Installation of rings on the piston motorcycles. Similar messages

Arrow on the piston of a two.stroke engine where to put a chainsaw

The heart of any chainsaw is an internal combustion engine that sets the working element. a sawing chain. During the operation of a garden tool, there is a need to disassemble the engine. This can be planned maintenance, cleaning from soot and soot, elimination of malfunctions or replacing nodes. If for this you will take the chainsaw to the service center, then you will not have any questions. However, with independent maintenance of a gasoline engine of a garden tool, the question often arises: how to correctly install the pistons back and where the arrow indicates them.

The heart of any chainsaw is an internal combustion engine that sets the working element. a sawing chain. During the operation of a garden tool, there is a need to disassemble the engine. This can be planned maintenance, cleaning from soot and soot, elimination of malfunctions or replacing nodes. If for this you will take the chainsaw to the service center, then you will not have any questions. However, with independent maintenance of a gasoline engine of a garden tool, the question often arises: how to correctly install the pistons back and where the arrow indicates them.

The algorithm for determining the malfunction

The reason for the refusal of the saw or the deterioration of its performance may be:

- a clogged battleship cover;

- Air sucker with a carburetor due to the destruction of the gasket or weakening of threaded fasteners;

- Mechanical sequel of removable saw equipment and other minor defects.

Before starting disassembly, you should verify the need for a more volumetric repair.

Independently assemble a new chainsaw after repair with initial quality, most likely it will not be possible. In the design of modern chainsaws, press plantings of conjugated parts are often used, which have minimal maintainability.

Even a partial analysis of a chainsaw with an improvised tool can lead to undesirable consequences. In most cases, to eliminate a malfunction, you can limit yourself to the dismantling of a separate node or system.

Progress:

First you need to make the base of the nozzle. To do this, cut a square with a side of 100 mm from a metal plate with a corner grinder. You need to mark it in such a way that there is a hole exactly in the center (at the intersection of the diagonals). To do this, from the center of the selected opening perpendicular to the short side of the plate, we measure a distance of 50 mm and outline the spitter cutting fishing line.

Cut the excess and get a square of 100 mm x 100 mm. Now it is necessary to twist the corners a little and drill the central hole for the shaft of a trimmer for the grass.

Twist the corners and drill the central hole for the shaft of a trimmer for grass

Cut the canvases for metal, measuring from each end 8 cm. We get 4 blanks with finished holes.

This workpieces must be given the shape of the knives. To do this, we plan a fishing line for the trimmer of the cut on the eye (special accuracy is not required), fasten all 4 blanks together and grind the excess.

As a result, we get the knives of the same weight and size, they can be sharpened a little on one side. Now all parts of a home.made nozzle for a trimmer for grass are prepared, you can start assembly.

We put a small puck on the screw and insert it into the corner hole. We put a knife on top, placing the sharpened side along the rotation of the shaft of the trimmer for the grass. Followed by a large puck and nut, which does not drag out, so that the knife rotates freely. We fasten the other 3 knives in the same way.

The end of the screw must be blown up so that the nut does not fly.

The nozzle is ready. It is installed by nuts to the ground and fixed in the same way as a three.lobed knife that comes with a trimmer. In a collision with a stone, the knives fold and go a little inside.

This idea was proposed by our constant author of the video Tatyana (Tula region). You can see in more detail the entire process of making such a nozzle for a trimmer for grass and find out some nuances by watching a video that she prepared.

When working with a trimmer, it is important not to forget about safety precautions using any nozzles, and especially homemade.

Where to put the piston with an arrow on 2 and 4-stroke engines | Finger displacement (disaxial) | Dnieper/Ural.

We offer to discuss this idea in the Комментарии и мнения владельцев on the publication. Share with us your thoughts, and also tell about your successful decisions.

Without accepting any of the sides of this acute (in the literal and figurative sense) discussion, let me show one of the last models of the Motokos of the German company Robert Bosch. It provides for a deviating knife and an arcuate bracket, excluding the “struck” of the knife on the objects unexpressed by the coat. I show the general view of the motorcycles and the knife itself, in two positions. General view of motorcycles

Good evening to everyone! Exactly three years as it sunk from the moment of discussing the “acute” problem for a trimmer for grass. Over the past 1000 days, a clear picture emerges: “Glory to the author is a craftsman who conducts an experiment on himself to achieve the limit of the metal from which these knives are made.

