Manual wood jigsaw how to use

How to saw a circle with a hand jigsaw

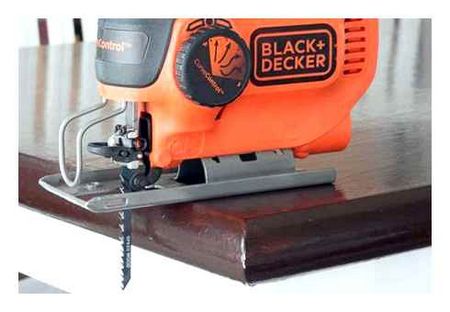

The hand jigsaw is of limited use for circular sawing because the frame-holder prevents the jigsaw from moving relative to the workpiece. If you start with the edge of the workpiece, you can only cut a few centimetres before the frame-holder hits the edge of the workpiece. Therefore, the hand jigsaw is used for sawing, not by moving the tool over the workpiece, but vice versa. The jigsaw blade stays almost in place, and the workpiece is moved toward it. Example on the picture:

Wood instead of plywood

For all the advantages of plywood, this material has a disadvantage. It is an industrial material, not completely natural like pure wood. In addition, plywood is made primarily from birch, which does not have the beautiful texture, fiber patterns and color that some other woods have. Therefore, even highly artistic products made of plywood do not have the same appeal and charm as purely wooden.

Before the mass production of plywood began, all carving was done on wood. Many vintage pieces are still intact, so wood is also well suited for artistic jigsaw carving.

In this case, you must be prepared for the workpiece to crack or warp during or immediately after work. To avoid this, you should use only well-prepared wood:

- completely and evenly dried throughout the entire array;

- sufficient time for all internal stresses in the form of cracks and warping to show up.

How to choose a jigsaw?

It is good when there are older friends, who already have experience working with this tool. they and a model, suitable for the price, will prompt, and advise a set of replacement tools, and even directly help with the choice of the model. The temptation to stop at the drive versions, such as battery-powered jigsaws, is great, but you should know that beginners should not use electric jigsaws. There are a number of reasons for this:

- Lack of practical skills often leads to fast breakage of saw blades, because they poorly absorb any bending loads.

- Driving jigsaws are more often purchased by craftsmen engaged in mass production of figured wood and plywood crafts.

- It is impossible to cut a complex profile with an electric jigsaw.

- The primary skills of sawing with a hand jigsaw on wood are already fixed at the level of manual labor lessons at school, so mastering the tool will go much faster.

So, a hand jigsaw is a tool that disposes to unhurried, thoughtful and quiet work somewhere in the cottage, or on the balcony. a good alternative to the mechanized options.

The first thing is to choose the hand jigsaw correctly. The selection criteria are usually:

- The shape of the frame: depending on its configuration it will become clear what is the maximum cutting length. Jigsaws with frame lengths up to 300 mm are commercially available, which significantly expands the technological capabilities of the tool, but also leads to an increase in its weight and dimensions. For home masters, who have no experience in shape sawing, it is worth to buy hand jigsaws with a frame length of not more than 150 mm.

- frame material: when pressing the bow, the frame should spring, which is a good sign of quality. such a frame will not break when a noticeable transverse load is applied to the hand-held wood jigsaw.

- Frame height: based on strength considerations, this parameter should not be more than three times the length, otherwise the stiffness of the jigsaw will decrease, and the quality of the miter saw will be unsatisfactory.

- The way of tensioning the saw blade: the wing nuts with different lengths, which in turn depends on the thread diameter, are usually used for this purpose. As the diameter increases, the length of the nut’s tendrils increases, making tightening more comfortable. The presence of holes in the tendons increases the accuracy of fixing. Nuts should not be cast, but stamped.

It is good when there are older comrades, who already have experience with this tool. they and the model, suitable for the price, will prompt, and advise a set of replacement tools, and even directly help with the choice of model. The temptation to settle for powered versions, such as battery-powered jigsaws, is great, but you should know that beginners should not use electric jigsaws. There are a number of reasons for this:

- Lack of practical skills often leads to a rapid failure of the saw blades, because they poorly absorb any bending loads.

