Is it possible to cut the LED strip with a remote control

Sticking materials

The LED strip has a standard self-adhesive backing. But for long-term fixation on rough surfaces, for example, wooden, it is unsuitable. The list of materials that can be used to glue the LED strip is as follows: aluminum profile, tape for led tape, aluminum tape, quick-setting glue. They improve the properties and increase the fastening efficiency.

Common mistakes and methods of their elimination

The most important mistake is gluing a powerful tape without a profile directly to the surface of the ceiling, wall, cabinet

The service life of the LED strip will increase if you do not make such mistakes:

- Bonding lighting on the surface of ceilings, walls, furniture without a profile. Such a fastening does not provide cooling of the tape, overheating, it will quickly detach, the LEDs will fail.

- Bonding bare LED strips. Installing the tape on a damaged base, through which the LED board protrudes, will cause a short circuit when connected. To avoid this, a layer of insulation is applied to the damaged areas.

- Using a stapler for fixing on wood and plasterboard surfaces. Attaching the backlight requires shooting the staples many times. If only one inaccuracy is allowed, the LED board will be damaged and the strip will be unusable.

- Mounting on a plastic profile from a cable duct. This type of profile is not intended for mounting LEDs: it does not provide heat dissipation, which leads to overheating of the structure.

- Hot glue application. When the LEDs work, it will heat up, preventing heat dissipation and emitting a harmful odor.

Stick the LED strip only with specially designed materials.

How and on what to glue the LED strip. glue or tape

LED strip is a modern type of lighting fixture. It is used in interior decoration of premises and for exterior decoration of building facades. Correct installation and fastening is a prerequisite for its reliable operation.

- Surface preparation

- Sticking materials

- Scotch tape for LED strip

- Aluminum profile

- Glue

- Aluminum tape

- Other mounts

- 220V tape sticker

- Rules for sticking on an uneven surface

- Where to hide the LED strip

- Common mistakes and methods of their elimination

- What to do if the LED strip comes off

Surface preparation

LED strip is used to create lighting in the living room, bedroom, bathroom, hallway, kitchen. Due to its flexibility and adhesive base, it attaches to wood, plasterboard, metal, plastic, ceramic surfaces. Their shape can be rectilinear, curved, spherical.

During installation, the following rules should be followed:

- Do not allow mechanical impact on the board.

- You can cut the tape at specially marked places.

- When the LEDs work, heat is generated, so the canvas must be cooled.

- Connectors are used to connect sections of the LED strip.

- The tape is connected to the network through a power supply unit of appropriate power, which provides a voltage of 12 or 24 V.

LED strips are divided into 2 types according to the degree of moisture protection

The adhesive base of the LED strip is 3M acrylic tape. For its strong adhesion to the surface, the following conditions must be met:

- The surface should be flat, without protrusions, sharp edges, bumps.

- The base is preliminarily prepared: cleaned, dedusted, degreased with isopropyl alcohol or a napkin with an adhesion activator. White spirit or acetone can be used to degrease metal and plastic substrates. Painted surfaces are treated with a vinegar solution.

- Marking is applied to the base, which allows you to fix the canvas along the required trajectory.

- The air temperature in the room is above 18 degrees. At room temperature, the adhesive tape sets as much as possible during the day. At temperatures above 60 degrees. within an hour.

The LED strip can be glued to wood. The wooden base must be smooth, painted or varnished. On an unprepared surface, it does not stick and quickly peels off.

Scotch tape for LED strip

The commercially available tapes are a printed circuit board with LEDs attached to double-sided tape. Its free side, used for mounting, is protected by a smooth transport foil. High-quality models have 3M markings on it.

Acrylic tape 3M for various applications

How to glue the LED strip:

- Marking is applied to a previously prepared surface.

- Soldered to the backlight contacts or using a connector connect wires, power supply; install a switch.

- Using a sharp object, separate the beginning of the tape from the protective film, release a 15-20 cm long section.

- Apply the LED strip to the surface and press firmly.

- Gradually freeing sections of the tape from the film, completely stick the tape along the marked trajectory. When making connections in the corners, they do not bend it, but use corner connectors or solder.

- Install the power supply in a convenient place protected from moisture.

If, when removing the protective film, the conductive paths are exposed, it is necessary to apply a substrate made of electrical tape to this place. Otherwise, there will be a short circuit when connecting.

