Husqvarna 142 How To Remove An Asterisk

The movement of the chain on the tire chainsaw is due to the drive sprocket connected to the engine gearbox.

Wear on the sprocket on the sprocket means that it needs to be replaced as soon as possible, otherwise it will not clutch with the chain and the chain itself will be damaged.

In this case, it must be taken into account that the drive sprocket has a number of features depending on the model of the saw and its type. In this article, we will highlight such a question as how to remove an asterisk from a chainsaw.

Feature of saw designs

Professional chainsaw brand STIHL

In operation, there are already several dozen chainsaws from different manufacturers, capacities, and most importantly special purposes. The saws are divided into:

- professional (for felling and construction);

- household (garden).

Accordingly, the drive gear will be different for them, as well as the sequence of actions. This is a feature of saw gearboxes. With most professional tools, the tire can change its location on the saw in two planes.

The main malfunctions of chainsaws and actions to eliminate them are described here.

Sequencing

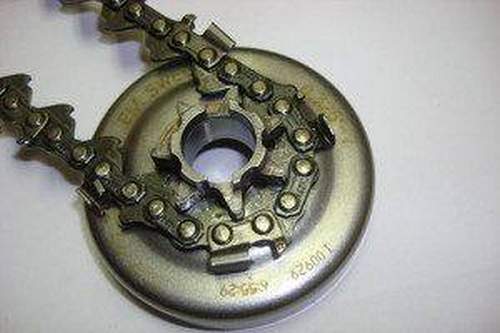

Chain sprocket, crown and bearing

The vast majority of household saws are sold under the brand name Partner. They simply change the star even at home, having bought a repair kit.

Since most often the asterisk in household saws is a prefabricated mechanism, it rotates due to the bearing. That is, changing the sprocket, you inevitably change the bearing and not the shaft.

In professional models (such as Stihl and Husqvarna), as well as in household ones, if it is not possible to have a specialized key for removing a star, use a soft cord with a diameter of 5-6 mm.

In all cases, the sequence of actions is as follows:

- You must open the side cover to gain access to the tire and sprocket.

- Next, remove the tire by loosening the chain.

It looks like a chainsaw tire

- After the sprocket is free, you need to unscrew the spark plug to access the engine piston.

You may also be interested in an article on how to make a vibrating table for paving slabs: //6sotok-dom.com/instrumenty/vibrostol-svoimi-rukami.html

- Manually rotating the sprocket, move the piston almost to the very top of the channel and fill the hole most tightly formed from the candle with a soft cord, thereby blocking the movement of the piston.

- Use the open-end wrench and unscrew the sprocket, depending on the model of the saw and the type of gearbox.

Thus, adhering to the recommendations given in the article, you can easily remove the sprocket from the chainsaw yourself.

How to remove and replace the drive sprocket on Husqvarna and Stihl chainsaws is described in detail in this video:

How to remove an asterisk from a chainsaw: varieties and design features

With the constant use of such a tool as a chainsaw, it is important to regularly carry out diagnostic measures, replacing consumables and parts. One such consumable is an asterisk or chain drive mechanism. If the question arises of how to remove the sprocket correctly from the chainsaw, then the time has come to replace it. When and how to correctly replace crowns on chainsaws, we will consider further.

What is the chainsaw sprocket for?

Chainsaw sprockets are clutch basket parts designed to rotate the chain. On chainsaws, a centrifugal drive type is used, the operation of which is automatic, which depends on the speed of the engine itself.

The device of the centrifugal mechanism is such that when the chainsaw is idling, the sprocket does not rotate. This is because the elements of the clutch basket have a degree of freedom. This freedom is ensured by friction pads and springs. As the number of revolutions increases, the centrifugal force increases the force of the springs, as a result of which the elements with friction pads are displaced. In this case, torque is transmitted to the drum and sprocket, which, in turn, moves the saw chain.

This design of the clutch mechanism is due to the fact that when the chain is jammed, it slips. Thus, it is possible to prevent jamming of the internal combustion engine, as well as to avoid its premature failure. Regular use of the saw causes the crown to wear out, and there is a need to replace it.

Design features

The leading sprocket of a chainsaw can be of two types: combined or solid (stationary). One-piece has the form of a monolithic device, which is located directly behind the clutch. Such asterisks in the form of a clutch plate with a welded gear star are also called stationary. This type of design is used in most chainsaws. Replacing such crowns on a chainsaw does not present any difficulties, but it will only be necessary to remove them entirely with a drum.

