Sawing logs with a chainsaw with your own hands

We make a carriage for a chainsaw with our own hands

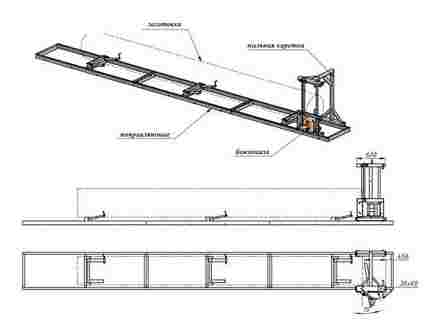

Do-it-yourself chainsaw carriage. Blueprints

Since the price of professionally produced equipment (similar to the one described in the previous section) fluctuates between 2,500 and 3,000, it is easy to come to the conclusion that you can make your own carriage design for longitudinal sawing of timber.

According to the dimensions of the chainsaws used, the dimensions of the carriage assembly, as well as its appearance are shown in the figure.

The manufacture and assembly of the carriage for the chainsaw is carried out in the following sequence. First, the drive motor is prepared for installation. To do this, remove the drive pulley and install the engagement clutch, resulting in a finished cutting head. A support bracket must be made for the motor mounting plate. Changing the pulley diameter can control the cutting speed of the timber. up to 2.5 times faster than the base engine speed. To reduce the temperature and eliminate the option of engine jamming, its output shaft is ground in such a way that the sprocket of the chain drive, without taking into account the dimensions of the central bearing, fits snugly to the bracket.

The presence of a belt drive on the shaft that drives the chain protects the motor from vibration and shock from the chain. It remains to adjust the engagement to get the correct chain speed. Then it is necessary to install bearings on the drive shaft for more intensive operating conditions, with increased bearing capacity.

Most home renovation work requires the necessary materials. It is not a problem to get boards or timber of the right size, but sometimes you need lumber of a certain size. Planks of one or another type of wood, non-standard thickness or width are often required. Finally, there is simply a few logs from which boards need to be sawed. To solve such problems, you may only need a hand-made chainsaw carriage.

This simple device allows you to make a gun carriage, timber or boards of the required thickness from logs of any kind. Such a device is especially valuable in that it makes it possible to process non-standard logs. short, uneven or strongly curved. Let’s take a closer look at this issue.

How to cut a log with your own hands

It is not necessary to purchase a device for sawing boards with a chainsaw. You can make it yourself. The simplest option is a device made of metal profiles. Such a nozzle will be not only convenient, but also stable, durable and reliable. Are you planning to make the most functional frame? Use mechanical gearboxes.

With them, the device will turn into a kind of machine for longitudinal cutting of logs. Mechanical gearboxes are needed to simplify the process of moving the chainsaw along the trunk. There is no need to apply force (to put pressure on the tool manually) to process the material. All you need to do is turn the gear knob. As for adjusting the thickness of the boards, it is convenient to adjust this indicator by using a nozzle made of metal profiles, raising the workpiece itself, and not displacing the gasoline saw in relation to it.

At home, you can also make a device that will cut a log not horizontally, but in a vertical plane. The only significant nuance is that it is more difficult to work with it compared to the previous frame (despite the fact that its design is simpler).

The difficulty lies in the fact that the operator has to apply force to move the tool along the workpiece. In addition to the chainsaw and the attachment, you will have to use a board and metal addition. This kind of support is attached to the log.

An alternative option is a carriage installation. To create such a frame structure, you need a pair of castors and a profile tube. This device differs from others in its mobility (ease of movement along the workpiece). In addition, the wheels will simultaneously serve as stops for the chainsaw, which means that additional devices will not be needed. In addition to these parts and the profile pipe, the only thing that is needed is an aluminum ladder (it will play the role of a guiding element).

It is necessary to select a ladder, taking into account its width, which should coincide with the distance between the wheels of the frame structure, which will be placed directly on its ends. The best option is attached to the log to be sawn using self-tapping screws, clamps or nails. The created device for cutting a board with a chainsaw with your own hands is placed horizontally.

It should lie as flat as possible. You can make sure that it is placed correctly using a building level. It is easy to align a ladder with a log, using boards (pieces) of different thicknesses. As for the tool itself with a nozzle, it is installed on a ladder, moving the saw along the workpiece, putting pressure on it with your hands.