He has every right to risk his own health “. Now in stunt films you can often see Frvza. “Do not try to repeat the cinema tricks that professional stunts performed.»The very first article was supposed to end with about the same phrase:

»Dear summer residents. This is my personal experiment. If you are not confident in your locksmith forces, please not repeat it. And most importantly. I do not bear responsibility for the operation of the tool performed in the wake of my article.”And the last. Do I see errors, judging by the photographs, performing this tool.

Alas, the author of this apparatus does not even suspect how the hole should be made for the shaft.

I inform you. the distance from the closest to the edge of the plate of the opening point to the edge should be no less than the diameter of the hole itself. Students of mechanics will learn this truth no later than the second year of the institute. And what do we see here? A thin isthmus reminiscent of a narrow pinch making the peninsula from the Crimea.

This is a priori, the place that is weak in this design. it experiences the same loads as other knives, and “Perekop” there is a very thin. Where it is thin, there and I want to hope, and completely sincerely that over these three years this crossbone has not undergone loads comparable to the limit of this metal, but rather an alloy from which a holey plate is stamped.

How to change a piston with a 4t scooter?

We will describe the process gradually step by step. First of all, it is necessary to relieve plastic, which prevents us from getting to the engine.

The next step is unscrewed and remove the carburetor (it does not have to disconnect all the hoses from the carburetor, and just take it aside).

We unscrew the silencer at the place of its mount with the cylinder head and at the place of mount with the engine card (2 long bolt). Now we remove the muffler.

The next step is to take the plastic lid of the cylinder head. (2 halves connected by two screws) After that we remove the lid of the cylinder head, unscrewing 4 bolt. Unscrew the chain tension controller, which is located near the carburetor.

Next, unscrew 4 nuts of the cylinder head mount, after which we can remove the cylinder head. When we removed the chain tensioning controller, we released the chain and can easily remove it (after we removed the chain from the camshaft, we must fix it, for example, with a wire so that it does not fall into the engine card)

In this photo, the head has not yet been removed, but only the camshaft is removed and the chain is fixed. The next step remove the cylinder from the hairpins. If problems arise with this, then you can slightly approached the wooden part of the hammer from all sides of the cylinder.

Put the piston in the upper dead point position (the highest position of the piston position, at the same time we focus on the marks on the generator rotor.) It is necessary to ensure that the chain does not fly away from the leading stars, so as not to bother with its installation in the opposite position. Take a clean rag and close the hole of the engine crankcase so that various garbage does not get into it. Remove the locking rings from the piston and thereby free your finger (here you can use round.liners or small pliers.) Remove your finger with a small wooden bar (we try not to create a load on the crankshaft connector). This is where the process of removing the old CPG is completed.

Piston group of chainsaws

The dimensions of the cylinder piston group are determined primarily by the diameter of the piston made of heat.resistant aluminum alloy. Regardless of the model of the CPH of the chainsaws, it consists of a cylinder, a piston holding a finger and two latches.

In order to increase compression in the working unit and, as a result, increase in power, many manufacturers install two piston rings. The compression rings made of special cast iron, the chainsaws are tightly adjacent to the cylinder, as a result of which the combustion chamber is ensured.

Replacing the piston group in a chainsaw or trimmer

Repair of such a level should always be balanced. In such small engines operating at high speeds, the substitution of the 1st piston, which burned out or jammed, gives a long result and, as needed, you need to change the entire piston group. Therefore, you need to think about whether to use this saw further or purchase a new saw.

If this is a professional model, then such a repair should be carried out, but if it is an old household model like Husqvarna 40 and it has worked for more than ten or twelve years, it is unprofitable to repair it. Installation of rings on the piston of the lawn mower. Because its repair will cost, as well as the purchase of a new saw, let not Husqvarna, but on the Partner P350XT Chrome, worth 165 for sure. over, Husqvarna sells such saws, since Partner is its subsidiary.

