Installation of interior doors with a miter saw

Fitting a doorway with casing

The casing construction is implemented in several stages:

- In the end part of the opening, a thorn is cut, the width of which is equal to the height of the ridge. As a rule, this width is 35-38 mm.

- A prepared tenon needs to be finished with tools manually.

- A wooden beam with a section of 100×100 will replace the casing structure. A groove is cut out in it, the width of which will be equal to the width of the groove. Its depth should be about 40 mm.

- To fasten the casing, it is necessary to prepare grooves in the lower part of the opening, their depth should not exceed 5 mm.

Two methods are used to attach the upper casing strip:

- In the first option, it is necessary to prepare a board, which is driven in between the installed beams and fastened.

- In the second case, one wooden bar is installed, a board is put behind it and a wooden bar is installed again. With this installation, the board does not need additional fastening.

Preparatory process

Before starting the installation of interior doors, you need to prepare the tools:

- level;

- scrap;

- nail puller;

- hacksaw and chainsaw;

- chisels;

- fastening parts;

- polyurethane foam.

Every experienced carpenter will tell you, so that the door does not warp, the doorway must be mowed. This can be done in two different ways.

Required set of tools

Assembling the box

In most cases, the manufacturer completes the door for the house with a box, which can be either assembled or disassembled. If your box came to you disassembled, then the first thing to do is to assemble it.

- if the box contains separate sawed elements, then you will have to knock out the plugs installed on the ends of the racks;

- The edges of the lintel should be fastened to the upper side of the vertical struts, and the plugs knocked out at the first stage should be installed in the holes obtained;

It is important! The frame is selected so that the distance between the door and the frame is 3 mm. For fastening the box parts, it is recommended to use galvanized self-tapping screws, which must be installed from the back.

- the box can be U-shaped, made of rectangular parts, or beveled, made of racks cut at an angle of 45 degrees;

- when the box is assembled, it is recommended to insert the door into it and measure the width of the gaps. Measure the interior opening right away, and notice at what distance the vertical posts need to be cut in order for the box to enter it. Please note that a small distance should remain under the installed door, about 8-15 mm.

Installing the nut also has its own nuances. Its size should be selected depending on the distance between the two uprights. The door and threshold should be spaced 3 mm apart. Use a chisel to prepare a place for the installation of door hinges and install them.

Assembling a box for an interior door

Methods for fixing the doorway

Installing doors in a wooden house is a very crucial moment, so we suggest using one of the mounting methods to bring the housewarming date closer.

Regardless of what material will be used for the door block, its installation can be done in two ways:

- using a casing;

- with casing.

Casing doorway equipment

The interior opening begins to be made out when it has already been formed in the walls. Further work takes place according to the following scheme:

- using a router, it is necessary to make a groove in the end part of the opening, its depth should be about 50 mm;

- tools you need to modify it manually;

- into the prepared groove, you need to hammer a wooden beam with a section of 50×50 mm. over, its length is determined by the degree of freshness of the log house. If this is a fresh log house, then the length of the timber should be 30 mm shorter than the groove; for a dry log house, its length should be 20 mm less.

It is important! If you do not trust wood, then you can arrange an interior opening with a metal channel. This technique is used when installing entrance metal doors, but this method is also suitable for interior models.

- A wooden beam is sometimes built up with a board, the width of which is equal to the thickness of the end of the wall, and the building itself is carried out with the help of nails;

- to the bottom of the timber, the upper and lower boards are filled with a raspor, thereby forming the threshold and the upper contour of the box.

Casing groove preparation

Installation of interior doors in a wooden house, the subtleties of the process

Repair work in wooden houses has its own characteristics, compared to brick or other buildings. The biggest problem arises when you need to install an interior door in a wooden house with your own hands. Any wooden house gives a fairly significant shrinkage of about 1-10 cm per floor, and this process can take about 6 years. If the door was installed incorrectly, then its structure may be distorted or damaged as a result of wall pressure. We will talk about how to install interior doors in a wooden house in our article. First you need to know the features of wooden houses.

Installation of interior design

A door block is a structure that includes:

- box;

- Door;

- hinges and locks.

For door decoration use:

- extras;

- crossbeams;

- platbands;

- threshold.