Types of nozzles

If you have a chainsaw, but you do not understand how to use it, and all the firewood has already been cut, then this information will help you to use the gasoline tool to its fullest.

Chainsaw attachments allow you to solve virtually any problem. Chainsaw attachment for removing attachment is also called metal cutting attachment. Buy diamond wire saw for stone cutting wholesale from china. Products directly from the factory on alibaba.com. There are a lot of species here.

So, there is a device that allows you to cut a tree species in a horizontal plane. With its help, you can cut the log into equal parts. Collets, collet, engraver attachment, for engraver, dremel. Tools »power tool. With all this, the frame structure of this device will be able to provide the required hardness.

Another attachment allows you to cut logs in a vertical plane.

Despite the simplicity, the cutting accuracy with this accessory is very high.

With the help of a gas cutter it is very comfortable to cut and saw a variety of metals and stone. this is the same grinder, but mobile.

Chainsaw debarkers make it possible to clear logs from bark or various growths. Also, the device is used to cut out cups, various grooves and grooves. There are two types of this attachment. So, there are drum debarkers and disc.

Design of various nozzles for longitudinal cutting of logs

Let’s start with a simple one, with the construction of a gas cutter. Visually, it resembles a bearing assembly, supplemented by a pulley and a movable shaft (performs rotational movements). This device drives the belt drive. The unit is equipped with a special mechanism designed to fix the disks. The latter must be chosen from an assortment designed for cutting metal, wood, stones. With the help of such discs and attachments, it is not difficult to transform a gasoline saw into a multi-tool.

An alternative version of the device for ripping is a debarker. This is popular not only for its ability to increase the efficiency of making boards, but also due to its ability to remove bark from logs. It can also be used to cut grooves in the material to be cut. These are just a few examples of why the debarker is being exploited. Such nozzles are found in two varieties:

- drum;

- disk.

How To Chainsaw Mill Without A Chainsaw Mill

They differ from each other mainly in functionality.

There are other devices for longitudinal cutting of logs. Most of them are developed by large companies, but homemade gadgets can also be seen on the net. From those made at factories of famous brands, they differ mainly in design features.

In this regard, homemade nozzles are much simpler. The most common option is a hand-held sawmill. At the heart of such a small sawmill is a gasoline chain saw, supplemented not only with guide elements, but also with wheels designed to move along the log (in order to reduce the resistance indicator). The wheels of this device are no more than 2 pieces, one piece on different sides of the workpiece.

The manual sawmill is a simple and convenient device. With its help, you can, without making any special efforts, make a large number of even and neat boards. The only essential condition is the correct installation of the chainsaw. It should be positioned horizontally (unless the operator needs a bevel cut).

Chainsaw Attachment For Cutting Metal

Chainsaw attachments (pendant equipment): motor-drill, compressor, cororder

Modern chainsaws can do more than just cut wood. It is a versatile device that can be adapted to the widest range of tasks. If desired, an ordinary chainsaw can be used as a pump, motor-drill, boat or bicycle motor.

In terms of the breadth of capabilities, no instrument can now compete with them. With additional equipment, the saw can pump water from wells or wells, cut stone, metal, stretch cars stuck in snow or dirt. All of this is made possible by the overhead equipment. Chainsaw attachments can significantly expand the functionality of this tool.

Design features of a snowmobile and snowmobile

A chainsaw snowmobile is considered one of the most difficult home-made devices, because its manufacture will require a large number of additional parts, including:

- frame;

- body;

- tracks and front skis;

- steering wheel;

- handle and clutch controls.

There is another complication. In order for the snowmobile to move, it needs to be equipped with a suspension and a transmission, so it will not be easy for a beginner to cope with such work.

Creating a snowmobile from a chainsaw with your own hands begins with a supporting frame, which is a steel profile measuring 20×20 or 20×30 cm.The swing arm is responsible for the shock absorption of the rear suspension, and the motorcycle-type steering fork is responsible for the front suspension.

To make a snowmobile from a chainsaw, you will need to purchase many additional parts. A more complex design consists of two skis, with the steering wheel it will be possible not only to turn the axle, but also to pull the steering linkage levers. Despite the fact that this method is technically more difficult, it provides more convenient control.

