How To Wind The Line On A Non-Separable Trimmer Reel

Single Barbed Trimmer Spool

Reel for single-barb lawn mowers

Many owners and experts note the ease of use and ease of refueling the bobbin with one mustache. Depending on the manufacturer, the length of the threaded line can vary from 2 to 5 meters. The end of the line is inserted into the head into a special technological groove or hole, and the winding is carried out in the direction opposite to the working rotation of the bobbin. Most reels have arrow marks on the outside of the body that indicate the direction of the trimmer reel movement.

After winding, you need to leave a free end of 15-30 cm to enhance the centrifugal force, which is decisive when removing the trimmer line in automatic and semi-automatic spools. Passing the left end through the working hole of the coil and assembling the head.

Trimmer head with two tendrils

Double flute head

After removing the spool from the spool body, we determine the number of strands for winding the fishing line (1 or 2). In principle, there is no difference between bobbins with one and two grooves, but with careless threading into the paired groove, there will be operational problems. Due to the likelihood of interlacing the adjacent line of the tool, a situation may arise when, after wear of the working antennae, it is impossible to remove new ones.

Regardless of the number of streams, a fishing line with a length of 1.5 to 3 meters is taken for refueling. Winding must be done in the opposite direction of rotation of the head, since winding in the direction of travel will lead to the fact that the line will not be removed from the reel. After the fishing line is tucked into the trimmer coil, the free ends (15-30 cm) are threaded into special holes. Next, we assemble the head in the reverse order of disassembly and check the operability. Do NOT worry if the ends of the two antennae are very different in size, because when you start the trimmer, the knife installed on the protection will cut off excess.

Winding the line to the trimmer

Measured and accurate dismantling of the spool from the spit coil makes it possible to go directly to winding the line. The design features of the head, the number and location of the fixing holes dictate the sequence of actions when performing this operation, and also determine the methods used. Today there are several types of reels, depending on the number of line antennae and the methods of threading it:

- Trimmer head with one working Mustache;

- Bobbin with two tendril fishing lines;

- Auto winding reel.

Preparing to wind the line

Before the winding process, it is necessary to remove the spool with line from the body. Depending on the manufacturer, power and type (electric or gasoline), there are three design types of trimmers:

-

Compact Electric Trimmers.

Straight bar trimmer

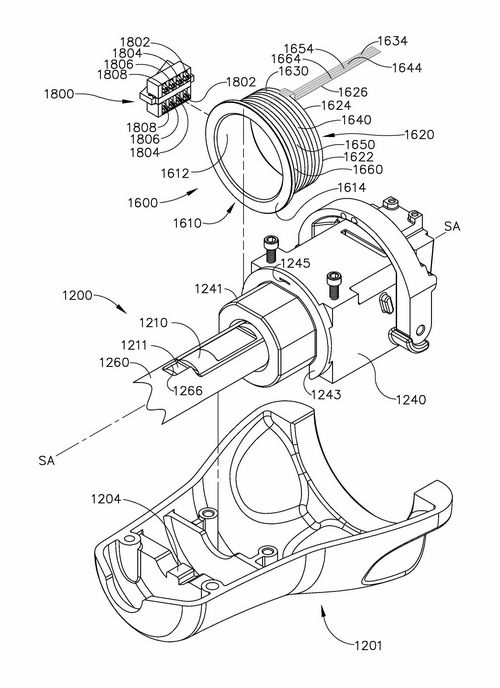

This model provides the ability to install a knife. Removing the coil in such models is done by means of two keys recessed into the coil body. To mount the trimmer knife, it is necessary to align the hole of the reel and the rod, and then insert the device in the form of a steel pin (screwdriver, iron bar). After fixing the coil, the body can be easily unscrewed by hand clockwise.

How to wind line on a trimmer reel: key points

A gasoline or electric trimmer is an indispensable tool in the arsenal of a modern summer resident or owner of his own home.

Thanks to these garden devices, even a large garden plot can be mowed with ease. After purchasing this tool and performing several mows, many people think about how to properly wind the line on the trimmer reel. For an inexperienced user, the first operation to replace it will seem problematic and time-consuming, since the developers often do not fully reflect the instructions for replacing the fishing line in the operating manual.