But if you still decide to repair a chainsaw or a trimmer for grass, then you need original spare parts that are not cheap. With proper operation of the engine, the first repair may not occur soon and only a piston ring or ring will have to be replaced, depending on the model. But if the saw jammed, then you need to change the entire piston group. a cylinder, piston and rings.

It should be noted that the Husqvarna 136/141 chainsaws have approximately a resource of 500-600 mothers, Husqvarna 340/350-1000-1200 mothers, professional chainsaws of at least 2000-2500 mothers, provided strictly compliance with the instruction manual. In fact, you can’t rely on these figures, since the real resource can differ significantly both in large and less. But it can be approximately that semi-professional saws work 3-4 times longer than amateur, and professional up to 10 times or more.

Of course, there is nothing eternal, but it is one thing if you change the piston group, after long years of operation and it has worked out my motorcycle chassis, has fully paid for itself, and another thing is that this saw was refined for example, with one gasoline, without oil, and it jammed. Such a saw has to be repaired, since all other details are normal.

In this video I will show how to quickly change the piston on the trimmer. I will change on the trimmer.

How to put a piston correctly

The trunk shows and tells how to correctly install the piston in the cylinder on a scooter and motorcycle

Many firms specially overstate the cost of spare parts to buy new models. On chainsaws and trimmers for grass, for example, STIHL, spare parts are in a greater assortment than on Husqvarna. Therefore, choosing a certain model, find out how things are with spare parts.

Partner chainsaw area how to put a piston correctly

The cylinder-piston group Partner 350-371 (Vityaz)

The cylinder-piston group of the Vityaz office has brilliant walls of the cylinder, 2-wh ring piston with a diameter of 41 mm.Suitable for chainsaws type Partner (Partner) 350, Partner (Partner) 351, Partner (Partner) 352, Partner (Partner) 371.

Composition of the kit: cylinder. 1pc., Piston. 1pc., Finger. 1pc., Piston rings. 2pcs., Stop rings. 2pcs.

Article: 41041 Manufacturer: Vityaz (Belarusian)

Together with the cylinder-piston group, we recommend replacing: a set of gaskets of the chainsaw Partner (Partner) 350. Partner 371 chainsaw. Replacing the piston group replacement piston, chainsaw Partner 350.351. Replacement piston, chainsaw Partner 350.351. Replacement. Partner 371 chainsaw. Replacing the piston group. When replacing the Partner chainsaw cylinder, be sure to pay attention to the condition of the crankshaft oil seals, air can suck through them and chainsaw

Read how to put a nozzle on an electric screwdriver

Clutch clutch

At low speeds, elements with friction pads (1), which have a degree of freedom in a circular direction, are attracted to the center of the shaft with springs (2) and do not transmit rotation to the drum (3), connected to the asterisk of the driving chain. Where he is in a chainsaw? In the tank there is a bacon’s bacon valve.

Where is the cabin in the chainsaw. Stroke, repairing your own sapun in. When the speed of the chainsaw motor achieves values in which the centrifugal force exceeds the force of the springs, the friction segments are pressed to the inner surface of the drum and begin to twist it. As a result, the leading star begins to spin, setting the saw chain.

As you can see in the photo, the asterisk is behind the clutch.

Other chainsaws, an asterisk can be on the outside of the clutch.

The main advantage of the couplings of this type will be that when jaming the circuit, the clutch of the chainsaw slopes, not the grinder of the engine and without causing a breakdown of devices that transmit movement from the motor to the circuit.

The algorithm for determining the malfunction

The reason for the refusal of the saw or the deterioration of its performance may be:

- a clogged battleship cover;

- Air sucker with a carburetor due to the destruction of the gasket or weakening of threaded fasteners;

- Mechanical sequel of removable saw equipment and other minor defects.

Before starting disassembly, you should verify the need for a more volumetric repair.

Independently assemble a new chainsaw after repair with initial quality, most likely it will not be possible. In the design of modern chainsaws, press plantings of conjugated parts are often used, which have minimal maintainability.

Piston Ring Gap. the importance of

Even a partial analysis of a chainsaw with an improvised tool can lead to undesirable consequences. In most cases, to eliminate a malfunction, you can limit yourself to the dismantling of a separate node or system.

