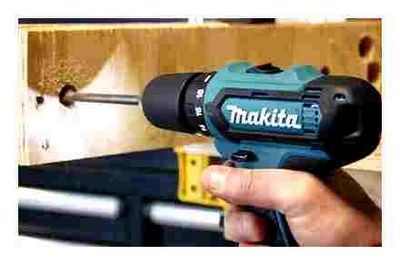

Makita screwdriver does not twist the chuck

Makita DF033DZ

The new model of the screwdriver from the Japanese manufacturer Makita immediately became one of the most popular professional tools in the domestic market. It is ideal for assemblers of furniture and frame wall systems as it weighs only 0.93 kg. The absence of a keyless chuck (designed for bits) and a lightweight 10.8 V battery. these solutions played an important role in making the Makita DF033DZ the lightest screwdriver of the brand.

At the same time, it fits perfectly in the hand thanks to the verified center of gravity and comfortable grip. There is a dot diode illumination, speed control and maximum rotation force limiter, reverse and trigger lock. in a word, all the attributes of a high-quality tool are present in this budget model. The delivery set does not include batteries and a charger, which can be purchased separately or taken from a used old screwdriver.

10 best Makita screwdrivers

Feature in the rating

When installing plasterboard structures, assembling cabinet furniture and many other types of work, such a specialized tool as a screwdriver is used. There are many offers on the market from different brands, but one of the most recognizable and popular in Russia is undoubtedly Makita.

The review presents the best models of this brand, both professional and amateur level. The rating was compiled on the basis of the technical characteristics of screwdrivers, the opinions of narrowly focused specialists and ordinary owners who use this equipment from time to time in the household.

Makita DF333DZ

One of the lightest screwdrivers with a keyless chuck, the Makita DF333DZ weighs just 1.1 kg. At the same time, he has everything you need for high-quality work. there is a dot diode illumination above the power button, there is a speed switch, a torque regulator and a trigger lock. It is sold without batteries and a charger, which is reflected in its popularity among the owners who use this tool in their professional activities.

Thus, Makita DF333DZ has an excellent opportunity to oust outdated and decently worn out models from circulation, which still retain their performance. And the owners also liked this decision. why buy a battery and a charger when the old batteries still have not exhausted their resource. In addition, purchasing a professional screwdriver at an affordable cost is the best way to update your working tool.

Makita DFR550RFE

This self-tapping screwdriver can multiply operator productivity. Makita DFR550RFE uses SPIT tape with screws tucked into it, and can withstand non-stop loading for a long time, practically without overheating and without interruption in work. Accurate and well-coordinated functioning is ensured by high quality assembly of the mechanical part of the tool.

The kit contains 2 rather powerful batteries of 3 Ah each. Li-Ion battery technology takes less than an hour to fully charge, which makes it possible to keep a charged battery ready even with intensive work. The comfortable handle and the relatively low weight of the tool (2.1 kg) allow the user to work tirelessly all day long. The manufacturer Makita has several similar models, but it was the DFR550RFE that became a member of our rating, since it is lighter than others and has a high performance. The tool comes in a handy and durable carrying case along with a charger. The complete set largely determines the decent cost of the screwdriver. a similar model (DFR550Z) without batteries, case and charger will come out almost twice as cheap.

Makita DHP451RFE

This model of a screwdriver belongs to the category of a professional tool and is distinguished by its high reliability and resistance to intense loads. The presence of an impact mechanism and a keyless chuck allows performing work on drilling concrete structures with drills up to 13 mm thick. A decent frequency (25500 bpm) determines the high efficiency of hammer drilling. At the same time, the idling speed reaches 1700 rpm.

The Makita drill / driver comes in a case and has a second Li-Ion battery with a capacity of 3 Ah. By timely charging a free battery, it is easy to maintain the constant readiness of the tool for large volumes of work. The charge is restored much faster than it is lost, even with intensive work. There is a backlight, a depth ruler and rotation speed adjustment (3 positions). In addition to all of the above, high performance, comfortable grip and average weight (2.2 kg) make Makita DHP451RFE one of the most demanded screwdrivers of this brand.

