Hydraulic press for juice with their own hands

Apple juice squeezing cloth. Presses for squeezing juice from apples, grapes, fruits and berries: types, making their own hands. The process of squeezing juice from apples at home

Apple trees periodically gift amateur gardeners with such a large-scale harvest that the excess fruit has nowhere to go. In addition to jams and compotes, there is another option for processing the fruit. juice. But many people do not mess with this type of blanks because of the high labor intensity of the process. Ordinary household juicers simply can not cope with a large volume of raw materials, and to buy a professional machine for the season is not everyone is ready. But there is a great option. quickly and qualitatively squeeze juice from apples on a handmade press.

To make a standard press yourself does not require special skills and drawings. Anyone can measure, saw off a rail, hammer a nail, or screw in a nut if they want to. It is not necessary to own a welding machine, any design can be reproduced in a wooden version with ordinary garden tools.

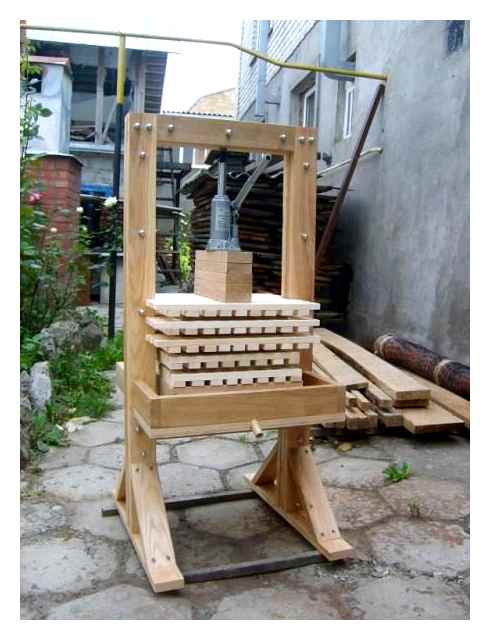

Homemade wooden apple press

For making home-made press tools are required wood and metal hacksaw (or angle grinder), welder, screwdriver, pliers, hammer. As for the materials, the following are mainly used:

- metal channel;

- wooden bars, slats, boards;

- Self-tapping screws, bolts and nuts;

- Tank or barrel, stainless steel sheet;

- Workbench screw and nut, valve, threaded rod or jack. depending on the chosen design;

- Sturdy fabric with good drainage properties for apple sacks: calico, cotton, jute sacking, flax.

Wooden elements are better made of oak, birch or beech, as materials from biologically active tree species (spruce, pine) can change the taste of the juice.Of wood particle board drainage grids do not do in any case: in the product will fall into the fine dust, impregnated with phenol-formaldehyde glue.

Types of designs: schemes and drawings

The main thing in the press. a solid base and working mechanism.

- The prepared raw material for pressing (crushed apples) is placed in fabric sacks in layers through drainage grids;

- with the help of a mechanism from above, a gnat is lowered and the juice is pressed.

A good press squeezes 65-70% of the juice, leaving an almost dry cake. It is quite realistic to make such a machine with your own hands.

Designs of the homemade press differ in the principle of operation of the main mechanism:

In most designs the pressure is from above, but in the combined version the compression goes in two directions: by means of a screw mechanism from above and a hydraulic jack from below.

The juice squeezer consists of the following parts:

- stable bed;

- quadrangular or cylindrical body, inside which bags of chopped apples are stacked;

- wooden straps for the bags to be moved around so that they do not fall apart;

- A piston-compressor, directly exerting pressure on the cake;

- jack footrest;

- Operating mechanism: screw with handle, mechanical or hydraulic jack;

- pallet bowl.

The main body can be:

Screw press for apples with single perforated body

- Double: a continuous shell with a slightly larger diameter is put on the perforated metal cylinder;

- in the form of a solid metal body with one drain hole at the bottom;

- Assembled from wooden slats connected by hoops;. barrel. The walls act as a drainage grid.

Screw press for apples with wooden slats bodyThe body may not exist at all. just a pyramid of wooden grids in a tray with the mouth at the bottom, under which the juice container is placed.

Hydraulic frame press

The design is quick and easy to install. For the bottom plate you can take a piece of countertop, for example.

How to make the main parts of the presses

First the metal base must be prepared, then the upper half of the frame is formed horizontally. For it choose a very strong material with thick walls, which will prevent the deformation of the components under load.