The tape should be precisely applied to the markings. If it is incorrectly positioned, the adhesive tape loses its properties after disconnecting. Reattaching it firmly will be problematic.

Other mounts

If the led strip is hidden or the appearance does not matter, you can use to fix it:

- disposable nylon ties;

- plastic clamps.

Do not attach the LED strip with staples with a construction stapler.

There are two ways to stick the LED strip: on tape and on glue. The scotch tape comes off over time. The strength of this mounting is increased by using super glue. Optimal fixing of the lighting with an aluminum profile.

Aluminum profile

Optimal mounting for LED lighting. aluminum profiles. They are used for extended powerful models SMD 2835 and SMD 5630, 5730 and for the popular ones based on SMD 5050 LEDs. For fastening structures with a power of more than 14 W, their use is mandatory.

Profiles are overhead, mortise, corner. LED lighting is glued into the profile, and it is mounted on the selected surface.

Using aluminum profile for LED strip

Aluminum profile properties:

- the self-adhesive surface of the tape ideally adheres to a flat and smooth base;

- easily and firmly attached to the mounting plane;

- heat generated during the operation of LEDs is removed through the aluminum surface;

- matt diffuser, which covers the front part of the profile, gives a pleasant appearance and makes the lighting softer.

An inexpensive alternative to the aluminum profile is the plastic cable duct without cover. Its disadvantage, which leads to premature loss of LED brightness, is poor heat dissipation during operation. Therefore, its use is not justified.

The correct adhesive for the LED strip ensures a quick-setting bond. Adhesives cope with this task:

- based on cyanoacrylate, called superglue, for example “Super Moment”;

- based on rubber or silicone, for example, liquid nails “Titanium” or “Moment Installation”.

Recommendations for fixing with glue:

- Superglue is applied pointwise every 50. 100 mm. So the tape is securely fixed and, if necessary, it is easier to dismantle it than when applying glue in a continuous layer.

- The strip with LEDs is applied with the base to the surface on which the adhesive is applied and pressed firmly.

The adhesive joint is used on vertical, inclined porous surfaces. It is resistant to temperature and humidity. The tape adheres to a properly processed surface in 20-60 seconds. They are completely glued together in no more than 2 hours. You can glue the LED strip to metal, wood, plastic, wallpaper, glass.

Cutting LED Strips

Hot melt glue is not recommended. It adheres well, but due to its low heat-dissipating properties, overheating of the emitting crystals is possible and their premature failure. Under the influence of elevated temperatures, it melts and gives off an unpleasant odor.

How to connect a colored LED strip with a remote control

There is not only a standard white LED strip, but also a multi-color RGB strip. If you want to add bright colors to your interior decoration, periodically changing colors and shades, then how to connect a colored LED strip with a remote control.

To begin with, we will reveal the advantages and disadvantages of connecting RGB tape, so that it is easier for you to make a choice in its favor and think over all the installation details.

What we need to connect RGB tape

The photo shows all the components of the chain for the proper operation of the diode tape. Let’s figure out what each of them is for and what function they have.

- RGB tape, which is important to choose carefully. This is the first element whose characteristics you need to decide in advance. It all depends on where and in what conditions it will be placed. When buying, consider moisture resistance and protection from external influences.

- The controller is an additional link that is necessary for the color diodes to work. Connecting the controller to RGB LED strip allows for color selection and adjustment function. With it, you can create your own highlight shade. RGB capital letters stand for:

R. red, translated from English red, G. green (green), B. blue (blue).

Using the remote control to control the controller remotely, you can also adjust the brightness of the glow, set a fixed hue, turn on and off the LED strip.

To select a controller, you need to calculate the required power. This can be easily done by applying the following formula:

Power consumption of one meter multiplied by the length of the LED strip. The final digital indicator will be the controller power (W).

- The transformer (power supply) is another important part for the operation of the entire circuit. It should be chosen individually, having determined the conditions of the room and correctly calculated the required power for the smooth operation of the LED backlight.

Prepare a place for mounting the transformer in advance, where air circulates freely to avoid overheating of the device. However, do not place it near flammable objects. Calculate the required power.

Important! It should be 20-30% higher than the total power of all LED strips. This power reserve is necessary in order to supply a stable current to the entire structure without interruptions and voltage surges.