Makita DF457DWE

Today, the most popular model in the line of screwdrivers of the Japanese brand is the Makita DF457DWE. The tool is designed for fast work, it easily handles fasteners, makes accurate holes. The device is equipped with a 16-stage torque control, a quick-release chuck and an electronic braking system. The 18 V, 1.5 Ah Li-ion battery combined with a spare battery provides ample battery life. Lightweight 1.7 kg and compact dimensions are complemented by a comfortable handle, making work comfortable.

Makita DHP481RTE

The Makita DHP481RTE impact driver is equipped with an 18-volt 5 Ah battery. Having a spare battery in the kit gives you unlimited possibilities for remote work without recharging. The keyless chuck saves time on tool changes, and the brushless design of the electric motor significantly extends the service life of the device. The torque of 115 Nm has 16 modes. Combined with 2 working speeds, built-in light and rubberized grip for maximum operator comfort.

Domestic consumers managed to test the model in the most difficult conditions. The screwdriver does an excellent job of drilling hardwoods and is a favorite with winter anglers who use it to drill holes. Among the shortcomings, users note the high price and high weight.

Cam mount

To quickly disassemble a tool with this type of fastening, perform the following steps:

Sizes and decoding

In order to choose a suitable replacement option, you need to know its standard size. There is a special marking on the cone, where:

- The first numbers (through a dash). options for the size of the shank, which can be installed on the product in millimeters.

- The letter and number next to it is the calibration of the cone. Allocate 9 different indicators.

- In some cases, numbers in the form “1 × 1” may be written on the cone after the letter (numerical values depend on the model), thus indicating the thread parameters. The size is indicated in millimeters or inches.

Some products have slightly different markings (eg 4. 15 mm ½. 22 UNF). In this case, it is assumed that 4. 15 mm is the diameter of the bits allowed for use, ½ is the thread size in inches, and 22 is the number of turns in one inch.

Vise may be needed in serious cases

Which way to turn the cartridge for disassembly

Unscrewing the chuck is carried out according to the scheme, which may differ depending on the model of the device.

How to disassemble a screwdriver chuck

Depending on the attachment of the element, the method of parsing may differ.

Jammed Shut Chuck Removed and Switch Replacement. Makita BHP452. Remove and Replace

How to remove a chuck with a tapered mount

If the fixation of the chuck is carried out as a Morse taper, then the impact of a hammer will be required. With its help, you need to carefully knock the shank out of the housing socket. If this method does not help, then carry out the following actions:

- Disassemble the screwdriver.

- Take out the shaft with the gearbox and the chuck.

- Pull out the clamping cylinder using a pipe wrench.

If none of the methods helps, then you can try to completely disassemble the products and remove the element in the process.

Features for single-sleeve fasteners

To remove a cartridge with one sleeve, it is recommended to use a screwdriver or knife to separate the sleeve. Then they remove the ring, which is pressed onto the body. carefully knock out with a bolt, and then squeeze it with cams. Then, with a quick push, squeeze the ring out and disassemble the part.

Subtleties of disassembling double-sleeve fasteners

For double sleeve chucks, the process of how to remove the bit from the screwdriver is similar, you may need to do more.

For reference! If the cartridge does not lend itself, then it is permissible to use a rubber mallet. But you have to beat very carefully.

The new element for replacement must be similar in all characteristics.

How to remove and change the cartridge

Knowing how to unscrew the chuck on a screwdriver is necessary not only for repairs, but also for servicing the device. Periodic cleaning will extend the life of the instrument. The methods depend on each specific manufacturer. However, there is one more popular option.

For the procedure, you must select a hex wrench. The parsing process is as follows:

- The short end of the key is well clamped in the chuck.

- Turn on the screwdriver so that it works until the key hits the table.

- The chuck rotates along the internal thread on which it is attached to the shaft.

The cartridge in different models is removed in different ways

Scheme 2

Repair of the gearbox of the Makita screwdriver (diagram)

To remove the gearbox, you need to disassemble the case by unscrewing the screws with a Phillips screwdriver. We take out the start button, the reverse switch button, disconnect the bolts securing the engine to the gearbox. Then you need to take out the contents of the gearbox (various gears), the speed selector washer. When examining an empty gearbox, special attention should be paid to the teeth located around the circumference of the gearbox housing. If they are worn out, the gearbox will not be able to perform its function: the speed switch will not work correctly. To restore the teeth, it is necessary to use small bolts, inserting them in place of the original plastic ones. The gearbox must be assembled in the reverse order. The gearbox diagram is shown in the figure below. It shows a general diagram of the gearbox.

