Oil Supply To The Chainsaw Chain

Lubrication system malfunctions and how they are eliminated

The main malfunctions of the oil supply system on a chainsaw can be divided into two main types, these are general malfunctions inherent in all chainsaws and individual ones, which may differ depending on the type of pump and worm gear installed on a particular model. Let’s start sorting out faults in order.

Signs of a malfunction of the lubrication system, checking its performance

- Chainsaw chain is dry and has a pale shade without shine.

- Shodo chain stretches quickly.

- The tire is very hot and can even partially melt the paint.

- The oil from the tank is practically NOT reduced.

- Decreased cutting efficiency on a sharp chain

All these signs indicate that the lubrication process is not working properly. In order to check the oil supply by the lubrication system, it is necessary to remove the side tire of the chainsaw and start it. Further, you need to slightly increase the speed while observing the place where the oil line ends. If oil is flowing in, it is most likely that there is not enough oil for proper lubrication and the filter needs to be cleaned or replaced and, if possible, adjusted the flow. In the case when it is NOT received, the problem is more serious and requires further diagnosis.

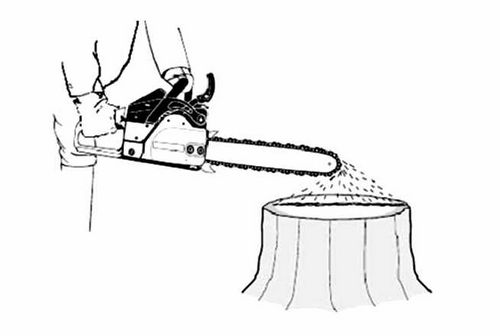

There is a way to check the oil supply without removing the tires. To do this, it is necessary to direct the end of the tire towards, for example, a freshly sawn block from the cutting side and increase the speed as much as possible, while trying to keep the end of the tire NOT more than 10 cm from the block. If oily spots begin to appear on its surface, it means that oil is being supplied.

Lubrication system device

Depending on the brand of the chainsaw, the details of the lubrication system may differ slightly in design, but their total number and connection diagram remains unchanged.

The main components of the lubrication system are:

- The oil tank is usually located in the crankcase.

- Filter element, installed in the tank.

- The oil line is a small diameter oil-resistant rubber hose.

- The heart of the system is the oil pump.

- Worm gear gear transmission force from engine to pump.

- A chainsaw tire, it can also be considered an element of the lubrication system, since it has special holes for supplying oil, by the way, the chain itself participates in the transportation of oil and, accordingly, also has some elements designed specifically to provide lubrication.

Troubleshooting

After it has been determined that no oil is supplied, further diagnostics is possible only if the oil system is completely removed. Of course, in some situations, changing the filter helps, but this is very rare.

Chainsaw chain lubrication system

To supply oil for lubricating the chainsaw chain, a special pump is used in the tool, which is dosed, depending on the number of engine revolutions, supplies lubricant to the saw bar.

The system uses oil to lubricate the chainsaw chain, which has increased adhesion properties, this is necessary to evenly distribute the oil around the entire perimeter of the tire and keep it on it even at high chain speeds. Let’s take a closer look at the oil supply system implemented in modern chainsaws.

Principle of operation

The main unit of the system is the pump. The principle of its operation is as follows. With an increase in engine speed, a gear mounted on the main shaft drives the pump shaft through a worm gear. In turn, the rotation of the shaft creates a certain pressure in the oil line, which forces the oil to move along it towards the tire.

The end of the oil channel is located at the point of contact of the tire with the tool housing, where there is a longitudinal groove, on which, when the tire is installed, its oil channel falls.

The groove is necessary to ensure the supply of oil to the tire, regardless of the chain tension of the chainsaw. Simply put, no matter what position the tire is in at the time of operation, oil through the groove will get onto it.

Further, a chain is included in the lubrication process, on the links of which, depending on the model of the chain, there is either a groove or a hole through which the oil is accelerated throughout the tire. As the engine speed increases, the oil flow rate also increases.

Some models of chainsaws are equipped with pumps, which additionally have a capacity adjustment, and if necessary, the amount of oil supplied by the lubrication system can be increased or decreased.

This function is quite convenient as it allows you to save money and does not waste extra oil.

Chainsaw chain lubrication system

One of the fundamental chainsaw systems, without which work is impossible, is the forced lubrication system of the chainsaw chain. It’s not a secret for anyone that at the time the saw is operating, the chain friction against the tire of the chainsaw, which causes it to heat up and premature wear. To soften friction, the chain mechanism must be constantly Lubricated.

Most common malfunctions

- Broken oil hose. It can sometimes be detected by visual inspection. The problem is solved by replacing the defective part.

