Personal protective equipment for working with angle grinders

Personal protective equipment when working with an angle grinder

These safety instructions for working with an angle grinder are available for free viewing and downloading.

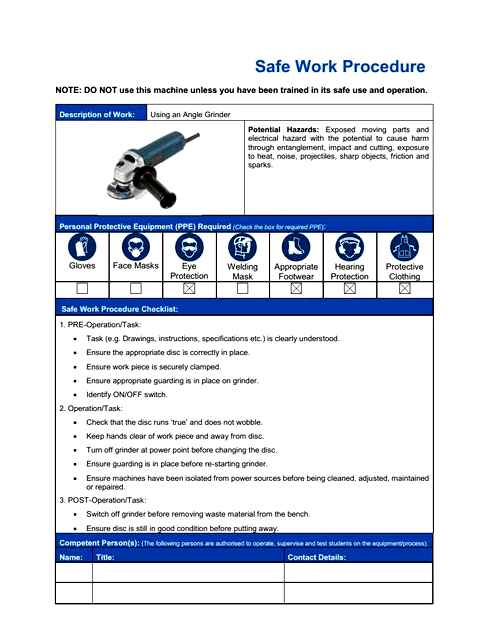

1.1. Workers must be at least 18 years old who have passed the following in accordance with current legislation:. A medical examination;. Induction training;. Instruction and on-the-job training;. Training and examination of electrical safety requirements in the scope of electrical safety group 3;. First aid training;. Occupational safety training and examination of knowledge of occupational safety requirements. 1.2. An employee assigned to participate in activities which are not related to his/her profession (e.g. subbotnik), must undergo special briefing on safe conduct of such activities. 1.3. The procedure, form, frequency and duration of the organization and conduct of the above activities are reflected in the local regulations of the enterprise. 1.4. An employee admitted to independent work must know:. The principle of operation of technological equipment, tools and appliances;. The requirements of existing rules, regulations and instructions on labor protection;. Rules for using primary fire extinguishing equipment;. Ways to provide first aid to victims;. Rules for using special clothing, special shoes and other personal protective equipment, as well as collective protective equipment;. Designation of signal colors, safety signs and signal markings;. Personal hygiene rules. 1. The worker may be exposed to the following hazardous and harmful production factors:. electric current, the path of which may pass through the human body when shorted;. unprotected rotating work tool (circle);. sharp edges, burrs, roughness on the surface of the power tool and work pieces;. increased noise and vibration level during operation of the power tool drive and during work piece processing;. increased dustiness of the working area air;. heated metal particles (sparks);. physical loads (e.g. 1.6. Employees are obliged to:. fulfill the requirements of regulations, rules and instructions on labor protection, internal regulations, instructions of enterprise officials and authorities;. use personal protective equipment only for its intended purpose (not to take it outside the enterprise), inform the management of the need for dry cleaning, washing, drying, repair of special clothing;. keep unauthorized persons away from their work places;. follow the rules for movement within the enterprise;. follow internal labor regulations of the enterprise. 1.7. An employee shall perform only those job functions, which are stipulated by his/her employment contract and other by-laws of the enterprise, and he/she is acquainted with such by-laws against his/her signature. An employee is prohibited from performing work functions that are not set out in the employment contract and other local regulations of the company. No employee shall be permitted to start work if he/she, in his/her objective or subjective opinion, is likely to suffer an injury and/or poisoning. If a risk of injury and/or poisoning arises in the process of performance of work functions, an employee is obliged to stop work and inform his/her immediate or supervisor about the risk he/she has discovered. 1.8. Employees are prohibited from using tools, devices and equipment, the safe handling of which they are not trained and have no practical experience in working with them. 1.9. An employee shall comply with labor and production discipline and internal work regulations. 1.10. 1 1 The employee must observe his/her agreed working hours and time off, in case of illness, feeling unwell or insufficient rest the employee must report his/her condition to his/her direct superior or his/her superior. In case of an accident the employee must stop working, inform his/her superior or superior and get medical advice. 1.11. If any employee is involved in an accident, first aid must be given to the injured person, the accident must be reported to his or her supervisor, and the incident must be preserved if it does not endanger others. 1.12. It is prohibited to stay on the company’s premises in places not related to: the performance of labor functions, instructions from the immediate or supervisory authority, places for rest and eating. 1.13. Employees must observe the rules of personal hygiene: wash their hands with warm water and soap before taking food and after finishing work. Eating, smoking and resting are permitted only in specially designated rooms and places. Drink water only from specially designed facilities (coolers). 1.14. Employees shall not be allowed to work intoxicated by alcohol or other intoxicating substances, and shall not drink alcohol, take drugs, psychotropic, toxic or other intoxicating substances at work or during working hours. 1.15. The employee, who has allowed violation or failure to comply with the requirements of this instruction on labor protection, is considered, as the infringer of production discipline and can be brought to disciplinary responsibility, and depending on consequences. to criminal liability; if the violation is connected with inflicting material damage, the guilty person can be brought to material responsibility in the established order.