Trimmer head with automatic line threading

Types of trimmer heads

Some models on the market are fitted with a reel with an automatic winding mechanism. It is enough for the owner to properly thread and fix the ends in the head, and the winding operation will be performed by the tool itself when it is turned on. It is almost impossible to wind the line incorrectly into a trimmer with such a head, since the coil independently determines the position of the antennae. The advantages of the automatic trimmer head include the ease of threading the line, and the disadvantages are frequent breakdowns of the mechanism due to the complexity of the design and the high cost.

How to change line to trimmer

Below we have provided Step-by-step instructions for replacing a whine trimmer.

The first thing to do is unplug the tool and turn off the engine. Then you need to remove the trimmer head. This can be done by using a simple screwdriver, lowered it into the hole of the gearbox to prevent the shaft from turning. And then just Unscrew

They are usually unscrewed in a clockwise direction, but different models have different mechanisms, so it may be necessary to twist in the opposite direction. But if suddenly, for some reason, you cannot figure it out, then we strongly recommend that you refer to the user manual to understand how to disconnect it

Second. After removing the mowing head, open it. This can be done by means of clamps, which are located opposite each other. Pressing on them, you can remove the head cover, and then pull out the spool on which the fishing line is wound. By pulling it out, you can determine what type it belongs to. There are bobbins one-piece and two-piece

We analyze how to thread the line into the trimmer spool in two versions

So, option one. load the fishing line into a single-section reel. The prepared piece of thread is folded in half and pushed into the spool. Then, we begin to wind both ends in the same direction, which will be indicated by the arrow on the spool. At the end of the winding, do not forget to check that the different ends of the thread are looking in different directions.

Option two. winding the line with a two-piece reel. The pre-prepared thread is divided into two parts, and its ends, must be fixed: this must be done by placing them in special fasteners

Winding is carried out, as in the first case, along the arrow indicated on the spool. Both segments must be wound so that they do NOT overlap. Further, the ends of the thread must be fixed in the grooves and spread on opposite sides.

The spring is then inserted into the reel and the whole thing is placed in the mowing head. When placing the coil in the trimmer you need to gently hold the spring parallel to insert the line into the cut of the mower head. And in the end, it just needs to be secured with the final part, that is, with a lid.

After threading the trimmer, you need to check it. If you did everything correctly, everything will work, but if you make a mistake, we recommend that you read the article again, or even better, if you look at how to install the line on the reel in the trimmers.

How to remove the line from the trimmer spool

Over time, the cutting element of the head wears out, and it becomes necessary to pull out the remnants of the old line. But not everyone knows how to do it. Our step-by-step instructions plus how to pull the thread from the trimmer spool, which you can find on the net, will help in solving this issue.

The mowing head must be disassembled

Remove the cover using the clips

Cleaning up the remnants of cutting material

Complicated? Of course not. But if, nevertheless, doubts creep into you that for some reason you will NOT be able to do this, then of course find and see how to pull out or how to wind the thread onto the spool of the lawn mowers.

How to wind the line onto the trimmer spool

05 July 2018

The trimmer is a great solution for those who have a large garden or lawn near the house, which needs to be constantly trimmed. But like any other tool, sometimes it requires intervention. After some time, it will become necessary to replace certain elements, and this will have to be learned.

How can this be done? To replace the main cutter, you must first select it correctly. In principle, the lawn mower instruction manual should indicate the diameter of the thread to be used in it.

When you have acquired the required cutting element, try to install it correctly. It should be noted that there are a huge number on the Internet. Which will help you figure out how to properly thread the line into the trimmer spool.

How to replace the line with an electric trimmer

In fact, it makes no difference which oblique you use, be it electric or gasoline. Threading is the same. The only difference is that if you use a gasoline scythe, you get more freedom, since it is NOT limited by the cable, which is present on the electric scythe

Yes, do not hesitate to use special rollers for installing or threading the line in an electric scythe, which can teach you much faster than simple reading.

engine’s type

Two types of motors are installed on the gasoline trimmer: two- and four-stroke. The first are cheap, powerful, but for refueling it is necessary to prepare a mixture of oil and A92 gasoline.