- Lack of threads on the oil pump shaft, replacing it will help.

- Defective thread on the pump drive gear is similarly solved by installing a new part.

- No corkscrew of the main shaft (relevant for Some models of tools, for example, Homelite). You can fix it by installing instead of the native corkscrew, suitable for the diameter of the studs, cutting it to the required length.

- Blockage in the line. Can be removed by blowing with compressed air or mechanically using a wire of suitable diameter.

- Clogged filter element.

- In the Stihl MS 180, the pump of which is not separable, it often clogs. You can try to rinse in clean gasoline if it does not help replace.

- In Chinese chainsaws (Gypsy), very often cuts off the grooves on the main gear, through which the force from the asterisk is transmitted to it.

Individual malfunction of the Stihl MS 180 lubrication system

In view of the fact that Stihl MS 180 is one of the most common models of chainsaws, I would like to dwell on one inherent only malfunction and describe a way to eliminate it without replacing parts.

Quite often, on the Stihl MS 180 Chainsaw, it is observed that the oil line is depressurized in the place where the oil line from the tank is installed in the saw body. The malfunction can be determined by the characteristic grease leakage on the bottom of the tool.

To eliminate the malfunction, it is necessary to remove the chainsaw handle, remove the hose from the bore, clean and degrease. After all THESE manipulations, apply sealant to the hose seat and install it in the chainsaw body.

For more information on troubleshooting and full diagnostics of the lubrication system of the Stihl chainsaw, you can find out by looking. In which step by step the process of disassembly and repair of the lubrication system is captured.

The principle of operation and the device of the pump

Oil pumps can be made of metal and plastic. They are also divided into two types, which differ in their design:

The pump is driven by the movement of the drive sprocket. During the movement of the chain, oil is fed into a special channel located on the guide bar. At idle speed (when the drive sprocket does NOT rotate), the pump does NOT supply lubricant. this is done to save.

The speed and volumes of lubricant supply to the chain are directly dependent on the number of revolutions of the sprocket. In some models of chainsaws, a manual adjustment system is provided using a special screw located on the body of the device. On expensive models, the dust oil supply is automatically regulated during operation.

Chainsaw chain lubrication

The only point that depends on the user is to make sure that the oil tank is not empty during operation. If this happens and the oil supply stops, the chain will acquire a bluish tint, which will indicate that it has overheated and has become unusable.

Chainsaw chain lubrication

I want to use it on the TAD 17 chain on the Stihl 250 chainsaw. In winter it is very thick. Will not it be worse from this oil pump, and will it fail from overload? And if you can. What is the principle, in the pump, supplying oil to the chain?

The oil pump, which is set at 180. 250 Stihl, is generally practically unkillable. it has a brass cylinder. Even working off eats twice as long as aluminum.

And the principle of operation is very simple. It’s a pity, there are illustrations, and I’ve never seen them anywhere. In words. two parts, a cylinder and a plunger rotating in it. The plunger has a milled flat at the end. When rotating, the plunger moves slightly back and forth.

Two holes are made in the cylinder opposite each other. When the flat of the plunger comes to the intake opening, it is slightly pulled out of the cylinder. a vacuum is created and a little oil is sucked in.

When the baldness turns to the discharge port, the plunger is pushed into the cylinder. pressure is created, oil flows through the channel to the tire. As you can see, in principle, you cannot damage the pump as much as you like with thick oil. it just won’t go, and that’s it.

_

Is it normal if oil leaks out of the reservoir when the chainsaw is idle? THOSE. If it is a little dusty, then pour a little? Otherwise, during the inactivity of the saw, oil flows out of the tank completely.

No. It is not normal. The problem is either with the oil pump or with the reservoir itself. In general, oil and fuel consumption is usually 1 to 1.

_

The leading sprocket of a tire on a chainsaw, how to Lubricate? For example, is Mobil or Jcb hydraulic lubricant suitable? What do you think?

Sprockets are smeared on all tires (except for Shtilev ones), if you do not smear them, then the bearing may crumble, and then the tire ends, but about Shtilev tires. on the one hand, this is kind of a plus, and on the other, I saw Shtilev almost new tires from Burnt bearings.

_

The chainsaw drives the chain lubrication oil. At idle it pours very slowly, you give gas. it pours in a stream. For five minutes of work, all the oil is poured.

Does NOT react to the position of the adjusting screw. Also, a little (0.5-1 mm), the sprocket, which rotates the chain, is loose. Who faced such a thing?

It is necessary to remove the asterisk and sort out the oil pump, and check the hoses for breaks. The leading sprocket must have a slight backlash. It does not have to be rigid, the vibrations will go to the crankshaft.

