Manual cultivator for the garden with their own hands

How to Make a Cultivator

Every dacha owner is familiar with all the difficulties of cultivating garden crops. And the most tiring part of all is cultivating the soil before planting and caring for your garden plants. To simplify your life, it is enough to make a homemade gasoline or electric cultivator for dacha, which will be used for various agricultural tasks.

Before proceeding with the assembly, it is necessary to understand the types, device and principle of operation of garden devices.

Depending on the type of engine, there are electric and fuel-powered cultivators. The first are characterized by environmental friendliness and low energy consumption. However, they are tied to source of electricity, so they can be used only in greenhouse conditions or in a small garden that has access to electricity. It is easy enough to make such a unit.

Models with internal combustion engines are superior to the previous type in terms of power and the ability to work without connection to the power grid. But maintenance of the machine becomes more expensive, and during operation harmful exhaust gases are emitted.

According to the method of tillage, homemade motocultivators are either self-propelled, equipped with powered wheels, or with a rotating working nozzle, which can be used as a means of moving.

The first version involves two gearboxes. The first one helps the mechanism to move at a predetermined speed, while the second one performs the rotation of the rotary nozzle for soil treatment. If there are driving wheels, the cultivator is additionally equipped with knives-ploughshares.

There are also simplified homemade, where the wheels only rest on the surface, making it easier to move.

From the starter

If there is an unnecessary starter from the car in the home workshop, it can be used to create a primitive version of a power tiller. To do this, you need to shorten its shaft and slightly modify the front cover, making a few holes in it with a diameter of up to 5 mm. This is necessary for the air intake from the ventilation system. Then the prepared starter is combined into a single unit with cutting elements (cutters).

Almost finished installation is fixed to the working platform of the cultivator and tested for operation. Make an electric trimmer with your own hands from a starter can be made in a couple of hours and with minimal financial outlay.

From an angle grinder

A variant of self-made mini-cultivator from an angle grinder is not characterized by high productivity, but perfectly solves the problem of weeding a small area with light soil. angle grinder in this homemade invention plays the role of an electric drive. The other parts and components can be taken from an old non-working cultivator.

An angle grinder is fixed to the frame created from improvised means or taken from an old frame, as well as an extension cord on a spool for connection to a power source.

After the basic elements are assembled, you can test the machine. If done right, the cutters will deliver up to 300 rpm.

From a washing machine

Folk craftsmen master the cultivator from an old, unnecessary washing machine, which still works, but can no longer be used for the main task of washing. Remove the motor from the old equipment. It will serve as the basis for the future cultivator and give the washer a second life.

In addition to the power unit, you will need to find a two-wire wire, a reducer, a three-meter metal angle, switches, car springs, a start button and a drum with a piece of tin.

Having prepared the necessary elements, you can proceed to the installation work. Initially, welding is carried out, and then the preparation of the cutting elements. It is important to ensure that each blade does not overlap with any other.

To the motor itself, the starting and working windings are connected. The first one is only needed to start the appliance, and the second one is used all the time.

After completing the above steps, you can begin testing the device.

From an old bicycle

No less interesting self-made is a manual cultivator from a bicycle. To make such a device you need to prepare a metal tube, a frame and a bicycle wheel. You will also need metal blanks, steel strips, a drill, an angle grinder, and a cultivator head.

Assembly work consists of the following steps:

- The head of the cultivator is attached to the frame from the bicycle. The crossbar and handles are made from a metal tube. They are connected by bolts.

- Then we use locknuts. They will be needed to fix the wheel on the frame.

- After completing these steps, the mechanism can be considered ready. This cultivator can be connected to a plow and other attachments that make it more functional.

From a chainsaw

Create a motokultivator with their own hands can be made from a chainsaw. Powerful chainsaw of domestic or foreign make is used as a basis. It is advisable to take the model “Druzhba”, t.к. It is cheaper than imported devices and has the required characteristics.

Garden helper on the basis of “Druzhba” accelerates to 2.5 km/h, and the power value is equal to 4 liters. с.

A step by step guide to assembly is as follows:

I’m BUILDING CULTIVATOR for tractor

- The main halyard is fitted with a collar. This is necessary for the subsequent connection of the axle gearboxes.