OCCUPATIONAL SAFETY AND HEALTH REQUIREMENTS BEFORE STARTING WORK

2.1. Before starting work, you must put on overalls to protect against hazards and harmful factors, and have the necessary personal protective equipment ready. 2.2. Wear protective clothing that is adequately sized, clean and unrestricted. 2.3. Before you start working with an angle grinder, find out what protection class the power tool belongs to (I, II or III), and what hazard category the room in which you are going to work belongs to. 2.4. Depending on the category of premises in terms of electric shock hazard, power tools of the following classes must be used:. Class I. when used in production conditions;. Class II and III. when used in production conditions in all cases, and during preparation and performance of construction and installation work indoors. in high risk and outdoors;. Class III. in especially adverse working conditions (in vessels, devices and other metal containers with limited possibility to move. 2.5. A hand-held electrical “angle grinder” powered from the mains must be equipped with a flexible cord with a plug. 2.6. The cord in the entry point of the power tool must be protected from abrasion and kinks by an elastic tube of insulating material; the tube must be fixed in the housing parts of the power tool, and protrude from them by at least five cable diameters. 2.7. Class III power tool plugs must be designed so that they cannot be coupled to sockets with a voltage greater than 42 V. 2.8. Before you start working with a manual electrical machine of the “angle grinder” type it is necessary to perform the following works:. check reliability of fastening of the working tool;. visual inspection to check serviceability of the cord, its protective tube and plug, insulating details of the housing, handle and covers of brush-holders;. availability of protective cover and its serviceability;. check the switch clearness;. check the power tool idle run. 2.9. Do not use a hand-held electric angle grinder if it is defective or has an expired periodic inspection date. 2.10. To check serviceability, the power hand-held tool must be checked and tested at regular intervals.