_

The holes coincide when I put it on, maybe when the chain is tightened, the hole moves off because of this, oil does not get on the chain, but the chains, you can use one, as it becomes blunt, remove puts a new one, sharpens the old, etc. Do in a cycle of three chains while the tire has not worn off?

The oval hole for lubrication on the body of the chainsaw is made in such a way that, in any position of the tire within the adjustment range of the chain tensioner, the alignment of the lubrication holes on the tire and the body does not disappear.

Ideally, a set of chains, when used on the saw one by one in a cyclic fashion, and the bar should fail at the same time. There are two lubrication options. Well, I mean. through what the oil is supplied.

Most tires have a separate hole for supplying lubricant to the chain, and these larger ones are used for tensioning. And some (and quite a few) do not have a separate lubricating hole.

And a free pull hole is used for lubrication. In this case, it will necessarily communicate with the tire groove. You can check with a wire. This is neither good nor bad, this is a feature.

So. in the second case, quite large oil losses are possible if the sprocket cover does not fit tightly. Then it just goes right through (unlike tires with a separate hole), and drips down.

_

After a minute of running the chainsaw at idle speed, I pressed a little on the gas several times, the oil to lubricate the chain began to flow very strongly onto the chain, which formed a pool of oil right under the saw. Where is the chain oil adjustment screw? And how to make this adjustment correctly?

Your model does not have regulation of the oil supply to the chain, oil is supplied automatically. Carefully Inspect and thoroughly clean the oil intake holes on the bar, carefully install the bar and chain. In theory, it should help.

If a puddle of oil forms under the saw, then the most likely is a sloppy tire or a skewed clutch cover, as a result of which a gap appears between the outlet of the oil pump and the lubricating hole of the tire, and the oil goes out.

_

Tell us more about the oil pumps installed in chainsaws.

Very rarely on modern chain saws (and electric ones as well), NOT plunger pumps are used.

Chainsaw chain oil: which is better to use

In this case, after prolonged operation, pools of lubricant may accumulate under the saw. This not only affects the consumption of oil, which will have to be constantly refilled, but also negatively affects the environment.

Both of THESE problems should be addressed as soon as possible after they are discovered. This will extend the life of the saw and reduce lubricant consumption.

DIY chainsaw repair

In fact, this is a worm gear pair. The oil pump drive is driven either by the drive chain sprocket (photo 4 pos. 1), or by the crankshaft (photo 4 pos. 2).

In the first case, the plunger is mechanically connected to the drive sprocket and rotates only with it. Photo 4 pos. 1 shows the drive of the Stihl MS-180 chainsaw. The steel tendril clings to a special groove on the drive sprocket cup. When the sprocket spins, the drive spins with it. At idle speed in this case, the oil supply is.

In the second case, the drive is rigidly fixed on the shaft and constantly rotates with it. Photo 4 pos. 2 shows the oil pump drive of the Husqvarna 137, 142 chainsaw. It is pressed onto the crankshaft shank and rotates with it constantly. Therefore, oil is supplied constantly, even if the saw is in idle mode.

Usually, one of the gears (either on the plunger or on the drive) is made of plastic in order to secure a part with a more complex design or complex installation. The plastic part will break and wear out first.

On some saws, the driven oil pump can be additionally closed with a special cover (photo 5, the oil pump cover of a Chinese chainsaw 45-52 cc), which protects the worm gear and the pump itself from dirt and wood dust. On some saws, such as Husqvarna 137, 142, the oil pump housing itself closes the connection between the drive and the plunger, thus acting as a protective cover.

A certain amount of lubrication is required for the bar and chain to function properly.

In order for the design of the lubrication system existing on the chainsaw to give it out, the oil must have a suitable viscosity. Judging by the mechanics, the oil pump does not care what kind of oil you use: automotive, transmission or special. The main thing is that the viscosity is within the specified permissible range. However, this does not mean that any oil can be poured. The purpose of chain oil is not to save you money on buying it, but to lubricate the bar and chain parts. Different oils do this differently. But more about this in another article “chain oil. What to pour? “.

Saw chain lubrication

The lubrication of the saw chain and bar is very important. The design of the chain saws includes a pump, which supplies oil from the tank to the cutting system through special holes. Further, the saw chain itself distributes it. The grease is captured by the shanks and distributed throughout the entire bar and chain. For additional retention of lubricant in the chainsaw, special holes are drilled in the shanks or channels are milled. Also, in the chain lubrication system for chainsaws, connecting links are often involved, in which additional grooves are made for lubrication. Sufficiently abundant lubrication Reduces friction and heat levels, thereby not only increasing the service life of each saw element, but also reducing the level of saw chain elongation. Therefore, it is in the interests of every saw owner. Follow the chain lubrication process so that in the event of a breakdown you do not have to look for new chains for chainsaws.