If you avoid this rule, you run the risk of LEDs failing quickly or not performing well enough. How to perform power calculations, as well as even more practical advice on choosing a transformer, you can find here.

The amplifier is used at will and when a separate case requires it. It should be used for a diode strip, the length of which is more than 5 m, if the whole structure is powered from one transformer.

It is especially recommended to use an RGB amplifier when connecting several LED segments in series. Thus, it realizes the supply of current directly from the transformer to each individual component.

The amplifier has a beneficial effect on the operation of the power supply and controller. It reduces the load by providing a stable power supply without voltage surges.

Also, if you decide to create a complex lighting structure from RGB tape, an amplifier will greatly help you with this.

- Remote control. The only note regarding it is to check for the presence of batteries inside.

- The aluminum profile can be used as desired. Most LED strips are already protected from external factors with a silicone coating, so there is no special need for a profile. But if your LED strip belongs to models with high power consumption, then such a profile is necessary. It will act as a cooling radiator.

How to connect RGB tape through a controller

How to connect RGB tape to the controller should be disassembled separately, as there are some features.

The photo below shows a diagram of connecting the RSL tape to the controller, connected using four wires: 3 of them are colored and 1 connecting for supplying current from the power supply. The controller must be strictly installed between the transformer and the diode section.

- The first thing to do. on one side where there are only two wires “” and “-“, connect the controller to the transformer, observing the polarity of the wires.

- Further, on the other hand, you need to connect a piece of LED strip with a controller, how to do this, see the details in the picture above. Connect four wires, 3 of them color-coded, and attach the fourth wire to the remaining space (it is usually white or black).

In fact, if you connect correctly, the process is not difficult at all. If the first time you did not succeed in making the connection correctly, then do not worry. it will not shock you. Just swap the wires.

Advantages and disadvantages of RGB tape

If you are already convinced that multicolor lighting is not enough for your interior, then it’s time to talk about the pros and cons of connecting an RGB LED strip.

The advantages are:

- Ease of installation.

- The service life is much longer compared to conventional incandescent bulbs. It can reach about 30-50 thousand hours of uninterrupted operation.

- Ease of use, compactness.

- The ability to implement any, even the most unusual design solutions due to the flexibility and use of lighting effects: flickering, changing colors and shades, brightness control, etc.

- Safety achieved through low voltage consumption.

The disadvantages of connecting an RSL tape include:

- Low moisture resistance, but it can be significantly increased if you purchase an LED strip with a silicone shell.

- Lack of protection against mechanical damage.

- Reduced color rendering quality compared to white LED, since the LEDs used have a relatively low color rendering index.

The characteristics are impressive, the disadvantages can be adjusted, adapting to your conditions and requirements. For example, if it is important for you that the LEDs are well protected from external factors, then use an aluminum profile for mounting. If the room in which the LED strip is supposed to be installed has high humidity, then select it, taking into account the moisture resistance of the lighting device. In general, think over all the details before buying.

Basic schemes for connecting RGB tape

Once you’ve figured out how to connect the controller to the RGB tape, your next step is to connect all the remaining parts into a common circuit. Consider several connection schemes when it is required to connect one or more segments, and also in which case an amplifier is needed.

- A simple option for installing all the elements together. This circuit will be useful for those who are going to connect only one diode strip, no more than 5 meters long. With this method, it is enough to use one power supply and an RGB controller. If the required power of the unit is calculated correctly, then the amplifier is not needed. Below is a visual connection diagram.

- A method for connecting two LED segments, each not more than 5 m long.This method of connecting an RGB strip is also simple, but requires some conditions for its implementation:

- the power of the power supply and the controller must be sufficient for servicing several diode sections with current, for which the total length is not more than 10 m.

- additional wires are required. As shown in the diagram below, this can be accomplished by connecting two wires to the corresponding outputs of the controller, which go to two different tapes, connecting them in parallel to each other. That is, two wires are connected to one contact of the controller at once.

How effective this method is is anyone’s guess. After all, the power of one power supply unit may not be enough for a long time of servicing two sections of tapes, and if you made mistakes in the calculations, then the design may not work at all.

There are more reliable ways to connect two pieces of diode strips. There are two main methods of connecting the entire circuit, over 5 m in length: using an additional power supply and using an amplifier.