Door installation is carried out in several stages:

- assembly and installation of the box;

- filling the gaps with polyurethane foam;

- hanging hinges;

- door installation;

- trim platbands.

Installation diagram of an interior door in a wooden house

Installation of sliding interior doors

Recently, not ordinary hinged interior doors have been in great demand, but sliding (slider) doors that slide along the rails or go to the side (into the opening, pencil case, wall) on rollers.

They are of two types:

- sliding door-accordion, consisting of small plastic or wooden slats, which, easily sliding, significantly save space;

- a door mounted in a pencil case or a wall, working according to wardrobe-compartment technology.

On a note! Inexpensive accordion doors are not practical. Sliding doors of any modification are usually accompanied by step-by-step instructions from the manufacturer for assembling them.

Advantages of sliding doors:

- custom design:

- more space in the room for furniture;

- security;

- do not open spontaneously in drafts.

The disadvantages include:

- poor noise and sound insulation, as well as the penetration of odors, but this is not difficult to eliminate by installing a felt gasket on the pediment;

- the difficulty in repairing it and in caring for the surface where the door moves;

- the high cost of installation, but if the installation of sliding interior doors is done by hand, then the costs are practically no higher than when setting up swing doors.

Do-it-yourself installation of interior doors: 10 video steps

Every owner wants to save money on building a house or renovating an apartment. Therefore, more and more often, homeowners tend to perform many repair and construction work on their own. Do-it-yourself installation of interior doors will help you save a lot.

There is nothing complicated in these works even for a novice master. You just need to carefully study the step-by-step instructions and watch the video.

The procedure for installing interior doors

There is a certain order of performing actions:

- Unpack the purchased door set and door frames. Everything must be done carefully so as not to damage the structure.

- Assemble the door frame. The kit contains 3 components and 1 tie bar, which will be used for short-term fixation.

It is more convenient to do the assembly on a flat floor with a soft underlay. The gable panels have inserts (plastic inserts). They are hammered into special grooves. They must be knocked out carefully so as not to damage the loot. Use wood blocks for this, since you cannot knock on fragile plastic inserts with a hammer.

- Fasten all parts of the door fixed base according to the “groove to groove” pattern, giving it a U-shape. Strict geometry must be observed, inaccuracies during assembly must not be allowed. Fasten the frame with inserts knocked out earlier from the grooves, hammering them into the formed holes. Work with a hammer, but be careful.

If the parts of the box have shifted when the inserts are hammered, then you need to correctly align the case with a hammer, placing a wooden plank.

Think over the direction of opening the doors. It all depends on the layout.

Advice! In the bathroom, pantry and toilet, it is better to make doors that open outward, since an inward opening door will reduce an already small space. Doors to large rooms (living room, bedroom, office) must, on the contrary, be made opening inward, otherwise the door leaf will interfere in the aisles and hallway.

- In the future, you will need some tools for work:

- drill;

- screwdriver;

- end saw and chisel;

- milling head;

- building level;

- dowels, tape measure and mounting foam.

After collecting the top of the box, you need to go to the lower zone. A clamping plate from the purchased set will come in handy, with which to fix the width of the door frame along the bottom. Screw it with screws in those areas that will later be embedded in the wall. Screw in the screws at an angle, starting work not from the very edge, otherwise you can easily split the bar.

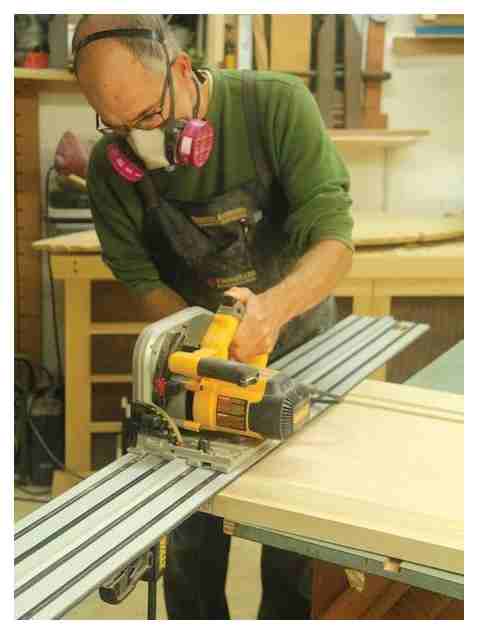

- Fit the patch to the size of the doorway. Usually the length of factory doors is 5–6 cm longer than standard openings. After measuring the opening, cut the bottom of the box with a miter saw.