The lubrication process is quite simple: during the acceleration of the saw chain, small oil droplets form an oil trace on any light surface if the end of the bar touches it. If there is a trace, there is no lubricant and you need to check for the presence of oil, cleans the groove of the tire, adjust the saw pump, etc.

And one more thing: in modern saws, it is allowed to install chains and bars of different lengths, but before using a new headset, you need to make sure that the oil pump installed in the dust will cope with its processing.

In the course of long-term operation of the chainsaw, some of its elements and units may become unusable. One of the most vulnerable components is the oil pump. In this regard, many owners of dust have a question about how to repair the oil supply on a chainsaw.

The task of the oil pump is to supply lubricant to the chain. this is necessary for its smooth movement along the guide bar. When the oil pump fails, the lubrication of the chain deteriorates, which reduces the efficiency of the chainsaw. In SEPARATE cases, this leads to an open circuit. To prevent negative moments, it is necessary to repair the oil supply in a timely manner. How to do it?

Troubleshooting

If oil is supplied to the chain in excessive quantities, and not only during saw operation, but also at idle speed, manual adjustment should be made (if the pump design allows this). This is done with a screw, which is located on the body close to the guide rail, usually from the bottom or the side. Tightening the screw reduces the oil supply, loosening it vice versa. If the adjustment does not help, it is necessary to check the serviceability of the pump, and also to inspect the tire. perhaps a gap has formed at the point of its connection with the body, through which oil flows past the chain.

Lack of oil can be caused by several reasons, for each of which there is a solution:

- Defective oil pump. As a rule, it consists in an unusable gasket. In order to replace it, it is necessary to carefully disassemble the pump so as not to damage its moving parts. Then a new gasket is installed, after which the pump is assembled and installed in place.

- Breakage of the oil hose. In the event that the pump gasket is intact, or its replacement did not lead to a result, check the hose for leaks. If it is defective, it must be replaced. Otherwise, it will NOT be superfluous to clean it and fix it with sealant.

If the reason lies not in pump breakdowns, it is necessary to inspect all conductive holes and channels for blockages, and, if necessary, clean them of foreign objects. This can be done with a jet of compressed air.

DO NOT want to mess with your chainsaw but need oil flow adjustments? Contact our specialists for help, who will diagnose and repair the chainsaw, and, if necessary, carry out repair work and adjust the lubrication level. Your saw will be like new!

Back to the list

Most modern oil pumps for chain chainsaws are arranged in the same way: a cylinder (photo 1, pos. 2) is placed in the body (photo 1, pos. 2), a plunger (photo 1, pos. 3) is inserted into it, making rotational-translational movements in it.

The cylinder in the lower part has two holes (in photo 1, item 4, only one of them is visible): through one oil it is sucked in, into the second it is pushed out.

The plunger (photo 2) is a steel rod, on one side it has a milling groove. a flat, and on the other a plastic or steel gear. As the plunger rotates, the baldness alternately opens and closes the inlet and outlet of the cylinder. When moving upwards, the flat first opens the inlet (at the same time we close the outlet) and creates a slight decrease in pressure. As a result, a portion of the oil is sucked into the cylinder. Then, turning, the plunger moves downward, opening the outlet with a flat (at the same time closing the inlet) and pushing the oil out of the cylinder. This is how it is fed to the tire in small portions. High cycle rate creates a constant and continuous flow of lubricant.

Two types of oil pumps are used (photo 3): with variable oil flow and with fixed flow. In the first case, the plunger gears have an oblique tooth, and the upward movement is provided by an additionally installed spring. The oil flow is controlled by changing the stroke length of the plunger in the cylinder. An example is an oil pump for Chinese dust with an engine capacity of 45-52 cc

In the case of an unregulated oil pump, there is an oblique closed groove on the plunger, against which the fixed stop of the body rests. Rotation causes the groove to slide against the stop, and since it is oblique this movement causes the plunger to move forward and backward. With this scheme, it is impossible to limit the stroke of the plunger and the oil is supplied in constant quantities. Example. the oil pump of the Husqvarna chainsaw 137, 142

The torque from the engine to the plunger is transmitted through a special drive, which also has a gear. the counterpart of the gear to the plunger.

What to check before working with a chainsaw

Checking the tightening of the nuts should be done before each start of work with the chainsaw. The fact is that a tool such as a chainsaw has a lot of vibration, and because of this, the screws and nuts in it can loosen. Therefore, it is very unsafe to operate a chainsaw in which parts are poorly fixed.

Checking the spark plugs of the chainsaw for carbon deposits (it does not have to be) should also be done, and if carbon deposits are found, replace the spark plug with a new one.