On expensive chainsaws, prefabricated sprockets are used. The crown is put on the drum shaft, resulting in the transmission of torque to the chain. Replacing a prefabricated device is even easier, since the crown is removed, while the drum remains in place. The prefabricated structure of the element under consideration is a way to extend the life of the clutch. After wear on the drive sprocket, replacement is required. If this is not done, then the resource of the tool is significantly reduced, as a result of which the wear rate of the internal combustion engine increases.

How to determine the need for crown replacement

The sprocket is replaced immediately after the product in question wears out and cannot fulfill its functions. The wear of the crown can be determined by the following characteristic properties:

- The presence of noticeable radii in the area of transition of the tooth to the cavity.

- Chipped metal on top of teeth.

- Uneven tooth width.

- Detection of scoring on the inside of the hub.

- Grooving from the tire.

- The chain is off the tire.

The most important sign by which to check on the above items is the occurrence of signs of jamming of the chain when starting the chainsaw. Any of the above factors requires immediate replacement of the item in question. Details on the types of leading stars and their differences can be seen in the video.

How to remove an asterisk on a chainsaw

Before changing an asterisk on a chainsaw, you must first purchase a new element. The drive sprocket should be changed based on what type of element is used on the chainsaw. One-piece devices are often used on domestic and semi-professional ones, and prefabricated ones on professional units.

The process of removing an entire product is the following:

- Initially, the casing is dismantled.

- After that, the saw bar is removed together with the chain.

- The snap ring and washer are removed.

- After that, you can remove the clutch together with the drum.

- The crown from the drum is removed using a special key, which is usually attached to the instrument.

After replacement, reassemble the removed parts in the reverse order. The process of replacing the crowns of the prefabricated type is almost similar to dismantling the whole product, only, ultimately, you should only change the gear element without a drum. After the work done, you need to check, evaluating the effectiveness of the actions taken. To do this, chain is tensioned using the tensioner adjusting screw.

It’s important to know! Stationary crowns can be replaced with prefabricated ones, which will save significantly.

From the above it follows that the replacement of crowns is an important diagnostic measure, if not observed, the owner of the chainsaw risks premature occurrence of the need for major repairs of the motor. The video above shows excellent material that describes all the details of the design, removal and replacement of the chain saw sprocket.

Replacing the drive sprocket on a chainsaw

Regardless of the class of the chainsaw and its operational characteristics, the design of removable saw sets is almost identical. The saw device kit includes a guide bar made of a special alloy and a chain, which is activated by the gear ring of the drive mechanism. To extend the life of the saw chain, timely replacement of the sprocket on the chainsaw is important.

Video: Husqvarna 142 How To Remove An Asterisk

The feasibility of timely replacement of worn parts of the drive chain

The design of its crown determines such an important parameter as the choice of chain by step.

- Installing a new part on a worn sprocket reduces its smoothness, accelerates wear, and initiates the risks of breakage and the creation of a traumatic situation.

- There is also an increase in operational loads on the engine and the elements of the kinematics of the tool.

- A similar process takes place when old extended chains are installed on the tire, the diameter of which is adjusted to the size of the tire by removing part of the links.

Experts also do not recommend arbitrarily changing the size of the stars. An experiment can adversely affect the engine resource and the kinematics of the instrument as a whole.

Safety of sawing operations of various degrees of complexity is ensured by the effective operation of the emergency stop brake and devices that block the expansion of the chain ends in case of an accidental break. In any case. the most reliable prevention of contingencies, maintaining the chainsaw in good condition.

A way to extend the leading sprocket resource

In practice, for uniform wear of the crown of the sprocket, a set of several chains of the same type is used, which alternately change as the cutting edges of the saw links become blunt. However, sooner or later, the user is faced with the need to replace a worn part.

Criteria for choosing a repair kit yourself

The desire of the owner to equip the headset with a saw chain with another step, leads to the need to change the asterisk to a part with a crown of the corresponding profile. This requirement applies to the entire range of European and Chinese chainsaws.

The operational reliability of a European-assembled saw, when operating in difficult conditions of increased loads, can significantly deteriorate if, instead of the original part, a Chinese asterisk is used.

Structural problems of different models

The problem is complicated by the design of branded chainsaws, which provides for the replacement of a worn drive only after the complete dismantling of the clutch mechanism and other components. In another embodiment, in order to remove the sprocket from the chainsaw, you must have a special key.