When deciding on the dimensions of the doorway, you need to take into account the height of the sill (if any) or its absence (when an interior door without a threshold is provided).

- For fitting, insert the door leaf into the assembled frame lying on the floor, without removing the cellophane from it. It is enough just to cut it in the area of the handles and the lock.

- Mount a finished box fitted in all parameters in the opening and use a building level to set it perfectly level. Screw the box to the opening with wood screws, screwing them at an angle in those areas that will then be covered with foam and door trim.

If the doorway is not made of wood or plasterboard sheets, where there are wooden blocks, then you will have to use dowels or similar fastening materials for fastening.

It is impossible to fasten the door frame through the front side, so as not to spoil its appearance and not to complicate the work (opening / closing) of the door over time.

Foam the crevices between the opening and the box later, using dry finishing mixtures, make a slope in this place.

- While the foam hardens, you can start installing hinges and handles on the moving part of the door, as well as inserting the lock. Mark the place for the castle on the pediment and outline the outline according to its shape. Using a milling saw, carefully remove the top wood layer until the face of the lock is level with the door leaf.

DIY How to install and custom cut prehung door

Make a deeper recess for the inner part of the lock with a drill with a suitable drill bit.

Then, on both sides of the canvas, drill holes for the handles with a drill (for household premises, latch-type handles such as a knob or with a latch pressure are well suited).

Secure the lock with the supplied fasteners, harmonious in color and style with locks, hinges, doors, plugs and door handles. To do this, insert the lock core into the drilled slot, put the handles on it on both sides and clamp everything with fasteners.

It’s time to install the loops, the pins of which should look up, and then the canvas is put on them. Work like a lock. Make sure that the hinges are on the same level with the canvas.

- Return to the loot, mark and hang the hinges, determine the entry point of the lock, make a hole with a chisel and fix the plug.

- Hang the door leaf.

Everywhere where wood was drilled, cut and sawn, it is necessary to cover its bare areas with paint in a general tone or varnish. This will not only improve the appearance, but also preserve the wood surface.

If you wish, you can easily install the interior door yourself.

Factory door sets are made for a typical wall thickness of about 7–8 cm for city apartments. Therefore, homeowners with thicker walls have to adapt to industrial dimensions.

With a wall thickness of 25 cm and above, the opening places, not covered by the door jamb, are sealed with plaster, plastic or plasterboard slopes. Up to 25 cm you can install interior doors with extensions, which is much faster and easier.

Dobor (additional boards) is a box expander, which, together with the platband, plays an aesthetic role, hiding uneven surfaces, making the door much stronger and preventing it from skewing.

It is made from grooved and edged boards for thick walls or from aircraft plywood (subsequently decorated with self-adhesive film) for very thick walls. The complement, assembled from 3 component parts, copies the letter P in shape and is attached (you can use PVA glue):

- to the door frame;

- to the wall in the opening area;

- on a vertical beam between the extrusion and the opening.

- speed of assembly and installation of the door block;

- absence of “wet” finishing works, which are undesirable for wood;

- extending the service life of doors.

Briefly about the hinges. Factory products are often sold with hinges already attached. Then the question of installing loops is not the key. But sometimes you have to install them yourself. Here many people think about whether to use classic loops or butterflies.

Butterfly hinge from the category of non-cut elements, i.e. when using it, you do not need to cut grooves. This is a plus.

Attention! But this design does not make it possible to quickly remove the doors as needed. You will have to unscrew the hinges, and this is inconvenient during repair work or when bringing in or taking out furniture.

Butterflies are easily installed, however, when choosing this type of hinge, you need to know: even a minimal deviation due to a possible defect in the door leaf or the hinge itself will lead to the fact that the doors will not close tightly. Therefore, you need to work with butterflies extremely carefully.

It is up to the owner to decide which hinges to install. Butterflies are more suitable for light doors, and for massive heavy doors it is better to choose the classic version, since it provides for a stronger connection, thanks to which classic hinges are able to hold more weight.

