In Which Direction The Nut Is Unscrewed On The Angle Grinder

Method # 1 remove the disc from the angle grinder

First, figure out which way to unscrew the nut.

The flange must always be turned in the direction in which the disc rotates.

For this kind of work, you will need either two gas keys or two clamps.

Here’s what you need to do: destroy the remains of the disc, fix the washer located behind the disc with one key, unscrew the flange with the second.

Cut-off wheels for an angle grinder, in turn, have their own subspecies, such as:

- Cutting wheels for metal work;

- Abrasive wheels for working with stone;

- Wheels for woodwork;

- Diamond discs (mentioned above).

The purpose of each type of disc usually corresponds to its name.

Among the grinding discs, there are four main subtypes. flap, wire, diamond and bakelite-based grinding discs (straight, T41 profile and disc-shaped, T27 profile).

- The flap disc is made from sandpaper. Its main purpose. This is the elimination of existing coatings such as old paint, primer or paint coat. Also, with disks of this type, wood products are polished.

- Wire discs are used by artisans to remove rust. They can also remove other types of stubborn dirt.

- Diamond discs are used for stone polishing.

- Disc discs are made of plastic or rubber and are used to polish metal surfaces.

How to properly place a disc on an angle grinder?

In order to correctly place the disc on the angle grinder, first it should be noted that the disc is mounted on the spindle of the angle grinder using a special clamping flange with M14 thread. Let’s take a closer look at how to remove a disc from an angle grinder. In order to unscrew the disc from the angle grinder, the flange must first be removed. Especially for such purposes, manufacturers complete the angle grinder with a special open-end wrench. It has a specific shape. The pins located on the horns of this key are inserted into specially provided holes on the flange.

To unscrew the flange, we fix the spindle. To do this, we clamp the latch, which is usually a button on the top of the case. When pressed, the cotter pin is placed in the hole of the driven disc of the gearbox, and this in turn prevents its rotation. Next, we insert the pins of the key into the specially provided holes on the flange, pressing the retainer, you must simultaneously turn it counterclockwise and move the flange from its place. If the manipulations were successful and the flange gave in, you can unscrew it by hand and put it aside.

Now let’s dismantle the disk. Often, in the process of intensive work with the tool, a certain deposit of small particles of metal and abrasive material forms on the inside of the protective casing. For optimal, stable and durable operation of the angle grinder, remove the bottom of the flange and clean the casing with a steel brush.

How to remove, change a jammed disc from an angle grinder?

How to remove a disc from an angle grinder. An angle grinder (hereinafter referred to as an angle grinder), popularly referred to as an angle grinder, is probably the most demanded inventory that is present in the arsenal of almost every master, regardless of his qualifications.

This tool is actively used in abrasive processing: cutting, grinding, cleaning workpieces made of stone, metal and many others. It is widely used in areas such as: construction, woodworking and other similar types of work. Like any other tool, the angle grinder is also divided into several classes.

This refers to the following: household, semi-professional and pro-class instrument. This classification is determined by the power resource of the tool, its performance, the presence of certain additional options, material and build quality, etc.

Consumables for an angle grinder, in addition to various types of cleaning brushes, are cut-off wheels and a variety of grinding discs. Attachments for angle grinders: how to make the right choice?

The main question: How to choose the right disc for your angle grinder?

When choosing accessories for an angle grinder, first of all, you should decide on the type of proposed work. The choice of the type of disc will depend on this. We also want to mention that when choosing a consumable, be sure to take into account the power characteristics of each specific model. Examine the labeling. Often, it is printed on the disc itself and includes a set of symbols by which you can determine the relevance of this consumable to perform the intended work.

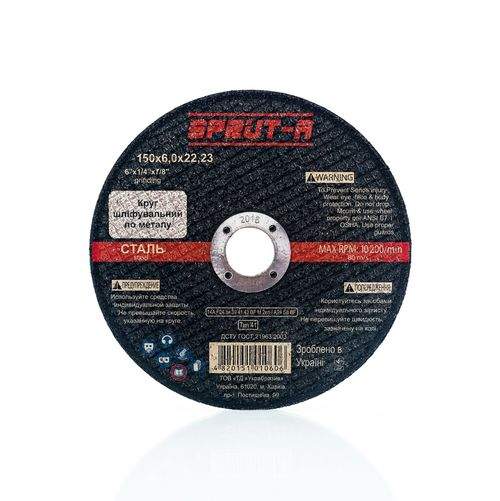

Also, focus your attention on such a parameter as the diameter of the disc. In no case should it exceed the size of the protective cover on the particular tool model. The size range of discs is usually represented by the following diameters: 115, 125, 150, 180 and 230 mm. The most common diameters are 125 mm. And 230 mm. They are optimal for most types of work and the capabilities of the tool itself.

