Is it possible to cut tiles with a hacksaw for metal

How to use a hacksaw

Special devices

Cutting paving slabs can be done with high quality using a special electric tool, which is a small circular saw. The saw type Eibenstock EST 350 is designed especially for paving pavements. The high-speed circular saw allows for a smooth cut, which is important when there is an increased demand for paving quality. Other mechanisms of the same type can be selected.

Application of the guillotine

Tile edges are sanded.

With large volumes of pavement laying, it is advisable to use a special guillotine knife for cutting paving stones.

This small machine includes a stacking table, rails, knife and handle to provide the required force. The block is laid in the gap between the table and the knife blade, and then using the handle, the knife is lowered and chops the material.

Cutting (more precisely, chipping) the tiles is carried out along the marked mowing line without much effort and quickly.

Currently, many different domestic and foreign devices are offered, providing the required quality and reliability. A number of mechanisms such as Maxim, AL and a number of others can be noted.

An important advantage of using guillotines is the absence of dust clouds and the speed of the process.

Tile cutting methods

The most responsible and difficult stage is the direct cutting of the element.

Cutting is carried out strictly along the marked mowing line, when the tile is firmly fixed on a flat hard surface.

The cutting process is carried out in two main ways. using an angle grinder or a guillotine. If possible, the ideal option would be to use a special electric tool for cutting paving slabs. In some cases, with small amounts of work, you can use a hand hacksaw for metal.

Preparatory work

Protective goggles must be used when cutting tiles.

A special place should be prepared for cutting paving slabs. This condition is caused by the fact that the smallest dust, falling on the surface of the elements, quickly eats into them, which spoils the appearance, especially when using colored bars. If they are moistened, the undesirable process intensifies. Therefore, it is necessary to protect the finished tiles as much as possible from dust that occurs during cutting.

The most important stage of preparation is the marking of the tiles for cutting. It is carried out using a metal ruler, protractor and construction pencil. When laying paving stones of a standard size, the marking is done before laying, after carefully measuring the area to be covered and calculating the length of the necessary pieces of the block. The marking of elements when performing patterned masonry is usually performed after the fact, i.e. in the process of laying when such a need arises, and the size is taken directly from the place of laying.

When marking, it is important to draw the line so that the cut piece fits clearly in the intended place. To do this, a technological gap of the order of 3-5 mm should be laid, which will allow the element to enter the remaining space for it; at the same time do not create gaps that are noticeable visually.

Diamond cutting of concrete and paving slabs

On a suburban area, platforms and paths made of concrete paving stones look great. If such a design is chosen, then the question of how to cut the paving slabs will undoubtedly arise before a person who wants to do it with his own hands. There are no cases when the site is made only from whole elements. getting neat tiled pieces is an important technological process. For diamond cutting of concrete, special equipment is needed, so the best choice would be to contact the professionals from the Almazorezservice company.

How to cut paving slabs? The question, although it seems rather complicated, is solved in a standard way: based on the material of the tile. The technology is quite well developed, and the recommendations of specialists allow us to ensure the required quality. Everything is very simple. before starting work, you should familiarize yourself with the well-known cutting methods, purchase the necessary tool and learn how to use it.

Features of paving slabs

Special tools for cutting tiles.

Paving slabs or paving stones are used for decorative and reliable coverage of sites and approaches to the house. It represents small elements of various geometric shapes and is most often made of concrete with the addition of granite screening. The most common forms are brick, square, paving stone, wave, hexagon, Z-profile and some others.

When laying the elements, a certain ornament is usually formed, which requires adjusting the tile to size, therefore, cutting it into clearly measured pieces. In this case, the cut edge should be flat; otherwise, the whole design will look sloppy. This condition is especially important for material with different colors, and this option is used quite often.

The sizes of the individual elements vary over a wide range. Fast installation is carried out using tiles with a length of each side 30-60 cm and a thickness of 5-8 cm; and to create a certain ornament, elements with a size of 10-25 cm and a thickness of 2-8 cm are used.Paving stones with dimensions of 20x10x6 cm are most often laid.

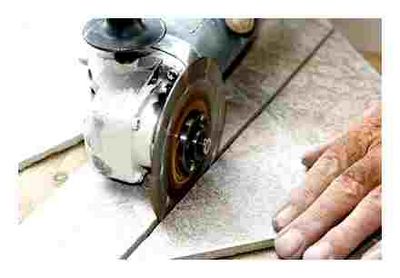

Cutting angle grinder

The most common way to cut paving slabs is to use an angle grinder with a diamond disc. The disc is selected for cutting on concrete or stone with a diameter of at least 230 mm. In this case, Bosch or Di Star wheels are very good. When cutting, use an angle grinder with a minimum power of 2 kW. If difficulties are observed during the cutting process, then the surface of the bar is periodically sprinkled with sand.

