How to wind the spring on the grass trimmer starter

Grass trimmer starter repair with his own hands video

The starter is one of the main nodes of the lawnmower, which greatly facilitates the start of the engine of the tool. Its breakdown can happen at the most inopportune time, which certainly entails significant changes in the daily plans of the owner of the site. To solve the problem you can in two ways: to repair the starter trimmer for grass with your own hands, or to replace the node as a whole. The easiest option for troubleshooting the starting system will be its complete replacement, but from a financial point of view, the purchase of a new starter may seem far beyond the reach. For self-repair it is enough to prepare a screwdriver with the appropriate tip and read the following recommendations.

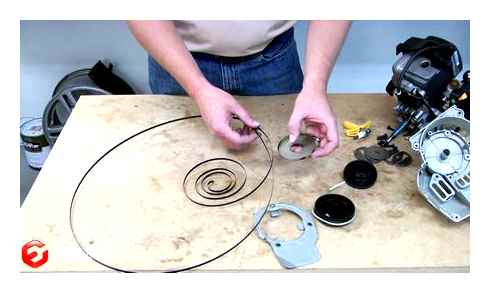

As with any garden or construction gasoline tools, the starter trimmer for grass consists of a plastic body, in which a pulley with a pre-wound cord (schmolgalka) is installed. In order to achieve automatic twisting of the rope after a jerk by the starter, a band spring made of alloy steel is fixed to the back of the pulley. On the front of the pulley a ratchet is mounted that engages the starter with the drive shaft of the grass trimmer engine. Depending on the brushcutter manufacturer and design, the pulley with the ratchet may be a single unit or made up of two separate parts.

The principle of operation of the grass trimmer starter is almost the same regardless of the model of the unit.

The main components of the grass trimmer starter

When jerking the starter lugs on the sheave come into contact with the pawls, which diverge in different directions under the action of centrifugal forces if the engine is successfully started. There are also models where the ratchet is spring-loaded on the housing side and the reverse rotation of the pulley removes the teeth from the engine shaft. Of course, with frequent and prolonged use of the grass trimmer no one is immune to breakage of the drive cord or wear of the belt spring. Because in this case you will need to repair the starter trimmer for grass, which can be done with their own hands.

Lawnmower design and common malfunctions

It is easiest to give the lawnmower in the repair, allocating a certain amount of money from the family budget, prompt and high-quality repair with their own hands is no less simple and convenient if you want to understand the design of the lawnmower and fix all the malfunctions.

Mass and piece production of trimmers is based on the use of common technology, the typical design scheme consists of certain elements and parts, it is important to know them when carrying out independent repair work:

- the upper part. The basis of the entire structure, where all the important elements are assembled, such as the starter, carburetor and lawnmower engine;

- middle part. The hollow rod, inside it there is a rope that connects the motor and the gearbox, which drives the cutting line for the trimmer. In this part there are mounts for weight distribution of the entire construction and a belt for fixing the grass trimmer on the belt of the person using the grass trimmer for its intended purpose;

- lower part. It contains the gearbox and cutting elements, which are hidden by the practical cover to protect the user. The cover provides an increased level of safety by preventing large debris, pebbles and glass from getting into the person while operating the chainsaw.

This is interesting: Device repair and adjustment of the carburetor to 151C

Knowing precisely the internal structure and the principle of operation of the grass trimmer, you can independently carry out repair measures for the structure or replace individual, failed nodes, using the repair manual.

The most common and frequently occurring, self-correctable breakdowns of the unit can be called the following problems:

- Engine malfunctions, due to which the lawnmower does not start and does not work;

- Increased vibration of the brushcutter bar, making it difficult to use as intended;

- increased overheating of the gearbox, its accelerated heating during operation;

- slow and weak functioning of the cutting line at insufficient RPM;

- Blockage of the starter grid which causes the engine to overheat and stop working;

- rapid and frequent clogging of the carburetor due to the use of low-quality fuel;

- The air filter becomes clogged if you do not take proper care of the machine.

All of these problems can cause the unit to become inoperable, before ordering the necessary spare parts for the knivesless machine a visual inspection and diagnosis of the unit should be performed.

Particular attention requires individual parts and units of the device, to check them will not need to go to a professional master, a set of diagnostic measures will help your own hands to identify the cause of the loss of performance.

How to start a lawn mower without a starter

At the moment, gasoline brushcutters are equipped with starter mechanisms 2. types:

The starter on the trimmer can run for a long time without breakage. It is not possible to give a definitive indication of the period of non-failure. Our client is determined by the initial quality of the device and the observance of the rules of using it.

It’s not hard to find the cause of the starter unit breakage. There are several main options:

The designated parts are shown in the photo below.

