Motobobok plow Preparation for work. How to install a plow on a single tractor

How to plow a plow on a walk.behind tract?

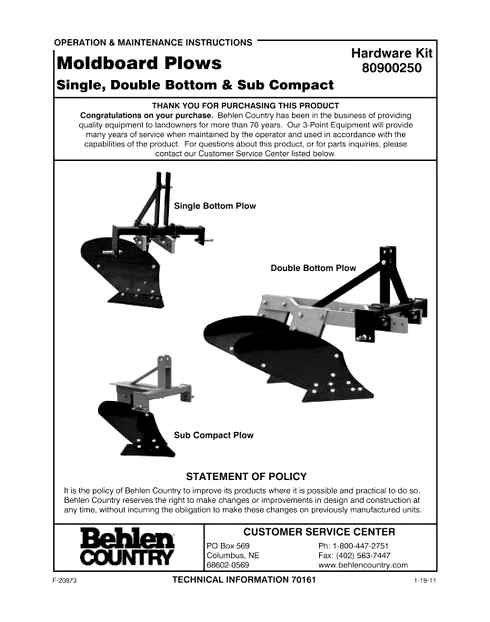

The uniform tractor is a universal unit for agricultural work on a personal or summer cottage. With it, you can plow the ground, plant and harvest. The purchase of such equipment will greatly facilitate agricultural work.

With the help of motor blocks, you can perform different types of agricultural work. Depending on the size of the processed site and the demand for equipment in various fields of activity, the equipment acquire light, middle and heavy class.

Lungs

A similar mini-technology is often called a motor cultivator. It does not exceed 4 and a half horsepower with power, therefore it costs cheaper than medium and large units. The pluses include the light weight of the monoblock and the availability of processing uncomfortable areas due to a slight capture of the cutter.

The downside is the quick overheating of a low.power motor. So, this technique will have to work for a short time. In addition, the depth of the soil of the soil is less than that of a heavy walk.behind tract. In addition, light equipment does not have mounts for additional equipment.

Medium

This technique has a rear.wheel drive. Motor power-5-12 horsepower. The device is able to process the plot in half a hectare. The same.based tractor weighs from 50 to 70 kilograms, it can be attached to most motoblocks of this category a plow and other equipment.

Such a technique has 2 programs, equipped with the front headlight. Compared to the heavy motor block, the middle one is more maneuverable, but the depth of plowing the earth does not exceed 12 cm. And this is unacceptable for planting some plants

Heavy

This equipment can plow vast territories, significantly higher than the area of half a hectare. The engine power is 12-30 horsepower, a plow, trailer, hip, potato-cutter and other equipment can be attached to a heavy walk-behind tractor. It’s easier to work with such equipment at times faster than with light and medium. It adjusts the steering wheel, wheels.

The disadvantages include the heavy weight of the model, lack of access to non.standard surface areas. In addition, you have to turn such a technique with an effort. As for the types of plow to the walk.behind tractor, they are cloaks with two cases that plow the soil with a dump, or rotary, open the soil due to rotating discs.

How to setup?

Installation of wheels

Before starting the summer season, you will need to configure the walk.behind tract for a plow. Before engaging in a plow, the rubber wheels should be replaced with metal luggage. This must be done so that the unit does not slip during land work. The choice of wheels should be taken seriously, otherwise the ground will not work to plow the ground after winter.

Firstly, their diameter should be at least 55 cm, and secondly, the width of the wheel is selected within 20 cm, otherwise, with too narrow wheels, the unoic tractor will lose stability, and it will download it in different directions. If the diameter is too small, the gearbox will hook the soil and may become unusable, and it, as you know, is the “heart” of the motorcycle unit.

A monolithic rim is suitable for the wheels so that the earth does not clog on the soil. Work with wheels is carried out by putting one.time tractor on special stands. The height of the elevation directly depends on the depth of the future plowing: to work with ordinary soil. 20 cm, with a freezing. 25 cm.

Installation of the plow

Thanks to the coupling (fasteners), the plow is mounted to the walk.behind tractor. This work is best done with an assistant, as it will require some effort and skills. First, the hitch is mounted on a single tractor, then connected to the plow mounting with steel pins. The connection should not be installed tightly, light movement horizontally is necessary, otherwise when treating the soil, the uno-ears tractor will “bring” to the sides due to soil uneven.