A design feature of a significant part of chainsaw imports is the placement of an asterisk on the clutch mechanism.

- With significant wear of the teeth, the drum is to be replaced, which is a single unit with the drive.

- The more progressive design of the drive sprocket allows you to restore the performance of the part by replacing the crown.

In the list of factory kits attached to the saws, such a tool is extremely rare. The problem is solved by replacing the parts that have exhausted the resource in the service workshop or by making the necessary fixtures at home.

The lack of prerequisites for the restoration of a worn star

The leading sprocket for a chainsaw of any power category is made of special steel, processed by a special technology, so repairing a part by welding by arc welding and subsequent milling is not possible.

The price of the part itself is several times lower than the cost of replacing it in service structures.

- The benefits of self-repairing a drive unit at a lower cost and time.

- If you have the appropriate tool, you can manage the work for a fairly short time interval.

Alternative solutions

The sequence of working moments is identical for almost all known models in the domestic market of chainsaw equipment. Experts advise using a branded part for replacement.

If we are talking about the modernization of this node, the feasibility of such a change should be clarified by consultation with an experienced specialist.

The best option is to buy a repair kit, which also includes a replacement bearing. In addition to the key, you may need an individual for each model puller of the clutch drum, a metal or plastic stopper to fix the piston in a predetermined position.

Algorithm for self-changing drum clutch with sprocket

Leading sprocket replacement technology provides for the implementation of the entire amount of work in a given sequence:

- dismantling the headset and air filter;

- installation of a piston retainer in the spark plug hole;

- the clutch and the gear drive made at the same time as the drum are removed by means of a puller; the sprocket can only be unscrewed clockwise.

If there is a lot of wear on the separator, breakdown of the springs of the centrifugal mechanism and cams, it is recommended to replace the entire kit.

If the condition of the removed parts is not in doubt, the whole mechanism is assembled in the reverse order. For reliable fixation of the clutch on the crankshaft, it is enough to unscrew the piston stopper, pull out the cord of the standard starter and return it to its original position.

It should be cautioned by amateur craftsmen from simplifying the requirements of repair technology and saving money on installing relatively cheap Chinese components.

The quality of the work done is guaranteed by attention, accuracy, compliance with the sequence of all dismantling and assembly operations.

Tips: how remove asterisk with chainsaw

- Features clutch drum in chainsaws

- Substitution Method clutch drum

Many tools require constant replacement of consumables. It concerns and drank. That is why the question is how remove asterisk with a chainsaw, which is often called a clutch disc or a centrifugal mechanism, is very popular among home craftsmen. In this regard, you need to make out what is called an asterisk and for what purpose it is needed.

The clutch drum, referred to as the asterisk, is an integral part of the chainsaw.

Features clutch drum in chainsaws

A drum located at the base of the clutch mechanism is an integral part of the chain drive system. This detail resembles a star in its own form, due to which it got its name. Depending on the type of chainsaw, the part can be professional or household. Because a professional saw is used more often than a household one, the leading sprocket asks for a constant change. If we talk about household tools, then everything depends on the amount of work performed and the load that is on the device circuit.

In most cases, the sprocket, crown and saw bearing require replacement.

Read the same

In any case, the main prerequisite for replacing the sprocket is the wear of its teeth on the chain. In this case, when a solid drum is installed in the device, the surface of the chain cuts through it almost completely, which asks for a complete replacement of the entire part. If chainsaw It has a drum with a replaceable crown, here you can restrict yourself to only replacing the crown.

Usually in order to take off an asterisk with a chainsaw, many people turn to special service centers, but if you need to save your home budget, you can do this work without the help of others. This event does not look complicated, but you need to have all the necessary parts and tools. The sprocket swap process is the same for any device model.

Replacement Algorithm clutch drum

Husqvarna 137, clutch and star replacement

A fairly frequent problem in chainsaws Husqvarna 137 and 142. breakdown of the oil pump. This video shows the fast-paced.

Quick repair Husqvarna 137/142. Replacing the oil pump.

The video will help to change the driven sprocket on the Husqvarna chainsaw. Carefully and step by step I will show how the action should be.

The chainsaw clutch closes the sprocket.

First, it is worth noting that when buying spare parts for a chainsaw, you must strictly observe the type of drum or use the advice of a specialist if it is a question of its modernization. Usually, while replacing the drum and the saw chain, the drum bearings are also replaced.