Accidental breakage of the starter mechanism. The consequences will turn out to be dire, if the torn rope will wrap around the flywheel of a working engine: then the spring will burst, the pulley will tear. But such cases, when you need a complete replacement starter unit, occur infrequently. As a rule, to fix the mechanism, rather put the latest spring as it is called to change the cord.

What to make a repair starter trimmer for grass, it is useful to first disassemble and then assemble. This process is not particularly difficult. A screwdriver with a suitable tip comes in handy at work.

Do our client remains neatly, observing safety precautions, primemorially, that the spring in an accidental loss did not injure the master.

Disassemble the starter mechanism with the intention of installing new parts in place of the broken in this order:

- Unscrew the screw that secures the pulley with the starter cover with a screwdriver;

- Remove the spring and tendons;

- Remove carefully the pulley (it is necessary for all this to turn the head or work, wearing beforehand goggles and gloves);

- Determine why the starting mechanism is broken;

- If the spring is 100% destroyed, it should be replaced;

- After the readiness of the spring from the hook, it is installed in its original place, bending before the tendons (the photo shows the process of laying);

Brovchenko Family. Installing the spring in the lawn mower’s hand starter.

To change the spring, you should work carefully and carefully: it can, under the influence of force caused by its installation to the area, accidentally rupture. Let even carefully remove the roller, the spring band in a short time flies off the coil and can hurt your hand with their sharp edges.

It is not often possible to put the spring plate back in its place. It often slips, so the test should be repeated until the desired result.

Assembly of the starter unit is carried out in a series of steps:

- Reel is turned over so that the spring bend fits exactly into the housing slot as shown in the photo below;

- put two washers, between which a spring is placed;

- Put a cup with the tendrils in the area;

- screw in the screw (picture below).

When making the above manipulations, you should always put two washers. If this is not done, the spring will gradually damage the plastic cup, and when it is tightened, it will start jamming. Because of this there is a feeling, one can think that the spring has come off. To remove this defect, you must install this part of a longer or additional washer.

When such parts are missing, you can just unscrew the screw, and the starter unit will work without podklinivaniya. However, this is a temporary option. it is better to repair a significantly faster.

After installing the spring, it should be tightened. For this purpose you do the following actions:

- Remove from the starter cord handle;

- Then the rope is inserted into the bobbin slot;

- create spring tension by turning the coil in the opposite direction to the clockwise (winding) direction;

- make the required image the number of revolutions designated in the operating manual to the applied model of the trimmer for grass and corresponding to the length of the cord used;

- at the very end, the rope is threaded through the hole created for this purpose, located in the starter cover;

- put the handle in the area, fixing it with a knot.

What to do if the starter shaft does not seize?

Often gardeners are faced with “idling” of the starter, when the mechanism emits a characteristic brief sound and stops. In most cases, the cause of this failure is a burst damper spring. Detecting the problem is simple enough. with the lid open, the faulty spring is immediately visible. Only complete replacement of the spring will help to eliminate this failure.

The second cause of malfunction is a defect in the ratchet. the most frequent problems are encountered by users of chainsaws, in which the ratchet mechanism is equipped with a plastic gear. During meshing, chipping and large cracks form on its teeth, which eventually lead to gear breakage. In such cases, the ratchet will need to be replaced completely.

Chainsaw starter cord replacement

Because of the constant manipulation of the starter cord, the factory cord can break. This problem can be solved by replacing it.

The work algorithm is as follows:

- First you need to carefully unscrew the metal screws that hold the cover of the unit body;

- Next, it will be necessary to remove the cover of the plastic housing;

- Then inspect the inside of the mechanism. Often, when the cord breaks, the spring of the mechanism unwinds. In this case, it automatically falls out of the landing cavity;

- After that, you need to carefully pick up the knot on the cord with pliers and pull it toward you;

- Next, it will be necessary to remove the broken cable assembly from the factory pulley;

- The other end of the broken cord should be extracted from the hole in the plastic handle;

- After that, you must take the new cord and shorten it to a size equal to the torn rope;

- Both ends of the new cord will need to be melted to prevent them from separating into separate strands;

- Next, the first end of the cord will need to be slipped into the spool and tied into a knot. The knot should then be carefully placed in the pulley. this will allow the rope to move freely through the spool arm;

- The second end of the cord will then need to be slipped into the holes provided in the body and handle;

- At the end of the handle the rope will need to be secured with a knot;

- Next, you will need to pull the cord on the regular spool. To do this, there are arrows on it that will tell you which way to wind the rope;

- Then the pulley needs to be placed over the factory return spring so that it is located in the chainsaw starter housing;

- Next, you need to turn the spool to the side. so the operator can be sure that the spring and the spool are properly engaged.

After installing the new rope the operator should assemble the body of the assembly and check the starter. If the starter mechanism does not make any extraneous sounds while pulling the cord, then the chainsaw is ready to work.