Repair of the chuck and other parts of the Makita screwdriver

In this article, we will consider a screwdriver from the well-known Makita brand, describe its technical characteristics and general device, talk about the main problems and malfunctions that arise during the operation of the tool, as well as how to diagnose a breakdown and repair one or another element with your own hands. screwdriver.

Brushes for the Makita screwdriver

The brushes used for the screwdriver are graphite-based. Their cost today varies between 2–5 USD. e. They are located in the motor housing and are two graphite cubes fixed on metal plates. With intensive work, they wear out and wear out.

For DIY repairs, you can file them out of brushes from another tool, such as a car starter, with a file. After grooving, they should be inserted into the brush holder and put in place by assembling the motor.

Screwdriver “Makita

Repair of the button of the screwdriver “Makita”

The on / off button of the instrument is a complex electronic mechanism. It consists of several elements that make it up:

- start buttons;

- reverse buttons;

- buttons for switching the speed of revolutions;

- soft start buttons.

When repairing a button, you first need to disassemble it by unscrewing the screws that secure the case and disconnecting the battery. After that, you must check the connections and contacts for dirt, clean them. If cleaning the contacts did not help to fix the problem, the button should be replaced as a complete.

“Makita” screwdriver battery repair

When repairing the battery with a Phillips screwdriver, unscrew the screws that secure the case. There are several cans inside the case. Visual inspection should be used to inspect them and identify abnormalities in geometry such as bulging, for example. We test the banks with a multimeter for residual charge. If it is absent, the bank is replaced with a new one.

Malfunctions of the Makita screwdriver

The most frequent breakdowns of a Makita screwdriver are as follows:

- The screwdriver does not turn on. Here and so everything is clear. The first step is to inspect the battery, as well as contacts and connections in the case, wiring. A multimeter will help you to check.

- The reverse button does not work. This means that you cannot either tighten or remove screws and bolts. Here you have to check the resistance of the button with a multimeter by placing probes on the input and output wires of the button.

- The speed regulator does not work. In this case, the revolutions will either be constantly lowered or constantly overestimated. The regulating transistor or brushes may be to blame here. Visual inspection of parts required.

Breakdown reasons

The simplest cause of breakdown is a worn out battery, which under load is not capable of delivering the required current. In this case, it is enough to purchase a new unit, charge it, connect and turn on the instrument.

Another cause of failure is exceeding the permissible loads, carelessness with the screwdriver or wear of spare parts, as a result of which the gears of the gearbox have become unusable. To do this, you will have to carry out repairs, and before that, check if the necessary spare parts for the power tool are available on the manufacturer’s aziatool.com or not.

The third cause of breakdown is the burnout of one of the motor windings or the wear of the brushes. In this case, the spindle without load may sometimes not even start, since the initial torque does not develop to crank the gearbox. Complete replacement of motors or brushes in a circle will solve the problem.

If there is audible noise during gear shifting, you should also pay attention to the alignment of the shafts, the presence of external damage to the gears, foreign objects inside the mechanisms.

The history of the appearance of the device

A screwdriver is a power tool. Its main purpose, following from the name, is to twist or unscrew the fastener. After the electric drill was invented in 1868, the development of the power tool became widespread. Founding companies DeWalt, Bosch, BlackDecker, Makita and Hitachi pushed the industry forward with new devices.

The advent of the Phillips screw in 1934 created a demand for an electric tool for tightening it. It turned out to be especially in demand in mechanical engineering. The first such device was called a wrench. With the advent of batteries, the device gained mobility, and the name screwdriver came into use. Its mass production began in the early 80s.

Modern devices are constantly being improved, but to a greater extent this relates to the method of autonomy and control. The design of the device remains unchanged.

Where to repair an electric motor?