After the main installation, the plow must be adjusted. You have to tinker with adjustment. the quality of plowing depends on it. Using the plow mounts, they are tilted so that its “heel” is directed horizontally to the earth. The adjusted uniform tractor is placed on the surface of the earth and check the control steering wheel. it should be in the area of the plowman belt.

It remains to check if the unit is ready for land work. It is necessary to make several trial grooves with depth measurement, check the quality of the soil decomposition. Pay attention to the strip between the furrows. it should not be too wide (not more than 10 cm) or crossed by a plow.

Choosing a motor block for plowing

Modern motoblocks are intended not only for land digging. Country equipment with a motor is able to cultivate and hill, carry out small cargo transportation, clean the territory of garbage and snow, mow unwanted vegetation. With their help, you can also water and harvest.

Separate models are equipped with a special shaft, so that the motoblocks can be combined with other devices and already saw firewood with them, provide electricity or pump water. This is also the main difference between motoblocks and motor cultivators.

In this video you will learn. How to choose a one.axle tractor:

- Lungs. Intended for small areas, the weight does not exceed 4.5 kg. Differ in a small cost, but they do not work for long. The motor due to a small volume easily overheat and breaks. Such devices do not have additional mounts, for example, for installing a plow.

- Medium. The weight of models does not exceed 80 kg. Equipped with rear.wheel drive, front headlights, have two transmissions, engines with a capacity of up to 12 horsepower. In comparison with heavy models, they are more mobile and maneuverable. The depth of the cigarette does not exceed 11 cm.

- Heavy. The ideal option to plow the large territory of the Earth with a motornote. Engine power. from 12 to 30 horsepower. Easily plow the soil and work faster than other models. Have a lot of additional functions. You can attach a plow, a potato coder, various trailers to them. Among the shortcomings are distinguished by heavy weight, which requires significant efforts during operation.

Preparation of a walk.behind tractor for plowing earth

Before starting plowing, the equipment needs to be correctly prepared. First you need to configure the parameters of the depth and width of the arable furrow. The optimal options are: width. up to 60 cm, depth. up to 15 cm. If the soil differs in hardness, the depth indicator can be increased to 20-25 cm. The final quality of the work depends on the correct configuration. The installation of soil hooks, hanging and adjusting the plow also include the installation of technology.

Installation of soil hooks

Ground hooks are special wheels on a one.legged tractor for plowing. Their diameter is usually 50 cm, width. 18 cm. If you take a smaller size, the equipment will “wind” on the sides, it will not work to make a flat furrow. It is required to arrange the same.based tractor on a flat surface, remove the main wheels and install in their place the hooks prepared with the axes. Only after that they move on to the installation of the plow.

Hanging and adjusting the plow

Clusts of various types are used for fastening. First of all, connect the plow itself and coupling itself. It is attached to one side, the backlash on the horizontal plane should be about 5-6 degrees. It is important to remember a few points. If you attach both sides (shkvorni) or not set the backlash, then the connection is excessively tough, and this is a typical error.

Then the plow is attached to the clutch device of the equipment. Nuts should not be tightened tightly. it is still necessary to adjust the adjustment. It is better to perform this action with an assistant. The same.based tractor is installed on the stands of about 25 cm (they can be made from improvised materials).

The soil hooks are fixed, the unoic tractor must stand evenly, without outweighing, this is necessary for high.quality plowing. The plow is located in such a way that the heel is parallel to the surface of the Earth, the setting goes with the help of bolts. After the stand, they are removed, and the blade of the plow drops to the level of the soil, the back of it should be approximately 2.5 cm higher.

Launch of the walk.behind tractor

Many owners have no idea how to properly launch the engine. Most do not even touch the instructions. However, you can make errors that will lead to a breakdown of the entire device, and repair often is not cheap.

First check the level of oil and fuel. The two.stroke engines should be poured with gas diluted with oil, the necessary proportions are given in the description to the device. Gasoline is used A-92 and A-95 brands. For diesel engines refueling diesel fuel, the temperature on the street should be taken into account, and from this to push off when choosing fuel.

Before the launch itself, clutch, reverse, gas, steering wheel are checked. The lever of the suction is installed in the “launch” position, about 5 movements are carried out by the starter. After the ignition turns on, the engine is launched, the suction is transferred to the “work”. Next begin to cultivate the Earth with a motorcycle unit.

How to make an equestrian plow yourself

Of course, you can buy a ready.made homemade plow on the Internet or on specialized sites, just choose the right one that would not always succeed in all the requests and criteria. Therefore, armed with suitable drawings, it can be made with your own hands with minimal costs.

Converting Truck Snow Plow Hydraulics to fit a Compact Tractor or Skid Steer

Important! Before making a plow, decide on the type of soil, which will need to plow, as well as with what kind of agriculture this land will be used then.

table 2. Step.by.step instructions for manufacturing horse plow

| Action | A photo |

| The drawing of a home.made plow is pre.drawn on a watman or cardboard, separately drawing each detail. | |

| Then the paper templates are transferred to the metal, circled and cut out the corner grinding of the workpiece. | |

| The dump can be made independently from the pipe 500-600 mm with a wall thickness of 5 mm, or a gas cylinder. The cardboard blank is transferred to steel by a marker or chalk and the part is cut out. Then it is processed on the anvil to the desired shape and grind. The dump part can be ordered separately. In order for the workpiece from a steel sheet to be driven through a special leaf.beam equipment, giving it the desired shape and bending. | |

| For the manufacture of a lemch, it is necessary to use strong steel 45 or 9xs. The cutting part is reinforced with a strip of thicker metal, beaten with a hammer on the anvil before work and pulled. Someone uses a disc from a digital saw and makes this element removable. Before starting welding and assembling the design of the plow from metal blanks into a single whole, collect its cardboard version to begin with. | |

| A lot of steel is installed on a sheet of steel thickness, the junction of the joint is fixed with point welding. Having fixed the rack shield in the right position, namely, protruding over a 5-6 mm linseed blade, welded the rack to the punch vertically. | |

| Next, the dump is fixed and attached, which is connected to the punch of the vault, thereby the surfaces of the elements are a single whole. And the angle should be 6-8 degrees. | |

| After the spacer bar is accurately welded to the shield. | |

| In the same way, stubborn corners for the knife are accurately welded to the base. | |

| The finished product is inspected, measured and fastened with capital welding, if necessary is finalized by corner grinding, with a hammer and emphasized. |

During operation, you can modernize the plow by complementing it with a two.wheeled unit.

Preparation for the working process of such necessary elements as a clutch. Plow and wrench; In order for the depth of plowing to be optimal, it is necessary to compare the huts of the coupling with the middle hole of the rack and the fastener bolt is used to connect them; The bolt for fasteners of the adjusting bolt is installed in the hole of the rack located on top, and is fixed using a nut. It is important to ensure that all the nuts are not completely fixed, so that during subsequent work they do not have to weaken. After installing the coupling, you can start the next operation; The time has come for the hanging of the plow on the uniform tractor Neva, as shown in the photo. For their connection, one or more pins are used, depending on the model of the walk.behind. After which the pins must be fixed with shplints.

Pachot of a motor block with a plow

Experienced experts advise novice gardeners their work on plowing to start with stretching the cord along the first row. Such a simple procedure will make the furrow even.

By plowing other rows, the wheel of a motor block will pass along the finished furrow of the first row. For this reason, all other furrows will turn out to be even, additional measures are not required.

In order to plow the garden was convenient, the procedure must be carried out along a long row. This will help get rid of additional efforts.

Plug adjustment

The quality of plowing will not be worthy if the plow is adjusted incorrectly. To ensure normal work, it is necessary:

- The mini.tractor needs to be raised a little above the ground. You can achieve this by choosing small stands 15 cm high (boards or bricks). The more the necessary depth of soil plowing, the higher the stands should be: if the operation is carried out in the fall, the height of the stands is made 20-25 cm. In spring, the height is left less-10-20 cm.

- Install the hitch without deviating from the instructions of equipment manufacturers. The edge of the Lemech should be in contact with the ground completely, while the plow rack must be installed vertically, and the riddle should be horizontally.

- Turning the handle at the base of the walk.behind tractor to the left, you can process the not yet plowed strip. This will also help to avoid the migration of the car. When turning the unit, it is necessary to try to ensure that its right wheel remains opposite the finished furrow.