When you need a piston replacement

The reasons why the piston must be replaced, as well as completely piston, there may be quite a lot, but all of them can be divided into natural and emerging as a result of improper operation. Natural, this wear is formed due to the prolonged operation of the Stihl 180 chainsaw. There are much more artificial ones, for example:

overheating of the engine and the appearance of thermal bullying;

- entering the cylinder of a foreign body and the appearance of mechanical bullying;

- the bummer of the piston ring as a result of exceeding the maximum engine speed;

- the wreck of the piston skirt due to excess revolutions;

- the use of poor.quality fuel, as a result of which the piston group of the chainsaws wears out from the side of the intake channel in the cylinder;

- Operation of a stihl chainsaw with contaminated fuel filter, as a result of which the percentage of oil in the fuel mixture is reduced;

Diagnosis of CPG is necessary if the STIHL MS 180 has sharply lost power or does not start, while the tool starter does not turn. If the starter is turning, but the saw does not start, while there is a spark and fuel enters the cylinder properly, it is necessary to measure the compression in the engine.

9.5. 11 atm. It is considered a normal indicator in which the StiHL chainsaw is regularly launched and gives out maximum power, if the compression is lower, there is a possibility that there are bunches on the cylinder.piston group, or its wear is large enough. In any case, with reduced compression, for further diagnosis, it is necessary to completely disassemble the saw.

Determine the presence of bully on the piston, as well as the wreck of the piston ring, if you remove the muffler and conduct a visual inspection of the visible part of the piston, while the rings for elasticity can be checked by pressing them with a small screwdriver. A small walk will be observed on the working rings, there will be no defective or clamped piston ring.

How to split the piston rings in a motorcycle

How much is the driver’s certificate issued

Will certainly be necessary to substitute oil in the engine, t.to. Part of the product through the rings seeps into the crankcase and mixed with butter, which changes its characteristics and will negatively affect rubber seals and seals. The spark plugs usually change. Glothing the rings in the movement “Dynamic” cleaning of the motor. burning of the breeding in motion. This is the simplest in execution, alas, two or more effective method by playing snowballs with soot. The essence of the method is the use of special additives in fuel for the battle of snowballs with a soil in the combustion chamber. Here, so far, our red.bidder edit has no analogues in the economic market of auto chemistry. Cleaning the engine using our additive is a simple, not laborious and cheap method. Its implementation does not require special abilities, tools and mass of time to remove and install candles or nozzles. In the time of introduction of the product you will spend no more than a minute.

How to split the piston rings on the engine?

It is enough for a period of 5-10 seconds to crank the motor by the starter, not forgetting to set neutral speed earlier.

access is prohibited

In a hot state, the piston from the duralumin alloy expands and presses thin rings into the grooves filled with very thick and viscous, resembling bitumen, “glue”.

Glotting piston rings with folk methods burning at high speed gives real results, if, this, the state of the motor allows for this kind of shift.

From time to time, in order to increase the efficiency of the process, special dissolving additives are added to the fuel, to a thin end, a mixture of alcohol and acetone, approximately 3 liters per 30 fuel, are poured into the full tank, and a mixture of alcohol and acetone are poured.

Glotting piston rings with kerosene, as a world, the method of exciting rings with kerosene is currently used by the owners of old engines, which has no desire to waste the means to “newfangled little things”.

Bearing the engine

For this purpose, you can make a car, set the highest gear to the checkpoint and twist the wheel of the leading axis. If necessary, there is an option clockwise to turn the crankshaft with a belt.

How and how to split the piston rings on the car engine

Cleaning product (“flushing oil allowing accounting (software) with the effect of the rings of rings”) is added to the engine oil for 100-200 km before it is replaced, and until the oil change, the engine must be operated in gentle mode, avoiding operation at the largest speeds at the highest speed.

The composition of the “soft” binger must erode the carbon fiber from the lower oil.cut rings (which, in most cases, are subject to “resting” or coke) and piston grooves. Typically, flushing oil is used for this purpose, 5- As it is also called 7-minute.

Trivial disadvantages of ordinary “soft” splitting: using them does not go out to clean the combustion chamber or the motor valve of the motion.

