Is it possible to cut the underfloor heating mat

Is it possible to shorten the wire of the underfloor heating sensor?

The answer is yes, you can. This will not affect the operation of the system.

If the warm floor is laid close to the wall on which the regulator is located, there is an excess of the sensor wire. It can be trimmed.

In this case, the contacts should be processed with tin using a soldering iron or crimped with copper tips.

Cutting excess wire does not affect the accuracy of the thermostat.

Is it possible to shorten the wire of the underfloor heating sensor?

Is it possible to shorten the temperature sensor for underfloor heating?

To adjust the operating temperature of warm floors, thermostats are used.

Thermostats are mounted on the walls, 30-150 cm from the floor level. A temperature sensor is drawn from the thermostat; it must be placed at least 30 cm in the heated area. The standard length of the sensors is 2.8-3.0 meters. Their installation is carried out first of all, since the sensor must be located under the heating elements, whether it is a cable in a screed, a heating mat or an infrared film.

The sensor can fail over time, so it is important to provide for the possibility of its replacement. For this, installation is carried out in a corrugated tube, which is placed in a screed under a warm floor.

It is very important to check at the initial stage of installation that it is possible to freely place it in the corrugation from the mounting box and freely get it out of it. At the same time, the corrugation is laid with smooth bends, this requires laying a deeper and wider groove, but it is the most correct and working option.

Is it possible to extend the wire of the underfloor heating sensor?

The answer is yes, you can. But there are features, which we will talk about below.

If the underfloor heating is located in the central part of the room, the length of the sensor wire may not be enough. Therefore, the wire is extended with an additional cable, no more than 5 meters long and with a cross section of 0.5-1 mm. The junction is soldered and insulated.

In such cases, instead of a corrugated tube, it is better to give preference to a thin water pipe, since it has a smooth inner surface and facilitates the process of placing the sensor in it.

When installing infrared films, some people try to lay two sensors without a groove and protective corrugation, one working, and the second spare. This method is for the amateur experimenter, since both the first and second sensors can fail. According to the technology, it is necessary to use the mortgage corrugation.

You can buy a floor sensor by following the link

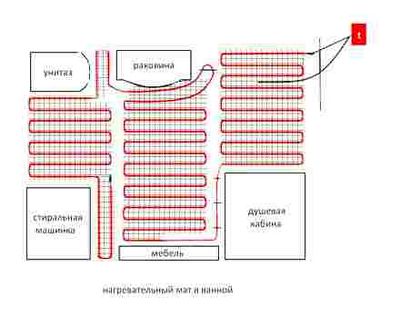

Heating mat

Where is it better to use heating single-core and double-core mats

Warm floor made of ready-made heating sections, mats, is much more convenient to install. The heating mat is a conventional heating cable fixed to a fiberglass mesh, the back of which has adhesive tapes to securely fix it to the base of the floor. Heating mats are designed for installation in tile adhesive, screed of insignificant thickness. This is a great alternative to other systems “Warm floor” if it is not possible to significantly raise the floor level.

Features of heating mats

- ease of styling. The roll of the heater is simply rolled around the perimeter of the room, and is fixed immovably due to the adhesive layer of the backing;

- insignificant thickness. The thermomat takes only a few millimeters and can be completely hidden in tile glue;

- reliability. Conductive elements are hidden under multi-layer insulation made of non-combustible materials;

- fast warm-up. Choosing the right power will help you achieve the required floor temperature in the room in a matter of seconds.

- heating mats often have expensive PTFE or Teflon insulation

Typically, the width of the heating mat is 50 cm, the power is 150-160 W m2, the maximum set is up to 15 m2. Most of them are about 4mm thick, power cable 2.5m

How to cut the heating mats:

Heating mats modifications

The type of mats depends on the type of heating cable fixed on the base:

- single-core. Both ends of the circuit leave the make-up point: the other end of the heater must be returned to the thermostat to loop the heating system. The need to return must be taken into account at the stage of drawing up a scheme for a warm floor, because the mats cannot be overlapped, it is only allowed to cut the mesh between the cable turns, preserving the integrity of the heater;

- two-core. The cable contains a combined heating and feeding element. The loop is closed by means of a plug at the end of the cable. The heating mat can be installed in any order without having to return to the connection point.

FAQ: Can I Cut Underfloor Heating Mats? Allbrite UK Ltd

The mats are supplied in rolls (standard width 50 cm). The length is calculated taking into account the heating area (excluding the installation sites of large-sized interior objects).

Criterias of choice

- Cost. The price of heating mats based on a single-core conductor is lower than that of two-core analogs.

- Electromagnetic radiation level. It is lower in two-core modifications, recommended for bedrooms, nurseries. rooms with increased safety requirements.

- Laying step. Heating mats contain a cable already fixed. It is laid according to the “snake” pattern with a pitch of turns from 5 cm. The more heat is required from the warm floor, the larger the square of the heated room, the less the step should be selected for laying.