Additionally, a do-it-yourself snow scooter with a motor is complemented by a centrifugal clutch with a V-belt and chain. To increase the traction force, a gear is attached to the track shaft, the diameter of which exceeds the drive part of the chainsaw shaft. For normal operation of a home-made device, you need to take a motor with a power of at least ten horsepower.

A simpler option is a snowmobile, which has a similar method of use, but is a propeller driven aircraft moving through the snow. Due to the simplified design, the sledges do not differ in high carrying capacity, maneuverability and stability. The main advantages are simple design and ease of manufacture. The rotating screw, installed behind the driver’s back, must be closed with a protective casing made of fine mesh. Control is carried out by turning the skis, throttle and brake. The optimal engine power is considered to be 5-6 horsepower.

Horizontal nozzle

This nozzle gives a higher accuracy. The device is a rigid frame that is fixed on the chainsaw tire from both sides. at the end of the tool and at its base. The device is suitable for small diameter logs not exceeding the length of the bar.

Longitudinal sawing of logs with a chainsaw with such a device should occur only after the log is well secured, since if it vibrates during operation, then it will not work to get a flat surface of the board.

Before proceeding with the dissolution of the log, it must be given a square shape by cutting off all unnecessary. It is clear that there will be much more waste in comparison with industrial production. When ripping a log with a chainsaw, the hardest part is to saw off the first board. To do this evenly, you can use a special frame that will serve as a guide and be the base for the stop. The quality of subsequent boards also depends on how smoothly you make the first cut, since the guide will rest on this surface in subsequent cuts.

Regular cut

If you do not have any tools at hand, sawing logs with a chainsaw into boards is as follows:

- Sand the log, that is, remove the bark from it.

- Mark the log by tracing the required board dimensions.

- Saw the board along these lines.

Please note that with this method, you need to separately draw each next board, since quite a lot of wood is lost during sawing. up to one centimeter.

Sawing process

- Lay the log on the trestle.

- Fasten the frame to the tire.

- Attach the supports that are designed to hold the ruler, making sure they are level.

- Fix the fasteners with self-tapping screws (it will be easier to remove them at the end of the work).

- Make sure the cut line is 1 cm above the ruler and not along it.

- Make the first cut.

- Release the log from the stops and move the device to the next cutting line.

- Further, the ruler can be removed, and further focus on the previously made cut.

Safety regulations

- Do not use the chainsaw when you are sick or drunk.

- Hold the chainsaw firmly with both hands for complete control during unexpected jerks.

- Keep your hands clean and dry to ensure a secure grip on the instrument.

- Use the chainsaw only on a stable surface with sufficient area.

- Do not operate the chainsaw with arms raised or extended.

Additional accessories

Most often, additional devices are used for sawing logs with a chainsaw into boards.

- Debarker. Chainsaw attachment, with which you can sand a log, clean it of knots and build-ups, or cut grooves in the log.

- Cross and longitudinal cutting attachments. It is this device for sawing logs with a chainsaw that is used to make boards.

- Gas cutter attachment. An attachment that allows you to turn your chainsaw into almost a full-fledged grinder. At least for home purposes, it is perfect.

In fact, there are a great many such nozzles, but we will not delve into them, since we have already listed above what we need for work.

Device for sawing logs with a chainsaw with your own hands

If desired, any such device can be made independently.

The first thing you need. these are goats for securing the log. Then the nozzle frame and guide.

Making goats for logs is not difficult. The main requirement is their height. Measure in advance a height that is comfortable for you so that you do not have to bend too low to the log or, conversely, work with your arms extended upward.

Making a frame-attachment will require more knowledge and skills.

First, you need to complete a drawing of the future frame, observing the scale. Then, from a square pipe with a cross section of 20 × 20 millimeters, weld the frame of the future fixture and weld the clamping elements onto it. Several holes must be made in the cross member for the bolt ties.

Oddly enough it sounds, but the most common difficulty in making a device for a do-it-yourself rip saw and other similar devices is the lack of welding. Therefore, before proceeding, calculate whether you have everything you need in stock.

Tool selection

Not every chainsaw is suitable for this purpose. In order to cut logs with a chainsaw into planks, it is better to use a professional tool with a capacity of more than seven horsepower. An ordinary household chainsaw will not have enough power for such a job.