Types of malfunction

Typical cases in which the chuck of the Metabo, DeWALT, etc. screwdriver wedges:

- when trying to use a drill of the maximum permissible size, the cams are bred to the maximum, after which it is impossible to bring them together with the application of regular efforts;

- it is not possible to remove the drill or bit clamped in the chuck. the jaws do not open. Often at the same time they are clamped unevenly, which worsens the fixation of the drill.

Less often, the jaws jam during their free stroke when compressed or unclenched. usually this is facilitated by particles of debris, scale, shavings, etc., caught under the shaped part of one of the cams.

Drill Repair. Removing a Stuck, Seized, Stripped or Stubborn Chuck (Makita LXPH01)

Runout of the screwdriver chuck

The runout of the screwdriver chuck indicates that there is a problem with the gearbox of the tool, which is located just behind the electric motor. This is another reason why a full recoil screwdriver does not work.

Screwdriver Planetary Gearbox Parts

The output shaft of this gearbox is the place where the chuck is attached, so if we talk about the runout of the chuck itself, one must bear in mind the runout of the gearbox shaft. The reasons for this may be the following:

- a) bending of the gearbox shaft;

- b) wear of the gears of the reducer;

- c) failure of the support bearing of the gearbox shaft;

- d) the limiting development of the pins on which the planetary gear satellites are attached.

All of the above parts are of factory origin and cannot be repaired. The problem of the beating of the screwdriver chuck in this case is solved by replacing the gearbox parts with new ones.

Screwdriver motor malfunctions are not much different from similar problems with an angle grinder, drill and other power tool. The first thing that can be the reason why the screwdriver does not work is the wear of the electric motor brushes, which can be easily replaced with new ones that are not very expensive. The second reason is the failure of the armature or stator winding of the motor.

The appearance of the electric motor of the screwdriver

Most often, an interturn short circuit occurs due to a violation of the insulation of the winding wires. A short circuit can occur due to overheating of the electric motor from, so to speak, overwork, that is, you need to let the tool cool down in time, give it a “rest”.

By the way, overheating of the screwdriver can lead to leakage of lubricant from the gearbox, which will lead to the failure of its main parts, which were mentioned above.

Another problem can be observed in the armature of the electric motor: contamination or oiling of the collector, which transfers electricity to the motor from the brushes.

Electric motor brushes and screwdriver

The collector can be repaired at home on your own by rinsing and cleaning it with fine emery cloth. But the stator and armature windings will have to be restored in a specialized workshop or the motor will have to be completely replaced with a new one.

In conclusion, I would like to note that the screwdriver will work for a long time and efficiently if you treat it carefully, without showing “fanaticism” during its operation.

Finding the cause of the breakdown and its elimination

The final breakdown of the instrument is often accompanied by preliminary events, paying attention to which a serious malfunction can be prevented: the appearance of extraneous sounds, sparks, burning odors, increased vibration, rapid battery discharge.

Having disassembled the device, you can understand which node is faulty. All device problems are divided into two types:

- electrical;

- mechanical.

Each type is characterized by its own primary signs, by which the damaged part is easily calculated. Battery malfunctions are of a special kind. The nature of the breakdown is due to the fact that the battery is quickly discharged, or the device does not want to start at all.

If purchasing a new battery is problematic, you can try to disassemble it and replace the defective element in it.

How To Remove The Chuck From A Makita Cordless Drill

The battery is disassembled by removing its latches from the grooves. Elements with a container are located under the casing. Their connection is made by contact welding. A multimeter can measure the voltage on each bank. The normal value of a charged cell is 1.2 volts. Defective elements are removed. for this they are carefully bite off with pliers at the point of contact, and similar ones are installed instead. If there is no welding, it is possible to use a soldering iron. Then the battery must be assembled and installed in a screwdriver to check.

But the problem is not always related to the battery. For example, when repairing a Bosch screwdriver with your own hands, damage to the charger circuit (charger), and not the battery, is often found. Repair of the memory consists in dialing the radio elements. First of all, the mains fuse and the rectifier bridge are checked.

Usually, when you open the memory case, by external signs in the form of blackening of radio elements or a PCB board, you can immediately see which element needs to be replaced. Most often, the transistors, which are located on the radiators, and the operational amplifier fail.

The screwdriver does not turn under load. Why the screwdriver does not work, stopped working