Cutting features

In general, cutting paving slabs is the process of cutting a concrete block from 20 to 80 mm thick granite crushed stone. It is required to cut the slabs both along the element and across, as well as at an angle. The length of the cut can be from 10 to 60 cm, but the most common length is in the range of 10-30 cm.The processed concrete has a dense structure, since it is made by vibrocompression and contains a filler in the form of granite (or other) crushed stone of medium and fine fractions.

Shapes and sizes of paving slabs.

The whole process of obtaining an element of the desired size can be conditionally divided into several stages: marking, cutting and processing of the cut. The complexity of the process and its volume depends on the type of surface laid out. If a simple ordinary laying of standard rectangular bars (brick, paving stones) is provided, then the task is simplified. only a transverse cutting of the tile is required.

A more complex problem arises in the formation of a certain ornament, and even different colors. In this case, accurate marking of the tiles becomes important, since the paving slabs will have to be cut in different directions, incl. at different angles; at the same time, it is difficult to do without the final finishing of the element directly during its laying.

The most difficult task is the corner cut to insert the element. Such cutting is rarely done, but when creating a pattern, the likelihood of it is not excluded. This process is carried out using a hand tool, such as a hacksaw for metal.

When planning to cut concrete tiles, you should immediately think about protective measures. During the high-speed process, a huge amount of the smallest harmful dust rises, from which it is necessary to protect eyes and faces. You should work using a respirator, wearing glasses, and it is advisable to cover your ears with headphones. It will not be superfluous to protect the whole body with the help of tight, closed clothing.

Tile preparation

The hard, and at the same time fragile structure of the tile, like glass, is prone to splitting and requires high precision and accuracy in processing. Acceleration of the stroke rate or increased pressure can easily deform the product, ruining the material and negating the effort expended. To cut the tiles with a jigsaw was most convenient, it must be soaked for a couple of hours in ordinary water at room temperature.

How to cut tiles with a jigsaw: evenly and without chips

Saw blade selection

In terms of its structure, the canvas on the tile departs from the familiar to us, the classical understanding of the file. It has no teeth, and the role of the cutting element is played by hard abrasive or diamond spraying. The quality and speed of cutting with such a nozzle depends on its grain size. The higher this indicator, the slower the cut, but the higher the quality of the cutting line. A low grit value, on the other hand, increases the cutting speed, but creates more chips in the material. Coarseness is measured in micrometers (microns) and is usually indicated on the packaging of the web.

Features of sawing tiles with a jigsaw

The workplace should be stable with as flat a surface as possible, and most of the tiles were pressed tightly against it. The smallest section should be located on the weight, even if it is exactly what is needed for laying. To reduce vibrations, it is better to fix the tile with a pair of three clamps with rubberized clamps. To avoid scratches, a piece of cardboard or plastic can be glued to the metal base of the jigsaw, on double-sided tape.

To reduce the likelihood of scrap, it is recommended to cut the tiles at minimum speed, while producing medium pressure, sufficient to keep the running jigsaw on the line and guide it forward.

Sawing tiles with a hand jigsaw

A nimble jigsaw with relatively massive saw blades does not always succeed in performing particularly delicate work or cutting with an inner contour. When it is necessary to make a neat, jewelry cut with a complex pattern, a reliable hand tool comes to the rescue. Of course, for these purposes, you can use a jigsaw machine that works with the same thin nail files, but this equipment is quite expensive and it is impractical to purchase it for a small amount of work.

As you might guess, ordinary saws for wood and metal for a hand jigsaw will not be able to cut tiles. To perform such an operation, you will need a special tungsten carbide wire or a diamond-coated file.

The process of cutting the inflow with a hand jigsaw is completely identical to its electric counterpart, except that it takes several times more time and effort. The tile is soaked for a couple of hours, after which it is fixed on a flat surface with clamps and during cutting, it is periodically moistened with water. Once again, we repeat that the speed of manual work is very slow, and it will take a lot of time even for a small figure. Before work, you should understand this and be patient in advance. To understand how to cut tiles with a jigsaw and estimate the pace of work, we recommend watching the following video.

