Husqvarna Chainsaw Carburetor Adjustment 137

Modern chainsaws have a complex system and consist of several main components, which periodically require maintenance and adjustment. In this article, we’ll talk about how to adjust the carburetor on a Husqvarna chainsaw.

When does the Husqvarna chainsaw carburetor require adjustment

There are many problems that can be solved by adjusting the carburetor. Husqvarna chainsaw carburetor adjustment is necessary when a malfunction occurs such as:

- increased idle;

- heavy smoke during tool operation;

- difficulty starting a cold or hot engine;

- lack of traction and lower maximum revs.

This is by no means a complete list of problems that can be solved by tuning the Husqvarna carburetor. In some cases, adjusting the quality and quantity of the fuel mixture is carried out after an overhaul of the engine or in the process of scheduled maintenance of the chainsaw.

The manufacturer Husqvarna AB recommends adjusting the carburetor before and after the break-in.

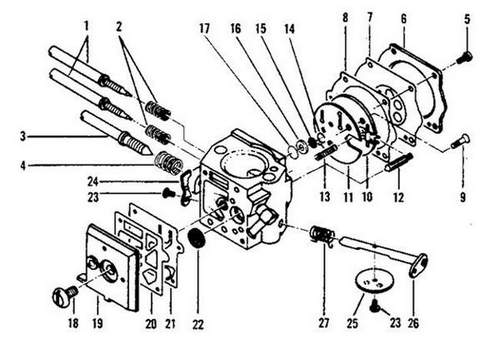

The device and principle of operation of the Husqvarna carburetor

To successfully set up a Husqvarna chainsaw carburetor, you need to know its device and understand how it works. In fact, everything is not as complicated as it seems at first glance.

The saw carburetor has a built-in fuel pump, which is responsible for transporting a mixture of gasoline with oil, as well as a diaphragm, a needle valve with a rocker. Their joint work allows metering the fuel supply to the main chamber and two shutters.

One of the dampers is designed to adjust the fuel supply to the cylinder when pressing the gas, it is called the throttle, the second is responsible for restricting the air supply from the air filter to facilitate the start of the Husqvarna cold chainsaw. At that moment, when the operator shuts off the air supply to the carburetor with the help of an air damper, the fuel mixture is depleted and its supply to the cylinder is increased, due to which the chainsaw starts up much easier than when the cold start is carried out in normal mode.

An injector valve is involved in the operation of the Husqvarna carburetor, which atomizes the fuel and prevents air from entering the main chamber. Often problems when working with a saw can be caused by defects in this particular element. For example, a valve, if the chainsaw is not stored properly, can stick, fuel supply will stop, which will make the engine impossible. Also, malfunctions of the nozzle can cause air to leak into the main fuel chamber of the carburetor. In such cases, adjusting the position of the adjusting screws will not correct the situation; repairs or replacement of the assembly will be required.

For adjusting the quality and quantity of the mixture, as well as the number of revolutions of the crankshaft in idle mode, there are three adjusting screws installed in the carburetor body:

- screw (L). adjusts the amount of fuel in low and medium speed mode;

- (H). responsible for traction at high speeds and their number;

- (T). changes the position of the throttle valve, thereby regulating the amount of fuel mixture entering the cylinder and the engine’s engine idling.

Screws (L) and (H) cannot be adjusted without specific knowledge and experience. Incorrect adjustment of the quality and quantity of the fuel mixture can cause the engine to stop working or malfunction, which will lead to its rapid deterioration or even jamming.

Видео: Husqvarna Chainsaw Carburetor Adjustment 137

Tools necessary for work

Before setting up the Husqvarna carburetor, you need to take care of the availability of all the tools that may come in handy. To carry out this type of work yourself, you will need:

An ordinary slotted screwdriver is not suitable for adjustment, because the adjustment screws on Husqvarna chainsaws can have a different cross-section. You have to purchase a special one, this is the peculiarity of repairing Husqvarna chainsaws, they did everything so that the saw could be repaired only in a specialized Husqvarna service.

