Replacing The Battery Of The Screwdriver With Li Ion Batteries

Accumulators and batteries What is the difference between a lithium battery and a nickel-cadmium battery. Calculation of t component schemes of alteration. Operating conditions of the lithium battery. Features of alteration of batteries and chargers from different manufacturers.

Converting a Makita screwdriver to a lithium battery

There is a Makita screwdriver with a 1.3 A / h battery and a voltage of 9.6 V. To change the power source to a lithium-ion one, you will need 3 18650 components. Alteration will give the old tool new opportunities: power, as the operating voltage rises to 10.8 V.

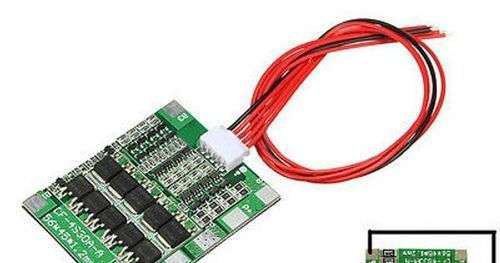

The design will require the use of a BMS, a control controller that maintains the lithium cell operating mode within operating limits. With this breaker, each cell will be charged evenly without exceeding 4.2V, lower voltage 2.7V. A built-in balancer is used here.

The parameters of the controller should accompany the operation of the instrument when the operating current rises to 10-20 A. The Sony VTC4 30 A board, designed for a capacity of 2100 A / h, can ensure operation without shutdown. Of the 20 amperes, the Sanyo UR18650NSX accepting energies of 2600A / h is suitable. The board is needed for 3 elements, which is marked in the 3S classification. In this case, the board must have 2 contacts, plus and minus. If the conclusions are designated with the letters P-, P, C-, they are intended for later models of screwdrivers.

A step-by-step instruction on how to convert a Makita screwdriver to lithium batteries looks like this.

- You can disassemble the battery with glue if you tap the junction with a soft-headed hammer while weighing. The direction of impact is downward, into the joint on the lower part of the body.

- Take only contact plates from the old assembly, carefully disconnecting them from the battery. Leave the sensor and breaker.

- Solder 3 elements in series using TAGS flux and insulated jumpers. The wire cross section must be greater than 0.75 mm2.

- Assemble the circuit with the controller, and connect the power supply to the contact connectors with 1.5 square wires.

- Check the functionality of the circuit and reassemble the case by placing it on the glue again.

In a screwdriver with an old DC9710 charger, after charging the 18650 lithium battery, the red LED on the panel will turn off. The built-in controller monitors the charge level.

The Makita DC1414 T charger is used to charge 7.2-14.4 V power sources. While charging, the red light is on. But when charging a lithium battery, its voltage does not fit into the standards of salt products, and after 12 V, the charger will flash red and green. But the required charging is already there. The screwdriver is ready for use.

Conversion of a screwdriver to lithium batteries 18650 14 V

When converting screwdrivers of different power and flashlights from Ni-Cd to Li-ion, batteries of the form factor 18650 are more often used. They easily fit into a container or a nest, since instead of two or three relatives, one lithium is installed. Alteration of the screwdriver battery should be carried out taking into account the peculiarities of lithium 18650 batteries.

This type of energy source does not tolerate deep discharge and excessive charge. Therefore, it is necessary to use voltage control boards. Since each battery has its own character, their charge is adjusted by a balancer. The point of reworking a screwdriver with a voltage of 14.4 V lies in creating a device using lithium batteries to facilitate a hand tool and increase its performance. Lithium 18650 batteries are most suitable for these purposes.

When selecting components, it should be taken into account that the starting current of the screwdriver is high, it is necessary to choose the appropriate BMS for the required number of cans and at least 30 A.

- Lithium-ion cans in the amount of 4 pcs.

- 4-cell li-ion battery controller, CF-4S30A-A works well. It has a built-in balancer that controls the charge of each element.

- Hot melt glue, flux for soldering TAGS, solder.

- Heat-resistant adhesive tape;

- Jumpers or thick insulated wire with a cross section of at least 0.75 squares, cut for bridges.

The procedure for converting a screwdriver for 18650:

- Disassemble the case and remove a bundle of 12 Ni-Cd cells from the container.

- Remove the garland, leaving the connector with leads and. Instead of a thermal sensor, a thermocouple from the controller will be installed.

- Solder the assembly, considering that you cannot use acid, only neutral flux and pure solder. During the connection period, do not warm up the covers. Work pointwise.

- Connect balancing points to the controller according to the diagram. The connectors are provided on the board.

- Connect the assembly to the plus and minus terminals.

- Check the functionality of the circuit. If everything works, the assembled battery, place the controller in the socket, secure with sealant.