Straight cut

The easiest way is to cut in a straight line. Operating procedure:

- Based on the results of measurements, a fishing line is drawn on the tile with a marker. It is impossible to make an angle grinder a perfectly straight cut, therefore, leave an allowance for trimming with a cylindrical grinding nozzle. If the edge is hidden by the skirting board, no cut correction is required.

- The tile is fastened face up on a workbench with the part to be cut hanging over. A clamp is used, in the absence of one, the module is stepped on.

- Holding the angle grinder so that the disc is cutting away from the user, the tool is carried along the mowing line also away from you, trying to make the cut in one pass. If the speed of rotation is regulated, it is reset at the beginning and at the end of the pass.

The rotation speed of the angle grinder should not exceed the value indicated on the disc.

Straight cutting

Tiles are easier to cut if they are pre-soaked for 40-50 minutes. Porcelain stoneware is not soaked.

How To Cut Metal. Ace Hardware

- It is advisable to fix a steel ruler along the cutting line with a clamp. the edge will be smoother.

- The angle grinder can be turned into a tile cutter for a perfectly straight cut. The tool is fastened with metal bolted clamps to a steel sheet with a disc slot. The tile is fed to the disc with two hands.

- If you need to cut tiles at an angle to join the cladding on mutually perpendicular walls, it is better for an inexperienced craftsman to first make an even cut, then cut off the excess with a grinding attachment.

Sawing paving stones with an angle grinder

Having a private house, it becomes necessary to lay paving slabs or paving stones, which must be cut to size. For this, they also use a universal device that is available in almost every home. an angle grinder.

Paving stone processing has its own characteristics, but basically it is carried out in the same way as cutting porcelain stoneware. The main differences are that the work is done outdoors. Material processing should be carried out on a separate site: the resulting dust settles on the laid paving stones and can spoil its appearance. If this happens, you should immediately sweep it off with a stiff brush.

To cut the paving stones, choose a diamond blade for concrete processing. The angle grinder should be held at right angles to the workpiece and the diamond wheel should be moved exactly along the mowing line. It is necessary to cut the tiles to a depth of a little more than half, and then just break and trim.

Segmented dry cutters

Segmented discs received the common name “dry cutters” for their ability to cut material dry, that is, without water cooling. The circle is divided into segments by radial cutouts, which provide efficient heat dissipation and free expansion of the metal when heated. Due to this, the time of continuous operation reaches 1 minute, after which they pause for 20. 30 seconds. the angle grinder is not turned off for this time. the disc rotates at idle for the purpose of cooling.

The disadvantage is low cut quality, a large number of chips. If the trimmed edge of the tile will remain visible, the cutting is carried out with a margin of 3. 5 mm and then the edge is trimmed with a grinding wheel.

Tools and supplies

Nevertheless, there is a way out, for example. an angle grinder with a diamond disc for stone and concrete. But do not rush to get to work, because there is a certain specificity both in the processing technique and in the choice of the appropriate equipment.

Let’s start by understanding which angle grinder is best to use. We immediately dismiss the options for a 230 mm disc: the tool is too heavy and cumbersome, poorly controlled during operation. You can use a 180 mm angle grinder, but only if you cut sufficiently thick porcelain stoneware, where a significant overhang of the disc is required. The best option is an angle grinder with a 125 mm disc, which can be held with one hand during operation. Even if the effective cutting depth of 40 mm does not cover the thickness of the porcelain stoneware, it’s okay. Practice shows that if you made a cut for more than half the thickness, the material breaks off perfectly along the cut’s mowing line, afterwards it is enough to only slightly process the edge.

Now about diamond discs. For cutting porcelain stoneware, do not select dry segment discs. Solid discs with stepped edge notches are ideal, but you need to make sure that the permissible speed of the diamond wheel matches the parameters of the tool.

In addition to an angle grinder with a diamond wheel, some other accessories are required. First of all. a plastic bottle with a pierced lid and a piece of thin silicone tube inserted into it. The cutting of porcelain stoneware must be carried out with a constant supply of a small amount of water, otherwise the spraying on the disc will not last long. You will also need a pair of quick-clamping clamps and a piece of steel angle with a shelf of 25 mm, the length of which is 15-20 cm longer than the cutting line of the cut.

Combined discs

Combination blades allow for both dry and wet cutting.

This is an average option:

- the quality of the cut is lower than that of a solid one, but higher than that of a segment one;

- continuous operation time. less than that of a segment, but more than that of a solid.