The best lawn mowers

Hand starter for lawnmowers or gasoline grass trimmer. a mechanical assembly, which includes a pulley, put on a ratchet. The rope is wound on the pulley in the start position. When you start, it pulls outward. The pulley is spring-loaded. once you let go of the end of the rope, it winds back up. The spring is a flat band coiled into a ring. It resembles the spring in a large mechanical watch that is wound once a day. The starter itself is located more on the back than closer to the front end of the mower or grass trimmer. To correctly perform all manipulations with the starter for a lawnmower, you need to know the peculiarities of the device and installation.

The main malfunctions of the grass trimmer starter

It’s not hard to find the cause of the starter failure. There are several basic options:

It happens that the starter mechanism will be broken by the housing. The consequences will be deplorable, if the wrapped rope is wrapped around the flywheel of the internal combustion engine: then the spring will burst, and the pulley will break. But there are cases when you need a complete replacement of the starter assembly, which occurs infrequently. In most cases, fixing a new spring or replacing the cord is enough to secure the mechanism.

Repair of the manual starter of a gasoline generator

Almost all petrol generators, even with the electric starter, have a manual starter, in case of battery failure. The starter is the main link in the start of the generator and it is also often the cause of problems with starting the engine.

Going to work far from civilization, add a spare manual starter assembly to your repair kit. To be able to replace a failed part and correctly assemble the manual starter, you need to know how this mechanism is constructed.

Pull the recoil starter cord through the hole in the recoil and tie a knot. 2. Hook the side hook of the recoil starter spring into the recoil starter housing slot, and install the recoil starter spring into the recoil starter housing by turning it counterclockwise. 3. Install the manual starter spring with the outer hook in the starter coil slot. 4. Attach the starter drive ratchet to the recoil of the recoil starter. 5. Install the recoil spring on the recoil of the recoil starter by hooking its hook to the drive ratchet. 6. Install spring, ratchet body and secure with locking screw. 7. Unwind the recoil starter rope, pass it through the back cover and recoil starter handle, and tie a knot. Pull the hand starter cord slightly to check the function of the ratchet.

1.Replacing the starter cord of the gasoline generator.(Wrap the starter cord on the pulley (from the end of the pulley tucked so he did not twist) the second end of the cord into the hole cover and tie the handle. Wrap as long as the lanyard is long enough (the crank is against the starter cover). Then pull the cord 15-20 cm., The pulley will turn, the spring will tighten. Hold the pulley so it doesn’t turn back and these 15-20 cm. Wind the lanyard on it. Check and release the lanyard. If it is normal, leave it like that, slightly wind the cord on the pulley for another 1 turn.)

If you need to repair the manual starter gasoline generator. You can contact our company and you will help with repair or selection of spare parts.

Need help repairing the starter motor gasoline generator? Contact us by phone: 063 202-90-70 097 023-42-42.

Lawn mower starters. design and installation features

Repair the starter gasoline trimmer for grass may need to suddenly. Here you can solve the problem in 2 ways: to change the broken part or change the whole node. The latter option is more expensive. The only tool that is almost always needed for doing the actual repair yourself is a screwdriver with a matching screwdriver tip. Repair work does not take much time and does not even require any special knowledge. To achieve a good result, it is enough to know the structure, mechanism of work, aspects of assembly and disassembly of the starter motor on the trimmer.

Design and operation of the starter motor on the trimmer

Gasoline engine. is, in principle, the main part of brushcutter Its power lies in the range of 0,5-2,5 l.с. The movement from it is transmitted to the shaft, which is located inside the hollow shaft, and then through a gearbox consisting of gears to the line or to the blade (operating device).

The lawnmower also has the following elements:

- protective cover;

- handle;

- A belt, designed for the convenience of using the device;

- Starter, which serves to start the internal combustion gasoline engine.

All parts of the brushcutter are shown in the illustration below.

The starter on the trimmer is an integral part that performs engine starting. It is shown separately in the two photos below.

Starter mechanisms of different models of chain saws work on a similar principle: during the start of the engine the lugs, marked in the photo above with the number 1, engage in a hitch with the pawls 3. When the engine starts, they return to their previous position because of the centrifugal force. The wires 2 also play a similar role.

The return to initial position of elements of the mechanism is due to the spring which is wound around the axis. It unfolds when the rope is pulled. After the cord is released, it retracts and winds up because of the coiling spring. When starting the engine of the lawnmower, the starting mechanism turns its shaft until it starts working (starts up).

To date, gasoline brushcutters are equipped with starter mechanisms of two types:

The first variant is much more common.

The starter on a trimmer can function for a long time without breakage. No fixed time limit for trouble-free work. Everything is determined by the original quality of the device and compliance with the rules for handling it.