If the charger is not universal, additional alteration will be required. Screwdrivers for 12 V with a universal charger are assembled in the same way, but a protective connection circuit 3×18650 3.7 V for lithium batteries is used. In the same way, a screwdriver is redesigned using a set of 18650 batteries in the amount of 2 cells.

Converting a screwdriver to lithium batteries 18650

Every craftsman faces the problem of reduced tool performance, or complete failure due to the battery. Manufacturers use nickel-cadmium batteries in 12, 14, 18 volt screwdrivers. The sequential assembly of several elements creates the required voltage. Replacing nickel-cadmium batteries with lithium batteries extends battery life, making the design easier. Mandatory BMS board installation adds reliability. Therefore, the conversion of a screwdriver to lithium batteries, mainly to the 18650 form factor, is justified.

The meaning and procedure for converting screwdrivers to lithium batteries

Why do nickel-cadmium batteries fail quickly? In a garland of series-connected cans, each is special. The chemical process is individual, the charge in closed systems is different. In the event of a malfunction in one bank, the design does not provide the required voltage. There is no provision for monitoring and balancing the charge in individual components.

- Each Ni-Cd bank provides 1.2V and the Li-ion 18650 3.6V.

- The capacity of a lithium battery is 2 times that of a nickel-cadmium battery of similar size.

- An overheated li-ion battery threatens an explosion and fire, therefore, the installation of control of the uniformity of the charge in the banks is mandatory. The manufacturer is not interested in BMS nickel-cadmium batteries.

- Lithium cells have no memory effect, unlike Ni-Cd, they can be charged at any time and within an hour.

- The screwdriver becomes much easier after converting the battery to li-ion, using 18650 cells.

There are only two obstacles to converting a screwdriver for lithium batteries, it is impossible to work with it at minus. The capacity of cans decreases, starting from a decrease already from 10 0 C. Lithium batteries are expensive.

Knowing what input voltage is required for the screwdriver, the charger is reworked, taking into account the placement of the lithium battery cans and control elements in the factory container. You can also do with a flashlight by upgrading the socket for a block of 18650 cells.

Let’s say you need to rework a 12 V screwdriver using Ni-Cd cans on li-ion. If you use 3 cans, the output voltage is not enough: 3.6 x 3 = 10.8 V. With 4 components, the power of the apparatus will be higher: 3.6 x 4 = 14.4 V. This will make the instrument 182 g lighter , its power will slightly increase, the capacity is solid pluses. But when dismantling, it is necessary to leave the terminals and the native thermal sensor.

Accumulators and batteries

Energy storage information website

Alteration of the Hitachi 12V screwdriver for lithium batteries 18640

Features of alteration of the Hitachi 12 V screwdriver for lithium batteries. The very compact battery compartment is designed for finger cells. Therefore, you should prepare a place for 18650 cells. It is necessary to cut one side of the partition to fit 1 element tightly.

You need to get a flux, a flat metal connecting tape, hot glue. It is necessary to install lithium batteries in a screwdriver during rework through a protective controller. It should serve 3 18650 cells, 3.7V, and rated for 20-30 amps.

Remove the old battery from the socket, carefully disconnect the contacts in the assembly with the temperature sensor and the power indicator. Clean up and sign contacts. They should be brought out to one side, connected with solder to the leads from thick wires and filled with hot melt glue over the assembly.

Assemble a power source with one of the 3 cell controllers. Build a serial circuit of 3 Li-ion cells. Connect the controller. The conversion of the 12-volt lithium battery is completed when the structure is installed in the unit, secured, and the charging indicator lights up. After fully charging, the measurements show 12.17 volts in the external network. But this is enough for trouble-free long-term operation of the device.

Which battery for a screwdriver is better to choose

A cordless screwdriver is a fairly convenient and demanded tool. The independence from the power supply makes this device mobile and allows you to work in hard-to-reach places. But despite all the advantages, the rechargeable battery (AKB) is the weak link in a screwdriver. Therefore, when choosing a power tool, you first need to understand what types of batteries exist, what is their difference, the pros and cons of different types of batteries.

Replacing batteries with similar ones

On some units, you can see the mounting screws that need to be removed. But on most battery blocks there are no self-tapping screws, since the body is glued together. To open such a block, you will need to carefully insert a screwdriver into the glued place (shown by the arrow) and press lightly to detach the walls of the case. The same actions need to be done around the entire perimeter.

After opening the block, you will see the batteries in it.

- You need to solder quickly, not allowing the battery to heat up, as it may become unusable.

- For connections, you need to use the “native” plates, desoldering them from the old batteries (they have the required section and resistance).

- It is important to correctly connect the plus and minus of the battery. The elements must be connected in series: the minus of the previous battery must be connected to the plus of the new one, and the minus of the new battery to the plus contact of the next battery.

