Installing the blade on a hacksaw for metal

What is a hacksaw

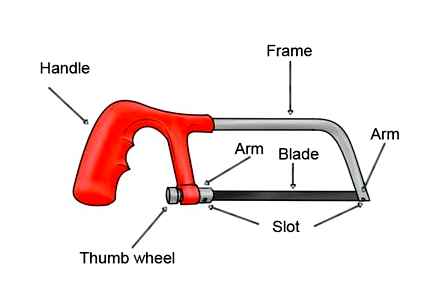

Hacksaw for metal. It is a metal frame saw mainly used for cutting plastic and metal pipes and other small household materials. The bow’s U-shaped frame holds a thin, wide blade between the lugs (clips) and a plastic or wooden handle at one end. Some models use an adjustable frame to accommodate 8-, 10-, or 12-inch blades as needed. Depending on the cut desired, metal blades will have 14, 18, 24 or 32 teeth per inch, with denser teeth being best suited for cutting smaller objects.

How to use a hacksaw safely

To install the blade, turn the adjuster on the handle or frame until there is slack and the holes on each end of the blade fit into the sleeves. Make sure the prongs are facing away from the handle.

For safe use of the hacksaw, place the material to be cut tightly in a vise (if possible). Place the center teeth of the saw on the line to be cut and press down on the saw with a short stroke to start the cut. Continue cutting, making sure the end of the object to be cut is held and will not crack due to unsupported weight. For safety, keep hands and other objects away from sharp teeth.

Tighten the wing nut

When the blade is in place, turn the wing nut clockwise to force the metal bar backward, pulling the blade tightly into the frame.

How to use power saw blades correctly

- It is important to pay the same attention to power saw blades as you would any other tool.

- Keep the machine in good technical condition. It is especially necessary to check:

- the lifting arm and its functions are OK, the oil pump

- lifting arm clean and free of air bubbles.

How to choose a blade for a hacksaw

- A type of manual hacksaw for metal, more precisely, the distance between the mounting holes. It is better if it is variable, then a hacksaw blade of any standard size is suitable for work.

- Tensile strength of the cut metal. If the tool is supposed to be used to separate soft, ductile metals. copper, aluminum, etc., then it is advisable to have a hacksaw blade with the lowest hardness. H6VF steel can be adopted as a material; imported canvases have the HCS designation on the lateral plane. High-speed steel blades are suitable for cutting harder metals (corresponding import marking. HSS).

- The thickness of the cut metal and the quality of the separation surface. Foreign practice recommends using the PPI parameter as a selection criterion. the number of tooth vertices per inch of blade length. So, for thin metals, where a very smooth cut surface is required, the PPI24 value is considered correct. If for the user the main factor of productivity than quality, then PPI should be read 6180 times

Working position when cutting with a hacksaw

a) set the height of the vise for growth. the right hand with a hacksaw should have an angle of 90 ° at the elbow. See the picture above.

b) stand in front of the vise freely and steadily, half-turn in relation to the vise jaws or to the axis of the object being cut

c) turn the body to the left of the vice at an angle of 45 °

d) put the left leg forward a little, approximately along the mowing line of the object to be cut and rest the body on it

e) the right leg should be turned in relation to the left at an angle of 60-70 °, while the distance between the heels should be 200-300 mm

Hacksaw blade for metal. How to choose and install?

The blade for a hacksaw for metal is one of the most short-lived elements from the entire range of consumables for tools. Of course, a lot depends on the technology of working with metal and the skills of using a hacksaw, but first of all you need to be able to make the right choice of the blade. Today, we will talk about the choice and types, and also learn how to easily change the hacksaw blade.

How to install a blade on a hacksaw for metal

The design of the tool in question allows for quick replacement of the hacksaw blade. It should be borne in mind that if a mistake is made, the product in question will not serve for a long period. How to install a blade in a hacksaw for metal is a very common question, since this tool is found in almost all home workshops. The main recommendations include the following:

- The instruction largely depends on the fastening system used in a particular case.

- The threaded clamp is widespread, in which the hacksaw blade is installed and stretched. A sharp change in the applied load becomes the reason why you have to periodically check the degree of tension.

- There are lever-type tools. In this case, the installation is greatly simplified, since it is enough to pull the lever and install the hacksaw blade for cutting metal, and then tighten it in the opposite direction.

When considering how to correctly insert the blade into a hacksaw for metal, it should be borne in mind that after proper installation, it creates a slight ringing during operation and may vibrate slightly. However, at the time of sawing, the product should not change its position, as this may damage the fastening holes.

Number of teeth

The determining factor is how many teeth there are per inch. The following depends on it:

- Performance depends on the indicator. With an increase in the number of cutting edges, the task is significantly more complicated, the chips become finer.

- A large number allows you to get a high quality cut. This is achieved by reducing the amount of chips produced.

In addition, an increase in quantity becomes a reason for an increase in the cost of the product.

Tooth pitch

The pitch of the teeth may also differ. This indicator of the hacksaw blade determines:

- Performance.

- Possible cut quality.

- Application area.

Fine pitch allows you to get a high-quality cut when working with various alloys.