The second type is more expensive, but less “capricious”, they are installed on professional instruments. They are 1.5 times more economical than their two-stroke counterparts, they work quieter and generate less exhaust gases. Fuel filling is carried out separately, the vibration level is lower than in cheaper samples.

What are the coils

In gasoline devices, one- and two-section coils are installed. Another difference is that cutting is done with one tendril or two. Based on THESE conditions, a working thread is wound.

Disassembled lower part of the tool. the coil consists of one section

The bobbins are divided into 2 sections, the line is wound on each level separately.

How to tuck the line into the trimmer

The method of winding the thread on the bobbin depends on the model of the gasoline trimmer. In devices with a line and in a sample with the possibility of changing the cutting element, the algorithm of actions is different. Let’s analyze each option separately. The diameter of the line is indicated on the side of the reel or in the tool’s passport. For winding, choose the line specified by the manufacturer.

A line with a diameter of 2 mm is considered universal. It is used for cutting grass of any hardness. The thicker the working thread, the harder vegetation it cuts. But, if too thick line is inserted into the spool, the engine will overheat, as the shaft rotation resistance will increase.

First option for double bobbin

- Insert the line fold into the special groove located in the dividing rib. One half of the segment is located at the top of the structure, the other half is at the bottom.

The thread is attached to the edge of the bobbin. Rotating in the direction of the arrow winds the line around both discs. After winding, loose ends remain

- Wind the thread along the arrows indicating the direction of rotation so that the upper part remains at the top, the lower, respectively, at the bottom.

- Leave 15 cm from each edge.

- Find the whining grooves on the bobbin and insert the remaining pieces into them.

- Assemble the trimmer head so that the free areas of the line fall into the holes of the working shaft.

- Insert the bobbin into the head, the spring has previously returned to its original place.

- Press the bobbin against the head and pull the ends of the line out. Check how the free sections of the cutting thread move. They must rotate the shaft freely, without jerking.

- Place the cover on the bobbin. Check the alignment of the holes in the case. After all the grooves are aligned, fix the cover.

- Replace the head in its original place.

Fuel filling method

In cheap, low-power samples, fuel is poured into the tank at the same time. This creates inconvenience for users, as oil and gasoline must be mixed before operation. In expensive mowers, 2 separate tanks for gasoline and oil are installed. Refueling occurs as you use it and is NOT interdependent.

Second winding option

- Cut the measured piece of thread in half.

- Before threading the line into the trimmer spool, bend one of the ends of each piece and press firmly to form a hook.

- Insert the resulting thread hook into the hole. Wind the sewing thread in the direction indicated on the bobbin case.

- When 15 cm remains of the original length, stop winding. Insert the remaining section into the groove.

- Wrap the line on the bottom of the body in the same way.

- Assemble the bottom of the trimmer, put the bobbin in place.

In a spool consisting of one section, the working thread changes in the same way. Unwind 15 cm from the finished piece, make a loop and fix it in the groove. The line is wound in the direction of the arrow. After the end of the process, the remaining end is fixed on the coil cover.

Handle shape

Manufacturers offer 2 handle options:

- T-shaped (in the form of a bicycle handlebar)

- D-shaped;

- In the shape of “J”.

The handle in the form of the letter “T” is installed on models with automatic line rewinding. The work is carried out with 2 hands located on both sides of the bar. This position is convenient for mowing large areas of vegetation. The cut is made according to the braid principle. from one side to the other. This option does NOT differ in maneuverability, does not work well on difficult terrain. The bicycle handlebars can be equipped with control buttons. In household trimmer types, the trigger buttons are installed on the bar.

Classic trimmer model with reversible handle with control buttons

The petrol trimmer with a D-shaped handle is more maneuverable, it is convenient for them to mow grass in areas with difficult terrain. In such an instrument, the hands are placed one above the other. The drawback of the handle is that it is difficult to hold, the control of such a device is more complicated.

D-shaped trimmer handle

Pen in the form of the English letter “J” The most inconvenient, therefore rarely found.

Petrol trimmer

Small mobile devices for cutting grass and young branches, consisting of a bar, motor, cutting part and a handle are called a trimmer.

The device without a trimmer is simple, it is easy to disassemble, if necessary

There are electric and gasoline modifications. The former do NOT refuel, but they depend on the length of the cord. The latter do NOT work suspension from the presence of electricity, anywhere in the garden or vegetable garden.

