How to use a perforator correctly. Shock mechanism

How to use a perforator correctly

To guarantee the maximum quality of processing of concrete surfaces, as well as preventing potentially traumatic situations, you need:

- Do not put pressure too much on the tool (the work will not accelerate, but the integrity of the nozzle will be broken);

- Put on gloves with special anti.Vibration inserts, leveling sliding of the massive apparatus and partially extinguishing vibration;

- Periodically take breaks in work, because overheating of the equipment will lead to its breakdown;

- Get special headphones due to increased work volume.

Before starting work, it is necessary to check the punch for the lack of breakdowns, damage to the cable or cord. It is recommended to equip the tool with nozzles made of high.Strength alloys, which are designed to process not only concrete, but also metal (such an aspect will allow you to high.Quality hut). Regularly lubricating the gearbox, the master several times reduces the risk of a malfunction and levels the increase in loads on the electrical equipment barrel.

After completing the detection process, it is necessary to clean the punch from dust particles and pollution

Particular attention should be paid to ventilation holes (in case of contamination, the probability of overheating of the tool increases). To increase the operational period of products, it is necessary to periodically moisten the nozzle with water or special oil to prevent an increase in the temperature of the product

Speed X Speed X SDS-Max series from Bosch

The peculiarity of the drills of this series lies in the fact that in their design there are additional cutting plates installed under the slope. Bosch, whose experts have developed such a design, has applied to receive a patent for this type of drill.

Speed X SDS-Max drill are positioned as a tool for quick drilling and durable use

The drills under consideration have the following design features.

- Dust channels made in the cutting head of the tool are enlarged, which contributes to a more uniform distribution of impact force and ensures the exact orientation of the shock waves.

- The angle under which the spiral part is located is more gentle, which turns such a tool into an effective archimedan screw. In addition, such a design feature allows the drill to more effectively delete the developed material from the formed hole.

Distinctive features of the deeds under consideration

Boers of the above type are available in the diameter range of 12–52 mm, and their length can be from 200 to 1200 mm.

If we talk about the most popular types of such a tool, then the most often used concrete drill, as well as drilling for drilling metal products.

Preparatory stages before the operator’s work

Before starting any work on drilling or hollowing, it is always necessary to add grease to the receiver, because in time the work occurs a very high temperature of the metal friction on the metal on the metal. And only in the presence of lubricant materials you will not have problems with deformation of consumables, jamming, or a clock exit of the entire device, so try to always keep the barrel (replaced cartridge) in perfect condition.

For perforators with a change base, such a procedure is done elementary:

- Remove the cartridge, clean it from dust and dirt with a rag;

- Then grease the insides of the cartridge;

- After moving the lubricant and install the cartridge in place;

- Crank it to fix it as reliably as possible;

- Release the lubricant and block the cartridge.

Having done these simple manipulations with the cartridge, turn on the perforator in idle. And literally 15-20 seconds is enough for the lubricant to part in the right places. So you will find out if the device is too much vibrates when installing a chisel or drill, is it too high.

Work tips with a perforator in various modes

I will give you some tips that need to adhere to work on time:

-

There is no need to fall on the tool during the detection of concrete or drilling with the whole body or press. At this moment, you reduce the stroke course, which in the process leads to overheating in the mechanical part and a faster failure of it;

Drilling and drilling with a punch

First of all, it is necessary to put the required equipment on the shaft of the perforator, a quick.Sitting clamping cartridge or a cpin fixer for the drill. Then install the switch on the case in the desired position.

Pre.Marking the hole can be started to work. The drilling itself must begin to smoothly, it should be borne in mind that the pressure pressure pressure regulates the speed of rotation. For this reason, you need to start drilling at small speeds, orienting the drill or drill as accurately as possible in place.

With a deep hole, sometimes weaken the pressure on the handle of the tool and take the drill a little back, this will remove the dust from the channel of the hole and cool the working surfaces.

The depth of drilling can be adjusted with a removable probe or strip of tape or insulating tape wrapped around the drill at the required depth of the hole.

Perforator MAKITA HR2450T lost the impact. Replacement of striker and piston rings

Rules for the safe use of the tool

In order for the use of a perforator to be safe, it is recommended to use individual protective equipment. At the same time, it is important to protect the eyes, face, hands.

During operation, there is a risk of heating the drill to elevated temperatures. This is due to his strong friction. Therefore, before extracting this element, he needs to let him cool or carry out a procedure in gloves.

In what cases can light bulbs blink

If there is a light alarm lamp in the perforator design, their flashing may indicate a breakdown or violation of the functions of a certain node or mechanism. If a red light flashes the tool, it is recommended to read the instructions for its use.

How to work with a perforator correctly

The construction tool largely simplifies repair work, so experts use different devices and equipment. Tools are also useful in everyday life, especially when it comes to a perforator, thanks to which you can solve various problems. Perforator is rightfully considered a universal device. It can be used to screw the bolts, drill and as a shock hammer, the main thing is to know how to use a perforator and what functions it can perform.

What are the perforators for?