Combination discs are easier to clog with dust than others. And if it is enough to rotate the segmented and solid discs for cleaning by 180 degrees, then this is not allowed with the combined one. For cleaning, they cut concrete or sand-lime brick.

Angle 45 0

Docking is often necessary, which means cutting the material at an angle of forty-five degrees. This angle can only be obtained with a large workout. But you can use this technique: first, cut the workpiece in a straight line, and then gently process the edge at the desired angle with a disc, sandpaper or sharpening stone.

How to get rid of dust when cutting tiles

Tile cutting with an angle grinder is not very difficult, but it generates a lot of dust. There are techniques that can help reduce dust formation. Specialists use special tile cutters for this, but buying them for one-time work is impractical due to the high cost. Therefore, when processing parts, the craftsmen act differently. First, a layer of glaze is cut through. it almost does not produce dust, the main dust appears when a layer of fired clay is processed. Then it remains to gently break the ceramic tile and process the edges with an abrasive material.

A common way to get rid of dust is to moisten the workpiece. For this, water is constantly poured into the working area with a diamond wheel. After each pass of the tool, fill the seam with water or install a special device for supplying water to the working area. This device attaches directly to the protective cover of the angle grinder. As a result, the workpiece is processed without dust.

Notched neckline

It is often necessary to cut a round hole in a tile. You can do the job correctly with an angle grinder if you have certain skills. To do this, mark a hole on the workpiece and circle the fishing line with a felt-tip pen, mark the center of the circle. They begin to cut at a slight angle, slowly, along the inside of the mowing line, gradually passing along the entire circumference. Then they cut through the sectors, take them out one by one, trimming the ceramics if necessary. Finally, the edges are processed with a file, getting an even circle. Such processing is called a dry cutter.

Such holes, as a rule, are cut for sewers or ventilation.

When performing shaped processing of a workpiece, it is easiest to make rectangular cuts. In order for the cuts to be smooth, without chips, it is necessary to regularly change the cutting wheel. If you use segmented discs, then chips will appear on the cut line of the mowing line.

Preparatory work

Before cutting the paving slabs, you need to carry out a number of preparatory work.

Before you start cutting the tiles:

- Find a comfortable, spacious and remote place from the warehouse or object.

- Carry out all measurements and calculations, mark the material using a protractor, ruler, pencil, etc. When installing ordinary tiles, all the markings are performed during preparation, when the drawing is created, the markings are made in fact, as the finished elements fit to each other on the canvas. When marking, you need to remember about a technological gap of 3-5 millimeters, which ensures easy installation of the tile in the place allotted to it, without the need to clog elements and cracks.

- The equipment for cutting, the availability of replacement parts, consumables are checked.

- Personal protective equipment is being prepared. clothes, gloves, glasses, respirator.

Angle Grinder

The cutting tool in the angle grinder is a diamond disc with a maximum diameter of 23 centimeters. The power of the tool must be 2 kW or more.

Paving slab cutting process angle grinder:

- Strong fixation of the element.

- Cutting along the marked mowing line, occasional sprinkling with a small amount of sand is allowed to facilitate the process. It is desirable that the rotational speed of the disk is a maximum of 3500 revolutions per minute. During cutting, they move away from themselves, making sure that the cutting depth along the edges is greater than in the middle of the element.

- When working with an angle grinder, it is forbidden: to hold the tiles in a canopy without reliable fixation (it is best to fasten on a hard, even and stable surface with a clamp), to work without the use of personal protective equipment, to cut with a tool with any damage, worn out parts, etc.

How and how to cut paving slabs at home: angle grinder, machine, guillotine

The question of how to cut paving slabs is relevant for everyone who is engaged in the arrangement of the local area, creates garden or pedestrian paths, mounts coverings of various types from this material. It is almost impossible to lay the tiles without cutting. there will still be zones where you need to mount a section that is smaller in size or of a different shape, especially when it comes to curly tiles.

Incorrect cutting of paving slabs can lead not only to considerable financial costs (the larger and more complex the configuration of the area of the covering to be laid, the more there will be cut tiles and, accordingly, waste if the task is performed incorrectly), but also a risk to health and life. The use of the tool presupposes knowledge of the safety rules and the peculiarities of the work.

In many ways, the complexity of cutting is influenced by the shape of the tile: it is easier to mark and cut square and rectangular than a wave, a hexagon, a Z profile, etc. In the process of laying paving stones, certain patterns are usually formed, ornaments that require careful adjustment of the elements in size. In addition, you need to be able to correctly process the edge of the cut of the tile so that the coating is neat and aesthetic.