Double-sided interior doors

In large apartments or houses where there is a lot of space, the owners often prefer double doors between rooms (swing or sliding). Installation of double doors of any version is also simple, but has its own specifics.

The installation process for double doors consists of the following steps:

- Unpack the kit and determine where the top and bottom are, the glossy side of the door and the matte side. How the doors will stand in the doorway and where to look. Which one will have a handle, and which bolt. Mark and sign everything.

- Assemble the box and fit the hinges. There are slight differences between the door types. For swing structures, you need to make 2 fragments of a frame beam from the scraps of the board, sawn down at 45 ° (this will be the top plate necessary when measuring the location of the hinges) and connect it to the side racks.

Install the crossbar (latch) before inserting the hinges. On each sash, cut the hinges into the door itself and into the side pillar. Remove the previously made fragment.

- Hang the first door on the hinges, leveling it, as when installing a single-leaf swing door. After that, carefully hang the second one, adjusting it in accordance with the first, mark a place for the second bar and fix it with self-tapping screws.

- After making sure that both sashes are level relative to each other, foame the seams. When solidifying, the foam increases many times in volume, therefore it is better to use foam with a low expansion coefficient.

- Before inserting the handles, fix the deadbolt counterplate in the door frame.

- Nails the cover strip (profile profile strip), having initially coated it with hot melt glue for greater strength, and install the trims.

It is not difficult to install interior doors with your own hands. It is important to consistently perform all stages of installation.

Step-by-step installation of interior doors

In general, there are many subtleties. We will try to describe and illustrate the most common moments in a photo or video material.

Do-it-yourself installation of interior doors: photo, video

Sooner or later, you have to change the interior doors. The procedure is not so complicated that it is imperative to hire a specialist. If you have at least some skills in handling a saw, a level and a plumb line, you can tighten a few screws. do it yourself. When replacing, before installing the interior door, the old one must be dismantled. And here, too, there are features. All the intricacies. in photos and videos with detailed instructions.

Interior doors are different not only in design, but also make them from different materials

Interior doors are made from different materials. over, the material of both the door leaf and the frame differs. The door leaf is:

- From fiberboard. These are the cheapest doors. They represent a wooden frame to which laminated fiberboard is attached. They are distinguished by low sound insulation, they are afraid of high humidity, they are easily damaged.

- Made of MDF. They cost much more, but the quality characteristics are much higher. They are better in sound insulation, are not afraid of moisture, stronger and more durable.

- Wood. The most expensive doors. Made from different types of wood. from pine to oak or more exotic species.

Door frames are made of the same materials. The worst choice is fiberboard boxes, they even bend under their own weight, and hanging the door leaf on them is sheer flour. So try to take either MDF or wood. There is one more material: laminated wood. The good thing is that you do not need to process and paint, but the service life depends on the quality of the film.

Assembling the door frame

If you did not buy a pre-assembled door unit, the first step is to assemble the door frame. It consists of two long posts located on the sides, and one shorter crossbar at the top. the lintel.

Dimensions and equipment

Interior doors are available in standard sizes, it is a pity that the standards differ in different countries. For example, in our country, swing doors are made with a width of 600. 900 mm with a step of 100 mm. In some EU countries, the norms are the same. in Germany, Italy and Spain. Others are standard in France. Here the narrowest doors are 690 mm and further with a step of 100 mm.

Is the difference so important? If you only want to change the door leaf without a box, then it is important. you will have to choose from your segment or completely change it together with the box. Interior doors of the same standard as in our country, the choice is much greater, as in France. several times less.

Recommended door leaf width for different door frame sizes

What width of the door you need depends on where you are going to put them. In terms of standards, the following values are recommended:

- in a living room, width from 60 to 120 cm, height 2 m;

- bathroom. width from 60 cm, height 1.9-2 m;

- in the kitchen, the width of the door leaf is at least 70 cm, the height is 2 m.

If, when replacing the door, it is decided to make the opening larger / smaller, you do not need permission for this, but you must stay within the limits set for each room.

How do you determine which door width to buy? Measure the door leaf that you have and you will know what you need. If there are no doors, find the narrowest point in the opening, by measuring it, you can find out how wide you need the door block. This door leaf is a door frame. So the outer dimensions of the door frame must be less than the measured value. For example, if you got 780 mm, look for a block with parameters 700 mm. The wider ones cannot be inserted into this opening.