3.1. During operation, the cord of the angle grinder must be protected against accidental damage and contact with hot, wet and oily metal surfaces or objects. 3.2. When using an electric angle grinder, the cord should not be pulled, twisted, kinked or loaded; if possible, the cord should be suspended. 3.3. The working tool (wheel) must be set and removed only after the angle grinder has been disconnected from the power supply using the plug and has come to a full stop. 3.4. An employee who works with an electric hand held angle grinder must not dismantle or repair the machine himself, but call in a specialist who is qualified to perform this work. 3.5. It is forbidden to work with hand electric tools from a ladder; to work at height, use sturdy scaffolding or scaffolding. 3.6. Sawdust and dust may not be removed by hand during operation of the power tool, but only after the machine has come to a complete standstill. 3.7. When working with a manual electric angle grinder of the “angle grinder” type, the objects to be processed must be securely clamped on the workbench using a vise. 3.8. To reduce the risk of injury, never touch a rotating power tool with your hand. 3.9. When working with a hand-held electric angle grinder it is essential that the operator maintain a stable position and maintains a balance at all times. 3.10. Do not operate power tools on icy or wet parts. 3.11. It is forbidden to operate an angle grinder without protection against dripping and splashing, or in open areas during rain or snowfall, under conditions of exposure to dripping and splashing. 3.12. Do not leave unattended power tools connected to the mains or hand them over to unauthorized persons. 3.13. It is forbidden to operate the power tool if at least one of the following malfunctions occurs:. the plugs, cord or its protective tube are damaged;. the cover of the brush holder is damaged;. the switch does not work clearly;. smoke or smell characteristic of burning insulation;. excessive noise, knocking, vibrations appear;. breaks or cracks appear in the body part, the handle, the protective guard;. damage to the working tool. 3.14. When carrying an angle grinder from one workstation to another or when work is interrupted or finished, the power tool must be disconnected from the electrical supply by the plug. 3.15. Do not carry a power tool connected to the mains with your finger on the switch. 3.16. During work, you must remain alert, concentrated, eyes must not be averted from the work in progress. 3.17. To reduce the risk of accidents, do not tie the wrench to the power tool with a rope or anything similar. 3.18. Do not use a wheel that is cracked or deformed for work. 3.19. Handle with care to avoid chipping and cracking. 3.20. Do not use a wheel that is larger than the maximum recommended size. 3.21. Only use the flanges supplied with the power tool to fasten the wheel. 3.22. After switching off the drive of the machine, the rotating power tool must not be stopped by pressing on its side. 3.23. To protect the eyes from dust and particulate matter at work, use a dust mask, goggles.

Varieties of safety glasses

GOST 12.4.253-2013 there are two basic design types of safety glasses for operation with grinders and other types of manual power tools: open and closed. In addition, the first type is divided into two subspecies: with and without side protection. The open goggles are designed for dust-free operation, so the space underneath is freely ventilated and they do not fog up. The side protection is designed to prevent particles flying parallel to the face of the angle grinder from reaching the operator’s eyes. This part is usually made of the same material as the front lens in order to ensure better visibility during work (see Operating Instructions No. 505). photo above).

Closed goggles superficially resemble a diving mask. They fully protect the eyes against dust and aggressive fumes produced by the angle grinder when working on rocks and plastics, but without special coatings are prone to fogging and are less comfortable. Inside of such glasses the air enters through special valves, which must be carefully cleaned after continuous work. On the head of the operator of angle grinder open glasses are held by springy temples, which, according to the regulations must be adjustable in length. In addition, some models have a swivel mounting of the sight glass, which allows tilting it in the process of work at a comfortable angle. Closed ones are fixed on the head with an elastic band or an elastic rim, the width of which, according to GOST, must be at least 10 mm. In the photo below: left. open goggles for angle grinder with side protection, right. closed with valves.

In the past, tempered glass was widely used as the material for sight lenses in personal eye-protectors, including hardened glass (in the form of triplex). Now it is used much more seldom, and shockproof plastics are now the main materials. They are 40% lighter than glass and have almost the same optical properties. It is recommended to use eye protection with polycarbonate lenses when working with grinders. This material has the highest impact and thermal resistance among optical plastics. Its main drawback is clouding under prolonged exposure to ultraviolet radiation and a tendency to form scratches in the course of work under the influence of flying metal and abrasive particles.

The first problem is solved by applying on the surface of the lens coating that protects against UV radiation, or adding to the polycarbonate still at the production stage of special stabilizing additives. To solve the second, the outer surface of the sight glass is covered with a protective layer of increased hardness. safety goggles with other plastics, which include the well-known plexiglass (plexiglass, acrylic resin) and acetylcellulose (CA plastic), when working with an angle grinder is better not to use, because. к. they are much less impact resistant. Picture below shows a piece of cut-off blade of an angle grinder stuck in a polycarbonate lens.