Chainsaw chain lubrication. Possible problems and their elimination. DIY repair

We can say that they are not even used at all. They all work in the same way.

The main parts are an aluminum cylinder, rigidly fixed in the body and a steel plunger with a plastic gear, rotating in this cylinder. How it works: There is a small hole in the blind end of the cylinder. There is another one opposite.

One of them is suction, the second is pumping. The plastic plunger gear has an oblique annular groove that aligns with the metal rod in the body.

Mechanics When the plunger rotates due to the oblique groove, it also reciprocates back and forth for each revolution.

Hydraulics When the sheared section of the end of the plunger approaches the suction port, the plunger is pulled back. A slight vacuum is created, a portion of oil is sucked into the cylinder.

Turning the plunger by about half a turn. the cut-off section (of course, with the oil in it) goes to the discharge port.

At this time, the plunger moves towards the blind end of the cylinder. Some pressure builds up, oil flows into the lubrication channel.

Now. about the differences in design: The pinion on the plunger can be metal. In this case, the worm on the crankshaft will be plastic, you will NOT go anywhere, it should be

weakness.

The pump housing can be metal. Well, not bad, of course, but not important.

And the most important thing is to adjust the oil flow. In the first case, when the axial movement of the plunger is driven by an oblique annular groove.

Capacity adjustment is not technically possible. If longitudinal movement is carried out by an oblique cut of the rear part of the plunger, it is possible to adjust the flow.

With the help of different options for the adjustable stop of the rear part of the plunger, the length of its axial movement is changed, and, accordingly, the amount of oil captured in one revolution of the plunger.

_

How often should you squirt your chainsaw tire? And as I understand it, the grease should be of the same consistency as lithol approximately? Or a valid same transmission?

I bought a new chain, installed it, it works fine. But after a couple of minutes, the hole in the tire for the oil supply is clogged and the chain runs dry.

Literally enough for one cut. I take it apart again, clean it, run it. The chain is lubricated without sawing. And after one cut, the tire is again clogged with shavings.

I didn’t try to gazanut, because I didn’t have time, the chain almost wedges, it won’t turn it by hand, and the tire and chain are terribly hot, the chainsaw stalls. Tell me what the problem is, with the old chain this was not observed?

There is a great suspicion that, in fact, oil for lubrication is coming, only because of the large amount of dust (perhaps now you are sawing dry wood, or even with dust in general) falling into the groove of the tire and it is not visible on the chain.

And what is the condition of the tire itself? Especially important in this case is the state of the driven sprocket and tire spacers (the chain slides along them during operation) in those places where the teeth of the sprocket “dive” into the tire or appear from there during rotation.

Also, in the event of excessive wear of the spacers, the groove depth of the tire could decrease below the permissible level and the chain shanks cling to the bottom of the groove when moving.

In this case, too, there will be excessive heating of the chain and bus. After all, apparently this chain for the bus is NOT the first.

In addition, the fact that the saw stalls when the chain is seized indicates a NOT engaging clutch. There is either dirt between the clutch cams and its cup, or the cup itself is deformed. Possibly stretched clutch springs.

DIY chainsaw repair

In fact, this is a worm gear pair. The oil pump drive is driven either by the drive chain sprocket (photo 4 pos. 1), or by the crankshaft (photo 4 pos. 2).

In the first case, the plunger is mechanically connected to the drive sprocket and rotates only with it. Photo 4 pos. 1 shows the drive of the Stihl MS-180 chainsaw. The steel tendril clings to a special groove on the drive sprocket cup. When the sprocket spins, the drive spins with it. At idle speed in this case, the oil supply is.

In the second case, the drive is rigidly fixed on the shaft and constantly rotates with it. Photo 4 pos. 2 shows the oil pump drive of the Husqvarna 137, 142 chainsaw. It is pressed onto the crankshaft shank and rotates with it constantly. Therefore, oil is supplied constantly, even if the saw is in idle mode.

Usually, one of the gears (either on the plunger or on the drive) is made of plastic in order to secure a part with a more complex design or complex installation. The plastic part will break and wear out first.

On some saws, the driven oil pump can be additionally closed with a special cover (photo 5, the oil pump cover of a Chinese chainsaw 45-52 cc), which protects the worm gear and the pump itself from dirt and wood dust. On some saws, such as Husqvarna 137, 142, the oil pump housing itself closes the connection between the drive and the plunger, thus acting as a protective cover.

A certain amount of lubrication is required for the bar and chain to function properly.

