Picking tiles how to use. Additional recommendations on the use of electrical tile cutter

How to use manual tile cutter? Acquaintance with the instrument. How to cut tiles correctly with various tile cutters?

Many people have no idea what tiles are and why do you need such an instrument at all. If we consider this issue in more detail, then this is the most ordinary apparatus that allows you to quickly and carefully cut ceramic tiles. To date, both the manual type of tool and electrical are actively used in construction. It is worth noting that it is easy to cope with operation only if manual tile cutter is used, but some difficulties may arise with an electric version.

What should you pay attention to when choosing a tile cutter video

Even given that the tools of both types have the same name, they are not at all like each other. The only exception, of course, is the final result of the use of the tool. In order to be able to use a manual tile, you need to make a furrow with it (the unit has very sharp incisors), and then make a tile breakdown. In turn, the electrical type of tile cutter works using a battery or from an electric network and in its appearance and, on the principle of operation, can slightly resemble a circular saw. Cutting tiles occurs using a very sharp diamond disk, which has an incredibly huge rotation speed.

How to use manual tile cutter correctly

Before how to use a tile, It is necessary to check its condition. All parts should be without visible damage, the cutting video should rotate without jamming. Its surface should be properly round, without burrs and potholes. Moving the carriage with it should also be carried out without jerks and jams. As a rule, for these purposes, a radial bearing is provided in the design of manual tile cutter. It is also worth checking the condition of the bed, before the operation of the tile cutter it is necessary to clean its surface from visible contaminants.

- Marking the surface of the tiles with a conventional building pencil according to the required sizes.

- The tile is located on a tile cutter so that the marked cut line coincides with the trajectory of moving the carriage, on which the cutting video is fixed. It is important that the distance to the cut from the edge of the tile is at least 10 mm, otherwise it will turn out to be a sloppy edge.

- The carriage is carried out along the markings with a slight pressure. It is important at the moment to feel the required pressure value so as not to pushing the tiles, but also to get a cut of the required depth so that the icing of the tiles is cut. It is allowed to carry out the roller on the surface of the tile only once, otherwise the cut can turn out to be uneven.

- Now the tile cutter handle rotates to the working position, the field of which it lowers with a sharp and confident movement, as a result, the tile is carefully broken down along the previously obtained cut.

Experts advise soak it in water before cutting ceramic tiles. A drop of machine oil applied along the cut line also simplifies the cutting process. You can also read an article on the topic of how to cut the tile with a tile cutter and without it.

And for a more detailed analysis, the use of manual tile cutter, I recommend watching the video (on the example of the tileproofer Walmer).

�� Glass tile what you need to know before you install it.

And one more (for example, tile cutter Rubi TX-N).

It will be convenient to work with a manual tile, if the volume of work is not too large, and the hardness of the tiles is small or medium. In the case of a stronger tile, it is better to resort to the use of an electric tile cutter.

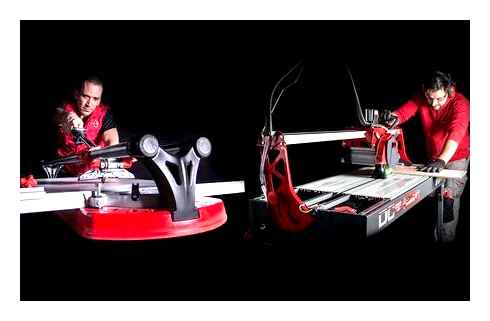

How to use an electric tile cutter correctly

The use of a more technological device. Electric tile cutter allows you to get a very neat cut with somewhat rounded and smooth edges. The sharp edges that are obtained when working with a manual tile cutter, when cutting a ceramic tile, there are no electric drives. It also allows you to cut off pieces of tiles with a width of less than 5 millimeters.

Autocad Electrical Toolset Webinar | AutoCAD

The technology of cutting tiles on the electric tile cutting looks like this:

- Before How to use a tile cutter, It is necessary to mark the tile.

- Place the tile on the table of the tile cutter along the configured guide.

- Turn on the rotation of the diamond disk and the supply of water to it.

- Gently move the tile to the disk with two hands. At the moment of tile supply to the disk, the pressure force on it should be minimal. After cutting it can be slightly increased. If you press on the tiles too much at the time of cutting, strong vibrations may appear, and the tile cracks. When the diamond circle is released during the completion of the cut, it is also necessary to reduce the pressure force so that chips and irregularities do not form.

- Get a neat cut and lay tiles to the side.

- Turn off the rotation of the disk and water supply.

