No Oil Is Supplied To The Chainsaw Chain

Chainsaw to saw to the side

When sawing, you will notice that the cut is uneven. Why does a chainsaw cut crooked? There are several reasons:

- Incorrect chain sharpening. The teeth are sharpened at the wrong angle or in one direction only. Correct sharpening required.

- Incorrect chain. At very high speeds, the difference even 0.2-0.3 mm between the width of the groove or the width of the landing will be visible, why the chainsaw and saw to the side. An appropriate circuit must be installed.

- Tire wear is uneven. Over time, the tire wears out on one side and then the chain is pulled to the side. Turning the tire over regularly so that wear is even on both sides. If the wear is too great, replace the tire.

The chain does NOT rotate

Why the chainsaw chain does not rotate when the engine is running even at full speed?

- Leading asterisk. Either it is jammed, or the wear ring is so much that it does NOT engage and the chain is spinning on the chainsaw. In any case, it is necessary to disassemble the sprocket in order to find out the exact reason why the chain does not spin. If the crown is worn out, it is necessary to replace the sprocket (or the crown itself, if the sprocket is of a prefabricated structure).

- The chain brake is seized. As a result, the sprocket is blocked by the brake mechanism, while the motor runs. Stop the engine and release the brake. If this happened under load, the brake mechanism will have to be changed, as well as the sprocket, because Due to the high temperature, many elements can melt and overheat.

Chain lubrication problems

For proper operation, the chain must be constantly lubricated to reduce friction between the tire and the links, and also prevent premature wear of the links.

- If the chain is lubricated on the chainsaw, then there is a problem with the oil pump. oil is not supplied due to a clogged channel. Lack of lubrication is the reason why the chain stretches or why the chain breaks. Clean the channels, the smallest particles of shavings constantly get there and clog them. May also cut off the oil hose. If you need to adjust the oil pump of the chainsaw or repair it, it is better to contact the service.

- Splashes oil from the chain. Incorrectly selected lubricant. it is too thin, therefore it does NOT lubricate the links as much as it splashes on the wood. Replaces grease with a thicker one.

Shoots the muffler:

- Enriched air-fuel mixture. Why does the chainsaw “shoot”? There is too much gasoline and too little air in the mixture, so the mixture does not completely burn out in the chamber and partially burns out in the muffler. Exhaust carbon is a clear sign of this. Air filter cleaning or carburetor adjustment required.

Saw the chainsaw under load and stalls

- Clogged air filter. It is necessary to take out the filter, clean it well or even rinse it, dry it and put it back.

- Incorrect proportion of oil / gasoline mixture. Drain fuel and remix oil and gasoline in the correct proportion.

10 chainsaw malfunctions that you can fix yourself

Even professional chainsaws from world famous manufacturers break down. no one is immune from this. The question is how often breakdowns occur and how serious they are. It is one thing when sharpening the chain or replacing the drive sprocket is required, and another thing when the chainsaw starts or shoots at the carburetor. In fact, most of the faults can be easily eliminated with your own hands, for example, when the chainsaw lubricates the chain or stalls.

The engine “shoots

If during operation there are extraneous sounds similar to shots, then there is a problem with the muffler or carburetor. How to make the chainsaw run quietly? It depends on which node the fault is in.

Chainsaw overheating

Why does the chainsaw get hot? The engine or the tire can warm up. in any case, a small amount of lubricant is to blame.

- Engine overheating. Incorrect proportion of fuel mixture or pure gasoline in general. Drain the fuel and mix with the correct proportions of oil and gasoline as indicated by the manufacturer.

- Overheating of the tire. Cleaning or adjustment of the oil pump is required, because Oil is supplied to the tire.

The chain does NOT cut

The decrease in the performance of the chainsaw is due to the bluntness of the chain teeth. This is the most common problem because Sharpening must be done regularly. How to do this using a machine, file or angle grinder, read the corresponding article.

Chainsaw chain does NOT receive oil: causes and solutions

When the chain of the chainsaw is moved into the groove of the tire, a large amount of heat is generated due to friction. If oil does not flow to the chainsaw chain, it is necessary to stop work and take all measures to eliminate the malfunction of the lubrication system. The combination of heavy loads and overheating of the headset is accompanied by its accelerated wear and tear and early failure.