Which is better: goggles or mask

In addition to goggles, protective masks (transparent face shields) are used for work with the angle grinder to protect not only the eyes but also the entire face area down to the chin and ears. This type of personal protective equipment has a number of undeniable advantages, the main of which is complete protection of the face from flying particles. This is especially important when working with an angle grinder in confined spaces, when metal and abrasive particles ricochet and get in the face from different directions. Another positive feature of face shields is the practically total absence of optical distortions which are more or less characteristic of all glasses and goggles. That is why many people prefer this type of protection when working continuously with an angle grinder for long periods of time. One of the disadvantages, or rather limitations, of the use of face shields is a free penetration of dust and vapors under them. That is why they cannot be used for grinding stone, concrete or ceramics with an angle grinder. In addition, face shields are much more massive and heavier than glasses and have the same quality of optical material and higher price. There is no point in arguing over which of these PPE is better and more comfortable, because. к. Each of them is used for certain types of works and certain situations. And in some cases the operators of lathes use them together, and some manufacturers even produce special face shields, attached to closed goggles (see the. photo below).

Protective mask

Another means of safety when working with an angle grinder is a protective mask. It can be reinforced with a special mesh, which makes it stronger. Such a mask is much better than glasses, because it protects not only the eyes, but also the rest of the face.

The main cause of injury is the splitting of the saw blade. Its splinters, flying with great speed, can injure not only the person working with the angle grinder, but also people nearby.

Principles of safe work

Having personal protective equipment certainly reduces the risk of injury when using an angle grinder. But other safety requirements must also be noted.

- Protective cover. This device should always be on the angle grinder. Some careless operators remove the protection in order to put on a wheel with a larger diameter, which is not designed to work with this angle grinder. Sometimes the guard is removed in cases where you need to use an angle grinder at an awkward angle. Such actions are not permissible. Of course, the protective cover does not give a hundred percent safety, but in most cases it will prevent injury. Recently at the protective cover for angle grinder appeared a useful modification. It is called dust extraction. The name says it clearly. it helps to direct the dust particles away from the operator, making the job much easier.

- Hand protection. To prevent sparks and red-hot metal particles on the skin of the hands it is recommended to use special welding sleeves. Small sparks on the skin do not cause obvious pain. But when a large burning particle hits, it causes severe pain. At this point, the hand can wobble, thereby creating an injurious situation. Hats help to avoid the red-hot metal to hands.

- Choice of abrasive wheel. Only use a wheel suitable for the angle grinder. If you use a wheel with a diameter larger than the given, it may split without even making contact

- with the object of the saw. The fact that different models of angle grinder have different revolutions, and abrasive wheels have different revolutions.

- Also discs with visible external defects such as chips, deep scratches or cracks should not be used.

- It is forbidden to mount a disk for sawing wooden products on the angle grinder. Firstly, it is dangerous. the saw blade can meet a knot, and the tool can tear from hands because of it. Secondly, the blade will soon become unusable, because it is not designed for this kind of work. к. It is not designed for this kind of work. The speed of the circular saw is much lower than that of the angle grinder.

- The object of sawing. If the machined element is small, you need to secure it with something. The best option would be to use a vise. Never saw with one hand and hold the product with the other. In this case, the sawing element can be ripped out of your hands.

If the saw is large and the workpiece is stationary, ensure that the disc does not bite. General rules:

- Always unplug the angle grinder when changing the disc. This is to prevent accidental start.

- When selecting a sanding disc, it is best to choose a blade from a reputable manufacturer.

- When working, keep the power cord away from the saw blade.

- When using an angle grinder, do not allow hair or clothing to become caught in the rotating disc.

The correct positioning of the power tool in your hand is essential for safe use. Do not disregard the instructions for work with the angle grinder, this tool is capable of causing serious injury if negligent handling.

Protective shields

Price in packs is more favorable! Price per unit 6 units.: 816 р. Price per unit. goods: 136 р. 157 р.