Petrol trimmers are lighter and less expensive than lawn mowers. They cope with grass and shrubs, so such mowers are used in everyday life and on an industrial scale. For convenience, the technique provides belts that are worn on the shoulder. Thus, the stress on the arms and back is reduced.

Model power

Lightweight and compact household devices for fighting grass on an area less than 15 acres have a capacity of up to 1 hp. This figure is enough for a summer residence, a small lawn.

Power within 1. 3 HP. It is necessary to combat shrubs, thin branches. This is an indicator of industrial and universal units. They have a longer service life, weight, some models can create a high noise level.

If you want to get rid of young shoots of trees, thick branches of shrubs, lawn mowers with a capacity of more than 3 hp are used. These are heavy apparatus that require great physical effort to work with. The advantages of such mowers are a large supply of fuel, separate refueling of gasoline and oil, high productivity.

Model with shoulder strap for easy operation

A Few Tips for Proper Trimming

- If the spool allows you to wind fifteen meters of thread, it is not worth winding so much, ten is enough, that is, if you fold it in two layers, you get five meters. With a different line capacity, you should use the same rule.

- In the case when an ordinary round thread is used, it is better that it be 3.3 mm in diameter. If this is a curly fishing line, then its thickness should be less, for example, 3 mm.

- It is better to wind both segments of the fishing line on the spool at once, and it is necessary to start from its bend. It is important not to overlap in the direction of the arrow. It is also important to be able to pull the thread perfectly. If the thread is tied, then it can overlap. If not reached, it can twist. In order not to cut your hands into a curly thread yourself, you should wind it with gloves.

- No need to leave long line ends. This can cause it to curl.

How to remove the spool from the trimmer and remove the line

Initially, before threading the trimmer spool, you need to remove it from there. A reel or aiming device is a device that sits inside the mowing head, bobbin or drum. There are different types of heads (depending on the manufacturers), but the principle of replacing the line on the reel is the same for everyone. First of all, we will figure out how to remove the head from the tool, as well as how to get the drum and fishing line out of it.

It is interesting! The tooling can be changed directly on the tool, but if doing this for the first time, it is still recommended to remove the head and study the Detailed winding process. After the technology is mastered, you can perform replacement work with a lawn mower trimmer or lawn mowers.

The instruction on how to unscrew the manual head onto the trimmer is as follows:

- Turn the tool upside down and, if necessary, clean it from dirt. With two fingers of one hand, grip the cover latches (on the mowing head), which are symmetrically positioned to each other. After lightly pressing them inward, remove the protective cover from the drum

- Next, remove the line spool from the drum shaft. It is mounted on a shaft without fasteners, therefore it can be removed with one hand

- The main part of the drum is fixed with a screw, which is necessary Unscrew with a screwdriver with an appropriate tip or bit

- To unscrew, hold the drum base with one hand, and unscrew it with a screwdriver counterclockwise with the other.

- After that, you can proceed to dismantling. To do this, you do not need to pull it with all force, but slightly shake it to the sides, slowly disengage it from the metal shaft on which the drum is set

- When reinstalling, fit the head into the square slots

This process is NOT difficult, and as you understand, it is not necessary to dismantle the entire head if you know how the replacement is performed. When dismantling, take into account the following nuances:

Knowing how to disassemble the drum, you should continue to figure out how to replace the trimmer line. Below is a detailed process on how to open the trimmer coil and disassemble it.

How to wind the line around the mowing head of lawn mowers (trimmers)

Find out more on our website: Subscribe to our YOUTUBE channel! We are always glad to cooperate!

Instructions with step-by-step descriptions of how to wind the trimmer reel and lawn mowers

In order not to be mistaken with the choice of a suitable fishing line for your tool, you should first disassemble the head and look at the side wall of the reel. This information is usually provided for a tip, which will NOT allow you to make a mistake using the appropriate equipment.

If the information on the reel is about the diameter of the fishing line you can fill in, then this information can be clarified in the instructions. Having decided on the thickness or diameter of the rig, it remains to figure out how to charge it. There are two ways to do this, but not all are applicable. We will consider both methods in detail, and depending on which models of lawn mowers and trimmers you use, you decide on your own which option is suitable.