- Appointment. Having decided before buying what exactly the heating mat is for, you can rationalize the purchase: to prevent frost on the porch or steps, insulate loggias and balconies, an inexpensive heater based on a single-core resistive cable is sufficient for intensive use (as the main source of heat) in a residential area it is better to prefer two-core.

- Brand. In Ukraine, heating mats are offered by the world’s leading FENIX (Czech Republic), HEMSTEDT (Germany), DEVI (Denmark), NEXANS (Norway), Profi Therm (Poland) and domestic manufacturers Gray Hot, Woks. They create thermomat on the basis of cables of different designs, conductor diameter and sheath protection degree, complete with additional components (for example, a corrugated tube for a cold wire or a temperature sensor). Each manufacturer tries to incorporate special features into their systems. many modifications of cables can easily withstand temporary immersion in water (moisture penetration on the mat is not critical).

Heating mat for tiles DEVI Denmark

Fully ready-to-install heating mats are supplied in a width of 50 cm in rolls of the required length. Equipped with a single-core / double-core shielded cable.

Complex structure of the cable element:

- outer PVC sheath;

- internal high-temperature insulation PVDF. polyvinylidene fluoride with acrylic particles;

- screen. copper or aluminum foil. This is an additional protective braid and a barrier against electromagnetic radiation.

The temperature range of the cable of conductive cores with a cross-section of 2.5-4 mm increased to 117 ° С.

The mat of standard thickness can be successfully used in semi-open, unheated rooms. Super-thin models are more specific in use and are used only for indoor premises, on top of them you can immediately lay laminate, linoleum or tiles without the need to form a screed.

Devi heating cable in the photo is shown under the 8th position

Devi heating cable sectional left

Contact Information

Belarus, Ukraine, Moldova, Armenia, Russia, Georgia, Kazakhstan, Israel.

Basic installation methods for underfloor heating mats

The heating mat is an advanced cable type heating system for underfloor heating. The device is quite efficient and very popular. Installation of equipment is not particularly difficult, but it requires compliance with certain rules. What are heating mats made of and can you install them yourself??

Electric twin-core mats

Equipment of this type consists of a heating core and a current-carrying wire. One side of the cable is closed with a sleeve, and the other is intended for connection to a regulating device.

This system design greatly simplifies the installation of underfloor heating equipment. At the same time, there is a significant suppression of the electromagnetic field, which makes it possible to use two-core mats for almost all types of premises.

Two core heating mat

Advantages and disadvantages

Heating mats belong to efficient cable heating devices. Their widespread use is justified by a considerable number of advantages:

- simplicity of installation work, which allows you to do it yourself;

- low price;

- the ability to automatically adjust the temperature regime;

- long term operational. from fifteen years;

- low power consumption;

- ensuring fast and uniform heating of the floor covering.

Small thickness of mats minimizes floor height increase.

There are practically no disadvantages of using heating mats with their correct selection and installation. The negative sides include a difficult preparatory stage and the need to wait a whole month to make the first launch of the system.

Device and principle of operation

The construction of the heating mat is a cable fixed in a fiberglass mesh. The thickness of one mat is no more than 3 millimeters, and the standard width of the reinforced base is 50 centimeters.

When laying, the mats can be cut into the required strips, which simplifies their installation and makes it possible to conveniently place any floor surface.

The operating principle of the mats is quite simple. The device is connected to the electrical network. The current flows through the conductors that make up the inside of the cable. As a result, the flooring heats up.

Two-core

Installation of mats with a two-core wire can be carried out on a rough base screed. The main condition for laying is a flat floor surface, free of debris and dust.

There are two options for installing dual core heating mats.

Floor mesh installation:

- cut the mat according to a certain pattern, while maintaining the integrity of the cable;

- apply a few drops of glue mixture to fix the system to the base;

- distribute the reinforced mesh with the cable up;

- cover the mats with a thin adhesive solution.

After the final hardening of the applied layer of glue, you can arrange the final flooring.

The laid mats are covered with a thin adhesive solution

Laying mesh up:

- cut the reinforced coating according to the planned plan;

- after cutting the mat, roll it up;

- evenly distribute the adhesive mixture on the rough base, the thickness of which should be three millimeters;

- spread the heating mats with a cable to the floor and press into the wet glue;

- cover the entire surface with a six millimeter thick adhesive solution.

In this case, it takes a longer time for the glue to dry completely. Only then can you start laying the topcoat.

After the glue has hardened, tiles are laid on the floor.

Single-core

Before laying the heating device, the layout of the mats on the base of the floor is outlined. In the future, it is recommended to keep it in order to avoid problems when drilling or punching the topcoat is necessary. When drawing up a plan, it is imperative that it is taken into account that the mats should be finished near the beginning of their installation.

The installation process for single-core thermomat consists of the following steps:

- Select a location near existing electrical wiring to install the thermostat. Install the tube and junction box.

- Perform a cement-sand floor screed. After the solution has completely solidified, spread the heat-insulating material over the entire area of an even and clean base.

- Cut the mesh with the cable fixed in it into parts according to the pre-planned laying scheme. In this case, only the reinforcing material is separated, and the cable must remain completely intact.