After connecting all the elements, you need to equalize the potentials on all batteries, since they are different. Carry out one charge-discharge cycle: connect the charger to the battery overnight, then let it cool down for a day and measure the output voltage in turn on all cells. If everything went well, then on all batteries the indicator will be the same within 1.3 V.

Now the battery needs to be discharged by inserting it into a screwdriver and loading the latter to the maximum. The main thing is not to overheat the engine of the tool. Give him a little rest. Bring the battery to full discharge. This procedure should be repeated 2 more times (full charge and full discharge).

Lithium-ion batteries

Li-Ion batteries significantly outperform other types of batteries. The advantages of lithium-ion batteries include the following:

- Almost complete absence of “memory effect”;

- You can recharge the lithium-ion battery at any stage of discharge, without fear of loss of capacity;

- No power loss at low battery charge;

- The effective service life is 5-8 years;

- Low self-discharge;

- Takes little time to charge;

- There are no toxic elements;

- High power with small dimensions.

Cons of lithium-ion batteries:

- Sensitivity to impacts (may explode with strong impacts);

- The battery does not tolerate a full discharge and overcharge from this battery fails;

- Discharges quickly at low temperatures;

- High price;

- Service life is lower than that of nickel-cadmium batteries.

It is difficult to say unequivocally which battery is better. Mainly, you must decide for what purpose you are going to purchase a screwdriver. If for home use, which implies infrequent switching on with long interruptions in work, then you need to choose a tool with a nickel-cadmium battery.

Lithium-ion batteries are the professional choice. They are designed for continuous, long-term and uninterrupted operation. The recharge time of the battery is also important for a professional tool. But it is worth remembering one rule: a lithium battery cannot be brought to full discharge.

How can you replace the “native” battery in a screwdriver

If the batteries in your screwdriver have worn out, they can be easily replaced. There is such a thing as battery interchangeability. For example, under the PowerPlant brand, batteries are produced that are compatible with most popular brands of power tools. They cost much less than the “native” batteries and are quite efficient.

But if this option does not suit you, then the batteries themselves in the unit can be replaced with new ones. To do this, you will have to disassemble the battery pack and remove the elements that make up it.

Nickel-cadmium batteries

This type of battery is the most common, although it is over 100 years old. NiCd batteries have good capacity and low cost.

Nickel-cadmium batteries have the following advantages.

- Durability. With proper operation, the battery can last 8-10 years.

- Ability to work at low temperatures. The battery power is practically not reduced, which allows using the tool outdoors in winter.

- A high degree of reliability and unpretentiousness to working conditions.

- The battery can withstand a thousand charge-discharge cycles.

- The battery can be stored for a long time in a discharged state.

Since NiCd batteries are not “afraid” of full discharge, you can work with the tool until it stops completely, that is, until the battery is deeply discharged. Only then can you put it on charge without fear that the battery capacity will decrease.

However, nickel-cadmium batteries are not without their drawbacks. The toxicity of the internal filling of the battery causes disposal problems.

Batteries of this type are quite heavy when compared to other types of batteries. In addition, they have a “memory effect”. This phenomenon occurs in a nickel-cadmium battery when it is prevented from fully discharging. If you turn on such a battery for recharging, then it will “remember” this value and during further work it will discharge exactly to this mark. This will lose a significant portion of the battery’s capacity. The figure below clearly demonstrates how the “memory effect” appears.

Replacement with lithium batteries

Replacing NiCd cells with Li-Ion is also not difficult. It is known from the school course that if the batteries are connected in series, then their voltage ratings will be summed up. For example, your screwdriver runs on a battery with a voltage of 14.4 V, which means that it can be replaced with four 3.3 V finger batteries. This voltage will be enough, because the lithium batteries do not “sag too much” when starting the device.

It is recommended to buy batteries from well-known manufacturers, for example, Sistem A123. The LiFePO4 battery of this company has a capacity of 2400 mAh, sufficient for the normal functioning of the screwdriver. If you buy batteries via the Internet, they will cost you less, around 900 rubles for 3 pieces.

You will also need to purchase soldering acid instead of alcohol flux. In this case, overheating of the batteries will be minimized. The soldering iron must have a power within 65 watts.

You can learn more about how batteries are replaced with lithium batteries by looking at this.