Packages are more profitable! Price per unit 8 units.: 2 568 р. Price per unit. goods: 321 р. 367 р.

expensive by the package! Price per bundle of 8.: 3 208 р. Price per unit. goods: 401 р. 459 р.

Best in bundle! Price per unit 8 units.: 2 568 р. Price per unit. goods: 321 р. 367 р.

expensive by the package! Price per unit 8 units.: 4 440 р. Price per unit. goods: 555 p. 635 р.

Bargain by the package! Price per unit 8 units.: 2 184 р. Price per unit. item : 273 p. 312 р.

Better by the package! Price per unit 6 units.: 4 080 р. Price per unit. goods: 680 р. 771 р.

Best by the package! Price per unit 8 units.: 1 928 р. Price per unit. 241 р. 276 р.

Best in bundles! Price per pack of 8 items.: 5 000 р. Price per unit. goods: 625 р. 709 р.

Price in packs is more favorable! Price per unit 8 units.: 2 056 р. Price per unit. goods: 257 р. 291 р.

The packaging is more profitable! Price per unit 8 units.: 2 504 р. Price per unit. item: 313 р. 339 р.

Cheaper by Package! Price per unit 6 units.: 3 750 р. Price per unit. For: 625 р. 709 р.

expensive by the package! Price per unit 8 units.: 2 568 р. Price per unit. goods: 321 р. 364 р.

Best by the package! Price per pack of 8 units.: 4 496 р. Price per unit. goods: 562 р. 643 р.

Price by the package is more favorable! Price per unit 8 units.: 4 496 р. Price per unit. goods: 562 r. 643 р.

By the package is more favorable! Price per pack of 6 pcs.: 540 р. Price per unit. item: 90 p. 104 р.

Best by the package! Price for pack of 6 pcs.: 1 530 р. Price per unit. goods: 255 р. 289 р.

expensive by the package! Price per unit 6 units.: 1 644 р. Price per unit. goods: 274 р. 311 р.

To protect your eyes and face against sparks, solid particles and chemical liquids in production and laboratories, on construction sites and in workshops, the protective shield.

The screen is a semicircular plate with two bands, fronto-occipital and parietal. Can be continuously or staggered to fit and hold protection securely in place during operation. Plastic visor can be provided to protect not only the face but also the forehead. Some models have an extended shield to protect the neck.

Types of face shields

With headband attachment. the belt system holds the transparent screen to the worker’s head. A swivel locking device holds the glass in a raised or lowered position.

Helmet-mounted. the shield is attached to the protective helmet by a lifting and locking device that moves it up/down.

Metal mesh face shields are a fine-meshed, heavy-duty mesh and protect against large, hard particles. Used in mining, timber processing industries. Not suitable for protection against liquids, metal splashes, sparks.

Of polycarbonate. transparent face shields are resistant to shock impacts. Protect against solid particles, sparks and metal splashes, electric shocks. They are used for maintenance of electrical networks.

Of polystyrene. durable, but not as transparent. Used for construction and repair work, protect against sparks, splashes of metal, splinters, chips, etc.

How to work correctly with the angle grinder: safety precautions operating instructions

Are you planning to use the power tool in the process of home repair, but do not know how to work properly with an angle grinder so as not to injure yourself?? You must agree that it would be unwise to unknowingly break a disk in the first minutes or, even worse, to injure yourself.

Or have you just decided to get an electric tool and study the rules of its use beforehand?? In this case, pay attention to the products of reputable manufacturers who sell really high-quality devices of excellent assembly with a long warranty.

Because it is safer to work with a reliable tool. One excellent option is the brand products Bosch, DeWALT, Makita, as well as Metabo angle grinder sold in a wide range of myo. Rules of operation and basic mistakes when working with this type of power tool, we will consider in detail in our article.