When working with an electric tile, it is worth considering the recommendations of specialists. It is important that when performing the operation, the tile is neatly and pressed smoothly to the tile cutter table, otherwise vibrations will appear. Also, the uneven arrangement of the tile on the table can lead to the sequet of the blade on the central section of the tile or to capture the tiles with the disk, as a result of which there will be an inaccurate incision directed not along the marking line. To accurately move the tiles, it is necessary to use the guides, as well as press on the tile with both hands, if pressed on it with one hand, then an uneven incision can also be obtained.

Do not forget about the periodic replacement of water in the tank, since all cutting products fall into it. Dust and larger particles of tiles. They can lead to pollution of the diamond disk and its subsequent jamming, which in the worst case can lead to breakdown of a disk or tile. Disk breakdown when the tile cutter is turned on is dangerous in terms of injury by the employee. If you see that the disk is overly contaminated or worn out, then it should be replaced with a new. In this case, you will be able to make a neat and smooth cut.

And for consolidation you can see Video how to use an electric tile cutter for example, caliber PLE-200 900.

Components of the tool

The main elements of electrical tile cutter are:

In the process of work, the water will enter the knife, extending the service life and reducing the amount of dust. The pressure force will affect the speed of cutting, which depends on the composition of the material of the blade and the density of the tile. At the first touch of the disk to the tile, the pressure should be easy. Next, you should increase it, and by the end of cutting again reduce.

Safety rules when working with a tile

In order to use the manual tile, it was as safe as possible and at the same time the result of the work was high.Quality, some safety rules must be observed, namely::

Testing the Cheapest Tile Cutter on AMAZON

- Before starting work, you need to inspect the tool used, so that you can determine all the breakdowns and irregularities of the guides in time, then find and eliminate visible damage to the tile cutter.

- You need to go through the tile a couple of times, and at the same time, all movements must be smooth, without any shocks.

- Do not forget to additionally check the tubular guides. They should be perfectly clean, without dust and dirt. Eliminate from them pieces of tiles, traces of the solution and, ultimately, to improve the work. Lubricate with a small amount of machine oil.

- In addition, you also need to pay attention to the cutting disc itself. His condition should be perfect, in no case with curved, and rotation around the fastening axis should occur without any difficulties. It is worth noting that no extraneous sounds should also arise during the work of manual tile cutter.

- In order not to get any injuries, it is best to work in special glasses and gloves.

- Some experts also recommend checking the water supply to the disk, which makes the work simpler.

- It is necessary to start work only after the disk gains those turns that can be called maximum.

Manual tiles. How to use it correctly, many people have been asking recently, but in fact there is nothing complicated in this process. Every inexperienced beginner will be able to cope with work. If you still can’t cut off the tiles you need, then on our website you will find a video with the most detailed instructions that will allow you to find out all the details and nuances of this type. Do not forget about safety rules, because your health largely depends on this and, of course, safety.

Tiles and methods of cutting it, types of tiles

Titty cutter. The first assistant in the cutting of tiles, giving the desired shape and size. During the repair, styling of the floor, the ceiling, the master always holds this tool at hand.

The composition of the tile includes clay, which is previously burned and covered with a layer of glaze. The tile is made very simple. The desired shape is formed from clay, then slightly dried to fix the volume. The next stage is the application of glaze and burning in the furnace. Fighting in the furnace is carried out in order to give the product strength, make the tile of durable, beautiful and aesthetic. Despite its fragility, the surface does not lend itself to deformation, does not bend.

Many are interested in the question of how to cut tiles.

How to work with a tile, depends on what kind of type (manual or electric).

Manual tile cutter

Stable, sufficiently heavy weight and stiffness along the base axis of a stamped bed, which serves as a support for the tool itself, on which tiles for cutting is laid, has a rubberized surface of the base, excluding the possibility of slipping during the cutting process. The weakness of the stanchous body will lead to the occurrence of vibration during the split of the tile, which will lead to the culling of the consumable and damage to the tool itself.

The bed is firmly connected to two metal guides, in which the carriage is fixed. The main working element, the components of which are:

- Handle-bucket. A strong handle gives a more powerful lever, which is especially valuable when working with porcelain tiles.

- Carular shift cutting wheel. The surface of the cutting roller should be properly round, without flaws, burrs and potholes. When the roller is blown, the quality of the cutting is significantly falls. The sharpening of the cutting roller is impossible, the dull must be replaced.

- Holding the blank from random shift during pressing the foot.

The guides and the lever are made of strong steel and silumin, which have the characteristics necessary for the attached pressure: strength and rigidity. Additional elements are made of high.Quality plastic.

Some models have a scale for choosing the size of the tiles, the size of the size is fixed with “lambs” screws (it can be very convenient to use the tools with a mirror double scale). The presence of a rotary line in professional models of tile cutters allows you to perform cuts of tiles at an arbitrary angle for figurative processing of the workpiece.