- Consider the diagram of connecting the RSL tape to two power supplies, which is presented below. This chain is much better suited for servicing longer sections of belts, since the power is distributed evenly to both sections in the required amount. The disadvantage of this method lies in the fact that the transformer is more expensive than the amplifier.

- The next connection method is to add a new element. an amplifier. When choosing it, you do not need to calculate the power of the entire tape, but only a separate segment to which it is connected. It is more convenient to use, as the transformer looks more bulky and heavy. In addition, not every controller can withstand this voltage. This is where the use of RGB signal amplifiers comes to the rescue. As a result, both segments will work synchronously. To make it clearer, take a look at the diagram.

- A connection method that allows you to create a more complex design of LEDs of any length and complexity. This will require several power supplies and amplifiers, in accordance with the number of LED strips. Whether an additional transformer needs to be added depends on the lighting power. Below is a diagram of how you can gradually increase the length of the backlight, adding one amplifier every 5 meters.

Here is another possible connection diagram for complex structures, similar to the previous ones. How to do it, see below.

Here is such a variety of connection variations, and this is not the limit, then it all depends on your imagination. The main thing is to find a place to place all this equipment.

Basic connection errors

We advise you to read these little tips when mounting an LED strip to avoid the most common mistakes. This will greatly simplify all stages of working with a decorative lighting fixture.

- Violation of the sequence in connecting RGB tape. If you do not follow the required sequence, then the LED strip will not shine, and may even burn out altogether. The above diagrams clearly explain how to properly connect all the elements.

- Incorrect sequential connection of tape segments longer than 5 m.It is important when connecting such long tapes to supplement the circuit with an amplifier or an additional power supply so that there is enough power for the entire length of the diode tape, and the load is evenly distributed.

- The power of the transformer must be greater than the total power of all LED segments. Otherwise, the structure may not last long.

- The connection between several pieces of LED strips can be done only in two possible ways: using special connectors or by soldering. Do not under any circumstances try to connect them by twisting.

- High power LED strips should be mounted in an aluminum profile for heat dissipation to avoid overheating and fire. The profile can also protect against external factors.

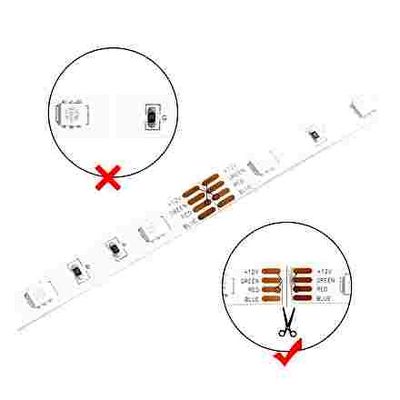

- The diode tape should be cut in specially designed places where a dotted line with scissors is drawn, otherwise it will lose its performance.

- Sometimes there is confusion with the wires of the controller, how to correctly connect it to the RGB LED strip, see the pictures and recommendations above.

It is better to learn from the mistakes of other people and initially set the LED lighting correctly, applying all the rules and tips.

I hope that of all the listed methods of installing RGB tape, you have found the most suitable one for yourself. Follow all of the above rules to create high-quality lighting and for safe use in the future.

Coated with silicone

Silicone coated strips may not be marked on the front surface. Installation diagram of LED chips and tracks is located on the back side.

Silicone can be applied to one or both sides of the board. Since the design of the LED strip is the same as the standard one, after removing the silicone, the blocks can be cut off with a knife (scissors can damage the contact pads).

- outline the place of the cut;

- remove silicone;

- cut off the required number of blocks;

- prepare the ends for installing the connector or soldering.

After connecting the segments, it is necessary to isolate the areas of the contact pads.

How to properly cut a diode tape with waterproofing

To shorten the LED board with waterproofing, the silicone must be peeled off with a knife. This must be done carefully so as not to damage diodes and other circuit elements.

How to connect pieces of LED strip

LED strips with various designs are increasingly used in lighting and backlighting systems. In addition to the problem of how to cut off, self-assembly requires a solution to the connection problem. The most reliable way is soldering, but not everyone has a soldering iron, not everyone knows how to handle it. Most are looking for a more affordable and simpler method. Most commonly used 2, 4 and 5 pin connectors.

Important! Models for 12 and 24 V strips are not suitable for 220 V products.