- It is necessary to spread the mats taking into account the distance from the batteries. 20 centimeters, and the walls. at least 10 centimeters.

- After laying, the cold wire is connected to the power supply.

- Make a recess in the heat-insulating material for the temperature sensor. Before installation, the device must be placed in a special corrugated tube.

- All power wires of the mats, as well as the sensor, must be connected to the thermostat. After connection, carry out a resistance test.

The mesh with the cable fixed in it is cut into panels of the required size

- fill the entire floor surface with the heating system installed on it with tile adhesive;

- when buying such a solution, its thermal stability should be taken into account;

- the thickness of the adhesive screed should not exceed five millimeters;

- so that in the future there are no cracks on the poured surface, it is recommended to avoid the appearance of air bubbles during the application of the adhesive mixture.

The topcoat is installed on the adhesive screed only when the solution is completely dry.

Mats are spread on the floor according to the planned scheme

Classification of species

Heating mats, depending on the number of built-in cores, are divided into two types. Each type has its own technical characteristics and connection features.

How to seal an end cap on a TempZone™ electric floor heating cable

Single core heating mat

Service center of the DEVI representative office in Ukraine with answers to frequently asked questions about the choice of an electric heating system, calculations and installation of underfloor heating based on DEVI, VERIA equipment.

Is it possible to heat the loggia and the kitchen with one cable?

Heating cable for wooden coverings, as source of complete heating in an apartment.

Heating mat and cable VERIA, what is this brand?

– The Danish brand VERIA, founded in 2006, is one of the leading European manufacturers of electrical heating systems, widely represented and successfully sold in 16 countries on different continents.

In Ukraine, VERIA products are sold by the exclusive supplier Danfoss. It is noteworthy that the DEVI A / S trademark has also been part of the Danfoss group of companies since 2003. Therefore, the quality of VERIA products is at the same high level as DEVI products.

VERIA heating mats and cables are produced on the same equipment as DEVI for factories in Denmark, France and Poland, with the same multi-level quality control in the production technology. All VERIA products are certified by the State Standard of Ukraine and approved by the Ministry of Health of Ukraine.

Now a little about the technical characteristics of VERIA heating mats and cables.

If we compare cable products for underfloor heating between VERIA and DEVI, then I would put the advantages of the VERIA brand even more. And the most important plus is the cost of production.

If we take the VERIA two-core heating mat, then it has high-temperature Teflon internal and external insulation, which corresponds in technical parameters to the most expensive DEVI DTIF-150 mat, and at a price much cheaper than even the usual, widely used DEVI DTIR-150 heating mat.

If we take the VERIA two-core heating cable, then it has the flat shape of the previously produced DEVI DTIP-18 heating cable, and in terms of specific power per linear meter, it is slightly higher, 20 W / m than 18 V / m, as has a modern round cable DEVI DEIflex 18T. This increased power per linear meter allows for reliable heating in rooms with increased heat loss, such as a bathroom, a loggia, a balcony, floors on the ground or without thermal insulation, without reducing the laying spacing and without increasing the length, in comparison with the DEVIflex 18T cable.

Of the minuses, only a slight complexity of installation due to twisting of the cable during laying, a smaller choice of cable lengths from a number of finished products can be attributed. And of course the biggest plus is its lower cost with a higher installed power than DEVIflex cables.

Of the thermostats, only two models are presented: VERIA Control T45 and B45.

The T45 programmable thermostat has a large LCD display, setting different temperatures for each of the four periods a day, but does not have intelligent prediction like DEVIreg Touch. Those. you yourself, when programming the heating periods for the warm floor, set the switch-on time in advance so that there is a comfortable temperature at the desired time. The thermostat has a built-in air sensor, which allows the thermostat to be used in the underfloor heating system as a complete heating. There is also a temperature correction function on the thermostat sensor. When connecting the heating cable, it should be borne in mind that the power relay is designed for 13A (max 3000 W).

And again, the biggest plus is its cost, which is less than a simple electronic mechanical thermostat DEVIreg 530.

Video on settings and programming of the VERIA Control T45 thermostat.

The VERIA Control B45 thermostat works only with an external floor temperature sensor on the wire, it is completed with the same sensor as in the DEVIreg series of thermostats. Has the same electronic circuitry, control and appearance as the DEVIreg 530 thermostat.

So, in a small comparative review of the VERIA brand products, we can say with confidence that this is a very worthy brand, not inferior in quality to the well-known DEVI brand. The official 12-year warranty for VERIA heating mats and cables is fully implemented and supported by all DEVI Service Centers.

You can purchase cable products, VERIA thermostats, calculate and install heating systems with a warranty for equipment and operation, contacting the DEVI Service Center in Kiev.

38066 9850088, 38097 0040088, 38044 5925145 Ilya Korchagin, DEVI Service Engineer

How long does it take to indent the heating cable, how far does it warm up the floor?

-During its operation, a resistive heating cable converts electrical energy into thermal energy along its entire length and also heats up evenly at the same temperature. So the heating cable, laid with a certain pitch, evenly heats up the entire location area, and the surface temperature begins to decrease immediately after the edge of the mowing line is laid. A maximum of 10 cm, the surface temperature behind the last line of the cable will have the same value as in the middle of the heating zone, and then it will decrease and literally after 30 cm it will be the same as on the unheated part.