It is possible to eliminate corrosion by treating the surface of the frame with paint. Then plywood is laid on the base, and the tank with the tray is placed on top.

Pallet

If the press is made by yourself, it is important to make the pallet correctly. Here sometimes a large pot is used, where a round hole is cut near the rim and a tube is fixed.

This pipe will allow the juice to run off from the pan into the sump. Working with the construction, you need to be careful.

Tray can break if you catch the tube, tray, or drop something on it accidentally. If you’re not careful, you can tear the tube.

For this reason, it is preferable to choose a pallet of stainless steel, and to the hole to weld a metal tube.

The tray can be made from a large plate or from a flowerpot stand

Filters

Strainers are sacks, in which the pulp is put. The strips of fabric necessary for making the sacks of fruit should be strong. Suitable for this: calico, cotton or burlap. Some use linen cloth. The density of the fabric should not reduce its filtering qualities, but it should not be fluffy either.

To filter the juice, it is worth using a strong cloth with a fine mesh, such as lavsan or polyester.

Drainage grid

A grid for the drainage function in the form of a basket can be made from oak, birch or beech boards. Choose the ones with the thickness of 20 mm or more.

For this purpose they take several identical planks, two steel strips, self-tapping screws with a special coating. Planks are screwed to the strips, bend the strips in a circle, fasten with bolts.

Basket is ready. The distance between the slats is about 10 mm.

Do not take plates of particle board, such material will release resin, sawdust and other harmful substances into the juice.

For sewing bags use any strong fabric that will not tear under the pressure of the raw material. In addition, the fabric should have filtering properties.

Berry squeezer nozzle

It is only for squeezing juice from soft berries. Special holes are made in it to hold the excess pulp. It comes out of the connector designed for the cake outlet. The result will be pure berry juice. Berry nozzles are also suitable for juicing herbs, as they squeeze them to a dry cake. Kenwood AT 644. a metal nozzle, suitable for kitchen machines (blenders and food processors) series. Chef, Major, Cooking Chef, as well as meat grinders MJ 510, MJ 517.

Meat grinder with a juicer. a device that performs the function of two in one.Modern food processors are made with the understanding of consumers’ needs. As a result, versatile appliances have been made that combine the function of mincing meat and juicing. Home appliances that combine several functions, ideal for a small kitchen with a small work area.

The meat grinder is an essential appliance in every housewife’s kitchen. They last for decades and help you process meat for mincemeat. Manufacturers of this technique decided to meet the wishes of many housewives and combined it with a juicer. As a result, consumers got a nice bonus. two in one.

DIYER IS A FRIEND

Dear visitors to the site “Samodelkin friend” in this material we will consider the process of creation of the screw press for squeezing juice from berries and fruits made by our own hands. In order to make a screw press you will need a sheet of stainless steel 1 mm to create the squeezing chamber with holes and a protective cover with a receiving tray. STATION is made of a channel and a pipe, in the upper channel is drilled a hole and welded nut for a coarse thread. The screw also should have a coarse thread pitch (tool thread) is an important point, because the specific pressure and stress is created a decent, here you need strength and reliability.

Every DACHANIK and the owner of the country site is well aware that with the advent of autumn you need to harvest, process it, canned, etc. One of the best ways.is of course squeezing juice from apples, pears, berries, grapes, which later can be rolled up in jars and put in the cellar for long term storage.

It works this PRESS simple enough, namely, in the squeezing chamber pre-loaded mulch apples, pears, grapes or berries, covered it all with a wooden circle (preferably oak) and twist the screw press on the thread, through the created pressure is squeezed juice flows down the walls into the tray, and then into a container (necessarily cover the bucket gauze in a couple of layers, so the juice obtained clean.

Step-by-step instructions for making a screw press with your own hands.

The first thing to do is to prepare and cut a piece of stainless steel to size, mark out and mark the place for drilling holes.

After that each hole needs to be countersinked with a drill of a larger diameter.

Next, a strong and sturdy frame made of channels and pipes should be welded.

The obtained bent plate is rolled into a cylinder and welded at the junction.

In addition, a protective cover is made, so that the juice does not splash on the sides, and flow evenly over the walls into the receiving tray, and then into the container. Freshly squeezed apple juice is very useful for a human body, refreshing and revitalizing in contrast to the store chemical products of unknown origin called “juice” Try nowadays to eat fruits and vegetables from your garden, you will be healthier!