Advantages of using connectors (compared to soldering):

- low cost;

- easy installation;

- eliminating the need to buy a soldering iron, solder and flux.

The disadvantages include:

- the inability to use if necessary in high current for LED chips;

- instability to oxidation;

- use for the manufacture of non-heat-resistant plastic.

The main criterion for choosing connecting elements is the width of the flexible board. For example, SMD 5050 models will not fit SMD 3528 products.

According to the connection method, the connectors are divided into:

- hold-down

- with a latch;

- piercing.

When connecting, slide the plate into the clamping connector and insert the strip until it stops. Contact is made after the plate is pushed into place. The advantages of such a connector are small dimensions in height and width. The disadvantage is the inability to see the density and reliability of the contact.

Models with a latch solve this problem, although they also have disadvantages:

- connector pads do not always fit snugly enough to the board contacts;

- at high power, the contacts melt;

- for products with high current cannot be used.

The most advanced piercing connectors, on one side of which there are contacts for tape (for connecting to power), on the other for wires. Models available for open and insulated boards. When connecting the segments, the end of the segment is inserted into the connector; there is a cover or transparent plastic for pressing. The pins pierce the board to form a secure contact. It is impossible to pull out the strip, the state of the contacts is visible through the cover.

Important! Regardless of the type of connector, the board contacts must be cleaned to a shine. When connecting the segments, it is important not to mix up the polarity.

Common mistakes when using connectors:

- varnish on contact pads;

- bent connector leg;

- wrong bandwidth;

- tape is not pushed in all the way.

If the product is waterproofed, you need to remove the silicone above the contact pads and the tape from the back.

Such a tape enters the connector hard, since the silicone on the sides and glue on the reverse side interfere.

The connector cannot be closed if the contact pad is too close to the chips. In such a situation, individual blocks from the tape can be cut off not along the dotted mowing line, but leaving 2 contacts. But one segment will have to be thrown away.

How to properly cut an LED strip: regular, unmarked, with waterproofing

The LED board is made of pieces that can be used as independent light sources. When connecting, it is important to know how to cut the LED strip if the entire product does not fit the installation site. For this, there are most often marks on the board, the length of the segments depends on the model. You can cut the source to the required length with scissors or a sharp knife.

Conventional 12V LED strip

The 12 V LED strip consists of blocks on which 3 diodes are installed (in 24 V products. 6 diodes). This means that they can be cut into very short pieces. The product is cut strictly along the dotted lines with sharp scissors.

You can cut off from the board from SMD 335 and DIP into pieces consisting of 3 diodes.

RGB color tape

The device of RGB and RGBW LED boards differs little from the design of a single-color LED strip. The difference lies in the number of paths that carry current (there are four or five of them on the multicolor strip). On the contact pads, the markings are “R”, “G”, “B” and “-” (on the RGBW strip “R”, “G”, “B”, “W” and “-”). You can cut a piece from such a strip in the same way as from a monochrome one. along the dotted lines.

When connecting to a power source and connecting stubs, it is important to connect each channel to a matching color pad. If this condition is violated, the light source will fail due to the difference in the power parameters of each color.

How to cut correctly

Each Led strip has many short blocks on which the number of chips and resistors is set, depending on the model. LEDs are transparent or white, current limiters are black. There is most often a mark between the blocks (dashed line and the image of scissors), along which the strip can be cut.

Attention! If there are no marks on the front side, inspect the wrong side.

On a thin strip, it is more convenient to make a cut with sharp scissors. An exception is boards installed in a silicone tube. You need to cut off between the two contact pads. When offset, it is difficult to solder wires to connect to other lengths or power supply.

On the LED strip, every 50 cm there are joints in which the individual blocks are overlapped. It is not advisable to cut the tape in these places (the contact pads are too small). If it is nevertheless necessary to cut off, the scissors must be replaced with a soldering iron (unsolder the joint).

LED strip 220 volts

LED strips for 220 volts are made from SMD 3528, 2835, 3014, 5050, 5630 LEDs and are of several types, differing in the chip installation scheme. The main difference from 220 V products is the cutting rate of 0.5, 1 or 2 meters. The number of diodes in one segment varies between 30-120 pieces. You can cut a piece from such a tape with scissors along the dotted lines.