Read the same

Here you should receive a special repair kit, in which the presence of a drive sprocket and a bearing is foreseen. Then you should prepare the tool and details that will be required for the work:

- universal key, sold complete with a chainsaw;

- mechanism piston stop (in standard cases it is plastic or iron);

- puller of a centrifugal mechanism or clutch (selected depending on the model of the chainsaw).

During the operation, the following acts are performed:

The location scheme of the chainsaw sprocket.

- At first, the saw headset is removed, the nuts of the tire cover are unscrewed using a universal key. The cover is removed, the tire and chain are removed.

- Then the air filter is removed.

- The universal key turns out the saw candle. Instead, the prepared piston stopper is inserted, which allows to fix the position of the piston in the cylinder.

- The clutch puller is installed in the universal key connector. Then, using the resulting device, the clutch is turned out. All actions must be carried out clockwise.

- The clutch is removed, freeing up access to internal parts. Now you can take off asterisk (clutch drum).

- Depending on the type of drum, it is inspected or checked. An asterisk or crown changes to new ones. When installing new parts, you must carefully check the condition of the clutch separator. Increased attention here needs to be paid to centrifugal springs and cams. If strong wear is detected, these parts also need a permanent change.

- If the condition of the parts does not cause complaints, all parts of the chainsaw are assembled in reverse order. First, the piston stop is twisted, the starter cord is stretched, then the stop is screwed in again. Such complex actions allow you to clamp the centrifugal mechanism of the chainsaw on the crankshaft.

- Using the universal standard key clutch clamped counterclockwise, in other words against chain rotation.

- After that, all the nodes and parts can be successfully screwed into their original places.

In order to change the asterisk on the chainsaw, all work must be done carefully and carefully.

Without the availability of special devices, repair work can fail: not only a star or a centrifugal mechanism, but also a saw chain can break.

As you can see from the information provided, the question is how take off an asterisk from a saw can be successfully resolved on its own. Once the operation is performed, it will be possible to carry out it again and again, as the need arises, and attention and accuracy will be the key to a job well done.

The movement of the chain on the tire chainsaw is due to the drive sprocket connected to the engine gearbox.

Wear on the sprocket on the sprocket means that it needs to be replaced as soon as possible, otherwise it will not clutch with the chain and the chain itself will be damaged.

In this case, it must be taken into account that the drive sprocket has a number of features depending on the model of the saw and its type. In this article, we will highlight such a question as how to remove an asterisk from a chainsaw.

Feature of saw designs

Professional chainsaw brand STIHL

In operation, there are already several dozen chainsaws from different manufacturers, capacities, and most importantly special purposes. The saws are divided into:

- professional (for felling and construction);

- household (garden).

Accordingly, the drive gear will be different for them, as well as the sequence of actions. This is a feature of saw gearboxes. With most professional tools, the tire can change its location on the saw in two planes.

The main malfunctions of chainsaws and actions to eliminate them are described here.

Sequencing

Chain sprocket, crown and bearing

The vast majority of household saws are sold under the brand name Partner. They simply change the star even at home, having bought a repair kit.

Since most often the asterisk in household saws is a prefabricated mechanism, it rotates due to the bearing. That is, changing the sprocket, you inevitably change the bearing and not the shaft.

In professional models (such as Stihl and Husqvarna), as well as in household ones, if it is not possible to have a specialized key for removing a star, use a soft cord with a diameter of 5-6 mm.

In all cases, the sequence of actions is as follows:

- You must open the side cover to gain access to the tire and sprocket.

- Next, remove the tire by loosening the chain.

It looks like a chainsaw tire

- After the sprocket is free, you need to unscrew the spark plug to access the engine piston.

You may also be interested in an article on how to make a vibrating table for paving slabs: //6sotok-dom.com/instrumenty/vibrostol-svoimi-rukami.html

- Manually rotating the sprocket, move the piston almost to the very top of the channel and fill the hole most tightly formed from the candle with a soft cord, thereby blocking the movement of the piston.

- Use the open-end wrench and unscrew the sprocket, depending on the model of the saw and the type of gearbox.

Thus, adhering to the recommendations given in the article, you can easily remove the sprocket from the chainsaw yourself.

How to remove and replace the drive sprocket on Husqvarna and Stihl chainsaws is described in detail in this. video: