Replacing the carburetor on the Patriot gasoline. Clead cleaning

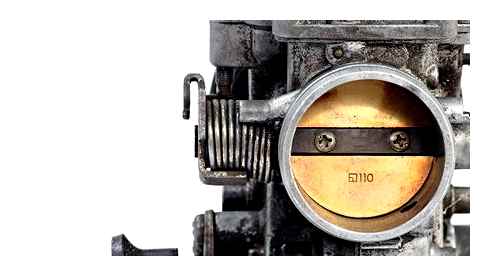

A trimmer carburetor device for gasoline grass

Motokosa carburetor adjustment is a process that needs to be mastered for the full operation of a trimmer for grass. Trimmer for grass is a completely simple device that can break in only a few places and demand a mechanical repair or replacement of part. Adjustment of the carburetor device of the float.type motorcycles may require knowledge of certain subtleties. The nuances due to the model and the specifics of its functioning will ensure a clear mixing and supply regime of the fuel mixture.

CHAMPION BAS carburetor, how to adjust? This is just a trimmer for floating type grass. a common option designed to mix air and fuel in the proportions provided. The main problems arising during the operation of the motor are approximately similar to the problems that overtake the carburetor in the car:

- the motor can stall immediately after it managed to start. The reason is that gasoline is supplied in insufficient quantities. This is called “poor” fuel;

- Excessively fed gasoline leads to its incomplete combustion, excessive density of the mixture and uneconomous consumption.

Repair of the carburetor

Important! It is necessary to regulate the carburetor under different circumstances: a change in the temperature regime, octane fuel or type of oil, after winter or end of the run.in, load or spontaneous turning of the screws from strong vibration of the body. Some owners prefer to configure the module before each use to make sure of its correct work.

The main problems

Malfunctions of the carburetor Motokos or trimmer for grass, despite the relative simplicity of their elimination, sometimes require a long search by excluding. The main reasons are as follows:

The most repeating breakdown is wear, rupture of the membrane. As a result, its lavation. Fuel moves are not sealed at certain stages of the engine cycle. The reasons here are as follows:

- You have been working on a motorcycle or trimmer for too long without a break;

- Poor.quality fuel was seasoned;

- Wheelled gases fall into the pulse channel.

A deformed membrane is fraught with several bad consequences:

- not enough gasoline or oxygen in the created combustible mixture;

- the launch of the motor occurs after 10 or more unsuccessful attempts;

- the engine knocks, clats during operation, and t. D.;

- The working piston is deformed.

HOW TO. Yamaha Warrior 350 Carburetor Clean Carb Rebuild Kit Gas Fuel Cleaner GUMOUT Repair Kit

We offer to familiarize yourself with how many citric acid for a liter jar of cucumbers

The reasons for the clogging of the mesh filter are poor.quality fuel cleaning, damage to the hose and/or the injection head.

Wear of the contact edge of the lever. a consequence of not completely purified fuel, into which grains of sand or particles of clay, metal or other inclusions that are not soluble in liquid hydrocarbons fell. A problem with fuel injection appears, the motor does not function with interruptions without load.

The inlet needle breaks due to the presence of metal and stone particles in gasoline. As a result, the saddle of the intake needle tightly adjacent to it, the fuel mixture flows. In the combustible mixture created by the carburetor, there is too much air, which is why the motor can “sneeze” during operation. Finally, the needle can stop due to poor-quality gasoline, or the unit was idle for a long time.

Seadoo Won’t Start Troubleshooting: Carburetor Removal/Cleaning, Replace Fuel Lines

Deposits may accumulate in the adjustment compartment. The needle does not completely cover the hole, and a lot of gasoline enters the fuel chamber. the motor pours it, perhaps floods the spark plugs. Because of this, the gasoline mixture contains an increased number of vapor of gasoline. The efficiency falls noticeably.

The membrane is often deformed (sometimes torn) due to continuous operation of motorcycles or trimmer for grass for several hours. If you abuse such a “shock” mode of operation, damage to the membrane occurs more often. New breakdowns will be sprinkled from a cornation of abundance:

- the piston will break;

- The number of attempts by the unsuccessful start of the engine will increase sharply;

- The fuel mixture will contain too little gasoline;

- Useful (thermal) power will drop sharply.

Sequeling of the adjusting lever. a consequence of the incorrect installation, random flexion. Contactive line will find an incorrect position. This will violate the additional injection of gasoline.

The damper has worn out

Throttle and air conditioning are unusable due to admission to the air flow of dust, metal particles, etc. D. Damaged shutters are similar to details subjected to streaming with sand. Due to wear of the damper, the efficiency of the motor decreases, breakdowns are detected. The piston and cylinder wear out.

In some cases, this filter is simply not suitable for your model motorcycles or trimmer for grass. In the end, the shaft of the motor will suffer. its pieces fall into the engine channels, which is why the piston will be broken.

The fact that the adjustment is too rough (it is not possible to accurately set the parameters) are to blame for the adjustment screws. The manufacturer Motokos or trimmer for grass can put excessively thick and hard springs. You can find others either in workshops where such equipment is repaired, or purchased from any dealer or official representative of the company who released the engine for your trimmer for grass or mechanical braid for grass.

The primer broke

Primer-a manual mini-pump for forced swinging fuel into a carburetor. For a successful start of the motor, it may be necessary to pump 20 ml of gasoline manually.

How to find out that the gas mowing carburetor needs to be adjusted

Many masters use benzocouses for a long time, and at the same time do not think about the need to adjust the carburetor of the tool. When it is necessary to adjust the carburetor on a benzocos or motorcycle? If you ask such a question, then changes in the work of the motor are probably not for the better. In order not to guess, and not to miss the moment of the need to configure the carburetor, you should adhere to the following recommendations on the need for adjusting measures:

- After passing the running.in. Typically, the running-in lasts over the burning of 4-5 liters of fuel

- Когда в бак заливается топливная смесь другого состава, то есть меняется тип масла (даже его цвет) и марка бензина

- When changing weather conditions, however, this is relevant more for chainsaws, gas generators and motorcypts, which are operated not only in the summer, but also in winter

- If the lawn mower was not used for a long time. The reason for the need to adjust may be a winter break

- When fuel consumption increases

- If black fog on the electrodes of the candle is detected

- In the absence of gasoline from the cylinder or poor engine start

- If a large amount of exhaust gases are detected

- Unstable engine operation, as well as its difficult start and a “sluggish” set of revolutions

As you can see, there are enough reasons for adjusting the carburetor. Typically, masters who work for a long time for a long time, find changes in the operation of the motor, which promises the need to conduct an adjustment process. Even if they are not sure of the need for adjustment, then their extraordinary execution will definitely not be superfluous.

Causes of carburetor breakdowns

When operating, motorcycles (for example, “Patriot” or “Union”) can be damaged, and the user will need to repair it on its own or with the involvement of specialists. This can happen for a number of reasons. One of the most common is non.compliance with the rules for using the device. If, with prolonged operation of the trimmer for the grass, the carburetor was not used and adjusted, the device breaks.

Another cause of the breakdown is an incorrectly prepared fuel mixture. Often the owners of the equipment buy oil and prepare fuel according to the recommendations written on the package of combustible materials, which is incorrect. When preparing fuel, you need to consider the instructions for the operation of the Motokos itself. In addition, the mixture “by eye” should not be made, since incorrect proportions also lead to breakdown of technology.

Most of the breakdowns of carburetors are equally characteristic of motorcycles of different brands, whether Echo, “cedar”, Homelite or the device of another manufacturer.

- https: // Sadovaja-tehnika.COM/Benzokosy/Karbyurator-Benzokosy/

- https: // smotri-dtp.ru/Obsluzhivanie/Video-Remonta-Karbjuratora-Trimmera-Svoimi-Rukami.HTML

- https: // GLAV-DACHA.ru/regulirovku-karbyuratora-Benzokosy/

- http: // yotools.ru/trimmeri/Regulirovka-Karbyuratora-Benzokosy-Sosnovnye-Momenty.HTML

- http: // tehnika.Expert/Dlya-Sada/Trimmer/Regulirovka-Karbyuratora.HTML

- https: // 7ogorod.RU/Prochee/Regulirovka-Karburatora-Motokosy.HTML

- https: // Serviceyard.Net/Gadgets/Regulirovka-Karbyuratora-Trimmera-Benzokosyi.HTML

- https: // tehnika4sad.ru/trimmey-motokosy/karbyuratory.HTML

- http: // Landshaftdizajn.ru/remont-Benzokosy/

- https: // moiinstrumentu.ru/ustrojstvo-i-segulirovka-karbjuratora-na-benzokosoko-I-Trimmerah.HTML

- https: // hitech-online.ru/Tehnika-Dlya-Sada/Trimmer/Regulirovka-I-Mont-Karbyuratora.HTML

What is the problem of a trimmer malfunction for grass

CHAMPION BAS carburetor, how to adjust? This is just a trimmer for floating type grass. a common option designed to mix air and fuel in the proportions provided. The main problems arising during the operation of the motor are approximately similar to the problems that overtake the carburetor in the car:

- the motor can stall immediately after it managed to start. The reason is that gasoline is supplied in insufficient quantities. This is called “poor” fuel;

- Excessively fed gasoline leads to its incomplete combustion, excessive density of the mixture and uneconomous consumption.

Important! It is necessary to regulate the carburetor under different circumstances: a change in the temperature regime, octane fuel or type of oil, after winter or end of the run.in, load or spontaneous turning of the screws from strong vibration of the body. Some owners prefer to configure the module before each use to make sure of its correct work

How to choose a machine for cutting grass in the country

The most important useful function of the lawn mower is, of course, in relief of labor. After all, the ideal beauty of the stalling French lawn or resistance to trampling the English launa can only be obtained by constant mowing. Some landscape designers consider this statement only by a historical stamp, others really recommend cutting grass with a frequency of several days. there may be a lot of disputes, the soil is blessed. But now it’s not about that, but about those useful functions that can make a haircut more pleasant. So, let’s begin.

“Why change the height of the spine of the grass at all?”. the first question that arises with the buyer who carefully studies the technical characteristics of his future assistant. But why lawns are of different types, for example, it is customary to cut sports very briefly (30 mm) so that they create a hard coating resistant to trampling.

Each lawn needs an individual approach

Mechanical. It is carried out by turning the lever. The position can be changed on all four wheels at once or on each individually. The operation does not take much time and can be performed without stopping the engine, literally on the move. This function is equipped with professional devices and premium models. As a rule, units with this way of height adjustment have a larger number of haircut height variations. in the range from 20 to 120 mm. The Denzel electric gas mowed 1400 watts allows you to expose the height of the grass in five positions: 20, 30, 40, 50 and 60 mm.

Drums of lawn mowers can cut grass below than rotary

The mowing cut off the grass can come in different ways. The first option is just to scatter it: the grass flies through the pipe to the side or back. This is not very convenient, since after the mowing you will have to thoroughly be equipped with rakes.

We offer to familiarize yourself with the top 10 of the best gasoline self.propelled lawn mowers: rating, characteristics, which is better, price, reviews

In the second case, mowed grass falls into a special container. grass collector. It will depend on its spaciousness, how often you have to interrupt the work in order to discard the contents. Hence the simple rule: the more the grass collector, the better. Its volume is indicated in liters: a grass collector for 30-40 liters (Denzel GC-1500 lawn mower) is enough for an average six-hundred-piece garden with a small lawn.

Removable grass cutter. In the photo Denzel GC-1500 mower with a grass collector 40 liters

This function is very simple, but it is extremely useful when different family members are alternately engaged in cutting the lawn. Adjust the height of the handle (

) in such cases it can be very useful. A trifle, it would seem, is pleasant! And if the handle also folds, then there will be no price to such a lawn mower. Models with folding handles are conveniently transported and stored. less space occupy.

How to repair a starter on a trimmer

Repair of the starter of a gasoline trimmer for grass may be required at the most inopportune moment. In this case, you can solve the problem in two ways: replace the broken part or change the entire node. The latter option will cost more. To repair the device with your own hands in most cases, you need only a screwdriver with an appropriate tip from the tools. Repair work will not take much time and do not require special knowledge. It is enough to know the device, the principle of operation, the nuances of the assembly-disassembly of the starter on the trimmer in order to achieve the desired positive result.

Parsing the starting node

They disassemble the launch mechanism in order to install new parts instead of broken in the following sequence:

- spin a screw with a screwdriver, fixing the pulley with a starter lid;

- take out a spring and antennae;

- Remove carefully with the pulley (you need to unscrew the head or work, having dressed the glasses and gloves before);

- determine why the launch mechanism has broken;

- If the spring collapses almost completely, then it is replaced;

- When the spring exits from the hook, it is installed in the original place, bending the antennae before this (the photographs show the laying process);

- After the spring plate is installed inside the groove, it is carefully twisted.

To change the spring, you should work carefully and accurately: it can, under the influence of the effort caused by the installation of it in place, accidentally burst. Even if you carefully remove the video, then the spring strip flies very quickly from the coil and can injure your hand with its sharp edges.

Immediately putting a springy plate in the same place does not always work. It often slips, so attempts are required to repeat until the desired result is achieved.

Adjustment of the carburetor of the chainsaw Patriot 3818, 4518, 5220

On the chainsaws Patriot 4518 and 5220 are similar carburetors. The only difference in performance. T.e. They allow you to work with a larger engine saw.

As for adjusting the carburetor on them, then everything is simple, it passes similarly to the model 3816. You can safely use the instructions described in the article.

The presence of a primer and a light start system Easy Start on models 4518 and 5220 facilitate the launch of a cold engine. Before adjusting the carburetor, you need to verify their serviceability.

In general, Patriot chainsaws due to their average cost and quality are equipped to the best of reliable carburetors, which you need to set up only in extreme measures. If you are not confident in your own abilities, then we strongly recommend entrusting this procedure to the specialists of the service center, t.to. Still, there is a risk of failure, as a result of incorrect tuning the maximum speed of the chainsaw.

Carbon regulation

Wash the air filter before adjusting the carburetor. It is recommended to rinse every 10 hours. After that you can start tuning. On the example of the photo shows a carburetor of a gasoline trimmer for PRorab-8406 grass. The numbers indicate the adjusting screws that we will use.

Rifles for adjusting the carburetor carburetor Prorab-8406

Run the brush and wait until it warms up.

Fuel adjustment

Start slowly tighten the propeller, which regulates the fuel mixture until the engine stops or freezes if you have not caught the moment. Then unscrew the screw for a quarter of turning if the engine does not work, or by half a turn, if it does not work. Run the stopped engine. Check, opening the throttle, as the engine accelerates. Continue to unscrew the screw for a quarter of turn, until the engine begins to confidently gain increased speed when supplying gas. This will be the moment of the most economical stable engine operation. On the gas trimmer, the Prorab-8406 adjusting screws are rotated clockwise, unscrewed. Counterclockwise, some other brands can be the other way around.

Cooper adjustment

We proceed to setting low speed. The screw limits the reverse movement of the throttle lever. Turning it, we increase the olfactory speed, unscrew it, reduce it. Adjust so that the engine works confidently at low speeds and even a little faster (for better launch), but so that the reel of the fishing line or the knife does not rotate, and before you start to rotate, there is a sufficient supply of speed. If the engine does not start well, still increase the idle speed.

Limiting maximum speed

After adjusting the consumption of the fuel mixture and low speed, check how the bush cutter engine works at maximum speed. If necessary, limit the maximum speed to the desired level using a hollow screw, unscrew the lockshop and tighten it to reduce the maximum speed, or unscrew it to increase it. After adjustment, tighten the nut. Installation of maximum speed is necessary to protect the trimmer motor for grass from overheating and the possibility of using keys blocking to reduce the fatigue of the right hand.

You may have to adjust the trimmer for the grass of the carburetor later. For example, if the engine begins to gain poorly when working at full load, unscrew the screw by another quarter turnover. If the launch is difficult, increase the blast speed. Weather conditions and the quality of the fuel mixture can affect the work of black cutters. Vibrating screws themselves can also overturn from vibration.

user’s manual

Each Makita brush, including RBC 411U, comes with the leadership; The manual contains complete information about the tool:

- Gas trimmer device for grass.

- Step.by.step collection of motorcycles (added schemes and descriptions).

- Characteristics table of the selected model.

- Safety requirements at work and when servicing.

- Preparing for the first run.

- The first time the guide

- Engine breakdown

- Motos maintenance.

- Problems with a gasoline trimmer.

The first start

The following simple steps will help you correctly prepare a trimmer for grass for use:

- Collection tool.

- Adjust the shoulder belt.

- Dress and fix a knife or court.

- Attach the protective cover to the trimmer.

- Connect the high.voltage wire to the candle.

- Check the contact of the spark plug.

- Make sure the fastening is reliable.

- Fill the fuel tank with fuel.

- Add motor oil.

- Starting power plant.

- Make sure the knife is in standby mode and in working mode.

- Check the mechanisms and controls.

When a trimmer for grass is fully tested, the engine works. Launch.

Works in

Opening hours 5 hours. During this time, the bureau is consumed a little, half the engine power. All details have begun. After the end of the input period, it is necessary to completely replace the engine oil (brand SAE10W-30 or semi-synthetic 2T).

Service

Proper care of the gas trimmer will extend its service life and eliminate frequent breakdowns. The manufacturer of Makita equipment recommends the following maintenance work on the RBC 411U bush:

- Replacement of motor oil: immediately after the refusal period and first after 20 hours of work, then every 50 hours of work.

- Replace the spark plug every 100 hours.

- Maintenance and cleaning of the air filter every 3 hours.

- Trimmer care, dust removal, vegetation, oil spots are performed after each operation.

- Lubrication of parts and mechanisms of gasoline tools.

- Sharpening (replacement) of cutting elements every three hours.

- Preparation for long.term storage.

Conservation of a trimmer for grass includes the following:

- disconnect the spark plugs wire;

- drain fuel, butter;

- Clean the air filter;

- clean, wash and lubricate the brush;

- Remove the knife, grease the shaft, wrap the knife in oiled paper;

- clean in a dry, ventilated room.

Basic errors and solutions

Even with proper maintenance, trimmers for grass can fail.

The engine does not start, delayed, heats up:

- There is no gasoline or has poor quality;

- oil level below normal;

- lost carbohydrate settings;

- the carburetor is clogged;

- Fuel highways are clogged with mud;

- no compression in the cylinder;

- hacking / in wires;

- no contact on the candle;

- a faulty spark plug;

- overflow of fuel;

- The beginning of the blow does not stretch;

- The magnet requires attention.

“I bought Makita two months ago, I decided not to choose it with a belt and a corset, mow it three times, get used to the tool, a little unusual. It processes well at low speed, cuts out both branches and bushes. “

“I’m looking for a suitable trimmer for grass, of course, gasoline. Power came to Makita RBC411U. I would like to know more about this trimmer. This is suitable for the story in hundreds of 10? Who will say what? “

The principle of operation of the carburetor of the lawn mower

The throttle dashes determines the amount of air for supply, and the engine power directly depends on this.