In addition to recommendations for use of angle grinder, the material contains visual photos on working with the angle grinder and useful video tips from experienced users. Having acquainted with the latter and, observing the rules of personal safety, you will be able to cope with the grinding of concrete walls, cutting tiles or bricks, without attracting specialists for these tasks.

Types and peculiarities of using an angle grinder

Popularly known as an angle grinder. this is nothing like an angle grinder. In the opinion of ordinary people, this power tool is indispensable for every self-respecting owner.

No wonder, because in addition to grinding, the device is able to perform high-quality cutting of different kinds of materials, ranging from simple wood to metal angles and rebar.

Most often in the home this tool is used not for grinding operations, but precisely for cutting materials.

Fittings, metal angles, metal pipes and other metal products most often have to cut it is the angle grinder. Therefore, its presence in the arsenal of the owner of the house or apartment is quite justified. not to invite the same for the elementary work of an outsider

Processing of brick products. a popular phenomenon, especially during the period of repair. For this purpose, the angle grinder must be equipped with special wheels. a device for cutting metal and fittings is not suitable in this case

For concrete or concrete products like walls, floors, individual elements you have to use the cutting disc recommended by the manufacturer for these specific tasks. over, in view of the increased dustiness it is necessary to protect the sense of smell

For wood and its derivatives it is necessary to use special discs, which the manufacturer proposes to use for working with wood. You should also wear the proper type of protective cover, which will protect you from heavy sawdust, chips and wood dust

Protecting yourself while working with an angle grinder

The main personal protective equipment when working with an angle grinder, are:

- Goggles. Use this accessory to protect your eyes from sparks, dross, dust and small particles flying around from metal or other materials.

- Gloves. Thick fabric work gloves or gloves to protect hands from burns if the worker has to pick up workpieces heated by cutting, as well as not to cut themselves on the sharp edges of the metal.

- Long-sleeved overalls. Protect your forearms from burns or pellets and sparks flying from under the cutting disk.

- Respirator. This accessory is relevant when you have to deal with rusty or old materials, the dust from handling which can get into the respiratory organs and cause dangerous diseases or allergic reactions.

- Earplugs. Work with the angle grinder is characterized by a strong noise, so to protect the hearing use this accessory, which can be replaced by ordinary absorbent cotton.

Basic rules for working with an angle grinder

Before starting work with an angle grinder, the worker should make sure of the following:

- Check that you have a safety guard and that it is facing the right way

- Make sure the right or left hand handle is properly installed and securely fastened

- The power tool must be disconnected from the mains before each disc change

- Before making any cutting or grinding, make sure the person is in a stable position and that the workpiece is not above chest height

- Make sure there are no flammable or combustible materials nearby that could be ignited by the flow of sparks

What kind of work is done with an angle grinder?

- Cutting. Using an angle grinder you can cut various types of building and construction materials, including ceramic, concrete or metal. For cutting each type of material, special grinding wheels provided by the manufacturer are used.

- Deburring. Old paint or rust can be removed from the material surface quickly and efficiently with a metal brush attached as an accessory to an angle grinder.

- Sanding. The discs designed for this work are called “bowls,” and they can be used not only to grind flat surfaces, but also to grind welding seams made in corners or other hard-to-reach places.

SAFETY REQUIREMENTS FOR EMERGENCY SITUATIONS

4.1. In the event of an emergency, STIHL must observe. Panic and similar conditions will only make things worse. 4.2. If you notice any faults in the production equipment or tools or if you touch the machine, tool or unit, or if you feel an electric current, or if electric wires, motors, electrical equipment become very hot, or if sparks appear, or if wires break, etc.д. 4 e) immediately stop working, switch off the equipment, warn colleagues about the danger, inform the direct superior or supervisor and act according to the instructions received from them. 4.3. If smoke is detected and a fire or a fire breaks out, immediately sound the fire alarm, take measures to extinguish the fire with the available primary fire extinguishing equipment, and notify your supervisor or supervisor. If necessary call the fire brigade on 101 or 112. 4.4. In case of an accident, immediately release the injured person from the traumatic factor, respecting his/her own safety, provide first aid according to the Company’s First Aid Procedure for Accident Victims, if necessary call the ambulance at 103 or 112. If possible, preserve the environment in which the accident occurred, provided it does not endanger the life and health of others or interfere with the production process, for investigation of the causes of the accident, or document it by photo or video. Notify the immediate or supervising manager. In case of injury, the employee must stop working, give himself/herself first aid if possible, inform the direct supervisor or the supervisor, no matter what time of day or day of week, or ask other people around, and if necessary, go to a medical facility.