How to find out the password for your WI-FI in Windows XP:

This completes the WI-FI connection setup on a laptop with Windows XP. Now, to connect the device to the network, enter the “View available networks” menu again, select the required name and click the “Connect” button.

If everything is done, then after connection the status “Connected” will appear, and in the lower right corner on the taskbar you will see a corresponding message, which indicates that your laptop is connected to the network.

If you cannot find the power button of the adapter on the laptop or it is broken or missing, then there is an option to enable it using Device Manager through Windows XP. To do this, right-click on the “My Computer” shortcut and enter “Properties”. Next, select the “Device Manager” item and look for your adapter in the list of devices that you need to enable.

Connection setup

First, let’s go over the theory a little. This will allow you to understand what Wi-Fi is and how to connect to it in a given situation and how to set up the system. It is one of the most advanced wireless technologies that allows you to create home networks without wiring. The main advantage of this technology is that the transmission speed is not inferior to the cable connection. At the same time, the range of one access point reaches 100 meters with line of sight and about 10 meters in buildings.

An access point is a base station to which all devices equipped with a WI-FI adapter are connected. As a rule, in the overwhelming majority of cases, a router is used as such a station.

And before creating your network, it should be configured. It is to it that laptops and other devices are connected. Up to 200 users can be connected to one router, however, in this case, the data exchange rate will greatly decrease, since it is distributed equally among all users.

For example, if a router supports a maximum speed of about 100 Mbit / s and at the same time connect 10 users, then the speed for each of them will be 10 Mbit / s. It’s not hard to imagine what will happen if you connect 100 or more users.

In some cases, you need to additionally configure the connection on a laptop in Windows XP. If you have followed the instructions, and there is still no access to the network, then you should check the IP address. To do this, in a networked environment, click on the wireless connection with the right mouse button and select “Properties”.

Next, in the window that appears, select “Internet Protocol TCPIP” and click “Properties”. After that, a window will appear in which you need to set a mark on the “Use the following IP address” section and enter the following values:

- IP address: 192.168.0.5. Please note that the numbers 192.168.0 are always the same, but the last digit “5” can be anything in the range from 1 to 150, depending on the settings and capabilities of the router;

- Subnet mask: 255.255.255.0;

- Default gateway: 192.168.1.1.

Then he clicks “Ok”, and close all windows.

Now you know how to set up WI-FI on a laptop with Windows XP. However, there are non-standard situations that can cause additional difficulties. In this case, the approach to solving the problem should be individual, since the standard setting will not help here.

As you can see from the above, connecting a Wi-Fi network on a laptop with Windows XP is quite simple and within the power of ordinary users with no special knowledge. At the same time, setting up the connection does not take much time and effort. However, it is worth noting that the Windows XP operating system is already outdated, today the newer versions are Windows 7 and 8. At the same time, the latter are much easier to configure.

Tooth setting

Removal of chips from the cutting zone is carried out due to a certain setting of the cutting edge. As noted earlier, according to this criterion, several options are distinguished:

Today, many tool manufacturers specialize in the production of hacksaw blades. At the same time, domestic products are much cheaper, foreign ones are more expensive, but at the same time they have higher performance characteristics. Several products are required for long-term operation, as they can wear out at a high rate.

Dewalt 5 in 1 Hacksaw Review (and how to use it) DWHT20547L

Choosing a blade for a hacksaw

When choosing a hacksaw for metal, special attention should be paid to the toothed blade, because the smallest flaws can negatively affect the quality of work in the future. The web must be free from cracks and corrosion and must also be smooth. When checking, you need to bend the canvas and release it. it must instantly restore its original form.

It should be noted that canvases exist at 32, 24, 18 teeth per inch. The more teeth there are on the blade, the faster and better the sawing of the material and vice versa. It is desirable that a hacksaw for metal has the ability to install the blade at an angle of 90 degrees in order to cut bulky sheet materials. If this is not possible, then the cutting depth is limited by the height of the hacksaw itself. There are models in which the blade mounts are made at an angle of 45 degrees.

The blade can be made of various materials, and you need to choose it based on what kind of alloys you will be sawing. It is better to choose bimetal or hardened canvas. The black blade, as a rule, is of very poor quality and is enough for only a few movements of the hacksaw, then the teeth begin to crumble, potholes appear, and it is impossible to work with such a blade anymore.

The hardened blade looks like a nickel-plated stainless steel with dark teeth. It is the dark color that speaks of their hardening. Bimetallic blades for hacksaws for metal are painted in some color (yellow, red, etc.) or even two-color. Such canvases will last much longer than budget black ones. After that, it remains only to make sure that the length of the blade corresponds to the length of the hacksaw, this is indicated both on the tool and on the blade.

Mowing line curved cut

Hacksaw for metal. quite a practical tool, since it allows you to cut along almost any curved line. the cut line must first be marked with something. with a marker, pencil, scratch with a nail so that it is noticeable during work. To cut the material in an arc, without crossing the translational movements of the tool, it is necessary to align it perpendicular to the end of the part and gradually smoothly turn the arc so that the blade moves along the intended mowing line.