Usually, a heating cable is indentated from walls and furniture by 15 centimeters, because a person’s foot does not get there, but there is one common mistake when installing a heating system in the kitchen, when they indent from the working wall of the kitchen. It turns out that on this edge heating zone, the floor temperature drops so much that it is not comfortable to stand near the working wall when the heels are in the warm zone, and the toes already feel all the coldness of the screed, as under the furniture.

Therefore, when laying a heating cable or mat in the kitchen, the area for laying the heating cable should start directly from the working wall of the kitchen, there is no need to indent from it.

Also, do not indent with a heating cable from the washbasin cabinet in the bathroom.

How long to choose the heating cable and in what step to lay it?

If choosing a length for the required heating zone with a heating mat is a little easier, then with a heating cable you need to make calculations based on the type of heated room, its number of storeys, heat loss or the presence of thermal insulation in the floor, the level of the poured screed or direct laying of the cable under the tile, the stability of the network stresses.

It is assumed that the warm floor will be as an additional source of heating to the existing one and will be controlled by a thermostat with a floor sensor on the wire to maintain a constant comfortable temperature of the floor surface.

Thermal insulation. If the bottom is a residential, heated room, then thermal insulation is desirable, but not required. Installation of thermal insulation is mandatory if there is a cold room under the floor or the floor is on the ground. the thickness of the insulation should be at least 2 cm, optimally 5 cm, if the floor on the balcony. insulation is at least 5 cm, and preferably 10 cm.

Thermal insulation is used from EPS (extruded polystyrene foam), not foam, which does not withstand mechanical stress, absorbs moisture and collapses, emitting gas harmful to health. The use of thin foil insulators, such as Penofol, was described above and their use in a floor screed is meaningless, and sometimes harmful.

The choice of the installed power.

If for residential premises, where a comfortable warm floor will be, as an additional source of heating, the power of the heating cable is set at least 130 W / m2, but if the heating system does not work well, i.e. the air temperature is below 18C, the room is humid, the installed power should be increased. When the supply voltage is reduced, a higher power should also be set. In any case, the increased power will not be superfluous when the underfloor heating system is operating, it will cope with heating the floor surface in severe frosts or in the off-season, when the heating is not yet turned on. And such a system will not consume more electricity, all the same, the floor temperature is limited by the thermostat, and even sometimes it will work less, the heating rate increases in a shorter period of time.

Choice of cable length. Each resistance heating cable has its own constant power input per meter of length. Using DEVIflex heating cables as an example, this could be 6, 10, 18, 20, 30 W / m.

In residential premises for underfloor heating systems, it is recommended to install two-core DEVIflex 18T heating cables (18 W / m at 230 V).

DEVIflex 18T Heating Cable Table.

Based on the heating area, from which the areas of the stationary standing furniture are subtracted, the total power is selected, which must be provided by the heating cable.

For example, underfloor heating in the kitchen of a new apartment building not on the first floor. Heating area 6 sq.m. The area is multiplied by 130 W / m2 = 780 W.

According to the table of cable lengths, a cable is selected that has a higher power than the calculated one. 855 W 52 m. This is very important and should not be economized here. The fact is that in the table the length of the cable is calculated, based on the minimum laid 130 W / m2. and if a shorter length is chosen, then the total installed power per sq.m. decreases, which can lead to underheating.

For example, underfloor heating 3 sq.m. on the balcony with mandatory thermal insulation in the floor structure. Select cable 563 W 34 m (188 W / m2) minimum or larger 622 W 37 m (207 W / m2)

Calculation of the step of laying the heating cable. The screed over the heating cable serves as a heat transfer accumulator. The higher the layer of the screed, the less the temperature drops above the heating cable and between the lines will be felt. The optimal screed over the heating cable is 3-5 cm. Above, 7-10 cm are already used in heat accumulation systems, when heating this accumulating screed layer at night at low night rates provides a comfortable temperature during cooling during the day with its maintenance. So over the heating cable, laid with a step of 12.5 cm in a screed layer of 3 cm, temperature drops will no longer be felt. If the heating cable is laid directly under the tiles, then the cable spacing should not be increased by more than 10 cm.This must be taken into account when choosing equipment.

For the convenience of installing the heating cable, keeping the step of its laying, its fastening and tension, a galvanized mounting tape is used. On the mounting tape, each fastening link is located every 2.5 cm and it turns out that it is possible to fix the heating cable on it with a step of 5, 7.5, 10, 12.5, 15 cm.

Estimated installed power 130 W / sq.m. corresponds to a laying step of 12.5 cm. But this step is the maximum, and when a longer cable with a higher installed power needs to be laid on the required area, you need to start alternating the laying step and place the mowing line of the cable more densely.

The laying step in cm can be calculated by multiplying the underfloor heating area by 100 and dividing by the cable length.