Different tools are used for cutting tiles, the choice depends on the master’s skills, the type of tiles, the conditions and characteristics of the work. But, first of all, you need to study all existing technologies.

Required tool

To cut off the desired part of the paving slabs, you need to stock up with a whole set of tools. Especially if the installation of a covering of a large area is being carried out and concrete elements will have to be cut in considerable volumes.

What you need to cut tiles:

- Guillotine knife or special electric circular saw

- angle grinder with diamond / grinding disc

- Hammer

- Chisel

- Hacksaw for metal

- Knife

- File

- Roulette

- Sandpaper

- Metal ruler

- Regular (but better construction) pencil

Depending on the tasks and features of the material, the set of tools may vary, but the main points look exactly like this.

Safety regulations

Before cutting the paving slabs with an angle grinder or a guillotine, by any other method, it is imperative to ensure the protection of the master. Otherwise, it is difficult to guarantee the safety of work and the absence of the risk of injury.

Safety measures when cutting tiles:

- Protective equipment (especially if a method is chosen for cutting tiles, which involves the appearance of a large amount of dust, a high speed of rotation of parts, etc.). goggles, a respirator, special clothing made of very dense material will save you from dust and injuries.

- Special headphones to protect against too loud noise.

- The study of the rules for operating the selected tool is general simple: do not bring your fingers to rapidly rotating mechanisms, carefully work with power tools, carefully check devices and parts before starting work, do not use broken or malfunctioning devices. Each method assumes its own set of rules: for example, if an angle grinder is used to cut paving slabs, then the tool must be held with both hands by the side handle, use a protective screen against dust and sparks, ensure electrical safety, etc.

- In the process of work, follow the details and mechanisms. the guillotine knife, angle grinder wheels need to be changed on time, used only if it fully complies with quality standards.

Things to Consider When Cutting

Cutting paving slabs, in essence, consists in processing a concrete product with a thickness of 2 to 8 centimeters in such a way as to end up with an element of the desired size and shape without damaging it and making neat edges. You can saw the tiles in different directions: across or along, diagonally or figured.

We must not forget that concrete has a rather dense structure due to the peculiarities of the manufacture of tiles by vibrocompression and the introduction of crushed granite into the material. Therefore, all work must be carried out with a special tool, accurately and correctly.

The main stages of tile cutting:

- Careful product marking

- Cutting by the selected method

- Accurate processing of the cut

The complexity of the cutting work and their volume depend on the pattern being created, the shape of the tile itself. Rectangular and square elements are simply cut across the markings. But when creating ornaments from tiles of complex shapes, different colors, you will need to apply certain efforts, because here you need to achieve the maximum clarity of the cut.

Application of the guillotine

The guillotine knife is a special machine specifically for cutting paving slabs, which is a laying table equipped with handles, guides and, in fact, a knife. The main advantage of this cutting method is the absence of dust during work and the ability to process large volumes of material.

How to cut tiles with a guillotine knife:

- Placing tiles in the gap formed by the table and knives.

- Bringing the knife into operation with the handle. the tool is lowered and, under the influence of its weight and high speed, breaks off a piece from the tile in the right place. During work, it is important that pressure is applied to the entire handle (not to the end), as otherwise the element can be damaged and injured due to unexpected tile splitting.

- It is important to monitor the sharpness of the knife. if it is dull, it will overheat, periodically get stuck in the cut, and undergo deformations. Sharpening is needed when visible traces of burns and ugly yellow spots remain on the cut tile, and the cut is very rough.

Cutting features

Before cutting the tiles, you need to prepare very carefully. And we are talking not only about measuring and marking the concrete elements themselves, but also about the place of work. It is advisable to set aside a special place for safe cutting of tiles, which will be at a sufficient distance from the rest of the material and the already installed coating, as well as machines, various objects, etc.

When dust gets on the wet surface of the elements, the dust spoils it much faster: for example, if the cut tile differs in color from the one already laid and dust from it sprinkles from above, there is a risk of the need to completely change the coating.

To cut the tiles properly, you need to correctly measure. Usually, about 10-15% of the stock is added to the obtained figures (then you can cut off the edges and remove the excess). For tiles of the original shape, the margin is increased.

They cut the tiles strictly according to the intended mowing line, trying not to press hard on the material, since the tiles can fall out of hands or break into pieces. In a situation where the cutting process of the angle grinder is difficult, you can sprinkle the tiles with masonry sand in a small amount.