VLUU L100, M100 / Samsung L100, M100

24V LED strip

As you know, 12 V LED strips have a limitation in the applied length of 5 m, which is associated with large losses in the power circuit. For longer tapes, you need to use recharge wires or go another way, use 24V LED strips. In this article, we will talk about them.

12V LED strip

Most often, for decoration and lighting, an LED strip with a supply voltage of 12V is used. The most important information about these ribbons can be found in this article.

How to Cut and Connect LED Light Strips.

How to connect LED strips together

It is very often necessary to assemble a longer strip from separate pieces of LED strip, sometimes literally one section of LEDs is not enough to get the desired strip length. Tapes can be cut or joined. With cutting, everything is clear, you can use ordinary scissors, but how to connect the LED strip is not immediately clear.

There are several options here, you can connect the LED strips to each other by soldering and without soldering, using a special plastic connector. The connector allows you to make the connection as quickly as possible, and with the help of soldering, such a connection will be as reliable as possible.

When connecting LED strips to each other by soldering, you can connect using wires even strips of different widths with different LEDs, but for the same voltage. Basically, pieces of the same LED strip are connected by soldering, then they can be joined end-to-end at the cut, soldering the contact pads together.

To securely connect the solders of two pieces of tapes without wires, you need to clean the contact pads if the tape is covered with a protective layer of silicone, and peel off the adhesive base from the bottom of one of the tapes at the soldering point. Then you need to fold these tapes overlapping and carefully solder with a low power soldering iron. After that, the place of the adhesion will need to be insulated, for example, with a heat shrink tube.

LED strip connectors

The connector for the LED strip is a product of a special design, in which there are contacts for connecting to the current-carrying contacts of the LED strip. Connecting LED strips using connectors is much easier and much faster, since for this you just need to take the connector and place the LED strip inside it. But this method is more financially costly.

It should be borne in mind that in this way it will be possible to connect only tapes of the same overall dimensions. Connectors are selected for a specific tape width and tape type, for example, for a single-color tape with two contacts and a width of 8 mm, or for an RGB tape with four contacts and a width of 10 mm.

Types of connectors for LED strips by tape fixation type:

With sliding clamps. This is the most compact LED strip connector option. To connect the LED strip to the connector, it is necessary to pull out the latch, which is usually black, and install the LED strip in the slot, then push the latch back, fixing the LED strip with such a cut. By this principle, the cables in the laptop are connected to the motherboard. The disadvantage of a connector with sliding clamps is considered to be the impossibility of visual control of the quality of the connection of the LED strip and the connector contacts.

With lateral pressure latches. The most common type of connectors used to quickly connect LED strips. To connect individual pieces of LED strips with it, you need to snap off the protective cover and install the LED strip in the grooves. In this case, the copper contact pads of the LED strip should be under the clamping terminals of the connector. The LED strip is additionally fixed when the lid is closed with a latch, due to the presence of special pins in it. This type of connector has one significant drawback. It cannot carry large currents and is highly susceptible to corrosion. Oxidized contacts significantly impair conductivity and, under heavy loads, can cause trouble in the form of a fire.

Piercing connectors. These connectors are considered the most reliable of all, but they are also the most expensive. Their contacts are made in the form of pointed teeth, and pierce through the LED strip in the area of the contact pads. It takes a lot of effort to install the piercing connectors, so it is best to use pliers to close the lid. At the moment of closing, the prongs pierce the tape at the locations of the copper conductive tracks and an electrical connection is formed.

Connectors for LED strips with sliding clips and with pressure side latches require preliminary preparation of the LED strips themselves. The contacts must first be cleaned if they have a protective coating, and cleaned of oxides for a better connection. Over time, these contacts oxidize. Piercing connectors do not require preliminary preparation, since, due to their design, their teeth cut through all protective coatings and oxides, eventually coming into contact with copper tracks.

Corner inserts for connecting LED strips at an angle

LED strips are flexible in design, but unfortunately, you cannot bend them arbitrarily, their bending radius is limited. To connect LED strips at an angle, corner inserts are used, which, in combination with connectors for LED strips, allow you to connect LED strips at the required angle. Such inserts can be L-shaped, T-shaped, cruciform and with wires, for connection at any arbitrary angle. With their help, you can turn into reality a wide variety of luminous designs, almost any fantasy of the designer.

To maintain the operability of all segments of the LED strip, it is necessary to cut it only in the places of the strip provided for this. If you cut anywhere in the strip between the LEDs, then the LEDs from the cut segment of the LED strip will not work.