August-September is the time of the apple harvest, every year the apple trees bear fruit in abundance and you can preserve real good juice for the whole winter, if not until the new harvest. It’s good when there is a quality home-made products, without preservatives and other crap.

Just out of apple juice can make good home wine or cider, which is also 100 times better than the store poison. So guys think with their heads, do not believe width=”1024″ height=”680″[/img] Making screw press juicer once, you will use it for the rest of his life, and maybe his grandchildren will get) Always be with a supply of delicious juice, good for health and cheerful body and spirit.

We hope that this material has been useful for you. Thank you for your attention!

Homemade screw press

Auger press resembles a meat grinder. It runs on an electric motor that turns the pulley with a belt drive. The feed chamber is filled with raw material, the screw crushes it and pushes it through the sieve. At the output screw press gives juice with pulp.

For home manufacturing is the most complex option. To assemble it, you will need drawings and diagrams, as well as:

- Robust stainless steel case,

- A screw press, which is placed inside the housing,

- Capacity for raw material intake,

- A container for the finished juice,

- Electric motor, giving from 1500 rpm.

The construction is assembled on a metal frame. Casing from an ordinary or electric meat grinder can be used as the body. A screw press is installed in it and connected to the motor by a drive. A sieve with the desired mesh diameter is mounted on the outlet opening. Jars, pots or basins can be used as the container for the finished juice.

The screw press has a higher capacity, since it is not powered by hand, but by an electric motor.

Capacity of such machine. up to 7 liters of juice in 5 minutes.

The creation of the press machine by hand

Today, drawings and dimensions for making your own press can be taken from the Internet. And there are a lot of variants.

And they all ensure that there will be no differences between the homemade equipment and the machine, produced in the factory.

At first, let’s analyze the advantages of the press from the jack with his own hands step by step:

Manufacturing process

When the drawing of your future hydraulic press is ready, and all the necessary materials, tools, equipment and accessories are available, proceed directly to the manufacturing. The first thing to do is to cut all the metal, guided by the dimensions specified in the drawing.

One of the options for the drawing for making the press

Now it is necessary to make the base of the press, for which the prepared square pipes are welded together, and a steel plate is welded on the rectangle formed from them. Then the sides and top of the frame are welded together, taking care to ensure that the resulting U-shaped structure is level and has strictly right angles in the joints. Now the obtained construction should be welded to the base and you can consider that the frame for your hydraulic press is ready.

The next element you will need to make for the press is a movable platform. It can be made using a channel, square or rectangular tube. In the central part of the platform weld a piece of pipe, which will serve as a socket for the head of the rod jack. To make the guide rails for the work platform, you will need two steel strips, whose length must match the width of the press frame on its outer contour.

A variant of the press construction with a movable bottom platform, which is fixed by bolts

Fix the strips to the sides of the sliding platform with bolt connections, preliminarily putting it inside the frame. According to the same scheme, and manufactured and removable stop, but in his guide strips are drilled holes opposite the racks of the frame for fixing the desired height. Completes the process of making a hydraulic press with their own hands, installing draw springs and the jack itself. Such a hydraulic press is also convenient by the fact that you can always remove the jack from it (for example, if you need to use it to repair the car).

The appearance of the finished homemade press

One of quite economical variations of the hydraulic press, made with your own hands in your garage using simple devices, welding, jack and channels.

Apple juice through the juicer for the winter

To make delicious apple juice, you can also use a juicer. The use of this device will speed up the process of making a fruit drink. Keep in mind that in this recipe, the number of ingredients is described for a juicer with a capacity of six liters.

Cut the washed fruit into quarters, be sure to cut out the seed box. Put the slices in the strainer of a pressure cooker colander and sprinkle with granulated sugar. And in the lower container, pour water and boil. Above the pan of water, place the vessel of the juicer, which is designed to collect the juices flowing out. And also the pan with the apples. Close the appliance tightly.

After it all boils for about half an hour, loosen the “grip” of the clamp on the tube and drain the first portion of juice. You should get about a glass. The first drink is not sterile, so be sure to pour it back into the container with the pulp to boil again.

Meanwhile, the fruit has steamed. The chunks have shrunk, thanks to giving up some of their juice. At this point the intensity of the fire must be reduced. Apple juice through the juicer for the winter should boil for another forty minutes. The last one hour.

It’s time to turn off the juicer. Now it should be left alone for another twenty minutes to let the juice run off. After that, you need to remove the clamp from the tube and drain the existing drink. Residue is drained through the wall of the liquid collector. Pour the drink into sterilized jars or glass bottles. That’s all it took to make.