For example, on a balcony of 3 sq.m. the selected cable is 34 m. The estimated laying step is 8.82 cm. This means that when laying the heating cable, the step must be alternated. The second line is laid on the mounting tape after 10 cm, the third after 7.5 cm, then after 10 cm, again 7.5 cm, etc., until the entire heating area is filled with the heating cable.

Sometimes it may not be possible to lay the entire heating cable at once, or it will not be enough, or it will be superfluous. An alternating laying step is selected again, but you need to try to ensure that the heating cable fills the entire heating area.

The heating cable must not be cut!

The length of the mounting tape is selected based on the heating area. So the area is multiplied by 2 and the length of the tape sufficient for installation is obtained. The tape can be fastened every 50-80 cm, depending on the laying step. With a frequent step of laying the cable, it is not necessary to move the strips of tape more than 50 cm apart so that the heating cable can be pulled sufficiently and it does not get confused.

Usually, the cable is first attached to the edge mounting tapes, so that, if necessary, it can be quickly removed and shifted with the desired pitch, and only when the cable is completely laid, it is unfastened, stretching over the remaining strips of tape.

On an underfloor heating area, it is better to lay the heating cable along the long side of the heating zone, fewer loops and change the laying pitch faster if you need to lay the entire length of the cable. The edge, coldest zone must be heated with maximum power, reducing the pitch of the cable.

When installing a full heating system under a stationary furniture, several cable lines can be laid through the floor structure with a heating cable for a slight heating of the screed in this area. The temperature in the cabinet will not be as low as in the edge cold zone.

A little advice. When laying the heating cable, use knee pads, do not kneel without a softening pad, this is very harmful to your health.

Heat storage systems, such as total heating with a heating cable through the floor structure.

-With the constant increase in energy prices, the question often arises whether it is possible to make the heating system with an electric heating cable more economical in operation and the installation of a heat storage system in some cases will be a good enough solution.

But here there are some peculiarities that must be taken into account when designing such a system.

The level of the screed above the heating cable should be 7-10 cm, which is poured for strength with a reinforcing mesh. Such an array of screeds is capable of accumulating, like a battery, and then, like a radiator, for a long time to give off its heat, warming up the air in the room with a large floor surface area.

The obligatory presence of thermal insulation in the construction of the EPPS floor min. 5 cm, not large heat loss of the entire room, so that the heat remains for a long time.

Two-tariff electricity metering, programmable thermostat for controlling the heating system.

Heat storage systems are most often installed in office premises, not in residential ones, where you rest at night. Why? Everything will be clear about this below.

How to Lay and Install Underfloor Heating Mats Prior to Tiling. Tile Mountain

The main energy costs occur during the initial heating of any electrical heating system through the floor, and not while maintaining the achieved comfortable temperature. What is the advantage of the heat accumulation system is that the main heating of the screed array occurs at night, about 2 cm per hour, at a rate that is twice as low as during the day, and then the other part of the total heating time will be spent only to maintain a comfortable temperature in the room during the day. The less heat loss in the room, the less often the underfloor heating will turn on to maintain the set temperature and the less consumption at the daily rate. Cost reduction and the main advantage of the heat storage system compared to conventional underfloor heating systems, where, on the contrary, they try to install the heating cable closer to the surface in order to reduce heating time and use the underfloor heating only during periods of time when it is necessary, by controlling a programmable thermostat.

Most often, an electric heating cable is laid in the floor structure, as a comfortable floor heating system, an additional source of heating to the existing heating, and floor heating is used as needed, trying to increase the system’s reaction speed, reducing the heating and consumption time. At night in sleeping rooms, in order to create a favorable microclimate during sleep, the air temperature in the room is lowered by opening the windows, and if the accumulative screed warms up at this time, this will cause an uncomfortable state. This must always be taken into account when choosing a heating system in different rooms.

An example of installing a heat storage system in office premises with a total underfloor heating area of 212 sq.m. and consumption of 31.1 kWh. Heating cables VERIA Flexicable 20W 1555 m are laid on 5 cm EPPS thermal insulation with an intermediate layer of 3 mm foam foam. Penofol in this case serves only to separate the heating cable from the thermal insulation, so that the cable does not press into the EPS and does not overheat locally, plus a slight heat distribution by the foil base and for quick installation. The entire heating system is distributed over 16 underfloor heating zones controlled by a DEVILink wireless system with the possibility of remote access from a mobile phone via a Wi-Fi network.

If you would like to know more about the technical calculations and selection of DEVI heating equipment for comfort floor heating systems and electric floor heating systems. you can download the installer’s manual from DEVI for free.

If you have questions related to the technical calculation and the correct choice of heating equipment, installation

and repair of heating systems, please contact international free on-line consultations via Viber, WhatsApp

by number 380669850088 Ilya Korchagin.

On the website of the DEVI Service Center, you can familiarize yourself with the catalog of the main items of heating equipment and the of heating cables, mats and DEVI and VERIA thermostats. http://devi-service.com.ua/

Good luck to everyone in construction and repair!

Why the heating cable should not be cut?