Modern perforators offered on the website https: // Machtz.Com.UA/Catalog/Perforatori is equipped with everything necessary to perform the following types of work, the tool is used as:

- Shurovyrt, putting on special adapters and cartridges. But carefully tighten the bolts in fragile materials will not work. There are special tools with a change of front base for this. They are more stringent and allow you to screw the screws evenly. And the dimensions of the perforator are not very convenient for screwing fasteners, so for this function it is rarely used.

- Mixer to knead the solution. The mechanical part helps the perforator to cope with this task. But do not get carried away much and prepare a cement mixture in this way. The tool will not withstand such loads. The maximum that can be made by a perforator is to stir the paint or cook glue. Too thick mixtures will disable the unit.

- A drill is the main function of the punch. The tool is designed to drill holes on wooden, ceramic and metal surfaces. The perforator is also used to drill holes in concrete, putting on more powerful nozzles.

Before using the tool, it is necessary to correctly install the operating mode. For example, if you need to drill a hole in a tree, then an unstressed mode of operation is included so as not to damage the surface.

Gently you need to work with tiles and concrete. In the first case, a strong pressure will spoil the fragile material, and in the second, the tool itself may fail. Before using the perforator, you need to carefully read the instructions and take into account the features of the working surface.

How To Use The Martin Yale SP100 Paper Scoring Perforating Machine

How to prepare a tool for work?

Before starting work by a perforator, it must be well lubricated. Lubrication will protect the tool from damage during intensive friction of metal surfaces. The greased punch will not jam and not damage the materials, so do not neglect this condition.

In order to lubricate the receiver, you need:

- Clean the cartridge of pollution.

- Lubricate it inside.

- Install the cartridge in place by shifting the lubricant ring.

- Crank the cartridge and fix it.

- Block the cartridge, lowering it.

All these manipulations take a few minutes, after which you can test the operator at idle. Thus, the lubricant quickly disperses and processes all the nodes, after which you can safely work with the tool.

Rules for working with a perforator.

In order for the perforator to serve longer and is convenient to use, experts advise adhere to the following recommendations:

- You can’t press too much on the tool working with concrete, because you can overheat the mechanical part, and it will fail.

- It is necessary to lubricate the unit so that it does not jam and does not arise emergency situations. If there is a large front of the work, the perforator is lubricated regularly.

- When working with a perforator, you need to wear personal protective equipment. This is the main requirement of safety precautions.

Adhering to these simple recommendations, you can significantly extend the life of any perforator.

The principle of operation of the perforator

The perforator is designed to perform three main types of work:

- Drilling solid materials, for example, metal;

- Drilling with a blow. Making holes in brick, tile, stone, concrete;

- D some. Shock mode. Is used for stroke. Riding the material between two grooves, piercing the walls, dismantling tiles, plaster, clogging metal rods.

Many people do not know how the perforator works. The principle of the functioning of the tool is to convert electrical energy into a mechanical one with its transmission of a working nozzle.

After clicking on the Start button, the engine starts. His rotational moment, thanks to the gears, is transmitted to the piston through a swinging bearing or a crooked-shaped mechanism. The piston moves the battles with compressed air. The battle strikes the nozzle, forcing the cartridge with it to perform reciprocating movements along the axis. In parallel to the cartridge, rotational movement is transmitted through the gearbox. Due to the drill spin and strikes the material, destroying it.

How to insert / pull a drill or drill

In order for the work with the perforator to be safe, it is necessary to master several simple skills. Mandatory skills include the installation and removal of a drill, drill or any other nozzle.

Installation of a working tool

All perforators have a cartridge type SDSthat does not require keys. Unlike fist cartridges, the drill installation takes seconds:

- Pull the base of the cartridge down.

- Insert the shank of the drill into the hole.

- Release the base of the cartridge, the spring will return the cartridge to its place, the mechanism of shut.Off balls will reliably clamp the drill in its metal embrace.

- Check the reliability of fastening the drill, pulling it over. The cutting tool should not be removed.

Installation of the drill in the perforator takes seconds

A properly installed drill should not leave the nest by more than 1 cm when trying to stretch it with your hands.

If a cam cartridge is installed in the perforator, you can fix the drill by the traditional method. By the rotation of the cartridge body around its own axis until the thread tightening.

Removing a working tool

To remove the drill or nozzle after work or to replace it: it is necessary:

- Wait for a complete stop of the rotation of the cartridge.

- Pull the base of the cartridge down to the stop.

- Take out a drill.

- Release the base of the cartridge.

Perforator. Purpose, types, characteristics and features

The closest relative of the drill who does not drill, but actually breaks the holes with a drill. A punch.

Combining the rotation of the working element with progressive strikes allows it to work according to materials that the classic tool is not able to cope with.

Perforators can have several operating modes, differs in the location of the engine and the type of drive as a whole.

This is one of the main tools during the repair and construction work, and in some situations it is simply indispensable.