The depth of plowing

To achieve the desired depth of a plow, you need to pay attention to the weight of the walk.behind tractor. It is better to choose the one that is harder. You can add weights on your own by clinging additional goods to the wheels.

The first furrow is made with a depth of no more than 10 cm. You need to plow it in a hurry and without pressing on the car. If it happened that the equipment has overheated, it is turned off for half an hour.

With relatively soft soil, a metal knife goes into the ground at a distance of a shovel bayonet. If the earth is more solid, it is difficult to achieve such a depth the first time. Therefore, the operation of plowing is carried out in two or even several receptions, each time lowering the plow deeper.

Very hard soil is easier to plow with a motor block in a wet state.

Plowing plow

The main plow should begin only after the trial option is completed and all the shortcomings are taken into account.

Two neighboring plowed stripes should be obtained with an interval not exceeding 10 cm from each other. Neighboring furrows should not fall asleep with the soil one another. The right wheel of the car should pass in the middle of the dump of the already finished furrow, and not on its basis.

Slightly increasing speed, it can be achieved that the surface of the plowing will become smoother, without lumps. The plow makes it possible to make the depth of the furrows 15-20 cm.

With qualitatively, plowed the soil with a motor block thanks to the speed mode. It is best when the one.axle tractor has several programs so that the owner can choose the most convenient for himself.

Plowing the site

With the help of a walk.behind engineer, a small area can be processed in half an hour (if you plow it correctly), while a week will be needed for manually. Technology can be prepared for landing a small field or garden.

How to Attach your BOSS Straight Blade Snowplow

The equipment is delivered to the site where it is necessary to plow the soil. To work with the plow, the equipment should be heavy or middle class. The same.based tractor weighing less than 70 kilograms of the plow will not pull.

Knowing the boundaries of the field, the furrows should be made in the length of the site. this will reduce the number of turns of the walk.behind tractor. During operation, the equipment always “takes away” the right slightly, therefore, for a clear plowing of the first furrow, the restrictive twine should be pulled. It will indicate the border of the site.

For subsequent grooves, the twine will no longer be needed.

The motor block is controlled from the side of the unnecessary field, so the steering wheel is turned slightly to the left. The first furrow is always trial: it is made at low speed, then check the depth of plowing-if it is less than 15-25 cm, then the unit will have to be adjusted.

Having reached the border of the site, the uniform tractor is unfolded, the right wheel is installed in the furrow (this position “transfers” the unit according to the horizon). It turns out that only on the front row of the plow takes a vertical position, and then the plow along with the walk.behind tractor leans slightly, so the plow should be slightly shifted in the opposite direction.

To do this, weaken the nut, regulate the position of the plow and the nut is tightened again. Properly put a plow will provide even, high.quality plowing.

It is better to work with solid soils when they are moistened. they may have to plow them several times.

Do not push the plow during movement. It is necessary to monitor the operation of the engine. it should not overheat. If this happens, the equipment is given time to “relax”, otherwise it will fail.

When plowing, the earth is enriched with oxygen. At this time, you can make fertilizers into the soil. It is useful to loosen the ground in the fall, then in the spring, after melting snow, the soil is well saturated with moisture. If you have to dig the same site with a walk.behind tractor from year to year, the direction of the furrows should be changed from vertical to horizontal ones. this is how the soil will acquire a more homogeneous structure.

Plowing plot

Setting up a plow on a walk.behind tractor is a very important matter, so a control plowing must be carried out before work, which will make it possible to evaluate regulation. This process includes the following stages:

Assessment of the furrow depth and the quality of the dump; Assessment of the plow course in the furrow; Motoblock load assessment; Hand load assessment.

Only after a full check can you start the main work. If at least one factor does not meet the requirements, then a re.adjustment of the mechanism will be required. The plowing process itself consists of the following processes:

For the final plow, install a mini.tractor on the edge of the field where you plan to make a furrow.

Parallel to the ground. Do not press the steering wheel much and push the one.axle tractor during work, it will do everything himself. The main thing is not to stop holding the steering wheel in parallel to the soil so that the mechanism does not plunge into the soil or does not rise up;

Having finished making the initial furrow, exercise control of its depth from the bottom of the furrow to the crest. If the depth of plowing is from 15 to 18 cm, then you can begin the main process.