The most complete set of interior doors. with a frame, accessories and platbands

When choosing a door, pay attention to the complete set. There are three types of assembly:

- Door leaf. Buy the box separately.

- Doors with a frame. Everything is included, but the box is in the form of separate boards. You will have to file the corners and connect, hang the loops yourself.

- Door block. These are doors ready for installation. the frame is assembled, the hinges are hung. Only cut along the sidewall height, align and secure.

With the same quality of the door leaf, the for these kits differ significantly. But the difference in the time you will spend on installation is decent.

Cut in loops

Most often, 2 hinges are installed on the interior doors, but 3 hinges are also possible. They are set backing 200-250 mm from the edge of the door leaf. If the frame and door leaf are made of wood, choose a location so that there are no knots. First, the hinges are attached to the door leaf. The procedure is as follows:

- We apply loops to the selected places, outline the contours. The easiest way to do this is with a finely sharpened pencil, but experts advise. with a knife blade. This makes it more accurate and the gaps remain smaller.

- If there is a milling cutter, they work with it; if not, they take a chisel and choose the material for the thickness of the loop. You don’t need to make more sampling, only for the thickness of the metal.

- A loop is installed in the prepared recess. Its plane should be flush with the surface of the canvas.

- The exposed loop is fixed with self-tapping screws.

Having fastened two hinges, the door leaf is laid in the assembled box, the correct gaps are set: from the side of the hinges. 5-6 mm, 3 mm from the opposite side and from above. Having set these gaps, the canvas is fixed with wedges. Exposed evenly horizontally and vertically (shims can be used if necessary).

After exposing, the locations of the mating parts of the loops are marked. Sometimes it is more convenient to remove the already installed loop, and then reinstall it. A notch is also made according to the markings. Depth. so that the surface of the hinge is flush with the surface of the door frame.

Do-it-yourself door hinge details are described in the video.

Connection methods

There are at least two options for how to connect these strips to each other:

-

At 45 °. The option is the most correct from the point of view of aesthetics, but the most difficult to perform. A high cutting accuracy is required. so that there are no gaps. With skill, you can saw off using a carpenter’s miter box, but you need to do it carefully. The second point. if you cut the laminated material with a hacksaw, chips remain on it. The way out is to use a well-sharpened tool.

One way to connect the door frame

How to connect a door frame

Regardless of which way you are going to connect the elements of the door frame, the first step is to wash down the racks and lintels on one side. Then they are put in a box on the floor, checking the correctness of the connection. Next, you need to decide on the height of the side parts of the door frame.

Determine the dimensions

When folded, the required length is measured along the inside of the rack. The racks are far from always made the same: the floor is often uneven and this must be taken into account. To do this, take a level and check how flat the floor is. If it is perfectly level, the racks will be the same. If there is a deviation, it must be taken into account: make one of the racks longer. Usually it is a few millimeters, but even this is enough for the doors to warp.

When calculating the height, keep in mind that the racks should be 1-2 cm longer than the door leaf (taking into account the cuts). A gap of 1 cm is made under the door, if they do not intend to put a rug under the door. If there will be a rug / carpet / carpet, it is better to make it larger. Don’t be afraid to leave gaps. They are necessary for normal ventilation in the room. We pay attention again: the height is measured along the inside of the door frame. from the bottom edge to the saw cut. Cutting off, try on the racks in the doorway.

Clearances when installing interior doors

Now it is necessary to saw off the lintel along the length and, if necessary, cut it on the other side (if the joint is at 45 °). The length of the lintel should be such that, when folded, the distance between the uprights is greater than the width of the door leaf. The minimum clearance is 7 mm, but it is often made larger. 7-8 mm are distributed as follows: 2 mm for hinges, and 2.5-3 mm for expansion gaps. Any interior doors. MDF, fiberboard, wood. change their dimensions depending on humidity. Clearances are required to accommodate these changes. And 5-6 mm is not always enough, especially in humid rooms. For the bathroom, just leave a little more, otherwise, with high humidity, they may be difficult to open.