Fuel is sucked into the carburetor system (its membrane). Then passes through the fitting in the carburetor. Next, the liquid moves through the intake and exhaust valve of the pump. Filtered with a net. The needle valve moves into the membrane chamber.

- Air supply to the tube with an air septum (damper). The partition regulates the intensity of the air flow.

- The fuel supply system is necessarily narrowed by a diffuser to increase the flow rate.

- Gasoline through the float chamber and nozzle with narrowing. The chamber with a float regulates the temporary volume of gasoline. In the float chamber, the pressure level is neutral, and in the tube with narrowing is already low. Thanks to the pressure drop, fuel penetrates through the jetler.

- Air flow acceleration contributes to the transfer of fuel (gasoline) and its spray. As a result, the air-fuel mixture of the necessary proportion or density is formed.

- The air-fuel mixture penetrates the engine cylinder through the fuel tube.

The level of air density in the system depends on the area of the open air damper. The wider the damper is, the greater the fuel consumption and power.

Simply put, adjusting the carburetor on a benzocos. creating an optimal fuel mixture due to the correct air supply.

Carbon regulation

Wash the air filter before adjusting the carburetor. It is recommended to rinse every 10 hours. After that you can start tuning. On the example of the photo shows a carburetor of a gasoline trimmer for PRorab-8406 grass. The numbers indicate the adjusting screws that we will use.

Rifles for adjusting the carburetor carburetor Prorab-8406

Run the brush and wait until it warms up.

Fuel adjustment

Start slowly tighten the propeller, which regulates the fuel mixture until the engine stops or freezes if you have not caught the moment. Then unscrew the screw for a quarter of turning if the engine does not work, or by half a turn, if it does not work. Run the stopped engine. Check, opening the throttle, as the engine accelerates. Continue to unscrew the screw for a quarter of turn, until the engine begins to confidently gain increased speed when supplying gas. This will be the moment of the most economical stable engine operation. On the gas trimmer, the Prorab-8406 adjusting screws are rotated clockwise, unscrewed. Counterclockwise, some other brands can be the other way around.

Cooper adjustment

We proceed to setting low speed. The screw limits the reverse movement of the throttle lever. Turning it, we increase the olfactory speed, unscrew it, reduce it. Adjust so that the engine works confidently at low speeds and even a little faster (for better launch), but so that the reel of the fishing line or the knife does not rotate, and before you start to rotate, there is a sufficient supply of speed. If the engine does not start well, still increase the idle speed.

Limiting maximum speed

After adjusting the consumption of the fuel mixture and low speed, check how the bush cutter engine works at maximum speed. If necessary, limit the maximum speed to the desired level using a hollow screw, unscrew the lockshop and tighten it to reduce the maximum speed, or unscrew it to increase it. After adjustment, tighten the nut. Installation of maximum speed is necessary to protect the trimmer motor for grass from overheating and the possibility of using keys blocking to reduce the fatigue of the right hand.

You may have to adjust the trimmer for the grass of the carburetor later. For example, if the engine begins to gain poorly when working at full load, unscrew the screw by another quarter turnover. If the launch is difficult, increase the blast speed. Weather conditions and the quality of the fuel mixture can affect the work of black cutters. Vibrating screws themselves can also overturn from vibration.

- Due to severe vibration, the protective cap is damaged, as a result, all three bolts lose their established fixation.

- Due to wear of the engine piston. In this case, the adjustment of the carburetor of the chainsaw will help only for a while, it is better to replace the worn part.

- Due to clogging caused by poor-quality fuel, scale or damage to the filter. The carburetor requires complete disassembly, washing and adjustment.

If the chainsaw suddenly stops working, it must be disassembled to find out the reasons.