- Driving jigsaws are more often purchased by craftsmen engaged in the mass production of shaped articles made of wood and plywood.

- It is impossible to saw a complex profile with an electric jigsaw.

- The basic skills of sawing with a hand jigsaw are already fixed at the level of manual labor lessons at school, therefore mastering the tool will go much faster.

So, a hand jigsaw. a tool for unhurried, thoughtful and quiet work somewhere in the countryside, or on the balcony. a good alternative to mechanized options.

The first thing to do is to choose the right jigsaw. The selection criteria are usually:

- The shape of the frame: depending on its configuration it becomes clear what is the maximum cutting length. On sale there are jigsaws, the frame length of which reaches 300 mm, which significantly expands the technological capabilities of the tool, but at the same time leads to an increase in its weight and dimensions. For home masters who have no experience in shape sawing, it is worth to buy hand jigsaws with a frame length of not more than 150 mm.

- Frame material: when pressing the bow the frame should be springy, which is a good sign of quality. such a frame will not break when applying noticeable lateral loads to the hand-held wood jigsaw.

- Frame height: based on strength considerations, this parameter should not be more than three times the length, otherwise the stiffness of the jigsaw will decrease, and the quality of the miter saw will be unsatisfactory.

- The way of tensioning the saw blade: usually for this purpose the wing nuts with different lengths are used, which, in turn, depends on the diameter of the thread. As the diameter of the nut increases, so does the length of the nut’s tendrils, which increases the convenience of tightening. The presence of holes in the tendrils increases the accuracy of fixing. Nuts should not be cast, but stamped.

How to carve wood with a hand and electric jigsaw: the process of sawing, a step-by-step guide for creating a cutting board

Interior and exterior decorations, carved shelves and photo frames, window casings, decorative elements and entire paintings can be created by yourself. sawed with the help of tools. Wood carving with the jigsaw is available to everyone. you just need to apply a little patience. Below we will tell in detail about this kind of art. about the tools that will be needed for work, about the stages, we will analyze the mistakes of novice craftsmen. We will touch on safety techniques, and, step by step, consider the stages of making a chopping board.

How it works

Jigsaw for metal manual means that it can handle alloys no thicker than 1 cm.

The strength of the material will not allow you to work with great speed, not enough physical strength of the master. Steel saw for this finish choose a steel saw with high m in the alloy of carbon and fine teeth. But no matter what kind of work is to be done, the principle of the jigsaw is the same.

If a worker saws with a simple log saw, the sawing takes place while the tool is pushed away from the body of the worker. The jigsaw cuts the object backwards, when the master pulls it towards himself. The beginning of creative actions consists, as in any sphere of production with preparation of a workplace, fastening of a necessary cloth in a frame. Processing is performed in the following order:

- select a workpiece, determine the configuration of the cutout, if necessary translate the scheme of the figure on the surface of the product through a copier or a pencil to score the contour;

- fix the base on the workbench or table top with clamps, fix the part to it and start sawing.

The worker sits comfortably himself, holding the jigsaw with the handle down. The tool must be in a vertical position, moving freely from top to bottom. If the clamps hold the blade firmly, there will be no shifts along the mowing line of the saw. When it is necessary to change the direction to make a curved configuration of the pattern, move the workpiece, the executive mechanism remains in an unchanged position. To cut a sharp corner, cut until the saw starts to turn freely, otherwise under the applied force it is possible to damage the quality of the pattern and the blade itself.

When forming patterns in the center of the workpiece make a mark, a hitch to start the work.

Drill a small diameter hole with a drill, then insert the frameless blade, then attach the base with the handle and begin sawing. The craftsman will distribute the dimensions so that no chipping occurs. After completing the work with the jigsaw, the kerfed places are sanded with sandpaper, the figure is varnished or painted.

Types of hand tools

The tool consists of 3 elements: the handle, the frame and the saw. When choosing a jigsaw, the material of the frame and handle, the weight of the product, the quality of fastening elements, the type of blade and design features are taken into account.