For the most part, these are classic flushing waters of the oil concrete system, with the addition of cleaning components for removing soil.

How to install piston rings

Of course, this way is not used in clinical cases of motor pollution, as prevention, using it with each oil substitution.

Trimmer for Echo 22 grass 2 piston cleaning from Nagar.

Even more information about repairing and choosing a tool here www.Looktool.Ru come in always ready for everyone.

- The “core” mixture of equal parts of kerosene, acetone, benzene is prepared in another Toluol is prepared;

- The mixture is actively beaten in a tightly closed bottle;

- The engine warms up to a temperature of not higher than 40 ° C, if necessary, cool;

- Using a syringe into who is refueling 40-50 ml of the consistency, the candle hole is locked with prepared wooden traffic jams.

After 8-10 hours, plugs are twisted and replaced by a rag. Having twisted several times by the starter, we clean the cylinders, the liquid is thrown through the openings of the candles into the rag. Advice! Despite the relatively low corroding ability of water for shift, before the procedure, it is better to drain the oil from the crankcase into a separate container.

After removing the split composition, 100-150 ml of old oil is poured into the pallet and re-drained.

How to split piston rings

The daily implementation of the car, provided that the town is very harsh tests and loads even for the most modern engines.

Invariable switching of the movement modes Start-stop, operation on low-grade combustible and other consumables, the process of oil substitution, performed not according to the regulations-all of the above leads to the need to urgently engage in the separation of the motor.

In the field of trading in the chemistry, special means for excavation are found piston rings

It is necessary to consider what kind of substances it is, how to use them, how they are effective.

The prerequisites for the shift of the parts of the combustion chamber that appears on the oil.shooting rings and in the cylinders, is not actually formed. There are several basic circumstances leading to its education and the need for urgent work to split.

Glothing of the piston engine rings.

Glotting piston rings without disassembling the engine. this procedure is often resorted to car owners, setting a goal to make the properties of the motor and extend the deadline for its use until it is renovated until half the repair. What is the shocking of the motor and how it is done, why it is necessary in its conduct, what type of shift should be preferred and how it is performed more well. try to figure it out. What is the shocking of the motor before answering this common hearing question, you should figure out that there are nooks, what are the main prerequisites for its appearance.

According to Wikipedia Oil Cox (this appears in the piston

The spring may interfere

My first attempt to adjust the gas mowing carburetor did not give anything, since the spring of the fuel mixture adjustment propeller prevented. The factory spring turned out to be too thick in a compressed state and did not make it possible to reduce the supply of fuel to the required level. I had to choose another spring and continue the adjustment after its replacement.

The adjusting screw for feeding the fuel mixture with the spring

In the photo above the factory spring, below the adjusting screw with a selected spring. I am writing about this, because I am not sure that this is an isolated case, and someone else may face the same situation.

Trammer device for grass

The float carburetor consists of an aluminum case with a hole (diffuser). Air injection is carried out through its passage hole, and gasoline is pulled through the fuel channels along with the air flow. This is the basis of the device. fuel chamber. The nozzle installed on top, the pump and the mixture adjustment system provide not only its saturation, but also the uniform supply.

Note! The float carburetor has been used for decades, and the main problems of all types are similar. The principle of functioning of the device depends on the quality of the mixture, and the setting is aimed at ensuring it.

Causes of malfunctions of the piston chainsaw

There are many reasons for the failure of the CPG, which are customary to divide into two main categories: natural wear and artificial malfunctions. The first type of malfunctions, as can be seen from the name, belongs to the physical wear of the rubbing parts of the piston group. The second category is more extensive and means:

- strong overheating of the internal combustion engine and, as a result, the appearance of thermal bully on the piston surface;

- bummer of the lower part of the piston (skirt) due to the duration of the chainsaw at maximum speed;

- getting into the combustion chamber of foreign particles and the occurrence of mechanical damage to CPH;

- the bummer of the compression (piston) ring due to severe wear or exceeding the permissible speed of the saw;

- The inconsistency of the recommended portions of gasoline and oil in the preparation of the fuel mixture.