- Without exception, all chainsaws and their electric counterparts are equipped with systems of the same type according to the principle of operation, through which the tire, saw chain and parts of its drive are lubricated.

- This unit comes standard with a reservoir from which chain oil is supplied to the inlet of a fixed or variable displacement pump.

- Further, the working fluid in a metered amount enters the groove of the tire, in which the shanks of the saw chain are evenly distributed over the entire set and the working surface of the crown of the drive sprocket.

Tires of productive headsets with a length of 400 mm are completed with a driven sprocket. Periodic bearing lubrication is done individually, after 6-8 hours of operation.

Signs of a malfunctioning lubrication system

The correct choice of consumable lubricants and perfect system performance contribute to real lubrication, effective cooling of the close equipment and the full depletion of its resource.

There are several external signs that the chain on the chainsaw is NOT lubricated. First of all, these are:

- The oil level in the reservoir is unchanged;

- Increased engine load;

- Accelerated wear of the cutting edges of the saw links;

- Corresponding smell of overheated wood.

In the most ordinary version, a prerequisite for oil starvation can be clogging of oil channels with sawdust. This defect is typical for economical headsets, and not having comfortable access to problem areas.

Chainsaw chain lubrication system

One of the fundamental chainsaw systems, without which work is impossible, is the forced lubrication system of the chainsaw chain. It’s not a secret for anyone that at the time the saw is operating, the chain friction against the tire of the chainsaw, which causes it to heat up and premature wear. To soften friction, the chain mechanism must be constantly Lubricated.

Chainsaw oil goes to the chain.

- Clogging of the filter located in the oil tanks;

- Mechanical breakdown of one of the elements of the pump worm drive;

- In winter, the performance of the pumping device decreases due to filling the system with too thick oil.

In the latter case, the drive and all pump parts operate under increased loads that initiate serious mechanical damage.

In modern chainsaws, a reliable supply of lubricant for the chain is organized, in case of malfunctioning of which, it is worth operating the chainsaw in order to avoid further breakdowns. It is better to troubleshoot the lubrication system by contacting a service center or an experienced repair specialist, this guarantees the quality of the final result.

Signs of a malfunction of the lubrication system, checking its performance

- Chainsaw chain is dry and has a pale shade without shine.

- Shodo chain stretches quickly.

- The tire is very hot and can even partially melt the paint.

- The oil from the tank is practically NOT reduced.

- Decreased cutting efficiency on a sharp chain

All these signs indicate that the lubrication process is not working properly. In order to check the oil supply by the lubrication system, it is necessary to remove the side tire of the chainsaw and start it. Further, you need to slightly increase the speed while observing the place where the oil line ends. If oil is flowing in, it is most likely that there is not enough oil for proper lubrication and the filter needs to be cleaned or replaced and, if possible, adjusted the flow. In the case when it is NOT received, the problem is more serious and requires further diagnosis.

There is a way to check the oil supply without removing the tires. To do this, it is necessary to direct the end of the tire towards, for example, a freshly sawn block from the cutting side and increase the speed as much as possible, while trying to keep the end of the tire NOT more than 10 cm from the block. If oily spots begin to appear on its surface, it means that oil is being supplied.

Principle of operation

The main unit of the system is the pump. The principle of its operation is as follows. With an increase in engine speed, a gear mounted on the main shaft drives the pump shaft through a worm gear. In turn, the rotation of the shaft creates a certain pressure in the oil line, which forces the oil to move along it towards the tire.

The end of the oil channel is located at the point of contact of the tire with the tool housing, where there is a longitudinal groove, on which, when the tire is installed, its oil channel falls.

The groove is necessary to ensure the supply of oil to the tire, regardless of the chain tension of the chainsaw. Simply put, no matter what position the tire is in at the time of operation, oil through the groove will get onto it.