Among the bakelite-based grinding discs, the most popular discs with a thickness of 6.00 mm. This parameter depends on the total diameter of the disc. The relationship is as follows: the larger the disk diameter, the greater its thickness and vice versa.

Method number 3 remove the disc from the angle grinder

This method is used in extreme cases.

When I disassembled my head and squeezed it in a vice from the other end, I unscrew it only with a gas key

It is naive to believe that the construction will ever end.

Cardboard circles help from biting, in most cases I twist 99% with my hands. You stop it with a button, and turn it right behind the disc, there have never been any problems.

And I heard that welded ones are specially made so that the disk spins in the other direction, but why? I do not know.

An arrow is stamped on the angle grinder (on the body). Here in what she is shown aside. In that side and the disk is spinning. And in that direction you need to tighten the disc. To do this, simply turn the disc by hand. All nut Tightened Right hand thread on nut.

If sparks are flying at you. That is the right-hand thread and upon impact (pulling out the angle grinder), the thread is automatically tightened.

If sparks come from you. Disc not fully tightened. Will be unscrewed. To avoid when your angle grinder is knocked out of your hands and the nut is jammed. It is necessary to put a cardboard gasket between the disk and the nut (even a pack of cigarettes will go)

Which way it is unscrewed. Which way the nut on the flywheel is unscrewed in shtil180 I do not want to knock off the thread on the bolt, tell me which way

Features of pedal repair

- Treat pedals with kerosene product or solvent. This procedure is necessary to remove dirt that interferes with rotation.

- Heat connecting rod with axle. Due to slight damage, the thread is easier to loosen and the axle is removed.

Install the axle carefully, as this will prevent damage to the threads. Otherwise, dismantling will be difficult.

Removing the pedals removes the carriage. Disassembling the parts will allow you to troubleshoot. Bicycle carriage repairs are carried out to restore transport operation. The condition of the bottom bracket depends on the contamination and wear of the bearings. If the last parts are broken, then they are changed. This happens when the carriage assembly has been used for more than 3-5 years.

A bicycle is an unstable transport, so it must be carefully secured when repairing. Once assembled, it can be used again.

Which way the carriage is unscrewed on a bicycle

Although the pedal is a simple element of a bicycle, it will only be possible to remove it if you have knowledge. This is usually required in the event of damage, lubrication or replacement of the connecting rod. Which way to unscrew the pedals? This is described in the article.

The pedal is an important component of the system, consisting of:

- Contact, where there is a mount for special shoes;

- Conventional.

What the pedal consists of?

The pedal is an important component of the system, consisting of:

- Sprocket set;

- Connecting rod carriages;

- Axes. the base part of the structure;

- Platforms. a support that is needed for contact with the feet;

- Bearings used to connect the axle to the platform;

- Fittings are bolts and nuts that hold the rest of the parts.

Pedals are divided into:

- Contact, where there is a mount for special shoes;

- Conventional.

These types of pedals are difficult to remove. Contact mechanisms have a more complex attachment. Combined devices are removed in the same way as contact devices. On the one hand, they include ordinary pads, and on the other, contact.

The secret to easily unscrewing the disc on an angle grinder. [Life Situations]

This roller, It can be seen, as well as with what, correctly clamp on the angle grinder. This feature will help you get rid of.

The disc spins clockwise.

))))))))))))))) Really? Clockwise. The nut, and the disc must rotate towards.

If you specifically bite, you can unscrew with an adjustable wrench.

How to unscrew the disc nut of an angle grinder (angle grinder) if it is bitten

So, if there is no way with the key, even if you insert it and hit it slightly with a hammer, then we begin to use something more serious.

The first thing to try, but again without fanaticism, is to take a rod, insert it into the holes on the nut and, using a hammer, slide the nut in the direction of its untwisting. The main thing here is not to break the button and not to rip the holes, as here

The second thing that many advise is to warm up the nut. We warm up the nut. As a result, it is a little, but physically still has to expand. Resizing may or may not help.

The third method is the most effective, and, oddly enough, one of the safest for the angle grinder itself. We take and break off the edges of the disk along the nut.

Next, we use a thin metal plate or another disc (thinner), and maybe a second angle grinder with a disc. In this case, a broken disc must be turned either with a plate or a disc. We try to sharpen the disc so as not to damage the nuts holding this disc, because they will still be useful to us. So we sharpen the whole broken circle until we grind it off and the nut is unscrewed.

This business is 4-5 minutes, no more.

If you will be using a second disc or metal plate, it is best to insert them in a vise to hold them. Since it is dangerous to hold such objects with your hands. This method is the most effective.!

Why bites the nut on the angle grinder that holds the disc

I will say, perhaps, a well-known truth. Bites nuts more often on angle grinders with a disc size of a significant size, say 150-180 mm or more. The thing is that the resulting torque, in the case of a disk impact at the time of the beginning of cutting, is much greater than for a disk, say 125 mm. As a result, the nut is tightened by inertia so much that it is very difficult to break it by the usual and usual methods. Now about the special ways.