It is possible to connect segments of LED strips into one long strip only with the same supply voltage, and monochrome only with monochrome, RGB with RGB.

How to cut or join an LED strip

How can you cut an LED strip

LED strips are flexible enough to follow the contours of various products and are often used for decorative lighting by winding them around or gluing them to the surface. They also illuminate shop windows, shelves in wardrobes, beds in bedrooms, ceilings. In such places, using an LED strip in multiples of 1m is quite problematic, so the question often arises, is it possible to cut an LED strip, and how to cut it correctly.

You can cut the LED strip with ordinary clerical scissors, but there are several nuances that you need to know about. If you cut the LED strip exactly to the required length, then some of the LEDs at the end of the strip may not glow, because their power circuit will be broken, and they will simply remain unconnected.

If you look closely at the LED strip, then most people will see the hint and guess for themselves how to cut the LED strip correctly. This hint lies in the scissors icon applied in the place where you can cut the LED strip.

Such an icon is indicated at the junction of the individual sections of the LED strip, which are an independent complete section of the circuit that can work independently when power is applied to it. In a 12V LED strip, such a section consists of three LEDs with three current-limiting resistors. If these three LEDs are cut off, they will work fine when connected to a 12V power supply.

If there is no such icon on the tape, then you need to look for the junction of the individual sections of the tape. As a rule, at this place on both sides of the sections there are contact pads for soldering wires or just noticeable long copper pads.

The length of a separate section of an LED strip with three LEDs, like a 12V strip, depends on the type of LEDs installed and on their density. For example, with a density of 240 LEDs per meter, the length of one section, when installing cheap small LEDs, will be 15 mm. And in an LED strip with 5050 LEDs and a density of their placement of 30 pieces per meter, the length of a section of three LEDs will be 100 mm.

You can even cut belts with a waterproof silicone coating, just as simply making a cut with scissors along the specified mowing line. But in such tapes, you will have to additionally cut off the section of the silicone coating that covers the tape contacts, unless, of course, this tape needs to be connected to another tape, or to a power source.

RGB LED strips

Monochrome colored LED strips cannot always cope with the task at hand. If you need a much larger variety of colors, use an RGB LED strip. Read more about the possibilities of RGB linen in the article below.

How to cut different ribbons?

You can cut an LED strip only according to specific marks that are set (or not set) by a certain manufacturer. Not all of them mark the tape accordingly. Sometimes you can determine the location of the cut only by carefully examining the topology of a kind of printed circuit board. a thin layer of textolite applied to a rubber or plastic substrate along with current-carrying tracks.

For a 12-volt tape, the topology is arranged in such a way that the LEDs are connected in series. 3 in each group. This group, together with the series connection of the current-limiting resistor, forms a cluster or sector operating from 12 volts. It would be more correct to connect not 3, but 4 LEDs, since each of them is powered by 3 volts. If such an LED is connected to 4 volts, it will overheat. and after a few minutes it will burn out. To avoid this, the manufacturer includes a 20-30 ohm current limiting resistor. Accordingly, from 12-13.8 V, the entire assembly heats up noticeably to 60 degrees or more. And since it is more profitable for the manufacturer to turn on the ballast resistor instead of the 4th LED. while calculating so that after several hundred hours of continuous glow the LEDs still degrade and fail due to significant heating. the assembly should not experience an overload. It would be wiser not to exceed the supply voltage above 12 volts by choosing the appropriate AC adapter or stabilized power supply.

If we are talking about a higher voltage, then the power supply should be limited by current by installing lowering voltage conventional diodes, or by including an additional resistor, rheostat, or lengthening the wires.

Cutting of the assembly is carried out at the scissor-shaped mark where the contacts “red”, “blue”, “green” and “mass” pass. It is not hard to guess that the three “colored” contacts are positive for each of the colored semiconductor crystals. In this case, the current-carrying paths go further, bypassing the LEDs and resistors soldered by the manufacturer. In LEDs that are not tricolor, or work as monochrome (red, yellow, green or blue separately), there are only contacts (and tracks) “plus” and “minus”. 12 volt LED strips, for example, for red (used as a brake light and tail lights), contain 6 LEDs connected in series: the maximum supply voltage for each of them, which is not recommended to be exceeded, is 2.2, and not 2.7-3.3 volts. For 24 V tapes, the number of LEDs per sector is doubled.