It is interesting! The principle of how to wind up the line to guide lawn mowers is appropriate Not only for autonomous gasoline units, but also for electric trimmers.

Trimmer head with two tendrils

Double flute head

After removing the spool from the spool body, we determine the number of strands for winding the fishing line (1 or 2). In principle, there is no difference between bobbins with one and two grooves, but with careless threading into the paired groove, there will be operational problems. Due to the likelihood of interlacing the adjacent line of the tool, a situation may arise when, after wear of the working antennae, it is impossible to remove new ones.

Regardless of the number of streams, a fishing line with a length of 1.5 to 3 meters is taken for refueling. Winding must be done in the opposite direction of rotation of the head, since winding in the direction of travel will lead to the fact that the line will not be removed from the reel. After the fishing line is tucked into the trimmer coil, the free ends (15-30 cm) are threaded into special holes. Next, we assemble the head in the reverse order of disassembly and check the operability. Do NOT worry if the ends of the two antennae are very different in size, because when you start the trimmer, the knife installed on the protection will cut off excess.

Now only I bite!

I caught this pike with a bite activator. No more fishing without a catch and searching for your bad luck! The time has come to change everything. The best bite activator of the year! Made in Italy.

How to wind line around the trimmer head or lawn mowers

Shows in detail how to wind the line on a trimmer reel or lawn mowers. Refueling with mowing line.

Single Barbed Trimmer Spool

Reel for single-barb lawn mowers

Many owners and experts note the ease of use and ease of refueling the bobbin with one mustache. Depending on the manufacturer, the length of the threaded line can vary from 2 to 5 meters. The end of the line is inserted into the head into a special technological groove or hole, and the winding is carried out in the direction opposite to the working rotation of the bobbin. Most reels have arrow marks on the outside of the body that indicate the direction of the trimmer reel movement.

After winding, you need to leave a free end of 15-30 cm to enhance the centrifugal force, which is decisive when removing the trimmer line in automatic and semi-automatic spools. Passing the left end through the working hole of the coil and assembling the head.

How to properly wind the line on the trimmer reel with your own hands: we paint the essence

What line is used for the trimmer? How to remove the spool from the trimmer? Threading bobbins with different types of bobbins. A Few Tips for Proper Trimming.

How to properly wind the line on the trimmer spool?

Despite the fact that gardening equipment has been used for quite some time, it is still a novelty for some owners of private houses. That is why there are often questions about how to properly wind the line on an electric or gasoline trimmer.

This is essentially a simple operation, but all its stages must be performed correctly in order to achieve the desired result. over, in the operating instructions, only a few manufacturers provide an answer to this sore question. Explore the article and find out how the line winds around the trimmer reel.

The procedure for winding the line on the trimmer spool

First of all, you should know that trimmers have different working attachments. The reel can be designed for different lengths and thicknesses of the line. this point should be taken into account when purchasing consumables.

So how does the line load into the trimmer reel? All work is divided into several stages:

- First you need to disassemble the trimmer head.

- Unscrew the nozzle by rotating the drum to the right.

- Press with your fingers on the two latches located on different sides of the tap holes and remove the top cover of the nozzle. You can pry off the cover with a screwdriver. This should be done carefully: reels with automatic line feed have a spring that can forcefully throw the cover along with all the contents of the reel.

- Remove old line scraps.

- Now you need to find the middle of the line. To do this, unwind it to the required length (for example, 10 m), cut and fold in half.

- Hook the middle of the line into the existing groove or insert it into the hole specially designed for this. And start winding. The direction is indicated by the arrow, which is usually marked on the trimmer reel body (usually against the rotation of the drum). Some models have a double-sided reel: in this case, the line should be wound in different directions: one end in one direction, the other in the other, while the loop of the line must be inserted into the dividing slot in the middle.

- Leave loose ends of the line about 20cm each. Later they will need to be fixed in the recess.

- And finally, the last step will be the assembly of the drum. Reinstall the washers and spring. On the top ring of the reel there are two notches where you need to tuck the antennae of the fishing line. Thread them through the holes and place the spool in the drum, trying to tighten the line without displacing the spring.

- Place the drum cover on top and close it with your fingers. The latches will snap into place with a distinctive click.