In order for the design of the lubrication system existing on the chainsaw to give it out, the oil must have a suitable viscosity. Judging by the mechanics, the oil pump does not care what kind of oil you use: automotive, transmission or special. The main thing is that the viscosity is within the specified permissible range. However, this does not mean that any oil can be poured. The purpose of chain oil is not to save you money on buying it, but to lubricate the bar and chain parts. Different oils do this differently. But more about this in another article “chain oil. What to pour? “.

What to check before working with a chainsaw

Checking the tightening of the nuts should be done before each start of work with the chainsaw. The fact is that a tool such as a chainsaw has a lot of vibration, and because of this, the screws and nuts in it can loosen. Therefore, it is very unsafe to operate a chainsaw in which parts are poorly fixed.

Checking the spark plugs of the chainsaw for carbon deposits (it does not have to be) should also be done, and if carbon deposits are found, replace the spark plug with a new one.

Saw chain lubrication

The lubrication of the saw chain and bar is very important. The design of the chain saws includes a pump, which supplies oil from the tank to the cutting system through special holes. Further, the saw chain itself distributes it. The grease is captured by the shanks and distributed throughout the entire bar and chain. For additional retention of lubricant in the chainsaw, special holes are drilled in the shanks or channels are milled. Also, in the chain lubrication system for chainsaws, connecting links are often involved, in which additional grooves are made for lubrication. Sufficiently abundant lubrication Reduces friction and heat levels, thereby not only increasing the service life of each saw element, but also reducing the level of saw chain elongation. Therefore, it is in the interests of every saw owner. Follow the chain lubrication process so that in the event of a breakdown you do not have to look for new chains for chainsaws.

The lubrication process is quite simple: during the acceleration of the saw chain, small oil droplets form an oil trace on any light surface if the end of the bar touches it. If there is a trace, there is no lubricant and you need to check for the presence of oil, cleans the groove of the tire, adjust the saw pump, etc.

And one more thing: in modern saws, it is allowed to install chains and bars of different lengths, but before using a new headset, you need to make sure that the oil pump installed in the dust will cope with its processing.

In the course of long-term operation of the chainsaw, some of its elements and units may become unusable. One of the most vulnerable components is the oil pump. In this regard, many owners of dust have a question about how to repair the oil supply on a chainsaw.

The task of the oil pump is to supply lubricant to the chain. this is necessary for its smooth movement along the guide bar. When the oil pump fails, the lubrication of the chain deteriorates, which reduces the efficiency of the chainsaw. In SEPARATE cases, this leads to an open circuit. To prevent negative moments, it is necessary to repair the oil supply in a timely manner. How to do it?

Chainsaw chain lubrication. Possible problems and their elimination. DIY repair

We can say that they are not even used at all. They all work in the same way.

The main parts are an aluminum cylinder, rigidly fixed in the body and a steel plunger with a plastic gear, rotating in this cylinder. How it works: There is a small hole in the blind end of the cylinder. There is another one opposite.

One of them is suction, the second is pumping. The plastic plunger gear has an oblique annular groove that aligns with the metal rod in the body.

Mechanics When the plunger rotates due to the oblique groove, it also reciprocates back and forth for each revolution.

Hydraulics When the sheared section of the end of the plunger approaches the suction port, the plunger is pulled back. A slight vacuum is created, a portion of oil is sucked into the cylinder.

Turning the plunger by about half a turn. the cut-off section (of course, with the oil in it) goes to the discharge port.

At this time, the plunger moves towards the blind end of the cylinder. Some pressure builds up, oil flows into the lubrication channel.

Now. about the differences in design: The pinion on the plunger can be metal. In this case, the worm on the crankshaft will be plastic, you will NOT go anywhere, it should be

weakness.

The pump housing can be metal. Well, not bad, of course, but not important.

And the most important thing is to adjust the oil flow. In the first case, when the axial movement of the plunger is driven by an oblique annular groove.

Capacity adjustment is not technically possible. If longitudinal movement is carried out by an oblique cut of the rear part of the plunger, it is possible to adjust the flow.

With the help of different options for the adjustable stop of the rear part of the plunger, the length of its axial movement is changed, and, accordingly, the amount of oil captured in one revolution of the plunger.

_

How often should you squirt your chainsaw tire? And as I understand it, the grease should be of the same consistency as lithol approximately? Or a valid same transmission?

I bought a new chain, installed it, it works fine. But after a couple of minutes, the hole in the tire for the oil supply is clogged and the chain runs dry.

Literally enough for one cut. I take it apart again, clean it, run it. The chain is lubricated without sawing. And after one cut, the tire is again clogged with shavings.

I didn’t try to gazanut, because I didn’t have time, the chain almost wedges, it won’t turn it by hand, and the tire and chain are terribly hot, the chainsaw stalls. Tell me what the problem is, with the old chain this was not observed?