Further, a chain is included in the lubrication process, on the links of which, depending on the model of the chain, there is either a groove or a hole through which the oil is accelerated throughout the tire. As the engine speed increases, the oil flow rate also increases.

Some models of chainsaws are equipped with pumps, which additionally have a capacity adjustment, and if necessary, the amount of oil supplied by the lubrication system can be increased or decreased.

This function is quite convenient as it allows you to save money and does not waste extra oil.

Signs of a malfunctioning lubrication system

The correct choice of consumable lubricants and the flawless operation of the system, contribute to full lubrication, effective cooling of close equipment and the full depletion of its resource.

There are several external signs that the chain on the chainsaw is NOT lubricated. First of all, these are:

- Constant oil level in the reservoir;

- Increased engine load;

- Accelerated wear of the cutting edges of the saw links;

- The characteristic smell of overheated wood.

In the simplest version, a prerequisite for oil starvation can be the clogging of oil channels with sawdust. This drawback is typical for budget headsets, and not having convenient access to problem areas.

The advantages of high-class oil pumps

The maintainability of collapsible pumps is sufficient to restore the unit’s performance at home.

The gears of the pump drive of budget chainsaws are mostly polymer. Proprietary variable capacity models, advanced in terms of technical equipment, are equipped with drive mechanisms made of non-ferrous metals. The cost of such systems is compensated by an economical, up to 50% consumption of working fluid.

How to adjust the oil supply to the chain in a regular chainsaw. Proper chain lubrication

One of the most vulnerable components is the oil pump. In this regard, many owners of dust have a question about how to repair the oil supply on a chainsaw.

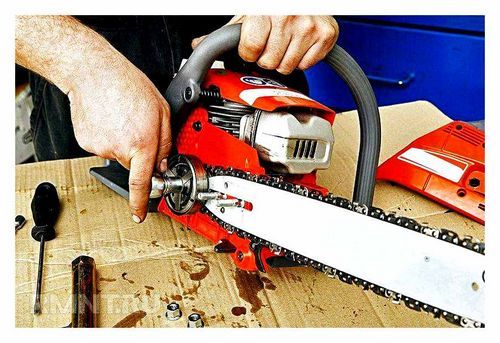

The task of the oil pump is to supply lubricant to the chain. this is necessary for its smooth movement along the guide bar. When the oil pump fails, the lubrication of the chain deteriorates, which reduces the efficiency of the chainsaw. In SEPARATE cases, this leads to an open circuit. To prevent negative moments, it is necessary to repair the oil supply in a timely manner. How to do it?

Tires. Chainsaw chains. Chain lubrication system, adjustment and sharpening. How to choose a chain

The study of their typology will help to choose a chain. Important differentiation criteria are:

- Tooth pitch. This parameter is measured in inches. The most common sizes are 0.325, 0.375 and 0.404. Each of them is selected depending on the assigned tasks. The smaller the specified parameter, the lower the productivity will be, which means that it will not be necessary to put a lot of effort. Therefore, it is necessary to purchase a chain whose power would correspond to a chainsaw.

- The thickness of the tail, the leading link, which means the choice of a product for different tires. A 1.1 mm tail is only present on small household dust chains. The most popular size is 1.3 mm. Such a model can even be present on semi-professional devices.

- The depth of the cut and the height of the profile. The performance of the device depends on this parameter. It is always possible to increase the value by cutting down the stops near each cutter. There are two choices: 0.025 “(0.635 mm) and 0.03” (0.762 mm). The high profile chain type makes the chainsaw aggressive and vigorous. Keeping a balance between high productivity and low vibration will help the product with a small pitch of Ponytails.

- Chain length, bar and number of teeth. The choice of this parameter directly depends on the power characteristics of the chainsaw. over, the best saws are not always characterized by an increased number of teeth and tire size.

- Types of cutting links. Types of chains according to this characteristic: chisel and chipper. The first option is the most optimal because of the straight working surface, which allows you to evenly cut into the wood. It is difficult to sharpen such links, and if even very small deviations from the upper corners are present, the performance of the chain will be reduced. Chippers have poorer cutting properties, but are more resistant to any kind of dirt and are easier to sharpen.

- Sequence of links. The model with one cutting link and two tails is popular. But non-standard options are also possible: with a half-admission. only one connecting link is inserted between every second pair of working teeth, with an allowance. the link is installed between all adjacent teeth. This allows for cost savings. But at the same time, aggressiveness and productivity decrease, and wear increases, including chainsaws.

- The method of cutting the material. Products with rip and cross cut allow you to guide the tire along and across the fibers, depending on the need. They differ in the angle of sharpening of the cutting links.

Chainsaw Oil Supply Adjustment Partner

Most modern oil pumps for chain chainsaws are arranged in the same way: a cylinder (photo 1, pos. 2) is placed in the body (photo 1, pos. 2), a plunger (photo 1, pos. 3) is inserted into it, making rotational-translational movements in it.

The cylinder in the lower part has two holes (in photo 1, item 4, only one of them is visible): through one oil it is sucked in, into the second it is pushed out.

The plunger (photo 2) is a steel rod, on one side it has a milling groove. a flat, and on the other a plastic or steel gear. As the plunger rotates, the baldness alternately opens and closes the inlet and outlet of the cylinder. When moving upwards, the flat first opens the inlet (at the same time we close the outlet) and creates a slight decrease in pressure. As a result, a portion of the oil is sucked into the cylinder. Then, turning, the plunger moves downward, opening the outlet with a flat (at the same time closing the inlet) and pushing the oil out of the cylinder. This is how it is fed to the tire in small portions. High cycle rate creates a constant and continuous flow of lubricant.

Two types of oil pumps are used (photo 3): with variable oil flow and with fixed flow. In the first case, the plunger gears have an oblique tooth, and the upward movement is provided by an additionally installed spring. The oil flow is controlled by changing the stroke length of the plunger in the cylinder. An example is an oil pump for Chinese dust with an engine capacity of 45-52 cc

In the case of an unregulated oil pump, there is an oblique closed groove on the plunger, against which the fixed stop of the body rests. Rotation causes the groove to slide against the stop, and since it is oblique this movement causes the plunger to move forward and backward. With this scheme, it is impossible to limit the stroke of the plunger and the oil is supplied in constant quantities. Example. the oil pump of the Husqvarna chainsaw 137, 142

The torque from the engine to the plunger is transmitted through a special drive, which also has a gear. the counterpart of the gear to the plunger. In fact, this is a worm gear pair. The oil pump drive is driven either by the drive chain sprocket (photo 4 pos. 1), or by the crankshaft (photo 4 pos. 2).

In the first case, the plunger is mechanically connected to the drive sprocket and rotates only with it. Photo 4 pos. 1 shows the drive of the Stihl MS-180 chainsaw. The steel tendril clings to a special groove on the drive sprocket cup. When the sprocket spins, the drive spins with it. At idle speed in this case, the oil supply is.

In the second case, the drive is rigidly fixed on the shaft and constantly rotates with it. Photo 4 pos. 2 shows the oil pump drive of the Husqvarna 137, 142 chainsaw. It is pressed onto the crankshaft shank and rotates with it constantly. Therefore, oil is supplied constantly, even if the saw is in idle mode.

Usually, one of the gears (either on the plunger or on the drive) is made of plastic in order to secure a part with a more complex design or complex installation. The plastic part will break and wear out first.

On some saws, the driven oil pump can be additionally closed with a special cover (photo 5, the oil pump cover of a Chinese chainsaw 45-52 cc), which protects the worm gear and the pump itself from dirt and wood dust. On some saws, such as Husqvarna 137, 142, the oil pump housing itself closes the connection between the drive and the plunger, thus acting as a protective cover.

A certain amount of lubrication is required for the bar and chain to function properly.

The chainsaw chain is NOT lubricated

In the process of long-term operation of the chainsaw, some of its elements and components may become unusable.

What oil to use for chain lubrication

This part requires constant lubrication, for which you can fill in a special oil for a chainsaw, and it must be of high quality. It is recommended that you select chain saw oil from the manufacturer of the saw itself. Its consumption is low, so it is not worth saving on the purchase. But it is not necessary to pour liquid onto the chain itself. There are entire systems for lubrication to help it flow to the tire smoothly.