When you turn on the trimmer, excess line will be cut off by the trimmer blade.

As you can see, winding the line on the trimmer reel is not difficult: the main thing is to do everything right. And here are some more tips that will come in handy when choosing a fishing line, winding it and subsequent work:

- The line comes in a variety of thicknesses and cross-sections. The best option for winding is the “native” line for this model;

- Never use fishing line or metal cables for the trimmer. This replacement may seem effective, but it is very dangerous. Jumping off a working trimmer, the cable can seriously injure Not only the lawnmower himself, but also those around him;

- The line is cut when the trimmer is in contact with hard objects. Try not to allow this, otherwise you will have to stop each time, turn off the device and rewind the line on the reel;

- Use regular line for cutting lawn grass and braid line for coarse weeds. It is more durable and will not constantly cut.

How to properly wind the line on the trimmer spool

Many, having worked out the factory line on the recently purchased trimmers, are trying to wind a new one, but they cannot, because they do not know how to properly wind the line on the spool (bobbin) of the trimmer. It seems that there is an instruction, but it still does not work. Let’s try in this article to deal with this issue.

So, in order to wind the line, you first need to remove the coil from the trimmer. this will be more convenient. The removal method will depend on the type of trimmer.

than 200 types of trimmers in one place at the lowest prices. Click and watch

Now, having removed and disassembled the coil, we proceed, in fact, to winding.

Removing the coil from the trimmer

On small electric trimmers with a bottom-mounted motor (when it is in the ground while working), the reels usually have two keys on the sides. Click on them and disconnect one half of the coil body from the second, which remains on the trimmer. Together with the first half, the inner part is also taken out, on which the fishing line is directly wound. When disassembling, be careful: there is a spring inside that can fly out and get lost.

On electric and gasoline trimmers with a curved bar (there is still no way to put a knife on such trimmers), you need to grab the coil body itself with one hand, and with the other hand you need to start rotating the lamb on it counterclockwise. It is he who attaches the coil to the Trimmer Bar. Having unscrewed the lamb, carefully remove the entire coil, trying NOT to lose the spring inside.

On electric and gasoline trimmers with a straight bar and a gearbox at its end (on such trimmers, in addition to fishing line, you can also install a knife), we look for a hole under the coil, insert, for example, a screwdriver into it, quietly rotate the coil until the screwdriver does NOT crawl even deeper and the coil will lock. Now steep the whole coil clockwise (since the thread is left-hand) and remove it from the trimmer. Then we disassemble the coil. It can be assembled using snaps or a twisted lamb. If the coil is on latches, then press on the sides on the base of the latches so that they bend and release one half of the coil body from the other. We just unscrew the lamb. There may also be a third type of connection between the two halves of such a coil: with it, you need to grab the lower part with one hand, and the upper part with the other, and start turning them in opposite directions. When disassembling such a coil, you also need to make sure that the spring inside is not lost.

Winding process

If your coil is designed to work with only one tendril, then it’s simple. You need to unwind 2-4 m of fishing line (depending on the size of the reel), find a hole on the inside of the reel for the fixing line, insert one end of the line there and start winding the line in the direction opposite to the direction of rotation of the reel on the trimmer. On the inside of the reel, they usually indicate with an arrow in which direction to wind the line. I wound the fishing line, we leave a small piece of it unwound to put it out. We fix this piece in a specially groove located on the inner part of the reel and designed so that at the time of collecting the reel, the line does NOT unwind. If there is such a groove, then you will have to hold the fishing line with your finger to prevent it from unwinding during the further collection of the coil. Next, we take the outer part of the coil and threading the outer piece of fishing line into the existing hole, collect and put the coil back on the trimmer.

If the coil is designed to work with two tendrils, then do the following. On the inside of the reel, we look at how many grooves there are for winding the fishing line. There may be one or two of them. If there is only one groove, then both tendrils are wound along this one groove. If there are two grooves, then each antenna is wound along its own groove. Reels with one groove should have a through hole through which the fishing line is threaded. We rewind 2-4 m of fishing line, threading it through this hole so that the fishing line sticks out equally on each side. And we simultaneously wind both tendrils of the fishing line in one direction, opposite to the direction of rotation of the coil to the trim tabs and coinciding with the direction indicated by the arrow on the inside of the coil. We leave a little of the fishing line unwound, the resulting ends We fix in the Special grooves, and if they are not there, we hold them with our fingers. Threading both ends into the existing holes on the outer casing of the coil. We collect the coil and fasten it to the trimmers.

