Making a plow for a power tiller with your own hands

Plowing technology

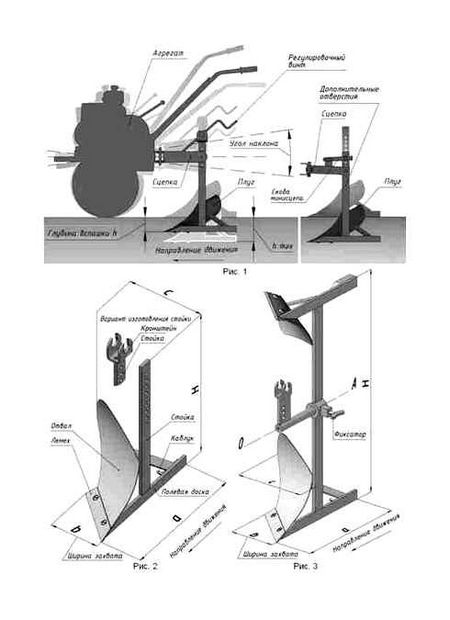

To describe the technology of plowing the soil you can get acquainted with the principle of the plow. Its work is that moving in soil, skimmer of device shears topsoil, with growing plants, and lays it on the bottom of furrow. Then, together with the tooling, the body removes part of the soil from the side of the furrow, loosens it and turns the layer at a set level, depending on the design of the plow. Afterwards, the earth is placed on top of the layer of turf turned over by the skimmer. To level furrow walls, a blade is installed in front of the last plough body.

General purpose ploughs are equipped with 25-40 cm wide body systems. Special purpose systems are equipped with bodies with working width of 45-100 cm.

Pivoting plow

This is a stand, to which are welded two plowshares: undercutting and overturning, and tilting the soil. To make the tilting ploughshare more rigid an angle is welded on top that rests on the upper edge of the tilter.

If you make it yourself, you can make a simpler knot to reset the plowing depth. Cross beam, bolted to the stand, welded to the plow, made longer. No need for a box. In front of cross beam is attached a bracket, in which strengthen additional vertical pole, the size of which is enough to leave the area of overturning the soil.

In the vertical small square stand at the front a few holes are drilled for bolts, through which at the required height is fixed rod, coming from the power tiller at an angle of 90°. Two welded eye plates hold the link to this front post. The two tine arms are bolted together with nuts. They connect the stand and drawbar. This type of connection is simpler and more efficient. Adjustable ploughing depth.

To keep the soil from sticking in the gap, a thin plate is welded between the lower and upper coulter, which helps the soil to run smoothly and quickly in an arc and rolls over.

Zykov swivel plow

The plowshares are reinforced in this case by bolted steel strips. Bottom and top at an angle. Cheap and easy. A turnover rod with a welded-on fixture holds two tines with stakes that are inserted into the fixture. Two sets of locking bolts hold the linkage together. For stability a wheel is attached to the undercarriage.

Turning plow for a power tiller, homemade

Swiveling plow. universal, used on power tillers, contains a manual swiveling mechanism on a standard single hitch. As you know, when tilling the soil with a regular plow, the layer of land is turned over to one side with the ploughshare during one pass. In order for the soil of the next row to turn over to the same side, you have to go back to the beginning of the previous row and start on the same side of the plot.

A swiveling plow will allow you to plow much faster. at the end of the row you simply turn the ploughshare to the other side after turning the motoblock and continue tillage.

Types of mounted plows

On the market you can find many manufacturers and types of such gadgets. They all differ from each other to one degree or another in certain characteristics. But for use on a small homestead plot it is enough to have one of the three basic types:

The single-hoe plow is rightly considered the most popular among landowners because it is very easy to use. Such a tool can be operated by a person even without experience in mechanized plowing. Fabrication requires a drawing of a home-built plough. It can be found on the internet.

A distinctive feature of the turnover plow is its use for processing hard surfaces. It is curved to one side, so the land is turned over. Such a plow to do with their own hands a little more difficult than a one-hoe, but in certain cases it is simply indispensable. Even an entry-level knowledge of how to make one for yourself is a must.