- Next, the sprockets are taken (can be from an old UAZ) and the double-row chain. Parts are needed to raise the distance from the axle with the gearbox to the ground. The timing sprockets are capable of increasing the distance by 15 cm.

- The key axle is fitted with housing bearings and a gearbox.

- To fix the cutting elements it is necessary to use a tube of steel. It is important to make sure that the direction of the cutters corresponds to the movement of the power tiller.

- After completing the assembly work, a weight is attached to the frame, which can hold the center of gravity.

- For convenient operation of the machine, it is equipped with handles.

The last step is to check the homemade cultivator for proper operation. If there are any defects or malfunctions, have them corrected.

From the grass trimmer

There are different attachments on the brushcutter that turn it into a potato digger, a device for making furrows or plowing the soil. Self-made cultivators on the basis of the grass trimmer are in particular demand for hard-to-get-at places, where it is impossible to work with a large power tiller with a trailer. The optimal variant is a handmade device called “Hedgehog”. Assembling simple parts and elements, “Hedgehogs” can be made by yourself. All that is needed is a U-shaped bracket with holes, a shaft, a cutterbar, and spiked wheels.

To move the device properly around the garden, it must be equipped with good wheels. To do this, you can take old pancakes and equip them with metal spikes. The spikes are made of rebar, sharpened in the shape of a cone. The ready-made cutting elements are attached to the axle, then it is inserted into the bracket and secured on both sides.

To the ends of the bracket, a mount is welded and inserted into the cutter. It remains to check the unit for malfunctions, eliminate them (if any) and start weeding the rows.

From a drill

Annual work on the garden brings many troubles and difficulties to dacha owners. To save time and effort, many craftsmen invent semi-automatic devices that provide efficient processing of soil and garden crops.

To create a compact el. For a cultivator with good KPI values (key performance indicators), you can use a construction drill. This version is suitable for weeding potatoes and performing simple agricultural tasks.

Cultivator models

There are three types of cultivators according to the feature of actuation:

- petrol ones;

- electrical;

- actuated by physical force (it is a cultivator of this type is easiest to make their own hands).

Depending on the function and design there are rotary cultivators, rippers and even miniature hand cultivators for houseplants.

Sprocket / rotary cultivator

This unit has the following design: discs (that’s why it is also called a disc cultivator) of star shape are put on a metal shaft, which plunge into the ground when rotating the shaft. The result is loosening the soil and uprooting harmful weeds (i.e. performs a dual function). The range of use of the rotary cultivator is vast. it can be useful in the treatment of lawns or flowerbeds, potato beds or the root zone of young trees.

Loosener

The Tornado is a classic example of a tedder. The device is surprisingly simple: the working part in the form of spiral-shaped sharpened teeth is attached to the shaft with a long perpendicular handle. The work is activated by turning the handle, which plunges the tines into the ground and removes them by loosening the soil. Even compacted or overgrown soil can be loosened with the rotary cultivator. In contrast to the star trimmer is used mainly for the treatment of small problem areas. Compared to other designs of this type, it is the easiest to make a manual soil ripper with your own hands.

Root Cutter

Both “Tornado” and hedgehog cultivators can be used as a root pulverizer. Working part of the hedgehog is represented by rotating steel bars. This part is attached to the cutter (with or without attached perpendicular manual). Like the “Tornado”, the hedgehog is used not only for extracting roots of weeds, but also for inter-row loosening, which is accompanied by compact dimensions of the working part.

Potato harvester

Domestic market agricultural equipment offers a lot of constructively different potato weeders (mostly vibrating, working as a hitch motoblok). A special niche is occupied by manual potato diggers used for moderately spacious areas. The work is carried out thanks to the two axes with teeth (one of which is stationary and serves to establish a support, while the other, when pressed, ejects undamaged tubers). You can make such a simple construction yourself from a fork.

For potted plants

A cultivator for houseplants is a small trident with pointed, curved teeth. This device can easily be made yourself, using a sturdy wire. The handle can be made of decorative materials or decorated to any taste.

What a cultivator can be?

Despite the fact that the most popular and in demand is a hand-held device, when choosing cultivators, it is necessary to remember that they come in several types. At the same time, they vary greatly in price, and may have some advantages to work in a particular situation.