Step.by.step instructions for disassembly

The device of the carburetor of models of different brands is almost identical, so as an example we consider the Partner chainsaw. Each element is neatly extracted and folded, so that later it is easier to collect it.

Chain carburators from different manufacturers, if they differ, this is not fundamentally

Remove the top cover by unscrewing three bolts. Followed by foam rubber, an integral part of the air filter.

The arrows indicate the bolts that need to be unscrewed to remove the lid

Then remove the fuel hose and then the drive stem.

The upper hand indicates the fuel hose, lower. on the drive.

The arrow shows the end of the cable that needs to be removed.

Tighten the gas hose to the left of the fitting.

Carefully remove the gas hose indicated by the arrow carefully

The carburetor is constantly disconnected, it is ready to adjust

Its mechanism is quite complex, therefore, if you need further disassembly of the carburetor, the elements should be removed very carefully. They are small so that they can be lost

The carburetor consists of many small details, which during disassembly should be laid out in order

Features of regulation and regulation

To find out how to adjust the carburetor

on a chainsaw, you need to learn to distinguish between three screws (for some models there is only one).

The screws l and h are similar only in appearance, in fact they are different

Each screw has its own letter designation:

- “L” is used to install low speed;

- “H” is required to adjust maximum speed;

- “T” is required to adjust the icy speed (only one screw is present on models with one screw).

The factory adjustment is optimal, and use the screws to adjust the engine operation in special situations (the work is related to various climatic conditions).

The diagram shows the conclusions of the adjusting screws of the carburetor with a closed lid

A special tool is used to install a chainsaw

Adjustment is carried out only by screws l and n. To increase the speed of rotation, they rotate clockwise. Lower. counterclock-wise. The sequence of use of screws: l. H. T.

If you doubt the adjustment, it is better to contact a specialist, since improper adjustment can damage the engine.

Adjustment of the carburetor of the chainsaw Patriot 3818, 4518, 5220

On the chainsaws Patriot 4518 and 5220 are similar carburetors. The only difference in performance. T.e. They allow you to work with a larger engine saw.

As for adjusting the carburetor on them, then everything is simple, it passes similarly to the model 3816. You can safely use the instructions described in the article.

The presence of a primer and a light start system Easy Start on models 4518 and 5220 facilitate the launch of a cold engine. Before adjusting the carburetor, you need to verify their serviceability.

In general, Patriot chainsaws due to their average cost and quality are equipped to the best of reliable carburetors, which you need to set up only in extreme measures. If you are not confident in your own abilities, then we strongly recommend entrusting this procedure to the specialists of the service center, t.to. Still, there is a risk of failure, as a result of incorrect tuning the maximum speed of the chainsaw.

and reviews of owners

Ilya, 38 years old, Krasnodar: “Last year it became necessary to purchase a lawn mower to care for a small summer cottage. ) seemed acceptable, but for the quality was a little worried. However, a year later I can say that in vain: mows without problems, starts well, works stably, cuts not only soft vegetation, but also bushes ”.

Mikhail, 42 years old, “acquired for 8800 trimmer for grass (model Patriot T 545 Pro) to work on a section of 15 acres and care for its perimeter. Kosha is 2 seasons, and while there are no complaints: the power is high, the rod is long, the handle is easily adjusted with the help of screwdrivers that are included. The adjusted angle of the gearbox was especially pleased: there is no need to bend to cutting plants under the root. Excellent value for money and quality”.

Battery

Patriot TR 300 Li Trimmer is a tool designed to final processing the lawn (cutting of blades around flower beds, colors, landscape design elements) and having special devices for this:

For the convenience of maneuvering, there is an adjustable handle. The device operates on a battery of 2.5 A ∙ h and a voltage of 18 V. Autonomous time is 25 minutes, full charging-30-40 minutes. Cutting element. a coil with a fishing line with a thickness of 1.6 mm, the weight of the unit. only 1.6 kg.