It is recommended to turn the blade smoothly and gently, otherwise it may break. The turns for the hacksaw blade are extreme. If you need to make a sharp turn, for example, 90 degrees, you should “stamp in place”, continue to saw and slowly turn the arc of the tool, periodically stepping back, using the side of the material that is external to the part to turn the hacksaw blade.

To cut the inner corner, you first need to drill a straight line with a thin drill, which has a length slightly longer than the width of the blade, then thread the blade into such a groove and then cut further.

Universal saw. hacksaws for all occasions

Even an ordinary, at first glance, hacksaw can cause confusion for the average consumer, he will find many different tools on the shelves! To simplify the choice, we list three main types of tools, into which, depending on the purpose, they are divided:

- Hacksaws for metal. a narrow saw with fine teeth. It has a characteristic recognizable appearance, basically it is a C-shaped or U-shaped frame, between the ends of which a canvas is attached tightly. Older hacksaw models often have a handle that runs parallel to the blade, modern products are equipped with a much more ergonomic pistol grip.

- – a classic carpentry tool used for sawing wooden building materials, as well as plywood sheets. As a rule, carpentry hacksaws have a wide beveled working part, on the edge of which there are cutting teeth. The teeth are set alternately left and right to facilitate cutting. At the same time, straight teeth in some models help to remove chips from the mowing line of the cut.

- A concrete hacksaw looks like a carpentry saw, with the difference that the first tool has larger teeth. Quite often, they have soldered carbide metals, thanks to which this tool can be used to saw foam blocks and sand concrete structures.

The quality of the tool is determined by the following indicators:

- Blade length. depending on the size of the workpiece, the appropriate tool is also selected. On average, the length of the working part ranges from 300-700 mm.

- Tooth pitch. this measure determines the thickness and hardness of the materials that the tool is able to handle. For example, a pitch of 3.5 mm is suitable for sawing wood materials from soft wood, 5 mm hacksaws work with hard wood.

Tooth pitch

The pitch of the teeth may also differ. This indicator of the hacksaw blade determines:

- Performance.

- Possible cut quality.

- Application area.

Fine pitch allows you to get a high-quality cut when working with various alloys.

Types of hacksaw blades and their design

Do not forget that the production of a working hacksaw blade is carried out in accordance with the established standards in GOST 53411-2009. The specified information in this regulatory and technical documentation defines the allocation of two main groups: for machine and manual cutting. It should be borne in mind that a hacksaw blade for metal is purchased extremely rarely, since such equipment is used extremely rarely. For a hand hacksaw, the following versions are produced:

- Single hacksaw blade for metal with a distance between fasteners 250 mm. In this case, the total length is 265 mm. This version is suitable for a tool that is used when there is no need for high performance.

- Single versions with a distance of 300 mm between two fasteners. The total length is 315 mm.

- For greater productivity, a double hacksaw blade is installed. The length of this version, like the previous one.

How to change a blade on a hacksaw

When choosing, attention is also paid to the width indicator, which for a single version is 0.63 mm, for a double 0.8 mm. The height of the tooth in the first case is 12.5 mm, in the second 20 mm.

The value and pitch of the location is regulated, since such an indicator determines many operational characteristics.

In the manufacture of such a product, a variety of alloys can be used, on which the main operational characteristics largely depend. The most widespread are the following alloys:

- X6VF.

- High speed alloys, for example, P5M5 and P12.

A hacksaw blade with tungsten carbide spraying has recently been quite common, as it is characterized by increased wear resistance. It should be borne in mind that spraying can have a wide variety of colors, there are blue versions on sale, ordinary steel is dark gray.

The quality is also influenced by the uniformity of the distribution. A good hacksaw blade for metal has a deviation of no more than 45% for a length of 10 mm. Also, a visual inspection allows you to determine how equal in height the individual teeth are. Accurate results can be obtained using a micrometer or other measuring instrument with high accuracy.

Metal hacksaw blade. knowledge driven choice!

When buying a canvas, pay attention, first of all, to its appearance. even the smallest flaws can affect its work. Avoid canvases with traces of corrosion, cracks, roughness. The ideal blade should be smooth, clean, with even teeth, and when folded, instantly restore its original shape. The more teeth per inch, the faster you can cut the part. So, there are canvases with 18 and 24 teeth per inch, most often, these are bought for the home, but 32 teeth per inch is the lot of professionals.

Avoid buying black products. these are enough for several passes, then the crumbling teeth make the work impossible. Although hardened products are not flexible, they are much more convenient to work with. In appearance, they look like a nickel-plated strip of stainless steel with dark teeth. it is by the color of the teeth that it is easiest to guess about their hardening. Bimetallic blades are usually painted in some colors, and although they are more expensive, they will last much longer. After choosing the right material, make sure that the length of the product and the length of the hacksaw match.

How to change a hacksaw blade

Tooth shape of blades for metal

Attention is also paid to the shape of the tooth. This indicator depends on:

- Installation direction of the metal plate.

- Wear during operation.

- Tool performance.

In most cases, the classic form is used, since it is considered a universal option.