One of the most comfortable variants is considered to be a rotary. This design, which consists of 4 identical discs that rotate when the cultivator is engaged in work. In addition, there is a moving knife, brackets, handle and handle with additional wheels.

When using such a design there is no need to hold it in your hands. Cultivator moves due to auxiliary wheels and discs, which immediately loosen the soil. In this configuration, the device can not only prepare the soil for further planting, but also rid it of weeds. This is a very convenient option for those who have a fairly large plot.

Those who use a little land for planting or are planning to buy a device to work in greenhouses and hothouses should choose a cultivator class mini. This is a small device, which is convenient to work on small areas and loosen the soil near bushes and trees. In addition, mini cultivators for dacha are suitable for the express removal of weeds in flowerbeds.

If the work is large, and the area of the site is not limited to 6 acres, it is worth choosing cultivator gasoline. This is already a single-axle tractor, but in the simplest version. It works quickly and is able to dig out soil up to a depth of 150 mm. It is convenient to use not only for loosening the soil in the garden, but also for landscaping the yard area.

Gasoline cultivators, unlike most manual cultivators, can handle even the toughest soil. At the same time, they remove weeds, roots and other unnecessary elements from the soil.

If the task of a gardener is only to loosen the soil in spring, it is possible to use a minicultivator-roller. This is a simple option that can be compared to a rake. The handle will have several pointed prongs at the end, which penetrate the soil and loosen it perfectly, while allowing you to dig out weeds that are not too deeply rooted. Such a ripper will be a great helper when taking care of flowerbeds and even houseplants.

One of the popular variants of such an opener is the Tornado. This is a device that not only qualitatively plows the top layer of soil, but also quickly removes a large number of weeds. Its peculiarity is the tines, which are directed in different directions. Due to this, the cultivator works quickly and qualitatively performs its task. Tornado can loosen the soil to a depth of 20 cm, which is considered an excellent indicator.

The most expensive models belong to the electric class. They are quite maneuverable and suitable for the lawn, that is, its planting, perching bushes, trees, processing beds. But when buying such a device, you need to pay attention to such a point as the presence of a battery. If the possibility of autonomous work at the cultivator will not, you will have to use a cord, that is, the device will not be able to function in the vegetable garden, which is located away from home.

Consider options on how to make a homemade hand cultivator

Ploughshare. It is a mechanized version of the ordinary hoe.

Rotary star. The principle of operation is to cut the soil alternately with flat knife-like elements.

Hand-held hedgehog cultivator. The design is similar to the star, but the ground pierce not knives, but sharp steel bars, similar to porcupine needles.

Tornado. Fork with teeth twisted into a small spiral. Cannot be mechanized, it just needs to be poked into the ground.

What cultivators are there

Tilling the land began quite a long time ago. When vegetable gardening was at its peak, hand-held cultivators were especially popular. Tools were purchased in the factory version and made with their own hands. Especially popular today are these types of hand-held cultivators:

- ploughshare. The product resembles a traditional trowel, but is a mechanized version;

- star. The operation is reduced to the sequential cutting of the soil by the sprockets in the form of knives;

- hedgehog cultivator. The principle of operation is similar to the previous version, but the soil is loosened with steel rods in the form of a porcupine;

- tornado. The tool is similar to an ordinary pitchfork, but only the bars are used twisted.

Cultivators can be used for a number of tasks, such as:

- Loosening the soil, making it breathable;

- Cutting rows for planting vegetable crops and the subsequent consolidation;

- removing weeds;

- breaking up large clods of earth and leveling the ground.

Features of hand cultivators

For working hard-to-reach places or where a more accurate approach is required, the manual rotary cultivator is well suited. It is driven by human effort.

Through hedgehogs copes with fluffing and loosening the soil. Also turns out ground strata, which helps control weeds.

There are also star cultivators, which remove the roots. They are usually easy to use, they replace the shovel, making digging up much easier.

A manual cultivator is designed for:

- loosening the soil;

- Recultivating the soil for further planting

- removal of weeds with the root;

- treatment of areas under trees, bushes;

- enriching the soil with oxygen.

Mini-cultivators are well suited for small plots, they do not take up much space, it is easy to move them because of their low weight. Suitable for loosening the soil under trees, bushes and in hard-to-reach places. Facilitation of land works is due to the proper distribution of the load on the muscles and the location of the person at work.