If there are two grooves, fold a piece of fishing line 2-4 m long in half. Insert the loop obtained at the place of the fold into the groove between the two grooves, and simultaneously wind both ends of the fishing line along its own groove. Further actions are similar to the previous option.

There are also spools in which the fishing line is threaded through a through hole on the inside. After that, the ends of the line, and not winding, are threaded completely through the holes on the outer body of the reel, assemble the reel and begin to rotate the button, which is usually pressed, in order to release the line during operation as it wears out. Turning the button. the line itself is wound inside. In this case, twisting it in the “wrong” direction will NOT work, since it can only rotate in one direction. If you get used to it, you can wind fishing line on such a reel without even disassembling it. you just need to combine the through hole of the inner drum with the holes on the outer body of the reel, and then thread the fishing line through them.

That’s all on this issue. Happy winding!

How to wind the line on the detachable reel trimmer with two tendrils

You can see before work. And also take into account the following recommendations.

- If there is only one track, both threads are wound parallel.

- If there are two tracks, each piece is wound in a separate groove.

- Wind the threads in the opposite direction to the rotation of the head.

- The length of the risers does not have to exceed fifteen centimeters.

- Thread the ends into the outlet holes.

- Assemble the head and check the trimmer performance.

How to properly wind the line around the trimmer: Step-by-step guide and instructions

A beautiful lawn will only look truly well-groomed if you regularly mow the grass. A trimmer is best for tackling difficult areas. Any owner of the unit will sooner or later face a solution to the problem of how to wind the line on a reel, because wrong actions can not only worsen the quality of the mowing, but also disable the equipment. Today in the Homius review we will tell you about all the methods and nuances of replacing the fishing line and the features of choosing consumables.

How to wind the line correctly: replacement features depending on the type of removable trimmer coil

To figure out how to tuck the line into the removable trimmer head, the following recommendations and instructions will help.

How to quickly and easily remove the coil with your own hands

Before replacing the old line with a new one in the detachable trimmer spool, you must remove the head.

The process is completely simple, even beginners can do the job:

- Remove the upper fixing cover.

- Remove the removable spool.

- Get the spring out, if any.

- Screwdriver Unscrew the bolt.

- Remove the housing from the shaft.

By size

Before threading the thread onto the trimmer spool, pay attention to its size. Most often used fishing line with a cross section of 2 mm.

You can choose a suitable diameter in the following ways:

- See recommendations in the manufacturer’s instructions for trimmers.

- Manufacturers often apply cross-sectional information to the bobbin.

- The cross-section of the cord must match the diameter of the reel hole.

What are the trimmers and features of their use

The trimmer is useful for mowing small or difficult areas, such as near hedges, between beds and along paths. Today manufacturers produce a wide variety of gasoline, electric and battery models, which can be selected for any owner’s request.

A fishing line is used as a cutting element of the trimmer. In the process of work, sooner or later, its length will end, and then the owner will have a question of how to correctly replace and fix the thread tucked into a removable coil.

Things to consider when choosing a line

It is important to choose the right material before inserting and locking the line into the detachable trimmer spool.

Rating of the best petrol trimmer models. An overview of manufacturers and models, as well as useful tips from experts, considered in this review, will help in a difficult choice among many device models.

Auto feed trimmer: how to wind the line into the removable spool

Some models of trimmers have a reel, the threading of which is automatic. It is enough for the owner to fix the ends in the head, after turning on the equipment, the mechanism will perform all the winding manipulations on its own.

How to wind the line correctly on the spool of the trimmer with one tendril

Most often, a thread up to five meters long is used. The procedure consists of the following steps:

- Bent the cord with a loop and insert into the groove of the head.

- Wind the thread in the direction opposite to the marks on the body. They indicate the direction of movement of the head.

- Leave the end of the thread up to fifteen centimeters long to increase the centrifugal force.

- Thread the free end through the spool outlet.

- Assemble the trimmer head.