Experts do not recommend disassembling the CPG for no reason. However, if the tool has significantly lost power, a metallic ringing in the internal combustion engine arose or when the starter jerks of the crankshaft does not turn, the piston chainsaw should be diagnosed. First of all, to identify the motor malfunctions, it is necessary to measure the compression in the cylinder. With a significant deviation from the values recommended by the manufacturer, it can be safely argued that there are scratches, production, and darling on the surface of the cylinder or piston. It is the decline in compression that is the basis for the complete disassembly and repair of the piston group of the chainsaw.

For operational diagnosis of CPG for a breakdown of a compression ring of a chainsaw or bully in the cylinder, professionals advise removing the muffler and evaluate their condition through the final window.

The algorithm for determining the malfunction

The reason for the refusal of the saw or the deterioration of its performance may be:

- a clogged battleship cover;

- Air sucker with a carburetor due to the destruction of the gasket or weakening of threaded fasteners;

- Mechanical sequel of removable saw equipment and other minor defects.

Before starting disassembly, you should verify the need for a more volumetric repair.

Independently assemble a new chainsaw after repair with initial quality, most likely it will not be possible. In the design of modern chainsaws, press plantings of conjugated parts are often used, which have minimal maintainability.

Even a partial analysis of a chainsaw with an improvised tool can lead to undesirable consequences. In most cases, to eliminate a malfunction, you can limit yourself to the dismantling of a separate node or system.

Diagnosis of pistons and ways to eliminate malfunctions

Knock when operating the engine, frequent overheating, power loss, increased smoke, increase in fuel consumption, sharp drop in oil level and other similar phenomena are an occasion for a thorough inspection of the motorcycle, in particular, the diagnosis of its cylinder-piston group.

It is almost impossible to measure the engine power in domestic conditions, so many note the fall of this indicator according to indirect signs: reducing the maximum speed of the motorcycle or reducing compression in the cylinder. The second method of assessing power is preferable, because speed reduction can be caused by the lawsuing of the exhaust system or impaired ignition adjustment.

If the drop in power has really occurred, there is no need for urgent replacement of the piston or boring cylinders. If problems with the cylinder-piston group arose for the first time (usually this happens after 6-7 thousand.km run), experienced owners of motorcycles change only piston rings. With repeated malfunctions, if the replacement of the rings no longer helps, new pistons are installed. As a rule, until this moment, the motorcycle manages to drive up to 40 thousand. km.

You can evaluate the degree of wear of the CPG only by dismantling it. This operation requires accuracy. It is especially necessary to monitor the safety of the locking ring. so as not to drop it into a crooked camera, close it with a rag. When nothing the piston group, it is not recommended to knock out a finger with a hammer, as there is a risk of bending the connecting rod. It is better to use a special puller.

In addition to the visual examination of the piston, it is necessary to measure the size of the clearance between him and the cylinder. It should not exceed 0.3-0.4 mm, otherwise the piston requires a replacement.

Assessing the condition of the piston, be sure to pay attention to the rings and grooves. If they have a lot of carbon deposits, rings can lose mobility. To avoid the so.called “occurrence”, pollution must be removed with the help of a sharp object (for example, Shaber)

You should not use the nadfili rings and grooves, hacksaw cloths and similar tools, as they can damage the piston, and this, in turn, will lead to a gases leak and the drop in engine compression

To avoid the so.called “occurrence”, pollution must be removed with the help of a sharp object (for example, Shaber). You should not use the nadfili rings and grooves, hacksaw cloths and similar tools, as they can damage the piston, and this, in turn, will lead to a gases leak and the drop in engine compression.

Two.stroke motorcycles have cylinders with three windows: inlet, graduation and purge. Stop pins fix the rings in the grooves and orient them on the area of the windows without windows.

If the pin falls out, the ring when the piston moves begins to rotate and at some point is in the zone of the intake or exhaust window of the cylinder. Since the ring is open, it seeks to get involved, its ends are straightened and cut into the window when entering the window. The fragments are in the muffler, which is extremely undesirable.

As the next diagnostic step, consider the hole for the piston finger. Stop rings are installed in its grooves on each side of the piston. Depending on the type of motorcycles, they can have a different structure (with or without “antennae”, however, in any case, they should be drowned in grooves at least half of the diameter.