Homemade power tiller: let’s disassemble it together

Assemble a functional cultivator with their own hands is simple enough. Talented craftsmen create it from improvised means with minimal financial costs. With the right materials, time and desire to make such a device for dacha can be a couple of weekends.

Homemade manual cultivator for the garden

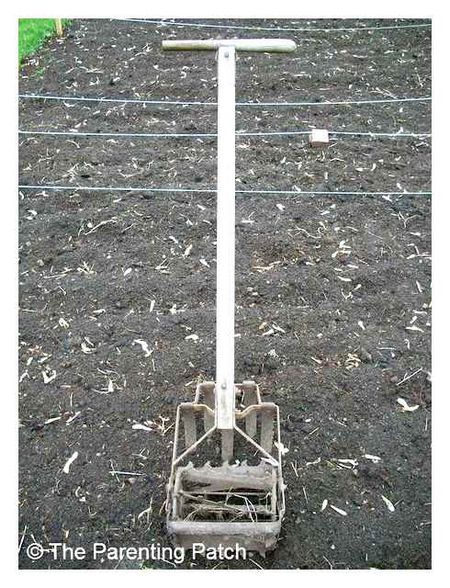

Cultivation, as you know, is the loosening of the upper layers of soil, with the simultaneous cutting of the roots of weeds growing in it. Devices that are used for this purpose are called cultivators. The figure below shows how to make a home-made cultivator for the garden, if buying such a device is difficult for some reason.

Makeshift hand cultivator for the garden

The main parts of the home-made hand cultivator are a wheel (1 on the picture), axis, two handles made of pipes (3) with the spacer (4) inserted between them, brackets (5 and 6), designed for mounting a tool changer and a tool changer itself (7 and 8).

Fix the arms to the frame, made of pipes, with bolts M12. The wheel should be 25-30 centimeters in diameter, and its rim should preferably be made of a steel strip 4 centimeters wide and 4 millimeters thick. The wheel must be equipped with 6 spokes of steel bars with a diameter of 8 millimeters and a hub with an existing hole in it for the axle, a diameter of 18 millimeters. The spokes are connected to the hub by threads, and to the rim by rivets.

If it is difficult to make such a wheel for a homemade hand cultivator, you can use a ready-made wheel, for example, from a children’s bicycle or baby carriage.

Cultivator handles are made from steel pipe, which diameter is 22-30 millimeters. A sleeve is welded to the lower ends of the handles, which connects the pipes to the axle. However, you can connect the handles of the cultivator to the axle in another way:. the ends of the pipes are simply flattened to a length of about 60-70 millimeters, and holes are drilled in them for the axle. The hole diameter is 14 mm.

The spacer is made from the same pipe that was used to make the handles. It is connected to the handles with four M8 bolts. In order to make the handmade self-made cultivator more convenient to use, a rubber hose is put on the bracket, and an insulated electric wire is wound around the handles, which are held by.

Arms, on which a replacement tool will be attached, are made of square steel bar with 25×25 mm cross section. A steel sleeve with a locking bolt is welded to one of them.

Interchangeable implements home-made hand cultivator for the garden. these are winged legs (7), which should make five with different working width (6,7,8,9 and 10 centimeters), and a tooth ripper (8). Various interchangeable tools are installed on the cultivator, depending on the size of row spacing in the garden and the type of agricultural work.

Construction and working principle of a cultivator

Most of cultivators have approximately the same design. They have a frame and implements. These can be milling blades, discs, tines, etc. Also, there are pivoting or supporting wheels (mounted models do not have them); a system for fixing the working tools, mechanisms to adjust the depth of their movement. With a special device, the cultivator can be transferred to the transport position from the working position.Tillage machines have a device by means of which working tools are installed on a specified inter-row area, as well as a mechanism that allows to control the motion of the cultivator. The working principle of the cultivator depends on what working parts it has.Foot cultivators allow you to prune weeds, loosen the soil and fertilize, and dip plants. If the cultivator is equipped with smooth serrated discs, it allows you to work the soil in clearings. Cultivator with needle-shaped discs rotating horizontally breaks soil crust and loosens soil in the protective zone and plant rows.

Rotary impellers and frame-wire impellers loosen the soil, destroy vegetation (grass) in the rows. Finger. loosen the soil, kill weeds.