There are other criteria for choosing a saw lubricant:

- Resistance to freezing, because the saw sometimes has to be used in winter, including Lubricating with oil, which means that at negative temperatures it does not have to freeze;

- Optimum chain oil viscosity;

- The oil that is used should not leave a residue on candles and other spare parts;

- No impurities.

It is necessary to replace the chain oil if the part heats up and various breakdowns appear.

NO oil is supplied to the chain

The fact that oil does not flow to the chain can be recognized by the following signs:

- Part dryness and lack of shine;

- Its rapid stretching;

- Heat;

- No reduction of oil from the tank;

- Decreased cutting efficiency.

If oil stains appear on the surface of the wood, then there are problems with the oil supply. Feeding may need to be adjusted.

The reasons for the lack of oil supply can be:

- Missing threads on the oil pump shaft. In this case, it will need to be replaced.

- Broken oil hose.

- Defective threads on the pump drive gear.

- No main shaft spin. You can solve the problem by installing a stud of a suitable diameter and required length.

- Blockage. You can clean the line by blowing it with compressed air or using a thin wire. If the blockage is in the filter or in the pump itself, then these parts are best replaced.

Signs of a malfunctioning lubrication system

The correct choice of consumable lubricants and the flawless operation of the system, contribute to full lubrication, effective cooling of close equipment and the full depletion of its resource.

There are several external signs that the chain on the chainsaw is NOT lubricated. First of all, these are:

- Constant oil level in the reservoir;

- Increased engine load;

- Accelerated wear of the cutting edges of the saw links;

- The characteristic smell of overheated wood.

In the simplest version, a prerequisite for oil starvation can be the clogging of oil channels with sawdust. This drawback is typical for budget headsets, and not having convenient access to problem areas.

Chain lubrication diagram

The chainsaw chain lubrication system consists of the following elements:

- Oil tank located in the engine crankcase;

- Tank filter;

- Oil pipeline, that is, a small diameter hose;

- Oil pump.

Chainsaws Equipped with an automatic lubrication system. This means that oil is supplied to the chain only if it comes into contact with the wood. The scheme of the system is as follows. The gear, which is located on the main shaft, drives the oil pump shaft. This creates pressure in the oil line, which forces the oil to move towards the tire.

The oil channel ends at the point of contact of the tire of the device with the crankcase of the chainsaw. Chainsaw chain tension for oil supply is not important. She lubricates herself anyway.

Individual malfunction of the Stihl MS 180 lubrication system

In view of the fact that Stihl MS 180 is one of the most common models of chainsaws, I would like to dwell on one inherent only malfunction and describe a way to eliminate it without replacing parts.

Quite often, on the Stihl MS 180 Chainsaw, it is observed that the oil line is depressurized in the place where the oil line from the tank is installed in the saw body. The malfunction can be determined by the characteristic grease leakage on the bottom of the tool.

To eliminate the malfunction, it is necessary to remove the chainsaw handle, remove the hose from the bore, clean and degrease. After all THESE manipulations, apply sealant to the hose seat and install it in the chainsaw body.

For more information on troubleshooting and full diagnostics of the lubrication system of the Stihl chainsaw, you can find out by looking. In which step by step the process of disassembly and repair of the lubrication system is captured.

Chainsaw chain lubrication system

One of the fundamental chainsaw systems, without which work is impossible, is the forced lubrication system of the chainsaw chain. It’s not a secret for anyone that at the time the saw is operating, the chain friction against the tire of the chainsaw, which causes it to heat up and premature wear. To soften friction, the chain mechanism must be constantly Lubricated.

Troubleshooting

After it has been determined that no oil is supplied, further diagnostics is possible only if the oil system is completely removed. Of course, in some situations, changing the filter helps, but this is very rare.

Lubrication system malfunctions and how they are eliminated

The main malfunctions of the oil supply system on a chainsaw can be divided into two main types, these are general malfunctions inherent in all chainsaws and individual ones, which may differ depending on the type of pump and worm gear installed on a particular model. Let’s start sorting out faults in order.