A tile cutter can be fixed on any even stable surface using bolt compounds for the convenience of work and get additional stiffness when working with tiles of a sufficiently thick width. For this, technological holes are provided on the platform of the bed.

Is there an alternative to a tile?

The closest replacement option is an angle grinding machine (Ushm). The main advantage of this tool is high performance, which provides the ability to work with blanks of different thicknesses of more than 15-20 mm. How to use a tile cutter of a manual Stayer 500 mm to provide a similar cut? Even such a powerful professional version is nominally designed for processing products up to 16 mm thick. You can increase this bar only in case of double cut on both sides. The complexity of the operation will be to ensure the convergence of two cutting lines and the execution of the subsequent even chip.

There are many worthy tile cutters on the market, which can be used both in everyday life and in professional construction. In addition to Stayer products, we can also note the Elitech, Matrix, Fubag and Prostrab tool. There are few significant differences between the models of these brands, so the result will depend on the skills of using the tool. How to use a hand.To.Hand newcomer? First of all, perform all actions without haste and jerks. Even the recommendation of cutting over one pass should not increase the risk of error. For this, as already mentioned, it is advisable to practice unnecessary tiles in the commission of even cuts under the optimal load.

Conclusion

Of course, tile cutter is not the only tool that allows you to perform cutting tile material. Such problems can also be solved by an angle-grinding machine that is often found in household chores and has a wider range of functions. Nevertheless, builders recommend using a tile cutter if possible.

A manual electrical version will be the best option for both a beginner and an experienced master. The advantage of this solution is associated with higher chances of obtaining a flat cut, as well as with convenience and safety. In extreme cases, you can save a little and purchase a mechanical performance of the tool.

Tile cutting methods: how and how to cut tiles and porcelain tiles?

If you decide to independently start laying ceramic tiles, the process of cutting it cannot be avoided. You will need certain skills and a set of tools. However, if you carefully consider the optimal arrangement of the tile, the number of cut tiles can be minimized. Basic rule: so that the masonry looks worthy, do not use too narrow stripes. The joints in the corners should be made of fairly wide strips (at least half of the tile).

Cut the tiles correctly. With the receipt of a perfectly even cut. Having bought several tiles more, you can practice cutting them yourself. And soon the result will please you. There are several ways of accurate tile cutting.

Preparation for work

Before you start sawing porcelain, glass or tiles, you need to prepare a working tool, and in some cases, configure it.

Any tool is preliminarily inspected for external damage. Mechanical models check:

- The condition of the roller. Free rotation, the presence of defects, severity, reliability of fixation;

- The smoothness of the carriage, the presence of a play;

- The bed for pollution, if necessary, deleting them;

- Defects on the handle;

- If there is an emphasis, then measure the size of the angle between him and the cut axis.

The cutting video should rotate freely, be pure and correct shape (without potholes, dents). It should be approached by size under the thickness of the sawn tile.

After preliminary verification and cleaning to the guides and the cutter, apply A small amount of lubrication (machine oil). Then, with the help of a construction pencil, marker or felt.Tip pen, marking lines are applied to the surface of the tile, along which.

Before cutting off the tiles with an electric stabresis, check the reliability of the disk fixing. The contaminated disk is cleaned of adhering garbage particles. If the power tool is equipped water cooling system, then support the presence of liquid in the right amount. Dirty water is completely replaced so that the cut site is well cool.

In electrical equipment, the supply cord should be integral and dry: only in this form it is allowed to insert the fork into the outlet. Also, during the operation of the device, the water circulating in the cooling system should not fall into the cable. After the electrical equipment works, it is required to make sure that the continuity of fluid supply.

Typically, the power tool is adjustable at the factory, but during transportation of settings can be violated. For this reason, it may be required Setting up the angle of cut and the length of the working movement of the disk. Adjustment of each model has its own characteristics. The setting process of the installation used is described in the operational instructions for it. To set the corners, you will need to use a transporter, an angular or a square.

Manual tile cutter

The device of manual tile cutters is the same, there are only some differences regarding the functionality. The following working parts are distinguished:

- The base serves as a platform for the location of all working elements;

- Tubular guides, along which a carriage with a cutting wheel moves;

- Carriage. In addition to the cutting roller, it is equipped with a special concave paw to break off the cut part of the tile;

- The cutting element is a carbide roller rotating on the axis;

- The handle with which the carriage moves.

Features of cutting porcelain tiles

It is clear how to cut tiles with a tile cutter with electric or manual models. But such material as porcelain tiles is much stronger than the classic tile. Therefore, for him manual devices practically do not use. It is best to use electric devices. Otherwise, you will have to deal with why the tile cutting breaks the tile.