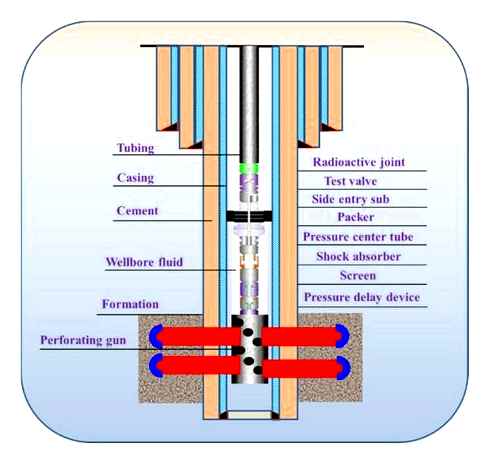

Tool device

To deal with the perforator, and how to use it, you should familiarize yourself with the device of this tool. This is a mechanism running from an electric motor. It consists of 5 main components indicated in the diagram.

How to use a puncher

The main element is an electric engine. When starting the chain, it begins to rotate quickly, so the nozzles rotate and at the same time make shock movements. The main details of the engine are the rotor, as well as the mechanism of the stator. There are several windings on each of them, creating electromagnetic fields.

The coils are displayed to the contacts of the anchor. Due to the fact that windings switch, force fields are created, which rotate the rotor. All perforator modes work on this principle.

Another element is a safety coupling. It is necessary to stop the rotation of the cartridge in case of jamming the working nozzle. The coupling is mounted on each device, otherwise the tool will “turn out” from the hands, which can lead to injury.

The next component is the shock mechanism. It provides all methods of how to work by a punch for concrete and other surfaces. In practice, 2 types of mechanisms are used:

The first option is most often used. When the main shaft rotates, the “drunk” (it is called the swinging) the bearing moves progressively and transfers the pulse to the ram, which is part of the cylinder. It contains compressed air, which pushes the piston. At the same time, the opera hit the working part of the cartridge. And the drill, fixed in the cartridge, beats directly on concrete or other surface.

The device of the makit perforator or other models necessarily includes a cartridge. It can be 2 types of SDS. Plus and Max. In the first case, the shank is clamped with 2 locking balls.

Automatic Perforating Machine

In the second case, tools with tailings of other types are fixed in cartridges.

Features of drilling different surface

As already mentioned, the perforator is a universal tool that can easily cope with any material.

But at the same time there are a number of features, which must be taken into account:

- Metal. To work with metal surfaces, the hardest drill will be needed. When drilling a thin sheet, the rubber substrate should be used, and the sheet itself should be fixed firmly.

- Wood. Despite the relatively soft structure, when processing a tree, it is necessary to fix the blanks and not much press on the unit.

- Concrete. In this case, a winning working element will be required. To begin with, a drilling point is noted, a small recess is made in it using a standard drill, a winning tip is installed and the necessary opening is created. During the process, it is necessary to cool the working body with water.

- Ceramics. For processing fragile finishing materials, it is recommended to use special tips with attacks from hard alloys. Thanks to these elements, the load on the material is minimized and it is easy to process. If the finish is already made, then for processing it, it is necessary to use tips designed for glass surfaces.

And general recommendations. In the process of performing work, you should use personal protective equipment, glasses, a headdress, gloves, follow the instructions of professional builders and strictly observe safety regulations. When using professional models, it is recommended to take a break for ten minutes every half hour.

Errors during the operation of the perforator

We are talking about such potentially dangerous situations and errors:

- The permissible load on the devices is exceeded;

- The perforator has been working for a very long time without interruptions, which is why drive elements and gearbox can overheat and fail;

- The requirements for maintenance are ignored, the recommended timing of the tool service is violated;

- Excessive or insufficient lubrication;

- Lubricants are used that are not suitable in composition or quality;

- Work is carried out not provided for by the purpose of the perforator.

Do not allow such errors, and also strictly adhere to all the rules for preparing for the operation of the perforator. This minimizes possible malfunctions and significantly extend the life of the tool.

How to insert and pull out a drill or drill

Models of perforators can be equipped with three types of cartridges:

The vast majority of the punch are equipped with a cartridge of the SDS system, so the operation of the drill installation is considered by the example of this cartridge.

Installation of the drill

SDS system cartridge is a fast.Packed cartridge. The drill (drill) with the corresponding shank is installed in such a cartridge for three actions:

The SDS mechanism is reliable, does not allow the drill to fall out and saves time to replace the drills. It is used for industrial and household items of small and medium power.

To work with a conventional cylindrical shank, you need to have a special clamping cam cartridge with a shank SDS system. Such a transitional cartridge allows you to operate with a perforator in the electric drill mode with standard cores. Nevertheless, on sale you can find a cord with sketches SDS.

Fist cartridge with a SDS shank for drilling with standard drill

Removing the drill

To remove the drill or drill from the SDS system, you need:

- Wait for a complete stop of the rotation of the cartridge.

- Fix the lower clutch of the cartridge with your hand.

- Unscrew or tighten the upper coupling with the other hand.

- Get a drill or drill.

Where to buy a punch

So, knowing how to use a perforator in different operating modes, you can go to the stage of choosing an appropriate tool. You will not have any problems with the choice, since it is described in detail how to choose the right punch for home.

You can get a tool by contacting the online store cylinder. The site catalog presents models of different manufacturers. Focusing on personal experience, reviews, as well as technical parameters, you can choose a good punch, and learn how to use it correctly.