In addition, you should be aware that thicker logs will require more power, so it is better to choose specimens up to 35 centimeters in diameter.

Do-it-yourself sawing logs with a chainsaw on boards

- November 27, 2018

- Equipment

- KaplyaDegtya

The most commonly used material for private construction is log and board. Knowing how to cut a log with a chainsaw into planks can significantly reduce construction costs as the cost of the finished plank is much higher. Let’s find out all the details of this process.

Cross-cut secrets

The cross saw is used to obtain firewood or decorative elements of the interior. Sawing is carried out according to the following principles:

- Place the log in a horizontal position on wooden supports, the height should be 0.5 m.

- Clean it from the bark.

- Using an ax or a saw, make small marks along the entire length, they should be located at the same distance from each other.

- Make a cut along the cuts.

Cross-cutting does not require the use of special tools or attachments. An ordinary chain is perfect for such work, but its rings must be strong.

The technology of sawing logs into boards with a chainsaw

The advantage of sawing logs with a chainsaw

The method of cutting logs with a chainsaw has several advantages.

The ability to work under any conditions. the chainsaw is not afraid of moisture, therefore specialists can saw logs in the rain, the equipment in this case will not deteriorate.

High productivity. it is allowed to carry out work on wood throughout the day, but it must be borne in mind that the power of the device must be at least 7 horsepower.

Autonomous device. the equipment runs on gasoline, does not depend on electricity, the workplace is mounted on any site where it will be more convenient to carry out the process.

Convenience in work. the chainsaw is equipped with a smooth start and regulation of the chain rotation speed, these conditions ensure a high-quality result for beginners in this business.

The undoubted advantage is that the equipment is much cheaper than a small sawmill. During a breakdown, repair is inexpensive, does not take much time.

Rip saw attachment

It is used for sawing a log lengthwise, the process takes place in a horizontal position. After work, the master gets the same thickness for the product. The finished materials undergo a drying process, after which the boards are used in construction.

In appearance, the device is a small frame, it is attached to the tire on each side.

Technique for sawing logs along

Longitudinal sawing is carried out using a horizontal nozzle. To get the boards even, it is important to use a specially prepared guide; a metal rail or a high-strength board plays its role.

The difficult thing in this process is to make the first saw cut, for this you need:

- Mount the guide ruler, it consists of two boards, fastened together at an angle of 90 degrees.

- Place the log on supports, firmly fix its position.

- Check if the log is level with a level.

- Using self-tapping screws, fasten the guide ruler to the supports.

- In a horizontal position, fix another guide, the element will abut against the ground, but at the same time fix the log.

- Cut the log.

During the second cut, specialists may not use the leading ruler, the resulting board will serve as a guide. The second cut is made perpendicular to the first.

Features of a homemade sawing option

Sawing a log into boards is easy with a do-it-yourself tool. Equipment manufacturing is simple:

Two Chainsaw Secrets | Turning a Tree into Perfect Boards

- As a support, it is necessary to use a frame from a school desk or a pipe with a cross-section in the form of a square, its optimal size is 20 × 20, and more is allowed.

- Build two clamps, at one end mount a cross member with two holes for tie bolts, make a projection for the bus in the middle.

- For longitudinal sawing of logs into boards, it is important to make a support frame, its width must be 7–8 cm less than the length.

- Then two elements 10 cm long are welded to both sides, holes for bolts are made, a handle is attached in the middle for ease of use.

- After that, insert the clamps into the grooves, the bus is installed, everything is carefully fixed.

It is not difficult to work with a homemade tool, this will require two goats, they will serve as a support, and you also need to prepare a metal rail or board, the element will be a guiding element. A log is laid from below, the required height for work is adjusted.

Drum debarker. gummer

With the help of such a nozzle, it is easy to dissolve the log, it works due to the V-belt transmission. Attaches to belts on both sides using special pulleys. The speed of rotation of the shaft depends on the size of the pulleys, so the performance of the nozzle is easy to change.

This technology forces the master to carefully monitor each stage of the process; some specialists use an assistant during this cut. But this option requires increased security measures.

Types of working attachments

Sawing logs with a chainsaw is carried out in different ways, craftsmen work with wood along the grain, as well as across it. It all depends on what attachments are used in the chainsaw.