Rotary machine to make on their own is even more difficult than the turnover and one-hoe. It includes two or more plowshares, which are located on one axis. The rotary plough can be used to effectively till the ground to a depth of up to 35 centimetres. But these are not all the advantages of such a plough for a power tiller. You can work the land in any direction, but only in a straight mowing line. It is also possible to choose the width of plowing in the more advanced models.

The easiest way to have a beautiful lawn in front of the house

Surely you’ve seen the perfect lawn in the movies, in the alley, or perhaps on your neighbor’s lawn. Those who have ever tried to grow a green area on their plot, no doubt they will say that it is a huge effort. Lawn requires careful planting, care, fertilization, watering. However, only inexperienced gardeners think so, professionals have long known about the innovative tool. liquid lawn AquaGrazz.

Read more

What tools and materials will be needed to make a plow

To design, made with their own hands, turned out to be reliable and durable, it is necessary to properly prepare the material. Metal for wet soils choose a thickness of at least 6 mm. For stony ground. 7 mm. For normal light black earth. 5 mm. Also prepare the following tools and materials for making a potato digger with their own hands:

- angle grinder;

- welding machine;

- drill;

- pencil;

- centimeter;

- angle piece;

- sheet of steel with a thickness of 5-7 mm;

- metal profile;

- bolts 10-12 mm in diameter;

- steel rod section of 8-10 mm;

- wheels.

When selecting wheels, preference is given to wide models, so that movement on the ground is easy. Rubber wheels are suitable for loose sandy soils. Wheels with tractor treads are good for wet ground. They do not bump. The disadvantage is the high weight. Metal wheels are chosen for stony soil. To facilitate the work of the plowshares, they weigh the design and do not go off course.

Types of plows

Three varieties of plows are used with power tillers, all of which have their own application area:

Single body models

Single-hulled units. the simplest in design. They have only one share and are used for plowing light soils in ordinary garden plots, which make up the majority of the land. They are not suitable for plowing heavy soils and fallow land, but require a more powerful design.

Dual furrow plough consists of two connected frames with plowshares. It is used for tillage of different types of soils and for initial plowing of virgin lands. Can plow and harrow at the same time and provides the best quality of soil cultivation.

Reversible ploughs

Reversible ploughs differ in shape of ploughshare, resembling a feather. The plough blade with curved top turns the soil. Recommended for plowing hard, stiff soil. This type of plough is compatible with medium and heavy duty tractors such as the MTZ. The ploughshare gets its name from a device that turns the share when changing the direction of ploughing, which is useful for long plots. The direction of the plow is retained.

How to make a PLOW for a mini tractor. Homemade plow

Rotary plows

Rotary models differ from other designs: the unit consists of a set of curved plowshares, which loosen the soil, placed on the axle, driven by the PTO of the unit. The depth of soil plowing with a rotary plough is 25-30 cm, and does not require much effort from workers.

A rotary plow allows plowing in different directions, important for plowing difficult terrain. This design is popular with homeowners for tilling soil with a layer of turf or saturated with roots. Rotary plows are compatible with medium and heavy duty tractors.

Shaft and no-shoulder plows

The ploughs can be divided into two other types according to the presence of the mouldboard:

- Shaft ploughs: These ploughs are designed to plow, turn over the plowed soil and loosen it;

- Non-shafted: these are intended for loosening the soil in regions with dry and windy weather.

The disc plow: an algorithm of actions

The disc plow-tiller is used to prepare even furrows for planting vegetables. Using the drawings, you can control the course of assembly and avoid defects.

Making a disc plow is carried out according to the described scheme:

- Supporting angle as a base. Manufactured from angle with equal sides, its flanks after cooling should converge at an angle of 700;

- A sock is welded to an angle. The heel is welded with a stubborn bar;

- The jaws are secured to the support angle with hinges. The end faces of the cheeks must not touch each other when opened;

- The swivel mechanism is welded to the stop angle at right angles.