Signs of a malfunction of the lubrication system, checking its performance

- Chainsaw chain is dry and has a pale shade without shine.

- Shodo chain stretches quickly.

- The tire is very hot and can even partially melt the paint.

- The oil from the tank is practically NOT reduced.

- Decreased cutting efficiency on a sharp chain

All these signs indicate that the lubrication process is not working properly. In order to check the oil supply by the lubrication system, it is necessary to remove the side tire of the chainsaw and start it. Further, you need to slightly increase the speed while observing the place where the oil line ends. If oil is flowing in, it is most likely that there is not enough oil for proper lubrication and the filter needs to be cleaned or replaced and, if possible, adjusted the flow. In the case when it is NOT received, the problem is more serious and requires further diagnosis.

There is a way to check the oil supply without removing the tires. To do this, it is necessary to direct the end of the tire towards, for example, a freshly sawn block from the cutting side and increase the speed as much as possible, while trying to keep the end of the tire NOT more than 10 cm from the block. If oily spots begin to appear on its surface, it means that oil is being supplied.

Lubrication system device

Depending on the brand of the chainsaw, the details of the lubrication system may differ slightly in design, but their total number and connection diagram remains unchanged.

The main components of the lubrication system are:

- The oil tank is usually located in the crankcase.

- Filter element, installed in the tank.

- The oil line is a small diameter oil-resistant rubber hose.

- The heart of the system is the oil pump.

- Worm gear gear transmission force from engine to pump.

- A chainsaw tire, it can also be considered an element of the lubrication system, since it has special holes for supplying oil, by the way, the chain itself participates in the transportation of oil and, accordingly, also has some elements designed specifically to provide lubrication.

Chainsaw chain lubrication system

To supply oil for lubricating the chainsaw chain, a special pump is used in the tool, which is dosed, depending on the number of engine revolutions, supplies lubricant to the saw bar.

The system uses oil to lubricate the chainsaw chain, which has increased adhesion properties, this is necessary to evenly distribute the oil around the entire perimeter of the tire and keep it on it even at high chain speeds. Let’s take a closer look at the oil supply system implemented in modern chainsaws.

Most common malfunctions

- Broken oil hose. It can sometimes be detected by visual inspection. The problem is solved by replacing the defective part.

- Lack of threads on the oil pump shaft, replacing it will help.

- Defective thread on the pump drive gear is similarly solved by installing a new part.

- No corkscrew of the main shaft (relevant for Some models of tools, for example, Homelite). You can fix it by installing instead of the native corkscrew, suitable for the diameter of the studs, cutting it to the required length.

- Blockage in the line. Can be removed by blowing with compressed air or mechanically using a wire of suitable diameter.

- Clogged filter element.

- In the Stihl MS 180, the pump of which is not separable, it often clogs. You can try to rinse in clean gasoline if it does not help replace.

- In Chinese chainsaws (Gypsy), very often cuts off the grooves on the main gear, through which the force from the asterisk is transmitted to it.

Principle of operation

The main unit of the system is the pump. The principle of its operation is as follows. With an increase in engine speed, a gear mounted on the main shaft drives the pump shaft through a worm gear. In turn, the rotation of the shaft creates a certain pressure in the oil line, which forces the oil to move along it towards the tire.

The end of the oil channel is located at the point of contact of the tire with the tool housing, where there is a longitudinal groove, on which, when the tire is installed, its oil channel falls.

The groove is necessary to ensure the supply of oil to the tire, regardless of the chain tension of the chainsaw. Simply put, no matter what position the tire is in at the time of operation, oil through the groove will get onto it.

Further, a chain is included in the lubrication process, on the links of which, depending on the model of the chain, there is either a groove or a hole through which the oil is accelerated throughout the tire. As the engine speed increases, the oil flow rate also increases.

Some models of chainsaws are equipped with pumps, which additionally have a capacity adjustment, and if necessary, the amount of oil supplied by the lubrication system can be increased or decreased.

This function is quite convenient as it allows you to save money and does not waste extra oil.