nodes on it

- Next, proceed to the unscrewing of the clutch itself. To do this, take a special key that should be in the kit. If there is no key, then you can use the tool from Ushm or make an independent puller, which will also not be difficult

- The key slots must be installed in the holes of the coupling, and then proceed to rotate the part. It is necessary to rotate in the direction clockwise. Typically, manufacturers indicate the directions for unscrewing in the form of an arrow

- With the rotation of the coupling, the piston will reach the upper dead point, after which the crankshaft will stoop. Then putting a small effort, tearing the clutch with the subsequent twisting of the mechanism

- The twisted coupling is dismantled from the chainsaw. If necessary, a drum with an asterisk is also extracted

The procedure is not at all difficult, and does not take much time. The assembly is performed in the reverse order of removal. In order to avoid any malfunctions, it is recommended to set a fully identical adhesion on the corresponding model of the tool.

It is interesting! Similarly, the procedure for removing and replacing the clutch for all brands of chainsaws of Khuskvarna, partner and others is performed.

Clutch for the chainsaw

Clutch is a connecting link located between the power unit and the cutting organs of the chainsaw. Its main function is the transfer of a rotational force created by the engine to the saw set. Most modern household and professional chainsaws are equipped with reliable metallic clutch details, but they eventually completely fail. You can eliminate the breakdown of the node at home, however, for this it is necessary to carefully study the order of disassembly and features of replacing the adhesion elements with your own hands.

Most high.Quality chainsaws of well.Known brands are originally equipped with centrifugal clutch. It is distinguished by high reliability, an increased working resource and works in automatic mode, that is, it independently works when the power unit reaches the necessary speed of rotation.

The device of the factory centrifugal mechanism constructively includes durable friction linings, a clutch drum for a chainsaw and return steel springs. The friction pads of the mechanism can move radially. They are pulled up to the crankshaft springs when the internal combustion engine is at low speed. At the same time, a standard metal drum is acted, which is initially connected to the star of the cutting circuit. When typing a fairly high motor speed, the force of built.In springs in relation to the created centrifugal force decreases. This makes the springs press against the inner surface of the drum and put it into effect. At the same time, an asterisk starting to rotate, responsible for the work of a saw chain. In different types of clutch chainsaws, it can be located behind the clutch mechanism or in front of it.

This principle of centrifugal adhesion has one important advantage. The mechanism automatically slips when jaming the cutting circuit. Thanks to this, the power unit does not stall, but continues to work further.

The design and principle of operation of the mechanism of clutch chainsaw

Most sawmills do not understand the principle of operation of the mechanism of clutch chainsaw. When working, knowing the principle of functioning is not necessary, but when the malfunctions arise, then in order to eliminate them, you will need to find out the design and features of the work of the chainsaws.

Modern chainsaws are equipped with centrifugal type adhesion mechanisms. Centrifugal clutch. This means that its performance depends on the rotating moment of the engine. The main purpose of the coupling on the chainsaw is to ensure the transmission of torque from the crankshaft of the engine to the saw set (chain). The device works in automatic mode, and how it happens, we will find out in detail.

The clutch mechanism consists of the following structural elements:

- A drum with a removable or non.Removable asterisk. Is a transmitted mechanism

- Friction linings. Under the influence of centrifugal force move, entering into the engagement with the drum

- Spring. Ensures the pressing of the linings to the crankshaft

Now about the principle of action.

When a two.Stroke engine engine starts, the crankshaft begins to rotate. The coupling is attached to the shaft, with which the chain is connected with a sprocket. When the chainsaw works at idle (the speed of rotation of the shaft up to 2700 revolutions per minute), that is, the accelerator trigger is not pressed, the spring presses the friction pads, as a result of which the torque is not transmitted to the drum.

As soon as the saw picks up the tool and begins to increase speeds (maximum to 14000 rpm), the chain begins to move along the bus. This is due to the fact that the speed of rotation of the crankshaft increases. Due to the force of inertia, friction linings (they are also called counterweights) move, and enter into a cloth with the internal walls of the drum. As a result, the drum is moved, which is connected to the asterisk. The rotating star drives the chain.

The principle of operation of the mechanism is simple, which is due to it is not a complex design. If this part comes out of the system, then there will be no chainsaw accordingly. A detailed description of the principle of operation of the clutch mechanism of the chainsaw is described in this material.

It is interesting!The coupling acts as not only the gear ratio, but also the protective device. It protects the chainsaw engine from premature failure when jamming the chain in the sawing wood.

Clutch setting of a chainsaw Ural

Clutch of the chainsaw of the Urals and all aspects.I carefully show how to correctly configure the clutch.

Turning on the brake of the quapia can be contact and inertial. The first occurs when you press the brake stop (1) on the hand of a worker, which spontaneously occurs when a saw was discharged. The displacement of the emphasis that occurs in this case leads to tightening the brake tape (2) on the drum of the clutch and its stop, as a result of which the saw chain stops.

The inertial inclusion of the brake is based on the inertial forces that occur during a sharp strike in the bus, which affects the brake elements, which leads to the same result as in the first case. Tightening the brake tape and stopping the chain. Inertial inclusion of the brake occurs faster than contact.

For greater convenience, the chain tension screw can be located on the side.

Oil pumps have a different design (piston or membrane type) and are made from different materials (metal or plastic). They are acted using a toothed gear that receives its movement from the leading star. Когда двигатель работает на холостом ходу (ведущая звездочка и цепь не вращаются), подача масла не происходит.

Clutch on a chainsaw how to change a star on a partner? Video will help change the leading. The performance of the pump depends on the number of revolutions of the leading star, the higher they are, the more oil enters the saw chain. How to remove clutch on a chainsaw of different brands. Some oil pumps are equipped with a manual mechanism of performance adjustment. Using an adjusting screw (1).