Resistive heating cables (underfloor heating) are sold in the form of ready-made lengths connected to a cold power cable. Each section has a specific length and capacity. When calculating heating systems, these values are used. But when an error creeps into the calculations and the remainder of the cable has nowhere to mount, then the first solution, which seems logical, is to cut off the excess.

The instructions supplied with the heating section prohibit any manipulation of shortening or extending the sections. Why? Indeed, in the catalogs the same heating cable, for example, with a power of 20W / m, is sold in the form of sections from 5m to 120m. And it seems that if you approach the matter thoroughly, then at home you can make a completely high-quality end sleeve, and use the rest of the cable somewhere else.

When repairing a heating resistive cable in a screed locally, the damaged section should be replaced with a piece of heating cable from a similar section so that there is no overheating in this place. Do not insert a piece of cold connecting cable, as this will break the resistance of the remaining heating cable.

What to do if there is a lot of warm floor?

- Exchange for another model

- Coupling (not recommended by the manufacturer). If a situation arises when the cable is purchased, the terms of return and exchange have expired, the layout of the heating places has changed and requires a smaller area. There is an opinion that the cable can be shortened by no more than 10% of its length. It is best to entrust this operation to specialists, since the installation of the final coupling will be required. High-quality coupling is made with special tools and materials. Couplings are a place of increased load, so it is very important to perform them correctly and accurately, the performance of the entire system depends on this. What manufacturers of underfloor heating tell us:

Underfloor heating is a very convenient and comfortable purchase, there is never a lot of it. Careful installation ensures trouble-free operation for many years.

During installation, we recommend drawing up a photo plan of the system or fixing it on paper. This will be needed during redevelopment and during construction work.

How to shorten the underfloor heating mat. Why can’t you cut the heating cable? Is it possible to cut a warm floor

Why shouldn’t the heating cable be cut? Is it possible to cut a warm floor

Household appliances store

How to shorten the underfloor heating cable

Underfloor heating is no longer a luxury, but often a forced need for many people, because our winters are cold, and developers rarely worried about everyone being warm.

So it is not surprising that many of us try to insulate ourselves as much as possible, including installing a warm floor. And everything goes very well if the floor is properly installed and everything works great. Yes, sometimes there are situations when the cable for the warm one is made too long, which causes great inconvenience, especially considering that during installation it is necessary to make sure that the cord does not bend or break anywhere, otherwise there may be big problems with operation, yes and no one then guarantees your safety. After all, you need to be more careful with electricity.

So it is best that even before the installation of a warm floor, its length is taken into account, because it is worth shortening the cable only in extreme cases. So take into account in advance that only the part on which there is no furniture is heated, and carefully measure all the parameters of the room.

But if, nevertheless, some mistake happened and not everything was taken into account, then sometimes it is necessary to shorten the cable of the warm floor.

But, before doing this, you should find out that manufacturers do not support such an idea and strongly do not recommend shortening the underfloor heating cable yourself. So if you had a valid warranty for such a floor, then its effect is automatic

How to shorten the underfloor heating cable

Underfloor heating is no longer a luxury, but often a forced need for many people, because our winters are cold, and developers rarely worried about everyone being warm.

So it is not surprising that many of us try to insulate ourselves as much as possible, including installing a warm floor. And everything goes very well if the floor is properly installed and everything works great. Yes, sometimes there are situations when the cable for the warm one is made too long, which causes great inconvenience, especially considering that during installation it is necessary to make sure that the cord does not bend or break anywhere, otherwise there may be big problems with operation, yes and no one then guarantees your safety. After all, you need to be more careful with electricity.

So it is best that even before the installation of a warm floor, its length is taken into account, because it is worth shortening the cable only in extreme cases. So take into account in advance that only the part on which there is no furniture is heated, and carefully measure all the parameters of the room.

But if, nevertheless, some mistake happened and not everything was taken into account, then sometimes it is necessary to shorten the cable of the warm floor.

But, before doing this, you should find out that manufacturers do not support such an idea and strongly do not recommend shortening the underfloor heating cable yourself. So if you had a valid warranty for such a floor, then its effect automatically ends when you decide to shorten the underfloor heating cable.

Don’t forget about it.

As for the process itself, try not to do it yourself, but still trust the hands of a professional. Find a good craftsman who will help you cut the cable correctly so that later there is no short circuit, and so that the whole structure does not burn out.

But still, if you decide to do it yourself, then, after you have cut the wire itself, put a resistor in the place of the cut that will limit the current.

It is imperative to do this, because when the cable is cut, its resistance decreases significantly, due to which the current increases.

It is also very important to choose the right resistor, because if its value does not correspond to the resistance that was inherent in the piece of wire that was cut off, then again problems may arise, due to which the entire structure will have to be changed.

Bath interior decoration options

Why shouldn’t the heating cable be cut? Is it possible to cut a warm floor

How to avoid mistakes when installing a warm floor

Underfloor heating installation: useful tips

Today we would like to talk about the mistakes that are quite often made when performing work on the installation of cable heating systems.