So, we decided on the minimum gaps when installing interior doors:

- on hinges. 5-6 mm;

- top, bottom and sides. 3 mm;

- bottom. 1-2 cm.

After you have cut off all the pieces and made the cuts, fold the box down on the floor. If you notice somewhere flaws in the docking, eliminate it with sandpaper fixed to the bar. The more accurate the match, the smaller the gap.

How to assemble a door frame correctly

Do-it-yourself door installation. step by step instructions

To achieve an impeccable result in installation, step-by-step instructions for installing interior doors with your own hands will help. Armed with patience and the necessary tools, you can start the process yourself.

Interior doors in the interior of the apartment. photos, models, color palette. Types of structures, ways of opening doors. Matching style and design. Benefits of light colors. Choice of colors and accessories.

Do-it-yourself installation of interior doors. Watch the video. installation of add-ons

Do-it-yourself installation of interior door accessories (a video tutorial is offered below) is carried out in the case when the door frame does not cover the width of the end of the wall. Previously, such a drawback was made out by means of a slope device. But it didn’t look very neat. Today it is disguised with the help of addons.

Having installed the box in the opening with our own hands, we measure the width of the section of the wall uncovered by the door jamb. This will be the width of the addition. If the door accessories you purchased are more than this size in width, it must be dissolved along.

Dark wood swing door in the bathroom

We measure the length of the vertical planks of the extension. This value will be equal to the distance from the floor to the horizontal jamb. Giving the required size to the transverse extension, you need to look to ensure that it fits clearly on the vertical additional strips.

We insert the extensions into the special grooves of the opening and fix them on the outside of the box with self-tapping screws. Holes for self-tapping screws must be drilled in advance.

Helpful advice! When purchasing door blocks and additional strips for them, make sure that they are uniform in texture and color. Be careful when choosing a door via the Internet or from a photo catalog. the shade may differ from the real one!

The video will tell you how to install the interior door yourself using addons.

Installing door handles on interior doors

Fastening and inserting accessories with your own hands: awnings, handles, locks

To attach the hinges to the door, mark 200 mm each at the top and bottom of the door leaf end. We fix with a pencil the places where the canopies begin. We apply loops between the marks so that the edge of the loop strip is aligned with the edge of the end of the canvas.

Having hooked on the loops in two places, we draw along the perimeter of the canopy with a knife. This denotes the boundaries of the loop surface. It is advisable to hold the knife several times and go a little deeper. When the contour of the loop is clearly marked, with the help of a chisel we remove the top layer of the covering under the canopy.

Do-it-yourself lock insert and do-it-yourself door hardware installation

We do this carefully so as not to damage the coating outside the perimeter of the canopy. The hinge must fit into the recess flush with the door surface. After that, having previously outlined the holes, we fasten the awnings with “native” self-tapping screws.

We attach the hinges to the box in the same way. In this case, we take into account that the distance from the top of the box to the beginning of the loop will be 3 mm more, and from the bottom. by 10 mm (these are the gaps).

We recommend watching photos and videos of installing interior doors with your own hands.

Double-leaf arched swing doors in the living room

Choosing a place to insert the handle and lock. As a rule, door handles are installed at a distance of about one meter from the bottom of the door leaf. You can insert the lock slightly higher or lower for your convenience. Having retreated from the edge the desired distance, we attach the lock with the body to the canvas. We mark where the door handles will be located. Using feathers and a drill, cut a hole slightly smaller in diameter than the handles.

On the end surface of the door, we circle the perimeter of the recess for the lock. Using feathers (feather drills), we make a recess for the lock mechanism. It should fit completely into this recess. As in the case of the hinges, with a chisel we remove the layer around the perimeter of the plate covering the lock.

Massive wooden doors in the room

Helpful advice! Hardware is an important accent in the composition of the door. Check out the photos in the catalogs, and choose models of handle locks that are suitable in style and solid in performance. Remember, a cheap thing cannot be of good quality.

When all the holes are prepared, we install the handle and the lock, fixing their position with screws.

In the same way, but already on the box, we cut out a recess for the striker and make a recess for the lock tongue. Having baited the bar, we check how the latch works when the door is closed. If the calculation is correct, we finally fasten the striker.

It is worth watching educational photos and videos on how to attach hardware to doors.