In general, the entire process of making apple juice through the pressure cooker for the winter takes about an hour and a half. In the end, the number of ingredients indicated in the list produces an average of three liters of drink. But in general, the cooking time may also depend on the type of fruit. If the apples have turned into mashed potatoes, then you can turn off the device.

As you can see, there are many ways to preserve apple juice. And they all differ from each other in detail. Once you learn the basics of sterilization, you can then make juices with different blends and even invent your own recipes!

In fact, it is not as difficult and troublesome as it may seem at first glance. But now you will always have a fresh, healthy juice in your house. Enjoy!

What to make an apple press from

The most popular and economical materials for the manufacture of the apple press. wood and metal (stainless steel). These materials can be purchased at any construction store, and they will last more than one season.

Apple press with his own hands from a jack

Creation stages and drawings

- Take a metal profile (size determined individually) and weld it to a U-shaped structure.

- At the end of the profile hole is made (through it passes the head with a thread). Fix the parts with a welder.

- Connect the support part to the pipes.

- At the bottom of the screw put a metal stop of a rounded shape.

- The body is created from planks (width. 4 cm and thickness. about 5 mm).

- Cut the iron plate, about 5 cm wide, into 4 equal strips.

- Next, the entire enclosure is assembled (the upper plates are attached to the lower plates).

- Make a metal tray (preferably with curved edges).

Screw press

The device for obtaining juice, which in many respects strongly resembles a meat grinder, is called a screw press. In most cases, dacha craftsmen connect an electric motor to such a press, which speeds up the process of squeezing the juice and greatly facilitates the work.

The principle of operation of such a press is to crush fruits with the help of an auger. The chopped fruit is then pressed through the installed grate. It is difficult to build such a press on your own. But some masters do not stop difficulties, and they are looking for alternative options.

auger press will succeed without much difficulty, if you get to buy or find a special screw, externally identical to the screw of a meat grinder.

This is where metalworking skills come in handy. You can ask for help from a professional turner, who will be able to turn such a screw, focusing on the given parameters.

Screw press

The screw press is a favorite of many gardeners. However, even in its creation it is difficult to do without the services of a turner. Some dacha owners install a jack at the bottom of the frame.

It is attached to the landing pad. When the jack is raised, the support is also raised, and when it is lowered it is lowered.

After that, proceed to the construction of the grid, which is set on a stand of small wooden bars. On the upper part fix the locking device for the part of the screw, which creates the pressure.

It is recommended to make such a press not from wood, but from strong steel. But to connect the parts of the press you will need a welder and the skills to use it.

In the upper part of the frame, a hole is cut, into which a screw is installed. Juice collecting tray is constructed of food metal, in the front of which a special groove is bent. through it the juice will flow into the prepared container. It is necessary to study the drawings beforehand in order to understand the sequence of operations and the operating principle of such a press.

Comparing the coefficients of usefulness of such varieties of presses, we can come to the conclusion that it is the screw press that has a higher efficiency when squeezing the juice.

Using ready-made drawings, you can build a juice squeezer with your own hands. It will be much easier and faster to do it, if you prepare all the necessary materials and tools in advance.

How to choose a baler

When buying an apple press, you should pay attention to the following design parameters:

- Container capacity for loading. The volume depends on the amount of raw materials that can be processed at one time.

- Material of the basket. Best choice. stainless steel. It lasts longer and is easier to care for.

- Features of design. Need to know whether it is necessary to connect to mains electricity or running water.

- Dimensions. The size determines the conditions for storing the unit, the convenience of its use.

- The need to apply physical force to work with the press. Some models will be difficult for girls to cope with.

- Performance of the construction (how much juice it produces per unit time). For large volumes of fruit, the optimal indicators. 200 and more liters per hour.

- Price. This parameter is considered relative, but it can not be ignored. The most affordable in cost are mechanical. In these, the price depends on the size of the basket. Optimal in price. hydraulic design (cost inexpensive and requires no physical effort).

Press juicer for apples with their own hands

As a rule, the press units are preferred by winemakers, because in the process they do not heat the pulp and do not crush the pips.

What you will need

You do not need to use special drawings and welding machine to assemble the classic press yourself. The construction can be made of wood with the usual tools and fasteners, viz:

- Boards, wooden bars or slats;

- stainless steel sheet;

- barrel or tank;

- valve;

- piston-bag;

- metal channel.