How to unscrew a disc (nut) on an angle grinder, if bitten, jammed, cannot be unscrewed # 128249;

The angle grinder, or as it is called more popularly and in the popular way, the angle grinder, is nowadays an irreplaceable and very useful tool. Without him, neither here nor there! And if it suddenly fails, then you have to dodge in every possible way, look for alternatives and think about restoring the instrument. At the same time, it is impossible to use an angle grinder for its intended purpose because of a kind of simple lining when the disc does not unscrew. Rather, the nut that holds this disc is not unscrewed. Here you can "break the wood", namely, bend or break the key, damage the lock button, break the case, but still not unscrew the very unfortunate nut. So, we will immediately warn you, if it is not too late. If you suddenly do not unscrew the nut holding the disc with a key, then you need to change tactics. And it is precisely the cardinal method of unscrewing that our article will be devoted.

How to avoid biting the disc nut on an angle grinder

And a few words about preventing such unpleasant precedents again. You can use small cardboard spacers by inserting them between the disc and the nut. As a last resort, we use a disc of a smaller diameter, unless of course the nut is tightened from above. As a result, it will be possible to unscrew such a nut without any problems. It will not be squeezed, for a bite on the thread.

And a little more on the topic, about the problem that I studied on my own experience.

How to unscrew if tightened?

Remember! Unscrew in the direction of rotation of the disc. THOSE. If the disc rotates clockwise, then you need to unscrew the nut clockwise.

The easiest way to unscrew the disc mount is to place the wrench and then hit it with a moderate hammer several times.

If that doesn’t work, there are alternative methods for solving the problem:

- Heat the fastening mechanism with a torch, which will lead to the expansion of the metal. As a result, the structure will become mobile;

- Use a small metal plate to grind the disc down to the nut. Continue grinding until its surface touches the nut and begins to twist it;

- Insert a steel pipe into the holes in the nut, use it as a lever to unscrew the tightened nut. Do not apply too much force so as not to break the thread;

- Lubricate the threads with a machine oil such as WD-40. Wait 3-5 minutes and then try unscrewing the mount with a wrench. Using this method, you can get rid of rust inside the landing shaft;

- If you need to remove a circle that has not been used for a long time, you can start tightening the fasteners even more. After that, try again to weaken it;

- Boiled or rusted threads on an angle grinder can be treated with turpentine, vinegar, white spirit or rust remover. After processing, you need to wait at least 30 minutes, and then try again to unscrew the nut.

If a situation arises when you are left without a key, you can cut down the stuck mount with a chisel or grind it off with a second angle grinder with a disc for working on metal. After that, you will have to restore the thread, and also look for a spare nut. If the circle still does not lend itself, you can try to combine different methods. For example, treat the shaft with machine oil, and then start unscrewing the nozzle with a lever or tapping the mechanism with a hammer.

What are the ways to unscrew a tightened nut on an angle grinder?

An angle grinder, or angle grinder, is a versatile tool with which you can perform a wide range of actions. It has a simple mechanism of action based on the rotation of the shaft by an electric motor. Essential for cutting metal parts, polishing surfaces and sanding various materials. One of the common problems during operation of an angle grinder is biting the nut that holds the disc. This does not allow replacing the nozzle, and strong impact can damage its thread, break the key or break the body.

- Reasons for biting

- How to unscrew if tightened?

- How to avoid snacking?

- Conclusions

How to avoid snacking?

To avoid trouble when changing the angle grinder attachment, it is advisable to prepare in advance for work. To do this, you can insert a small spacer between the disc and the nut. Suitable material is cardboard, a piece of linoleum or plastic.

If the fastener is constantly tightening too tightly, it is advisable to use a circle with a smaller diameter. It is also important to monitor the cleanliness of the tool, timely treat the thread with oil, WD-40.

Reasons for biting

As a rule, this problem occurs on an angle grinder with a working surface diameter in the range of 150-180 mm. When a strong torque occurs, the disc bites. This leads to the fact that the attachment cannot be removed with a conventional wrench, even with the application of serious physical effort.

The second common reason is the use of an angle grinder disc that does not match the factory parameters of the tool. This leads to a disruption in the operation of the entire mechanism and jamming. In rare cases, the nut does not lend itself to loosening when rust appears on its threads. This most often occurs during prolonged use of the instrument or storage without changing the tip.

Conclusions

An angle grinder is a simple and useful tool for home or professional use. The most common problem while working with it is biting the nut that holds the disc. This can be dealt with by mechanical action on the mechanism (blows to the mount, using a lever and grinding the disc), and by chemical methods. treating the thread with oil or rust solvent.