It is very important to know how to set up a plow on a walk.behind tractor, which will allow you to correctly carry out all the required work. True adjustment is the key to the quality of the process. After the end of the work, do not forget to clean the mechanism, remove the plow from the walk.behind tractor and fold it until the next time.

Odin on the record “Setting and adjusting the plow on a walk.behind tractor”

I want to buy such a plow for the Nikkey Motoboblock 1550 13 liters.With. 8044 461 17 00

Popular articles

How to plow a motor block with milling cutters correctly

The appearance of milling plants for motoblocks has greatly simplified the procedure for cultivating land for many gardeners. Instead of traditional works, such as plowing and harrowing, a comprehensive operation has appeared, which allows you to get a loose soil structure 1 time suitable for sowing work. This significantly reduced labor costs and gave a significant winning time.

How to adjust the depth of plowing with a motor block with milling

The maximum depth of cultivation by a motorcycle unit (it is more correct to call the process of plowing with cutters) to the greatest extent depends on the diameter of the cutter and usually half of this value. Attempts to plow to a great depth will lead to the fact that the cultivator will simply be overwhelmed. Adjust the deepening to the soil within the required limits using a coupon.

How to dig a garden with a motor block with milling

The standard process of cultivation of the Earth by a motor block is usually carried out in 2 stages.

- Install a couch on a small deepening. They process the plot throughout the area, bypassing it in a circle and gradually shifting to the center. At the same time, the cultivator works at small speeds or in the first gear.

- Set a couch to the required depth of cultivation. The site is processed over the entire area at high speeds or at 2 speeds.

As a rule, to dig a previously processed area by a motor block, 2 passes are enough.

How to plow the virgin soil with a motoblock with milling

The virgin soil plowing with cutters with cutters is carried out in several techniques. The first passage at low speed with minimal deepening violates the integrity of the turf, destroys the strongest surface layer. On the second and subsequent passages, the deepening is increased, gradually increase the engine speed. In total, 3-4 processing may be required, it is highly dependent on the density and structure of the soil.

Plug drawings to the walk.behind tractor

Using the experience of the craftsmen who made the plow for the walk.behind tractor and left the drawings, should be done so that it starred, this will facilitate its sharpening before plowing.

Steel of brand 45 is suitable, when hardening, brought to hardness HRC 50-55. If there is only ordinary steel at hand, say carbon ST5PS that is not subject to heat treatment, then having beaten off the cutting edge on the anvil and imprisoning it, it is quite suitable for processing the soil.

Dump for the plow of a motor block

The dump of the plow, this is the part that takes the earth to the side.

The working surface of the dump should be given a curved shape. If there is a meter.pilling machine or leaf.bearing rollers, then giving the workpiece the desired shape will not be difficult.

It is necessary to blank metal with a thickness of 3-5 mm, the rollers are directed at an angle of 20-22 degrees, as shown in the drawing, and the desired bend is given.

Here, a workpiece. A pipe with a diameter of 600-650 mm can serve (this diameter will require less labor costs, since the bend of the pipe will repeat the desired bend of the future dump) and 3-5 mm thick. From cardboard, make a template, and apply to the pipe, not forgetting about an angle of 20-22 degrees, as shown in the drawing below.

We circle the template with a pencil or chalk, and cut out with gas. welding, if necessary, grind the workpiece and bring to the desired condition.

Probably the most difficult way to make a dump, when the workpiece is heated and with the help of a matrix, they give the desired shape that the dump from another plow can serve.

The material of the plow case serves the steel sheet of the brand ST3. ST10 with a thickness of 3 mm.

Drawing details of the plow for a walk.behind tractor

We advise first to make the details of the plow of cardboard and attach them to each other in compliance with the desired angles. So, the values of the angle α on different parts of the plow body will be from 25 ° to 130 °, the angle γ is from 42 ° to 50 °. If a home.made model of a cardboard plow has arranged you in all respects, you can proceed to work with metal.

When the metal parts of the plow are ready, you need to find an additional sheet of steel 3 mm thick, 600×600 mm in size, it will be needed to assemble the plow, and the welding machine (preferably inverter). On this sheet we retreat from the edges of 40 mm and measure the angle γ0.