For wood

To work comfortably in wood you need to pay attention to the following:

- It is necessary to choose the right frame shape for the task at hand. For example, a rectangular or pointed form of the tool can be used.

- The wood jigsaw should be lightweight. Lightweight tools reduce stress and hand fatigue when doing painstaking sawing. Tools with an anatomical handle should be chosen. Such models are more often found in the range of foreign manufacturers.

- The strength of the frame is important. It is recommended to give preference to titanium or steel jigsaws. The aluminum blade is not very strong, and will change position in contact with the material.

Comfortable use depends on the design of the clamps. When choosing between the nuts and the reels, it is better to give preference to the latter option. No wrenches are needed to change the blade in this case, since they would be much easier to handle with a hand tool.к. these clamps are easy to unscrew.

For metal

Metal pieces up to 1 cm thick can be handled with a manual tool. Cutting speed is slower than for wood. Choose a tool with a blade of high-strength material. Metal saw blades are made from hardened high-carbon steel. The most effective work with a fine tooth.

Jewelry

When performing a decorative sawing, a jeweler’s jigsaw is used to make fine mitered lines and curves. It differs from standard models in its lightness and small size. In this variant the frame is sliding, has a clamping connection. This design ensures a strong stretching of the webs.

In jewelry work, decorative wood carving jigsaws use thin jigsaws that often tear. Due to the structure of the tool, the longer piece is inserted into the tool to continue working.

For additional carving tension in some models, the frame is located in the opposite direction from the handle.

How to choose a jigsaw?

When choosing a hand tool, you need to focus on:

The first determines the maximum cutting length.

The second is responsible for the possibility of quality tensioning of the saw blade.

Weight. The parameter affects the comfort and duration of work, because it determines how often and how much the hand will be tired.

Type of clamps, their quality and usability.

How to use a Jigsaw. Basics

Determines the speed of removal and insertion of the blade, which you have to do often when cutting holes.

It is preferable to choose jigsaws with embossed surfaces and hardened inserts, as this affects the reliability of fixation.

Thin saws allow you to cut complex geometric shapes, but it is difficult to control the cut.

Design features of the tool and possibility of using additional accessories.

When choosing an electric tool, the following parameters are decisive:

Power. affects the work speed and efficiency in general.

Weight. determines how long you can work with the tool before your hand gets tired.

Larger. the faster you can cut.

The clamp can be bolted or with a clamping device.

The latter option is more practical and convenient.

Among them may be the working space illumination, the possibility of connection to a vacuum cleaner, the frequency regulator.

The latter is a very useful addition, because when working with some materials the speed of the saw blade movement requires precise adjustment.

How to choose?

In order to choose the right jigsaw of the manual type, it is necessary to pay attention to several factors that are important for the peculiarities of the tool’s operation.

- Shape. They can be rectangular or pointed, and each is used for different types of sawing.

- Tool weight. Work with a hand tool is usually quite long and laborious, so the hand gets tired very quickly. That is why you should give preference to small models with ergonomic handles. Optimally, if the shape of the handle is anatomic, that is corresponds to the curves of the human palm (it is much more convenient to use them).

Keep in mind that lightweight models in most cases are produced abroad, domestic manufacturers are increasingly offering tools that have a very solid weight.

- Jigsaw frames can be aluminum, iron, titanium or steel. If you need a durable and strong tool, it does not make sense to choose jigsaws with an aluminum frame, because the strength of this metal is not great. It is better to give preference to titanium or steel versions. They, of course, are much more expensive, but they can cope with heavy loads, last much longer, and the work process itself is much more comfortable.

- The tool’s clamps can be represented by nuts or drums. The second option is considered more preferable, as it determines the most comfortable work with such a jigsaw in this case does not require any additional devices, such as wrenches to replace the blade. All you have to do is simply unscrew the drum and then replace the blade manually.

- The company that makes them is. Chinese tools are cheap, but you should not buy them because their service life is usually very short. Professionals recommend working with products of world famous brands Stanley and Intertool, Mastertool as well as Topex. These companies have long and firmly established themselves in the market as manufacturers of the highest quality reliable sets of locksmith tools.