Some of them can be critical and cause a breakdown of the warm floor immediately, partly. will appear only some time after installation and start of operation. In any case, the cost of the mistake is high enough to take this matter seriously.

If you are not confident in your abilities or you are offered to install a warm floor of a person who do not have much experience in this regard, it is better to entrust this work to specialists. see the section underfloor heating installation.

Our many years of experience in the field of installation of cable heating systems suggests that most faults are caused by improper installation and damage to the cable during or after laying it.

Advice When choosing a heating cable or mat for a warm floor, focus not on the total area of the room, but on the area not occupied by furniture, san. technical devices, etc. Remember that under stationary furniture or such fixed objects of a large area as bathrooms, washing machines, sofas, etc., the warm floor should not be laid in order to prevent the cable from overheating, and this does not make much sense, because you won’t be able to walk there anyway.

Advice Some technicians believe that if a too long cable was chosen, then the cable can be shortened without problems. In fact, heating cables must not be cut! This applies to most cables that are used in modern floor heating systems. “Shortening” the cable leads to an increase in its power, overheating and failure! In case you still have a cable. you need to reduce the laying step or increase the heated area.

Tip It is strictly forbidden to turn on the cable to test the functionality until the moment when it is laid (especially in the bay) and the solution is completely dry! Turning on the cable in such conditions may damage it. The cable is checked by measuring its resistance and insulation resistance. After laying the cable, it can only be switched on for a very short time.

Tip Do not lay the heating cable on a dirty or dusty surface. Use an industrial vacuum cleaner to prepare the floor. Treat the surface with a primer.

Tip Conventional heating tape should not have points of contact, intersections and lines that are close to each other. The minimum distance is indicated in the product passport and is usually 5-7 cm.

Advice Observe the minimum bending radius of the heating cable. This is also the passport value, usually it is 5-10 cable thicknesses.

Tip Do not brick the floor sensor in the solution! The underfloor heating sensor must be in the corrugated tube. The tube should not have holes through which solution could penetrate and should not be bent too much. The tube must also be sealed directly on the side of the sensor. Remember that it must be possible to remove the temperature sensor if it needs to be replaced. Quite often this simple requirement is not met, making it impossible to replace the sensor in the event of a failure.

Tip When installing the sensor tube, try to keep the tip of the sensor as close to the new floor surface as possible. This applies primarily to screed floors, where the screed thickness increases by 3-5 cm).

Tip Do not use the same heating cable to heat different rooms. This is prohibited by regulatory documents. The desire to save money on the purchase of a thermostat leads to incorrect operation of the system, since different rooms are in different thermal modes.

Tip 0 Avoid walking on the heating tape with sturdy shoes. If you can’t do without walking on it, do it with caution. Eliminate the presence of unauthorized workers and other people in the room where the warm floor is installed.

Tip 1 Do not neglect some “formalities”. Measure the underfloor heating resistance and insulation resistance before and after installation, make sure that it corresponds to the value in the product passport. If the value is not indicated in the passport, enter it, be sure to indicate the date of installation.

Tip 2 Do not forget to draw a scheme for installing a warm floor! When doing this, indicate the distance to walls and other objects, the location of the end sleeves and couplings, and the location of the sensor. For this, most instructions for underfloor heating have a corresponding lined page. We advise you to take a picture of the heating cable. The diagram and photos will always come in handy when you subsequently need to drill the floor for installing plumbing and door fences.

Tip 3 Do not leave air voids around the “hot” part of the heating cable. This is especially true when laying the so-called. “Thin” warm floor in tile adhesive. Failure to comply with this requirement in order to save the solution or simply out of ignorance will lead to overheating and failure of cables.

Advice 4 Do not turn on the warm floor so that the screed dries faster! Wait several weeks depending on the thickness and type of mortar used. SNiPs standardize a period of 28 days.

Installing underfloor heating. Basic steps step by step

Warm floor. heating mats: how to choose and lay with your own hands?

The system of underfloor heating has long and firmly entered the life of people who seek to make their home more cozy, warm and comfortable. For those who live in a country house, it is more advisable to install water floors, and for residents of city apartments, an electric underfloor heating is recommended. As a rule, the electric underfloor heating system does not serve as the main source of heating, but is used as an auxiliary one. Since there are several types of electric floors, the question arises which one to choose: cable, infrared or heating mats. This article will focus on the last type of floor heating system.

Underfloor heating mats

Device and functions

What is a heating mat? In essence, it is a combination of conventional cables and a multi-layer sheath on the mesh. The cable consists of steel or copper wires and insulating protection. It is laid on the substrate with a snake with a step of at least 50 mm. When a current passes through it, it heats up. To connect to the mains, a cold wire is used, the length of which is at least 1.5 m and which is connected with a sleeve to the heating element.

Heating mat cable device

The cable sheath is a mixture of rubber, polymer fibers and fiberglass. Unlike cable floor heating, heating mats are not fixed on a metal mesh, but on a mesh made of synthetic fibers (kevlar, fiberglass, etc.). The upper part of the substrate has an aluminum shell and is covered with a PVC film. Are there too many insulators? No, multilayer insulation reliably protects the wires from possible mechanical damage.