Assembly of the plow

With the help of wedges with an angle of α0 = 25 degrees and an angle γ0 = 42 degrees on an additional sheet, a piece is installed and grabbed to the sheet with welding, pointwise on two sides.

The side panel of the rack is connected to the lumber so that its edge goes beyond the plug by 4-7 mm, while the shield should be raised to be higher than the lumber blade (that is, above the additional sheet) by 6-8 mm, so as not to interfere with the prayer, Cut the ground. The shield is also grabbed to the plunder and to an additional sheet.

Further to the lignh very tightly, leaving the clearance of the dump is joined so that their surface is one whole. The angle between the upper cut of the dump and the blade of the lime is equal (γmax-γ0) = 6-8 °.

Fastening of the plow’s ligne

If you find that the corners and/or surfaces do not correspond, the dump is brought using a hammer. After adjusting the dump to the plug, he is welded from behind to the plunder, and to the side panel. Then the side panel is welded with a spacer bar and a plate of the base, stubborn corners for the lime are grabbed to the last welding.

Followed by. Once again, inspect the finished plow, and if everything is clearly welded finally. Additional. the sheet is separated from the body with a chisel or mush. All welded seams are polished.

Homemade rotary plow for a walk.behind tractor

The rotary plow is universality. As you know, with soil plowing with a single.hobby plow over one pass, the soil layer is turned over in one direction with a piece. To turn the earth in the same direction with a second passage, you have to return to the beginning of the previous row and start from the same side of the site.

Preparation for the use of a walk.behind tractor

Soil opening begins with the preparation of a walk.behind tractor. Let’s find out how to do it.

- Before plowing, motorcycle equipment must be unlearned. To the workplace, the uniform tractor must be transported without carts and other hinged equipment. As a rule, the transportation of the unit to the destination is carried out through vehicles. If the land that you intend to process are located near your house, mounting a walk.behind tractor must be performed on a flat plane in any suitable place.

- Remove transport wheels. After the one.axine tractor was delivered to the site, which must be plowed, it is required to dismantle the transport wheels to change them to specialized soil.spaces (iron wheels). To facilitate this work, under the clutch located on the back of the unit, you can put the goats. Soil.freezaces are necessary for more thorough adhesion to the soil. They are an indispensable equipment for plowing, planting beets, carrots, potatoes.

- Rotation of the Stupits. At the next stage of preparation of the unit, before plowing, it is necessary to change the hubs on which the transport wheels stood for longer. This is necessary to increase the distance between the soil.spaces. Such a solution will significantly improve the stability of the unit during operation.

- Installation of soil.spaces. We proceed to mount iron wheels. Fundamentally, that these elements are correctly mounted. The correct installation is determined by the focus of the tread pattern. The narrowing of the picture shows the direction of movement forward.

Installation

Now the goats can be removed and proceeded to aggregate the plow. It consists in the installation of a plow of a coupling mechanism called a hitch. The coupling mechanism is what the plow is fixed to the traction-linked device (TSU, Fragment) of the unit. It can be 2 types: universal and stationary. One hitch makes it possible to use various objects (boron, diggers, plows, etc. D.), and the other is needed to conjure the adapter and device.

In order for the installation of the tool for plowing the earth more comfortable, install motor vehicles on supports, the function of which can perform stones, bricks or boards. Plug fixation is very simple-the coupling for the unit has its own place on the traction-linker and is fixed by the only shkvorn. Many people believe that, firmly fixing the plow on the unit, it will go easier and rather. In practice, everything is exactly the opposite. Because in the process of opening, the forces are affected by the vertical vertically blade of the dump, there is opposition, which is still trying to drag the entire unoic tractor to the side.

With a “dead” fixation, the employee needs to attach strength, in the literal sense of the word, setting the unit in the soil, this is one of the most common mistakes. Therefore, it is required to leave the gap in a horizontal plane by approximately 5 degrees.

Assembly of the plow and a hanging plow on a single tractor

The plow and hitch are two main components that you need to perform soil plowing. To do this, you need to assemble a plow and a hitch into one whole to install a plow on a single tractor and adjust it for a plow.