The wood elements should preferably be of oak, beech or birch, as conifers change the taste of the juice due to their biological activity.

Drainage grids must not be made of particle board, as the dust containing phenol-formaldehyde glue will enter the finished product.

Step-by-step instructions for making

The algorithm for assembling the press unit is as follows

- Create a stable structure. not only metal material can be used for this purpose, but also wood. At the same time, the upper lintel must be made of a metal bar.

- Weld a nut to the crosspiece located on the upper bar. In the future a screw will be driven through it, which provides directional load.

- Attach to the base of the screw a platform that exerts pressure on the raw material in the hopper.

- Make a peorized tank, equipped with holes responsible for the juice drainage.

- Attach a filter cloth to the walls of the tank.

- Install a tank at the bottom of the structure, which will receive the finished product.

Important! It is recommended to use lavsan or polyester, characterized by a mesh structure, as a material for juice filtration.

Correctly made juicer will serve for many years and will help to process a large amount of crops.

The process of squeezing juice from apples at home

After the raw material is prepared, it is placed in cloth sacks or wrapped in pieces of cloth according to the envelope principle. Next, the rolls are placed in a container, basket or simply on the bottom of the structure in layers through drainage grates. Approximately 3 to 4 pouches fit. A pressure sleeve is lowered from above, the juice flows into the pan. When the squeezing process is finished, the pulp is taken out and the next batch is loaded.

The remaining cake after a qualitative pressure is usually taken out dry and compressed into “pills.

Apple cake after the press

It is better to dispose of the squeezed juice in a compost heap. Worms multiply very well on this material, creating a valuable fertilizer for the garden.

The resulting juice can not only drink fresh, but also make preparations for the winter:

Apples are very valuable for your health. It is extremely inconsiderate and wasteful to bury and give the neighboring piggies the surplus harvest. With a couple of simple attachments, you can quickly and easily process all the fruit. And in winter it will be so nice to get out of the cellar or the refrigerator useful and delicious amber drinks!

The post Ways to make an apple press with your own hands first appeared Pro Farm.

Options for homemade presses

The easiest way to make a screw press. The gradual increase of pressure by the head on the pulp ensures the best effect on the cells, destroying them as the liquid is taken away. The apparatus may be made of wood or metal. A basket with a tray is placed on the base of the frame to take the juice into the container. The whole inside of the basket is covered with filtering material. The pulp is placed, covered with the remnants of the cloth. On the surface is lowered a circle, on which the press is pressed by the movement of the rod. Make a juice press with their own hands, as in the picture, will help drawings:

clamps; 2, 3. frame with a crossbar; 4, 5. screw pair with a fixed circle.

To collect the juice use an enamel pan with a soldered hole for juice drainage. Inside it is necessary to install a basket with peoria, the tank from the washing machine will do. It is necessary to arrange the external stiffeners in order to install the basket in the center. When laying the pulp, use spacers to create a uniform pressure on small portions of the pulp. It is possible to fill the cavity with filtering envelopes laid flat. A wooden circle should be placed underneath the metal basket to prevent the pressure from destroying the outer pan. In one cycle, for 5 minutes, the screw press will squeeze up to 1.8 liters of juice.

A sugar bag can be used as a material that can withstand a high pressing load. You can use kapron lavsan stockings, polyester or a new cotton, linen cloth.

If there is no possibility of turning out a screw pair, you can use a jack, which is available in every household.

In the wooden construction between the wooden frames put bags of filtering material. The pulp is placed between the drainage frames and the juice flows into the pan. It is clear that the textile is chosen to be strong enough to withstand the pressure of the press. In such a machine there are no metal parts, the juice is in contact only with the wood. Therefore, it is impossible to take resinous species, so as not to “flavor” the product. We need oak or beech planks. The planks for the frames should be pressure-resistant, and be thicker than 20mm. Juice separation in this press is up to 70%.

The design of the press to squeeze the juice made with his own hands from the jack with a lower fixation is more complicated.

The screw on the top is only needed to hold the lid in place. The movable skid lifts the tank up on a skid. There is no limit to the craftsmen’s imagination.

Use a wedge press for squeezing juice. The simplest device works on the principle of squeezing a bag of pulp placed in a cone of boards. When the angle is narrowed, due to the wedges slide in, the planes of the boards tend to join, the bag is compressed, the juice flows down into the substituted vessel. At other times, goats are used for making firewood.