Husqvarna carburetor algorithm and description

Husqvarna carburetor, is regulated similarly to how carburetors are adjusted on chainsaws from other manufacturers.

Immediately before the adjustment, it is necessary to conduct a complete diagnosis of the saw and make sure that there is no difficulty in supplying fuel and air intake into the crankcase of the chainsaw. You must also make sure the air filter is clean and replace it with a new one if necessary.

The procedure for the work is as follows:

- Husqvarna carburettor factory settings are set on the muffled saw.

- The engine starts and the saw warms up for several minutes.

- By turning the screw (L) clockwise, there is a position at which the engine develops maximum speed, after which the screw must be turned back 1⁄4. If at the same time the chain of the chainsaw rotates, then it is necessary to reduce the idle speed by adjusting the position of the screw (T).

- The next stage is the adjustment of the power of Husqvarna at maximum speed and the adjustment of their number. To do this, the tachometer is connected to the wound chainsaw, the throttle stick is squeezed to full, after which the tachometer readings are checked. If the maximum speed value differs from the maximum quantity recommended by the manufacturer, then by changing the position of the screw (H), the tachometer readings are normalized.

Adjustment nuances

After adjustment, the chainsaw should easily gain and lose speed, work stably at low and high speeds. If the saw chain rotates at idle after adjusting the carburetor control screws, this is a sign that the setting is incorrect and that the position of the screw (T) needs to be adjusted.

Also, when adjusting the Husqvarna carburetor, it is worth considering the response time of the chainsaw to the rotation of the screws. Settings do not change immediately, but within five, ten seconds.

One of the indicators of incorrect adjustment is a strong smoke during the operation of the saw, which indicates a large amount of fuel entering the combustion chamber. If this situation arises, adjust the position of the screw (L).

Factory settings

The factory default settings for the Husqvarna carburetor are the position of the screws (H) and (L), in which a working chainsaw must be guaranteed to start. For Husqvarna tools, this is one and a half turns from fully tightened screws (H) and (L). In the process of adjustment, you must first set the screws in the standard position, then start the chainsaw and make an accurate adjustment of power, the number of maximum revolutions and idle revolutions.

DIY carburetor repair

If during the complete diagnosis of the Husqvarna chainsaw, carburetor defects were detected, some of them can be eliminated without contacting the Husqvarna AB service center. For example, you can independently:

- change gaskets under the covers of the main chamber and fuel pump;

- clean or replace the strainer;

- replace the diaphragm or needle valve of the main chamber;

- repair the diaphragm of the fuel pump.

Gaskets, diaphragms and a needle valve with a rocker arm can be found in the repair kit that is available for each model of Husqvarna chainsaw carburetors.

Also, if you have some experience, you can try to restore the faulty valve-nozzle, but you cannot guarantee a positive result when trying to restore the nozzle, if it is faulty, manufacturers recommend changing the carburetor completely.

The first thing to do before removing the carburetor from Husqvarna is to clean the saw with a compressor, since dirt can interfere with a quality repair. Next, you need to open the top cover of the chainsaw, remove the air filter, disconnect the rods from the control levers of the air and throttle valves. After that, unscrew the screws securing the carburetor.

Dismantling the carburetor body for repairs is quite simple. The cover of the main chamber is held by four screws, which can be removed using a conventional screw, the cover of the fuel pump is fixed with one wide screw.

Below is a video, watching which it becomes clear how it is possible to repair a carburetor without contacting a Husqvarna service center.

Conclusion

Work on setting up or repairing a carburetor on Husqvarna chainsaws can be completed without any specific experience. In order to do everything right, you must follow the algorithm and have a minimal set of tools. It is also worthwhile to evaluate your strengths in advance and not risk it if you do not understand anything at all in the technique. Believe me, sometimes it’s better to pay a small amount to the master than to spoil the instrument by self-regulation.