Difficulties in rework

There are objective disadvantages in Li-Ion batteries, such as poor performance at low temperatures. In addition, when converting a screwdriver to lithium 18650 batteries, a number of difficulties can be encountered:

- The 18650 standard means that a single cell has a diameter of 18 mm and a length of 65 mm. These dimensions do not match the dimensions of the nickel-cadmium or nickel-metal hydride elements previously installed in the screwdriver. Replacing batteries will require placing them in a standard battery case, plus installing a protective microcircuit and connecting wires;

- The voltage at the output of the lithium cells is 3.6 V, and on the nickel-cadmium cells it is 1.2 V. Let us assume that the nominal voltage of the old battery is 12 V. Such a voltage cannot be ensured when Li-Ion cells are connected in series. The range of voltage fluctuations during the charge-discharge cycles of the ion battery also changes. Accordingly, converted batteries may not be compatible with the screwdriver;

- Ionic batteries differ in the specifics of their work. They do not withstand overcharging voltage more than 4.2 V and discharge less than 2.7 V until they fail. Therefore, when a battery is being reworked, a protective board must be installed in a screwdriver;

- The existing charger can sometimes not be used for a screwdriver with a Li-Ion battery. You will also need to redo it or purchase another.

Important! If the drill or screwdriver is cheap and not of very high quality, then it is better not to rework. This can cost more than the cost of the tool itself.

Tips for choosing a security chip

The lithium-ion battery of the screwdriver cannot function normally without the BMS protection board. Instances on sale have different parameters. BMS 3S marking assumes, for example, that the board is designed for 3 elements.

What you need to pay attention to in order to choose a suitable microcircuit:

- The presence of balancing to ensure uniformity of the charge of the cells. If it is present, the value of the balancing current should be in the description of the technical data;

- Maximum long-term operating current. On average, you need to focus on 20-30 A. But this depends on the power of the screwdriver. Low-power enough 20 A, powerful from 30 A;

- Voltage, upon reaching which the batteries are disconnected when overcharging (about 4.3 V);

- Voltage at which the screwdriver turns off. It is necessary to select this value based on the technical parameters of the battery cell (minimum voltage is about 2.6 V);

- Overload protection operation current;

- Resistance of transistor elements (minimum value is selected).

Important! The magnitude of the overload tripping current is of little importance. This value is offset from the workload current. In case of short-term overloads, even if the tool has turned off, you must release the start button, and then you can continue to work.

Connection diagram of elements with a protective board

Whether the controller has an autorun function can be determined by the presence of an Automatic recovery entry in the technical data. If there is no such function, then in order to restart the screwdriver after the protection is triggered, it will be necessary to remove the battery and connect it to the charger.

The advantages of lithium-ion batteries

Nickel-cadmium batteries have a low price, withstand many charging cycles, and are not afraid of low temperatures. But the capacity of the battery will decrease if you put it on charge without waiting for a full discharge (memory effect).

Lithium-ion batteries offer the following benefits:

- High capacity, which will provide longer operating time of the screwdriver;

- Smaller size and weight;

- Keeps charge well when inoperative.

But the lithium battery for a screwdriver does not withstand a full discharge, therefore, factory tools on such batteries are equipped with additional boards that protect the battery from overheating, short-circuit, overcharge in order to avoid an explosion, a complete discharge. Placing the microcircuit directly into the battery will open the circuit if the unused battery is separated from the tool.

Battery selection

12 V batteries are often used for screwdrivers. Factors to consider when choosing a Li-Ion battery for a screwdriver:

- In such instruments, elements with high values of the discharge current are used;

- In many cases, the cell capacity is inversely related to the discharge current, so it cannot be selected based on capacity alone. The main indicator is the current. The value of the operating current of the screwdriver can be found in the tool passport. Usually it is from 15 to 30-40 A;

- It is not recommended to use cells with different capacities when replacing a screwdriver battery with a Li-Ion 18650;

- Sometimes there are tips to use a lithium battery from an old laptop. This is absolutely unacceptable. They are designed for much lower discharge current and have inappropriate technical characteristics;

- The number of elements is calculated based on the approximate ratio of 1 Li-Ion to 3 Ni-Cd. For a 12-volt battery, you will need to install 3 new ones to replace 10 old cans. The voltage level will be slightly reduced, but if 4 cells are installed, the overvoltage will shorten the life of the motor.

Important! Before assembly, all elements must be fully charged for equalization.

Disassembling the battery case

The body is often assembled with self-tapping screws, other options with latches or glue. The glued block is the most difficult to disassemble, you have to use a special hammer with a plastic head so as not to damage the parts of the case. Everything is removed from the inside. You can reapply only the contact plates or the entire terminal assembly for connection to the tool, charger.

Battery assembly

Further battery replacement consists of the following steps:

- The disassembled parts of the case are well cleaned;

- Since the dimensions of the new battery cells will be smaller, they must be securely fixed: glue them to the inner wall of the case with Moment glue or sealant;

- The positive and negative wires are soldered to the old terminal block, it is placed in the same place in the case and fixed. The protective board is laid, the parts of the battery pack are connected. If they were previously glued, then Moment is used again.