There is a great suspicion that, in fact, oil for lubrication is coming, only because of the large amount of dust (perhaps now you are sawing dry wood, or even with dust in general) falling into the groove of the tire and it is not visible on the chain.

And what is the condition of the tire itself? Especially important in this case is the state of the driven sprocket and tire spacers (the chain slides along them during operation) in those places where the teeth of the sprocket “dive” into the tire or appear from there during rotation.

Also, in the event of excessive wear of the spacers, the groove depth of the tire could decrease below the permissible level and the chain shanks cling to the bottom of the groove when moving.

In this case, too, there will be excessive heating of the chain and bus. After all, apparently this chain for the bus is NOT the first.

In addition, the fact that the saw stalls when the chain is seized indicates a NOT engaging clutch. There is either dirt between the clutch cams and its cup, or the cup itself is deformed. Possibly stretched clutch springs.

Chainsaw chain lubrication

I want to use it on the TAD 17 chain on the Stihl 250 chainsaw. In winter it is very thick. Will not it be worse from this oil pump, and will it fail from overload? And if you can. What is the principle, in the pump, supplying oil to the chain?

The oil pump, which is set at 180. 250 Stihl, is generally practically unkillable. it has a brass cylinder. Even working off eats twice as long as aluminum.

And the principle of operation is very simple. It’s a pity, there are illustrations, and I’ve never seen them anywhere. In words. two parts, a cylinder and a plunger rotating in it. The plunger has a milled flat at the end. When rotating, the plunger moves slightly back and forth.

Two holes are made in the cylinder opposite each other. When the flat of the plunger comes to the intake opening, it is slightly pulled out of the cylinder. a vacuum is created and a little oil is sucked in.

When the baldness turns to the discharge port, the plunger is pushed into the cylinder. pressure is created, oil flows through the channel to the tire. As you can see, in principle, you cannot damage the pump as much as you like with thick oil. it just won’t go, and that’s it.

_

Is it normal if oil leaks out of the reservoir when the chainsaw is idle? THOSE. If it is a little dusty, then pour a little? Otherwise, during the inactivity of the saw, oil flows out of the tank completely.

No. It is not normal. The problem is either with the oil pump or with the reservoir itself. In general, oil and fuel consumption is usually 1 to 1.

_

The leading sprocket of a tire on a chainsaw, how to Lubricate? For example, is Mobil or Jcb hydraulic lubricant suitable? What do you think?

Sprockets are smeared on all tires (except for Shtilev ones), if you do not smear them, then the bearing may crumble, and then the tire ends, but about Shtilev tires. on the one hand, this is kind of a plus, and on the other, I saw Shtilev almost new tires from Burnt bearings.

_

The chainsaw drives the chain lubrication oil. At idle it pours very slowly, you give gas. it pours in a stream. For five minutes of work, all the oil is poured.

Does NOT react to the position of the adjusting screw. Also, a little (0.5-1 mm), the sprocket, which rotates the chain, is loose. Who faced such a thing?

It is necessary to remove the asterisk and sort out the oil pump, and check the hoses for breaks. The leading sprocket must have a slight backlash. It does not have to be rigid, the vibrations will go to the crankshaft.

_

The holes coincide when I put it on, maybe when the chain is tightened, the hole moves off because of this, oil does not get on the chain, but the chains, you can use one, as it becomes blunt, remove puts a new one, sharpens the old, etc. Do in a cycle of three chains while the tire has not worn off?

The oval hole for lubrication on the body of the chainsaw is made in such a way that, in any position of the tire within the adjustment range of the chain tensioner, the alignment of the lubrication holes on the tire and the body does not disappear.

Ideally, a set of chains, when used on the saw one by one in a cyclic fashion, and the bar should fail at the same time. There are two lubrication options. Well, I mean. through what the oil is supplied.

Most tires have a separate hole for supplying lubricant to the chain, and these larger ones are used for tensioning. And some (and quite a few) do not have a separate lubricating hole.

And a free pull hole is used for lubrication. In this case, it will necessarily communicate with the tire groove. You can check with a wire. This is neither good nor bad, this is a feature.

So. in the second case, quite large oil losses are possible if the sprocket cover does not fit tightly. Then it just goes right through (unlike tires with a separate hole), and drips down.

_

After a minute of running the chainsaw at idle speed, I pressed a little on the gas several times, the oil to lubricate the chain began to flow very strongly onto the chain, which formed a pool of oil right under the saw. Where is the chain oil adjustment screw? And how to make this adjustment correctly?

Your model does not have regulation of the oil supply to the chain, oil is supplied automatically. Carefully Inspect and thoroughly clean the oil intake holes on the bar, carefully install the bar and chain. In theory, it should help.