List of tools

The required minimum of tools that will be needed to install doors with your own hands:

- tape measure, pencil, construction knife;

- level, square;

- chisel, hammer;

- drills in a set, pen drills;

- angle cutter or miter box and saw;

- puncher;

- screwdriver or drill.

How to correctly install an interior door with your own hands, using power tools, photo and video will prompt.

Do-it-yourself installation of interior doors. Watch from A to Z

Experts say there can be no trifles in the repair. Every element, every detail of the interior must be executed competently, organically fitting into the overall picture. over, when it comes to installing doors. Installation of an interior door is a painstaking but completely feasible process. To help craftsmen who decide to independently install door structures, a master class. do-it-yourself installation of interior doors. It is better to watch the video with practical tips before starting the installation work.

Following the instructions, it is not at all difficult to install the interior door yourself.

At what stage of the repair are the doors in the apartment inserted??

Of course, before starting to install interior doors, their owners have many different questions: how to do it, which doors are better, how to make them more durable and more reliable? Probably one of the most basic and very first. at what stage of the repair are the doors inserted in the apartment?

In fact, there may be several options here:

- The first option is best considered when the doorway is planned to be expanded in the future. In this case, the process of installing the door should be done before finishing the room. This is done in order to ensure that during such an action as installing a door, a very large amount of dust settles on various pieces of furniture, and it, like ceilings with walls, cannot remain clean.

- The second option should be considered when the door already fits exactly the size of the doorway. In this case, it will be most correct to install the doors after the ceilings and walls have been finished. Then the new door will not be damaged during renovation work.

- And finally, the last case, the third. after gluing wallpaper, as well as processing and washing ceilings, floors and walls. This will also help keep all furniture, doors and the room as a whole clean.

Installation of interior doors

- At what stage of the repair are the doors in the apartment inserted??

- Which is better to insert and from what material?

- What tools and materials will be needed?

- Making measurements

- Preparing the opening

- How to assemble the product yourself?

- How to put the loops correctly?

- Mounting options

- DIY installation: step by step instructions

- Installation of the box

- How to insert with addons?

- Finishing

- How to check if the installation is correct?

- Beautiful interiors

Installation of interior doors is a very important process in the renovation of an apartment or a private house. It is quite simple and does not require special skills, but nevertheless it is worth recognizing that making doors strong, reliable and durable is a very important job, which should be approached as responsibly as possible.

Which is better to insert and from what material?

The second question that arises among the owners of renovated apartments before installing doors, concerns the material of manufacture and the very type of door. In fact, there is no single correct answer to this question, since something individual will suit each person and each apartment. But in this article we will try to weigh the pros and cons of each door option from each material.

The choice of such an item in an apartment or house as a door depends on several parameters:

- The first is, of course. The most expensive and “elite” option is a solid block and a door made of it, it costs about 20 thousand rubles, which is quite expensive. Of course, there are also intermediate price categories: for example, a door made of a sheet-like sheet costs in most cases 4500 rubles, which is quite acceptable.

- The second parameter also follows from the first parameter. the material of the product. About the honeycomb material, solid massif and sheet-like fabric has already been mentioned above. The first is, due to its cheapness, the most substandard, the second is very high quality, reliable and durable, while the average quality is possessed by sheet (or typesetting) canvas, MDF, chipboard, as well as glued wood. The middle price category also includes a door with metal and glass.

There are also doors classified by material, such as: glass, from eco-veneer:

- The choice of a door also depends on its design and color. Naturally, classic, very simple designs will cost less in price and fit into the vast majority of interior styles, but at the same time they will not have a special personality and will not become a decoration for a house or apartment. So, a smart option would be to invest in a beautiful, distinctive door design, as it can make the atmosphere of the home even more comfortable and pleasant. Do not forget that the combination of this product with the interior and style of the apartment is very important, and the wrong selection can spoil the appearance of the house.

- The next parameter is, of course, the construction. Naturally, for the most part, the door has a classic, standard rectangular shape and medium thickness, but it, like the shape, can vary. It is necessary to focus on the width, height and other measurements of the doorway, as well as, as in other cases, on the interior of the home. By design, there are also doors: double, sliding, sliding, double-leaf, hidden, swing, folding, single-rail, on rollers, as well as telescopic and soundproof.