If there is no mark on the front side, the cut line may end up on the back. A thin strip is cut with scissors. You need to cut exactly in the middle between the contacts: in case of accidental capture on either side, soldering the power wires will be an extremely difficult action.

Color RGB

RGB color strips have four lanes. common, red, green, and blue. A more advanced version. RGBW (white is added as the fourth LED). contains 5 tracks in the ribbon topology (the 5th is the positive pin for the white LED). These assemblies are most commonly rated for 5 volts and have current limiting resistors for each color group. One cluster of RGBW tape contains 4 LEDs and 4 resistors (up to several tens of ohms). There are RGB strips in which two red, green and blue LEDs are connected in parallel. in series with a limiting resistor in groups. If we are talking about 12 volts, then the number of LEDs triples. six red, green and blue. In 24-volt tapes, each color group is longer. it already contains 12 LEDs.

They are also cut according to marks (cutting lines) and consist of clusters corresponding to their number.

Trimming tape with waterproofing

There are no cut marks on the face of the print ribbon. But they can be found on the flip side. To cut at the point through which the cutting line passes, you must first remove the silicone. They are cut off with a clerical knife. Having soldered the wires, the soldering contact points must be re-insulated.

Is it possible to cut LED strip and how to do it?

- How to cut different ribbons?

- 12V

- 220 volt

- Color RGB

- Trimming tape with waterproofing

- Helpful hints

Not always a solid LED strip. for example, on a reel of 5 meters. turns out to be needed in a specific place. If we are talking, for example, about a car interior, then only one segment of 3-4 LEDs can be used in each backlighting place.

220 volt

In the case of a 220 volt tape, cutting off clusters is much more difficult. These are mainly the series of products SMD-3528/2835/3014/5050/5630 and several others, similar in power and operating current. They are cut by footage. 0.5, 1, 2 m. The number of LEDs is 30-120. As white, double LEDs are often used. 2 to 3 volts, connected in series in one light crystal. Accordingly, for uninterrupted operation, they require 30 pieces per segment. It is easy to calculate that 30 double LEDs (60 single. this is the conversion) are designed for a voltage of 180 volts. To make them glow as brightly as possible (3.3 volts on each LED), a voltage of about 200 volts is required. However, here, too, manufacturers interested in the constant sale of LEDs make a deliberate mistake, including only 30 (and not 35-40, as it should be) double LEDs in the cluster. A network diode bridge with a current-limiting resistor and a CHIP fuse can be installed as a rectifier on each cluster. Each section plugs directly into the outlet.

Needless to say, LEDs are forced to overheat. Some craftsmen rework the tapes, soldering additional groups of LEDs into it, or reworking the driver. As a result, the supply voltage on each light element (and the brightness of the glow) decreases slightly, which prolongs the life of the tape.

Tapes for 220 volts are also cut according to special marks. It is important not to cut the driver (or pins for the external driver). Their multiplicity remains at the level of 30-120 LEDs. dividing mowing lines are indicated by the presence of a current-limiting assembly at the beginning of each composite cluster.

Helpful hints

Anywhere the LED strip contains conductive tracks. Using an ultra-sharp blade (razor, scalpel) with a certain skill, the craftsmen clean the polymer layer to metal (copper), even when the tape is not cut quite correctly, but the LEDs and other parts are not damaged. It is better not to bring the situation to this. if there are marks, cut along them. If the scissors (or knife) damaged the parts (components) themselves, then the failed segment will most likely not be able to be restored.

Even when only one of the three LEDs is damaged, extreme care and accuracy will be required so as not to damage the rest.

If one of the three LEDs in the 12-volt cluster is damaged, then the current limiting resistor will need to be replaced as well. Otherwise, the remaining LEDs, hitting too high a voltage, immediately burn out (the glow “subsides”).

A sharp bend of some belts, even at the cut point, can lead to their breaking. Even when the LEDs are located on opposite sides of the point of a sharp bend, the tracks themselves can break. due to the fragility of the textolite or other composite material, of which the tape is made. It is forbidden to weave ribbons into knots, weave patterns from them. in addition to gaining the risk of being torn, the ribbon may lose part of the useful light flux due to overlapping of several LEDs with its own opaque substrate for light.