If a puddle of oil forms under the saw, then the most likely is a sloppy tire or a skewed clutch cover, as a result of which a gap appears between the outlet of the oil pump and the lubricating hole of the tire, and the oil goes out.

_

Tell us more about the oil pumps installed in chainsaws.

Very rarely on modern chain saws (and electric ones as well), NOT plunger pumps are used.

Chainsaw chain oil: which is better to use

In this case, after prolonged operation, pools of lubricant may accumulate under the saw. This not only affects the consumption of oil, which will have to be constantly refilled, but also negatively affects the environment.

Both of THESE problems should be addressed as soon as possible after they are discovered. This will extend the life of the saw and reduce lubricant consumption.

The principle of operation and the device of the pump

Oil pumps can be made of metal and plastic. They are also divided into two types, which differ in their design:

The pump is driven by the movement of the drive sprocket. During the movement of the chain, oil is fed into a special channel located on the guide bar. At idle speed (when the drive sprocket does NOT rotate), the pump does NOT supply lubricant. this is done to save.

The speed and volumes of lubricant supply to the chain are directly dependent on the number of revolutions of the sprocket. In some models of chainsaws, a manual adjustment system is provided using a special screw located on the body of the device. On expensive models, the dust oil supply is automatically regulated during operation.

Major problems with oil supply

When running a chainsaw, there are two types of chain lubrication problems:

- Insufficient oil flow, which can be caused for various reasons. If measures are NOT taken in time, the quality of work will noticeably deteriorate, and the chain itself may become unusable altogether.

- Excess oil.

Troubleshooting

If oil is supplied to the chain in excessive quantities, and not only during saw operation, but also at idle speed, manual adjustment should be made (if the pump design allows this). This is done with a screw, which is located on the body close to the guide rail, usually from the bottom or the side. Tightening the screw reduces the oil supply, loosening it vice versa. If the adjustment does not help, it is necessary to check the serviceability of the pump, and also to inspect the tire. perhaps a gap has formed at the point of its connection with the body, through which oil flows past the chain.

Lack of oil can be caused by several reasons, for each of which there is a solution:

- Defective oil pump. As a rule, it consists in an unusable gasket. In order to replace it, it is necessary to carefully disassemble the pump so as not to damage its moving parts. Then a new gasket is installed, after which the pump is assembled and installed in place.

- Breakage of the oil hose. In the event that the pump gasket is intact, or its replacement did not lead to a result, check the hose for leaks. If it is defective, it must be replaced. Otherwise, it will NOT be superfluous to clean it and fix it with sealant.

If the reason lies not in pump breakdowns, it is necessary to inspect all conductive holes and channels for blockages, and, if necessary, clean them of foreign objects. This can be done with a jet of compressed air.

DO NOT want to mess with your chainsaw but need oil flow adjustments? Contact our specialists for help, who will diagnose and repair the chainsaw, and, if necessary, carry out repair work and adjust the lubrication level. Your saw will be like new!

Back to the list

Most modern oil pumps for chain chainsaws are arranged in the same way: a cylinder (photo 1, pos. 2) is placed in the body (photo 1, pos. 2), a plunger (photo 1, pos. 3) is inserted into it, making rotational-translational movements in it.

The cylinder in the lower part has two holes (in photo 1, item 4, only one of them is visible): through one oil it is sucked in, into the second it is pushed out.

The plunger (photo 2) is a steel rod, on one side it has a milling groove. a flat, and on the other a plastic or steel gear. As the plunger rotates, the baldness alternately opens and closes the inlet and outlet of the cylinder. When moving upwards, the flat first opens the inlet (at the same time we close the outlet) and creates a slight decrease in pressure. As a result, a portion of the oil is sucked into the cylinder. Then, turning, the plunger moves downward, opening the outlet with a flat (at the same time closing the inlet) and pushing the oil out of the cylinder. This is how it is fed to the tire in small portions. High cycle rate creates a constant and continuous flow of lubricant.

Two types of oil pumps are used (photo 3): with variable oil flow and with fixed flow. In the first case, the plunger gears have an oblique tooth, and the upward movement is provided by an additionally installed spring. The oil flow is controlled by changing the stroke length of the plunger in the cylinder. An example is an oil pump for Chinese dust with an engine capacity of 45-52 cc

In the case of an unregulated oil pump, there is an oblique closed groove on the plunger, against which the fixed stop of the body rests. Rotation causes the groove to slide against the stop, and since it is oblique this movement causes the plunger to move forward and backward. With this scheme, it is impossible to limit the stroke of the plunger and the oil is supplied in constant quantities. Example. the oil pump of the Husqvarna chainsaw 137, 142

The torque from the engine to the plunger is transmitted through a special drive, which also has a gear. the counterpart of the gear to the plunger.