If during installation it is necessary to lay the mat in a different direction, the mesh can be cut.

The cable can be bent but not cut.

Since both the heating cable and the substrate are very thin, the warm floor will practically not reduce the height of the room, which is an undoubted plus.

The main purpose of thermomats is an additional, local source of heating. Most often, mats are placed in bathrooms, kitchens or balconies. And if you have a private home, they can help prevent icing on the stairs and porch in front of the entrance.

Selection of heating mats

There are two types of heating mats, depending on the type of cables:

The main difference between a single-core mat is that when connected to a thermostat, both ends of the cable are used. And here comes the difficulty during installation: the installation must be completed where it began. If this is not done, the cold wire from the other end of the cable will need to be pulled back.

With two-core thermomats, everything is easier. In addition to the heating cable, an electric wire is provided in the system. That is, only one end is used to connect to the thermostat. However, the price of such mats is higher and they reduce the height of the ceilings more than single-core mats.

There is one more difference. Single core heating mats, when switched on, are capable of generating electromagnetic radiation that can be harmful to human health. Despite the fact that the indicators are at an acceptable level, it is not recommended to install this type of underfloor heating in living quarters, especially in children’s rooms. Experts advise using the mats in industrial premises or outdoors. Two-core cables have a second wire that “dampens” the electromagnetic field, so they are considered safe.

Before choosing thermomats as additional heating, study the positive and negative aspects of the system.

Adhesive tape on the mat mesh speeds up the installation of the underfloor heating without problems by gluing the cable to the base

- Security. Multi-layer insulation and non-combustible materials from which the heating mats are made make them absolutely reliable.

- Easy installation. An adhesive layer is applied to the substrate, which eliminates additional work and saves time and effort.

Among the disadvantages are the following:

- Price. Electric cable floor is cheaper compared to mats.

- Thin floors are not suitable as main heat source.

When choosing a warm electric floor, power must also be taken into account. Having determined the place where the thermomats will be laid, its area, as well as their place in the general heating system of the room, it is not difficult to determine the power. So, for a kitchen or a corridor, an indicator of 120 W / m2 will be sufficient, for a bathroom. 150 W / m2, and for a bedroom, nursery or balcony. 200 W / m2.

The power of the thermomat for different finishes may vary.

How to shorten the underfloor heating cable

Underfloor heating is no longer a luxury, but often a forced need for many people, because our winters are cold, and developers rarely worried about everyone being warm.

So it is not surprising that many of us try to insulate ourselves as much as possible, including installing a warm floor. And everything goes very well if the floor is properly installed and everything works great. Yes, sometimes there are situations when the cable for the warm one is made too long, which causes great inconvenience, especially considering that during installation it is necessary to make sure that the cord does not bend or break anywhere, otherwise there may be big problems with operation, yes and no one then guarantees your safety. After all, you need to be more careful with electricity.

So it is best that even before the installation of a warm floor, its length is taken into account, because it is worth shortening the cable only in extreme cases. So take into account in advance that only the part on which there is no furniture is heated, and carefully measure all the parameters of the room.

But if, nevertheless, some mistake happened and not everything was taken into account, then sometimes it is necessary to shorten the cable of the warm floor.

But, before doing this, you should find out that manufacturers do not support such an idea and strongly do not recommend shortening the underfloor heating cable yourself. So if you had a valid warranty for such a floor, then its effect automatically ends when you decide to shorten the underfloor heating cable.

Don’t forget about it.

As for the process itself, try not to do it yourself, but still trust the hands of a professional. Find a good craftsman who will help you cut the cable correctly so that later there is no short circuit, and so that the whole structure does not burn out.

But still, if you decide to do it yourself, then, after you have cut the wire itself, put a resistor in the place of the cut that will limit the current.

It is imperative to do this, because when the cable is cut, its resistance decreases significantly, due to which the current increases.

It is also very important to choose the right resistor, because if its value does not correspond to the resistance that was inherent in the piece of wire that was cut off, then again problems may arise, due to which the entire structure will have to be changed.

Bath interior decoration options

Finishing floor covering

Most often, electric underfloor heating is used for “cold” coatings, for example, tiles or porcelain stoneware. But it can be used with laminate or parquet, but there are some features that should not be forgotten. If you plan to lay a laminate, then the coating should be specifically designed for laying over a warm floor. Do not allow overheating of wooden floors, as the material can dry out over time, as a result of which the wood will crack. Heating temperature should not exceed 27 ° C.

Underfloor heating cake

As a rule, flooring manufacturers indicate whether the material can be used with underfloor heating. There is a wide range of models of heating mats on the market that are focused on working in tandem with carpet, linoleum or other topcoats. So it will be very easy to choose the right one.

If there is not enough heat in any room of your house or apartment, then the question of the advisability of installing a warm electric floor is removed by itself. And if the choice fell on heating mats, then the task is all the more easily feasible, since the installation of the system does not require special skills and it is easy to do it yourself. Dear readers, leave your comments, share your opinions about the article and this underfloor heating system.

Loading.