For work, it is better to choose a tool with a high.Quality cutting element of high.Quality steel. But even such a device will not be easy to work, so a greater effort is required. Over, the manual device will also be useful. It is used to form direct incisions according to a product from porcelain. The result will be good if the thickness of the tile does not exceed 15 mm.

Pros and cons of manual model

The undoubted advantages of manual tile cutter include:

- Independence from the mains. This device can also be used where there is no electricity or it is temporarily disconnected. When working in wet rooms. For example, when facing a bathroom, pool, sauna. The ability to cut a tile directly at the workplace without going into another room with a working outlet, is very important;

- Lack of temperature restrictions.

- Injuries when using the device are practically excluded. Maximum. Damage in case of accidental falling on the leg or pinching of the finger;

- Mobility. The products are small, even the most overall options, have weight up to 1 3 kg, are easily transported and do not require special conditions for transportation and storage.

- Difficulty cutting off small stripes along the edge of the tile. If the distance from the edge to the cut is less than 3 cm, only an experienced cutter with a hand tool can make an even pruning;

- Problems when working with tiles of non.Standard sizes. Both very small and very large samples are difficult to cut, sometimes impossible;

- The need to make physical efforts to perform a cut.

Other possible flaws depend on the specific selected model:

- Broken tiles due to excessive depreciation;

- Excessive force as a result of insufficient lever length;

- Insufficient size of the working area;

- Uneven carriage stroke;

- The difficulty of replacing the roller (cutter) or its insufficient quality.

At these points (except for the latter, it is not always possible to check the quality of the cutter in the store) should pay attention to when buying.

Is it possible to cut porcelain tiles with a manual tile

Porcelain stoneware is durable material, therefore, for its sawing, you should use the unit that has special characteristics. If you have to work in a large volume, it is preferable to use an electric tile cutter. However, you can use a manual device, but it is important to consider some subtleties:

- For cutting such material, a tool will go made of durable steel and equipped with a high.Quality cutter. Most often, such manual models belong to the category of professional. A simple model for such cutting is not suitable.

- Even an expensive model of manual tile cutter, a section of porcelain tile is quite difficult. Therefore, the device should only be used if there is a minimum volume of work.

- Only direct incisions are performed by a manual unit, the thickness of which does not exceed 15 mm.

Having studied the process of cutting ceramic tiles using a tile cutter, even a novice worker will be able to qualitatively perform work. It is only necessary to observe the sequence and safety regulations.

Cutting curly edges and oblique lines

To perform such a complex cutting, it is necessary to mark the cut shape on the plate. The angle or circumference, for example, to exit the pipe or fastening the tiles in the area of the wall protrusion. Then, with tweezers or on an electric machine, all unnecessary ones should be carefully cut in parts and, using pliers or pliers, “bite” a piece of tiles, gradually approaching the edge of the restrictive line.

To get a perfectly even, smooth end, experts recommend using a file or rough sandpaper.

In conclusion, it should be noted that all the recommendations relate to the cutting of exclusively glazed ceramic tiles and are not suitable for porcelain, stone or unglazed ceramics.

Tip: You will try to cut tiles for the first time? Then don’t risk and buy a few tiles more. Only having received certain skills, you can quickly and easily make even, beautiful cuts without attracting third.Party specialists.

Electric tile cutter: use rules

In the case when facing work is associated with large volumes or the laying scheme implies a significant amount of tile trimming. Also, if ceramics is quite durable or has a large thickness, the use of electrical tools for cutting tiles will be rational and correctly. In addition, an electric tile cutting machine allows you to get a neat cut with even and smooth edges and the width of the cut strip of tiles can be less than 5 mm.

Given the complexity and potential danger in working with a power tool, before using a tile, you need to carefully read the measures of safe work, which the instructions attached to any tool and equipment will tell about.

After the use of electrical tile cutter, the edges of the tiles remain smooth and slightly rounded

The technology of processing ceramics with an electric stabresis consists of the following stages:

- As in working with a manual tool, the process begins with the marking of the fragment and applying the line of the future cut;

- Placement of the element on the working surface of the machine;

- Turn on the equipment and ensure the supply of water to the cutting disk;

- With minimal effort, we direct the tile to the rotating disk, after the disk began to cut ceramics, the pressure can be strengthened, and after the end, weaken again, otherwise the edges of the fragment may turn out to be uneven with the formation of chips;

- At the end of the cutting process, the equipment is disconnected from the mains and the water supply to the cutting element stops.

Correctly operating an electric tile cutting machine, avoiding its overload, without using in conditions with high humidity, the equipment will last a long time, ensuring the high.Quality cutting of any ceramic tile.