5.1. When you have finished working with the angle grinder, disconnect it from the power supply using the plug. 5.2. At the end of the job, clean off dirt, dust, sawdust, and clean up the electric hand grinder and the personal protective equipment used. 5.3. After finishing work, you must remove protective clothing, safety shoes and other personal protective equipment and put them in a designated storage place, if necessary. turn them in for washing, cleaning. 5.4. All the malfunctions and other violations of labor safety requirements noticed at work must be reported to the direct supervisor and measures must be taken to eliminate them. 5.5. After finishing your work please wash your hands with warm water and soap, if needed take a shower. 5.6. Leave the factory using the designated paths.

Polishing ceramic tiles

In construction, the angle grinder is the leader among the tools. Use special wheels and nozzles to cut and polish ceramic tiles, preparing them for installation. Requires a special consumable on the diamond grinder angle grinder, because cutting ceramics usual cutting wheel will lead to breakage or cracking in the tile.

The dry-cutting tile discs are divided into segmented and solid discs. Both types do not need constant cooling. that’s why they get their name.

Continuous discs only cool down after 1-2 minutes of work by dipping the disc into cold water. The segmented type cools itself by cutting, but they are not always suitable for cutting ceramic tiles due to the formation of chips on the surface of the material. Segmented or solid discs cut ceramic material and any natural stone. Sometimes with quality work it is possible to cut paving tiles without deformation with a household angle grinder or to process the edge part of the cut.

Cutting in a straight line

Unlike cutting wood, ceramic is a fragile and demanding material that deforms easily under high loads. That is why discs are preselected according to the density of the stone. Speed should be higher than with low-density materials.

The most effective way to cut ceramic tiles is to use 115 mm circles at about 6-8 thousand rpm. Not every household angle grinder has such power, so you have to find a tool with the necessary characteristics.

The procedure when working with the material is divided into several stages:

- Lay the tile on a flat surface with a clamp fastened to it, and mark it in the cutting area.

- Cutting begins gradually along the surface of the entire tile. At first you need to make a 1-1,5 mm deep groove, gradually increasing it.

- Move the angle grinder during the cutting evenly and slowly. No pressure should be applied to the machine, because it goes deeper into the tile under its own weight.

- It doesn’t make sense to cut the material all the way through. Most often, a nail is placed under the tile and simply pressed to break it.

Metal processing with angle grinder

To treat metal with an angle grinder is the most difficult. This is mainly due to the large amount of red-hot sparks that appear when cutting this material. Work only when wearing flame retardant gloves. In addition, you should clean the work area of objects that can catch fire if sparks are struck.

Cutting metal requires care, patience and basic skills. This will help keep the angle grinder in the weight, which will prevent jerking and sucking the disc into the hole.

When cutting metal products, a number of rules should be observed:

- All workpieces are securely clamped and stripped of any rust.

- It is best to cool the metal before you start cutting.

- The disc can jam the workpiece, so it is better to gradually increase the depth of cut.

- There is no need to push the angle grinder, because it easily cuts under its own weight.

Angle grinder. it is an indispensable assistant in any household or large construction works. It helps to machine any material with minimum effort and time. Beginning experience and tips are sufficient for successful manipulation with this tool. The main thing is to observe safety while working, which will help to avoid serious injuries.