In what cases is it required to replace?

Most often removed for replacement in case of wear of the teeth of the drive gear and walls.

Other cases when the entire basket is required:

- The clutch does not turn off, the gap between the centrifugal mechanism and the outer lid is clogged with sawdust and dirt mixed with butter, the chain is spinning at idle, it cannot be cleaned without removing.

- Worn, erased or broken and require replacement of parts (springs, segments) or the whole basket.

- The clutch jammed for various reasons (extraneous objects, dirt, breakdown of parts, destruction or change of springs).

- With a complete disassembly of the engine.

Recommendations when replacing clutch on a chainsaw

In addition to the basic rules of work told in the previous section, it is worth remembering some nuances when replacing clutch. Use only original manufacturer details. This is the key to a long and productive work of the tool. Clutch thread on all chainsaws of any manufacturer is always the left. Before removing the coupling, carefully remove all dirt and dust from the tool so that it does not get inside. During reverse assembly, do not forget to put all small details in place, including pucks and bearings. Follow the installation of a special spring (it is not in all chainsaws). If it is not installed, oil will not be supplied to the saw tire.

Basil for a household man is an indispensable tool that comes to the rescue when performing forestry work of various volumes, the implementation of construction projects from the beam, the improvement of private possessions, the garden, the court, on the farm.

The power unit consists of several important nodes, among which the clutch. Often the tool can fail due to a faulty clutch clutch of chainsaws. This is a typical breakdown that the owners of the chainsaw are faced, regardless of its class, power, model and manufacturer. To fix the coupling or at least accurately diagnose the cause of the breakdown, the operators need to know how to unscrew the clutch on the chainsaw. This knowledge will allow not only forced repair work, but also planned cleaning, inspection for preventive purposes. Do not forget that the clutch and its serviceability affect the long and effective work of the tool.

When you need to change the clutch disc and how to do it

The faults of the driven disk are evidenced by the so.Called clutch slip. That is, the torque is not transmitted from the flywheel to the disk, the clutch “slips” or skidding. The signs of this phenomenon are as follows:

- A characteristic smell of burning with an increase in engine speed;

- The car is slowly accelerating, it pulls poorly when the road goes to rise or under loads;

- Increased vibrations appear, strokes in the clutch area are possible;

- The free stroke of the clutch pedal increases (the clutch “grasps” already at the very top).

All this indicates that the disk is poorly pressed against the flywheel. And if we talk about the disk, then the following options are possible: mechanical breakdown (clamping springs, damping springs, hub slots) or friction linings are worn out. In the first case, most likely, you will have to change the clutch disc, and in the second you can do the replacement of friction lining.

If we talk about friction linings, ordinary friction linings are made of organic materials. With normal operation of the car under ordinary conditions (for example, riding on the city and on the highway), their replacement will be required, after 80 thousand kilometers of mileage.

However, the habit of sharply starting, an increased load on the car (for example, aggressive riding, slipping in mud, snow, sand, tugging trailers, etc.D.) lead to a significant reduction in the life of the linings.

If the machine is constantly operated in conditions close to extreme, it is worth checking the condition of the overlays after 20-40 thousand kilometers of mileage. Better yet, it would be immediately installed when replacing the overlay from more wear.Resistant materials. For example, from Kevlar fiber, carbon composite materials or cermet.

How to remove a chainsaw clutch.

One. In order to remove the clutch on the chainsaw, you must first remove the cutting headset, then the air filter lid and clutch cover.

Then you need to lock the crankshaft so that it does not rotate when the clutch will be unscrewed. To stall the crankshaft, for example, with a large screw, it is necessary to remove the lid of the manual starter and screw two bolts into the rotor of the ignition system. Or unscrew the spark plug, lower the piston in the NMT and stall it there, pushing the rope into the candle hole.

Next, unscrew the clutch itself. The key from the set of the chainsaw, or the key for the disks of the grinder, or with a home.Made key (for example, from the old tire with two bolts), the clutch (there is left thread) to disrupt a significant force clockwise.

Then remove the drum with a leading asterisk from the chainsaw. Replacing the clutch drum of a chainsaw is carried out according to the rule: replaced two tires. Replaced one drum.

Then put a new clutch and twist it with your hands until it stops (twists counterclockwise). In this case, you must again lock the crankshaft so that the wrapping clutch does not break the starter located at the other end of the crankshaft of the chainsaw.

Then everything is going in the order of the reverse disassembly.

To tighten the clutch on the chainsaw finally, you need to serve the cutting brake of the quapi, start a chainsaw and then remove from the brake.

Reviews of the owners

“After six months of operation, the chain on the chainsaw began to spin constantly. I decided that the problems with idle. No carburetor adjustments helped. They dismantled the workshop. It turned out to be bursting the spring on the clutch. Changed everything in 10 minutes, and I could not find a malfunction for two months. The main thing is the correct diagnosis of a malfunction.””

“I can drink mainly solid wood of wood. Quite often you have to sharpen the chain, and the leading star wears out. The first time I took off the clutch. I had to sweat. The metal tightly seized. Not unscrewed. He sprayed with kerosene. Did not help. Only after use in the kids managed to disrupt. And all because the oil flowed somewhere, so the coupling was welded to the asterisk. I think so.””

Andrey Kosuglazov, 23 years old, Primorsky Territory

“After three months of operation of the chainsaws, a longitudinal groove appeared in the asterisk. Everything works, and the chain does not rotate. Said that the problem is in the clutch. It is not at all difficult to make it out, the main thing is to find a puller and not forget that the nut of the coupling has a left thread. In short, unscrewed and changed everything without problems. It works fine, and there was nothing complicated there, only carefully needed.””