Finally, it is necessary to adjust the cheeks of the plough. They are fixed in a vise and adjusted until they point in different directions.

The plow with their own hands

After I have motolevyodka agricultural, manufactured their own hands, which is used for plowing the garden has become a question: buy a plow or make their own forces? Going through the stores and the bazaar in Moscow. Smolensk, there is a strange feeling that produced by industry plows for power tillers is a sad spectacle.

And these creatures of industry are suitable only for “picking” but not for plowing, and even with the turnover of the layer, and about the depth and width of plowing we can conclude that the potato planting with distance between the rows of 60 cm. not a single plough offered in the trade. Either our manufacturers save money, or the power of the most popular power tillers is not enough to work with a normal plough with a width of 30 cm. Not to plow the same furrow three times when planting potatoes. Yes, and (for a couple of pieces of scrap metal).

The next step is to find something sensible. searching on the internet. To my surprise on the expanse of the Russian-language network floats 3-4 original description with drawings (this fact surprises me a lot). The next step is to look at what others are using. It was impossible to buy a suitable plow, so it was decided to make a plow with my own hands. Based on the fact that the plow was supposed to be used for planting potatoes with a winch for plowing:

The plough must hold the furrow without burying itself or popping out of the furrow. The geometry of the plough must be able to withstand the movement of the furrow without the ploughman having to help him.

4.Ability to adjust the depth and width of the plow.

Minimum weight and sufficient strength.

My uncle has been using his self-made winch for more than 10 years for plowing and tried out several options, the last few years he settled on the option, optimized for self-made winch for the garden, namely, for planting potatoes with a row spacing of 60 cm. So there is also a homemade ocular for Moto-winch and potato trowel, made by his own hands, all of this can be viewed on the relevant pages of the site.

According to this template, the moldboard is bent to match the two profiles and then welded at an angle.

Using the drawing of a homemade plow, it is necessary to draw a template of the plow pattern on heavy paper, and then transfer the picture to metal and cut out a workpiece with an angle grinder. I personally used 1.8 mm thick stainless steel material. Many often use 2-3mm sheet. The cutting part of the plow is reinforced with a thicker metal strip. Some people suggest using a disk from a circular saw for this purpose, and some suggest using a spring from a Moskvich. From personal experience, if a summer cottage for a family of 4 people to plow in the spring and fall, cultivating six acres, it is not necessary to chase after svehstrekosti. It is more advantageous to make a lightweight but fairly rugged plough. It is better to make some repairs or replace something in 10 years, and that if necessary, than to drag the weighted structure of a self-made plough for all 10 years. There’s no need for extra weight.

This is how the system of adjusting the ploughing width looks like. By moving the big wheel one can change the width of plowing within a significant range. When I plant potatoes I set the working width of 30 cm, in two passes the distance between the rows is 60 cm. When plowing a vegetable garden in autumn or plowing virgin land, I use a smaller working width. The small wheel is made so wide that the plow is not pressed into the ground.

Looking at the pictures below, you can imagine the basic principles of self-made plow, or rather guiding system, which allows the plow to move without the plowman’s participation strictly along the straight line at a set depth and width of plowing. Adjustment of plowing width is made by moving big wheel which is pressed against furrow when pulling force point is shifted as shown on picture and this allows plow to repeat the direction of previous furrow. The plow turns slightly, which increases the width of the plow. The actual width of the nose in the perpendicular direction to the plough’s axis of motion is less than 300 mm, however, the indicated width is available for plowing.

The plough wheel runs along the bottom of the ploughed furrow and this situation is observed from the previous furrow to the next. As a result of the pulling force, a force is exerted to deepen the plough until the plough is on the wheel axis as shown in the figure, as a result all forces are balanced and the system works very steadily. Coarse adjustment of ploughing depth is done by selecting appropriate difference in wheel diameters, and smooth adjustment of plough tilt. At this stage there is no need to use the handles to control the plow, except for some special plowing conditions.