How to install a piston on a scooter. Installation of rings on the piston of a scooter

Deterioration of traction, falling maximum speed, blue smoke from the muffler and weak dynamics of a scooter-a sure sign of worn piston rings, or worn-out cylinder-piston group. Most often we wear out exactly. t.to. The diameter of the piston group of scooters is small, the working area of the rings is very small and therefore they do not go for so long.

So, if you are faced with the need to replace the piston rings on a scooter, and in addition to the main problem, that they need to be changed, there is another way to put the rings on the piston correctly. You can’t just take any ring and put in any of the “grooves” on the piston. You need to understand which ring is the upper compression, which is the lower compression, as well as how to put an oilfield ring correctly.

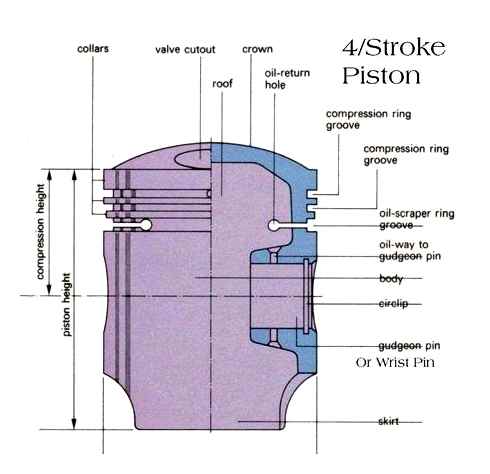

Installation of piston rings on a 4-stroke Chinese scooter. In the photo below it is noted where what kind of piston ring.

How did you manage to notice that the set of piston rings consists of two compression rings (upper and lower), as well as the oilfold, which consists of two ordinary (thin) rings and central expander.

The second compression ring has a dark black

color, as well as unique (beveled) geometry.

For different manufacturers, the color of the rings may vary, for example, CMR. the lower compression ring has a redhead

The following scheme shows the correct location of the rings.

On the compression rings you can see the inscriptions, they can be different depending on the company of the rings, but the essence of them is one. installing the rings should be carried out upwards

! T.e. inscriptions should be directed to the cylinder head.

On the oil.welded (two thin) rings of the inscription, as a rule, you can put them with any side, the main thing is that the so.called expander is installed between them, as shown below the photo.

The process of installing the rings on we will lower, t.to. there is nothing complicated there

Only caution should be observed during the establishment of rings in the grooves, t.to. The rings are made of high.strength cast iron and a strong exposure to stretching can lead to breakdown of the rings

If you did everything right, then in the end the rings on the piston should be installed, as shown in the next photo.

On this, all the features of the installation of piston rings on a four.stroke scores are voiced, now you can put the piston in the cylinder, lubricating the rings and cylinder in oil.

Installation of piston rings on a 2-stroke scooter. So, let’s say you purchased a new piston with rings and want to install it on a scooter. Only two compression rings are included with a piston on a two.stroke scooter.

In some cases, depending on the scooter model, there may still be the so.called expander or as it is also called. the expander can be also in the kit. Such an expander is installed for the second (lower) ring.

Before you stand to install the rings on the piston, you need to understand where the upper compression ring is, and where is the lower. T.to. The rings are very different in geometry, the wrong installation of one of the rings will lead to its breakdown

Please note that the upper ring has an internal bevel, before installation, carefully inspect each ring. Below is the installation circuit, which clearly shows where which ring should stand, and also where the expander is installed, if any in the kit is present

Dismantling and cleaner cleaning

If the engine at low speeds works perfectly, and starts to stall at large ones, the reason can lie in the frantic sparkle, clogged with combustion products.

- remove the muffler;

- to disassemble (there are also non.devastated models);

- clean from soot using detergents;

- dry with a hairdryer;

- Install in place.

Dry cleaning is unacceptable, since there are carcinogens in the Nagar, whose inhalation is dangerous to health. After removing the muffler, the exhaust hole is closed with a clean rag.

Merps in the work of the chainsaws signal the possible clogging of the muffler

In order not to clog the muffler, it is necessary to monitor the composition of the fuel mixture. The amount of oil should not exceed the norm recommended by the manufacturer. Poor oil quality also negatively affects engine operation.