The plow is attached to the walk.behind tractor using a hitch. Since the clutches have various modifications and each model has its own differences, in some cases you will have to carry out preliminary work on installing the clutch on the plow. Когда сцепка установлена на плуг, приступаем к навеске плуга на одноосный трактор.

Fastening the plow to the walk.behind tractor through a universal coupling provides a reliable attachment of the plow to the power block, and also allows you to perform a number of accurate adjustments to the plow for soil plow.

Types of collapse for a walk.behind tractor

If we use a universal coupling, as shown in photo 3, I recommend not to fix the adjusting screw, the locknuts (a) are left weakened, we also weaken the counterthops (b) fixing the coupling to the plow rack. Now we can start adjusting the plow.

Adjustment of the motoroblock plow

The adjustment of the motoblock plow includes the following. adjusting the plow of the plow, adjusting the angle of inclination of the dump of the plow and adjusting the angle of inclination of the field board, relative to the nose of the lime. We will first talk about how the motor block plow works.

Plug device for a walk.behind tractor

Photo 4 in photo 4, we can see the device of a standard plow for a walk.behind tractor. In some cases, plows have some differences, but mostly most plows for walk.behind engines have just such a device.

First, we will adjust the plow for the depth of plowing. To do this, we will need two stands 12-20 cm high, the height of the stands depends on what depth we will plow our land with you and we will plow our land. If the depth of the plowing is 15-18 cm, then the stands are needed 15 cm high, if the depth of plowing is 20-23 cm, then accordingly we take the stands with a height of 20 cm.

Note: You can use bricks or bars as stands.

The first stage of the plow adjustment and cutting of the grooves

Having chosen the stands suitable for us, we lay them on the even surface of the soil at a distance from each other equal to the width of the track between the primrose, after which we install the same tractor on them. The plow should touch the surface of the soil of the field board along its entire length. As shown in photo 5, the plow stand should be parallel to the inner end of the soil and strictly perpendicular to the surface of the soil.

The next stage of adjusting the plow is the angle of inclination of the field board. It is important to withstand the height of the heel of the plow (field board) relative to the nose of the plow (Lemeha), as shown in photo 6, this distance should not exceed 30 mm (matchbox), otherwise the plow will explode into the soil and the quality of plowing will worsen much or in a motorcycle unit not enough traction and the engine will overheat and die out.

Photo 6 (right) shows an example of how you and I can adjust the angle of inclination of the field board using the adjusting screw. Ring.on A and B must be completely weakened, rotating the screw clockwise, we will thereby increase the height of the heel of the plow relative to the nose and vice versa. After performing this adjustment, it is necessary to tighten the nuts a and b using a wrench.

After adjusting the plow, we remove the stands from under the ground-bearing motorcycle unit and, along the pre-planned line, we pass through the motor block by cutting the first roller groove with a plow. It is important that the first striped furrow is as flat as possible.

Roller grooves can be one, two or more, it all depends on the type of plowing. For example, with plowing in “dump”. We will need to make two rowing stripes in the center of the site (left and right), and after that, again return to the adjustment of the plow.

The second stage of adjustment of the plow and plow

After we cut the rowing furrows, we go to the second stage of adjusting the motor block plow. We take one stand and put it under the left gilling. After that, we need to change the angle of inclination of the dump, so that the plow as in the first case is located perpendicular to the surface of the soil.

To change the angle of inclination of the dump of the plow, it is necessary to weaken the nuts of the plow attachment to the cap (the footnote is indicated by the arrow) and turn the plow so that it takes the position as shown in photo 8.

Having finished adjusting the plow, we remove the stand from under the left soil-bearing and roll out the one-axic tractor to the place of plowing, the right heater should be located in the proper furrow (photo 9, left).

We turn on the first (low) gear, begin the motion movement, so that the right ceremonial is moved strictly in the prophetic furrow. At the same time, the uniform tractor is tilted to the right side, but the plow during movement is located perpendicular to the soil surface (photo 9, right). And so we continue to plow the entire site.

The unoic tractor with proper adjustment of the plow moves without jerking, the engine works in optimal mode, the plow does not bury the nose of the lameck in the soil. From under the dump of the plow, the soil when turning over the edge of the previous furrow.

Внимание! На видео пока представлен только первый этап регулировки плуга мотоблока, пробное видео, эта регулировка плуга предназначена только для прохождения пропашных борозд.