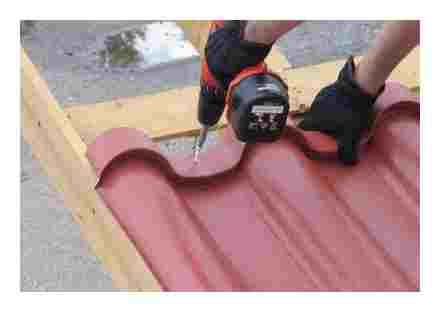

Screwdriver attachment for cutting metal tiles

Tool for cutting metal tiles

Installation of metal tiles: features

- prepare for installation work;

- measure the roof, calculate the required amount of metal tiles;

- equip a waterproofing carpet;

- make the roof lathing;

- install the roof covering.

- roulette;

- rubber hammer (mallet);

- level;

- long rail;

- marker;

- brush with soft bristles;

- special screwdriver or drill;

- tool designed for work related to cutting roofing material.

Features of metal tiles

- decorative appearance;

- a long service life, which is up to 50 years, of which the first 10-20 years such a roof does not need repair, then the sheets can be tinted, and some of them can be replaced;

- low cost;

- relatively easy installation;

- the possibility of self-installation;

- due to the fact that the material is lightweight, there is little load on the foundation of the building. This is especially important for buildings with a weak foundation and insufficient load-bearing capacity of the rafters;

- the widest range of colors and variety of shapes does not allow limiting creative ideas;

- work on the arrangement of a roof made of metal tiles can be performed throughout the year, since temperature drops and high humidity are not dangerous for this roofing material;

- due to the smooth surface, a free drain and self-cleaning of the roof from snow drifts is provided;

- the material withstands well mechanical and ultraviolet effects, high temperatures.

Tools for cutting metal tiles

- hacksaw for metal;

- disc for cutting metal tiles;

- electric jigsaw;

- circular saw with carbide teeth;

- nibblers for metal tiles, electric or manual.

Since the material has a complex profile, which has turns at right angles, it is rather difficult and rather problematic to use simple hand-held punching shears for working with metal sheets.

Drill attachment

When performing repair and construction work, it is often necessary to cut a sheet of metal or cut out any metal workpiece or part. In this case, a scissor attachment for cutting metal with a drill can help you out. Tools such as a drill or screwdriver are always at hand with a household man.

Therefore, all you need to do is just put on the nozzle and with this simple device you can easily cut a metal structure of small thickness. It is worth buying a metal cutting attachment for everyone who is not used to stopping repairs because of the difficulties that have arisen.

Door metal cutter

By purchasing a drill bit, you will realize that a conventional drill can be used for more than just drilling holes. This tool is very functional. And if used correctly, you can save a decent amount of money on the purchase of new tools. The drill attachment will easily handle metal tiles and thin sheet steel. You can cut a metal structure much faster than a grinder, and more accurately.

When cutting metal with a grinder, sparks from under it scatter in different directions, and you constantly risk your health or are forced to wear a mask. Where sparks hit, stains can form on the metal coating, which over time will cause rust to develop. The attachment for the screwdriver for cutting metal sheets will do its job efficiently, quickly and safely. With the metal scissors drill attachment, you can repair your roof yourself.

The set of a metal cutting nozzle includes: a nozzle body, 2 matrices, a handle and a key. The dies are made of durable metal, they allow you to create an even and smooth cut during the processing of the structure. Unlike cutting with a grinder, you will not get a burnt edge of the product.

Screwdriver attachment for cutting metal sheets

The metal cutting attachment for the drill has two cutting tips located on either side of the tool. The cutting shafts have a movable metal rod, and it is he who cuts the metal. A groove located on the edge of the cutter serves to hold the sheet metal during machining. Nozzle for cutting metal for a screwdriver, due to its design, will exclude any snagging and slipping of the cutter during operation.

Rotary cutters allow you to cut the product at any angle. Only with this attachment you can easily make an internal cut of the structure. For example, if you need to cut a circle in the middle of a sheet of metal, the Beaver tool will do just that. On the back of the scissor attachment for cutting metal there is a clamping shaft that is inserted into a drill or screwdriver. The affordable price for a drill bit for metal cutting will delight budget-conscious owners. The kit is quite compact and will not take up much space in your construction case.

The Beaver metal cutting attachment is quite easy to use. Any man who has ever held a repair tool in his hands at least once in his life will understand how to use a sheet metal cutting attachment. Simply screw the handle onto one of the cutters of the sheet metal drill bit, then lock the Steel Beaver scissor head into the main tool.

While holding the drill in one hand, grip the handle of the sheet metal cutter with the other. Insert the edge of the metal part into the groove in the cutter and press the start button of the screwdriver. The rod inside the cutter will start to move back and forth and you only need to make a little effort to cut the structure.

2 Awesome Drill Attachment ! Metal Sheet Cutter Test

Professionals recommend using a screwdriver for small volumes. If you need to work with large volumes and for a long time, then do it with a screwdriver or drill.

Attachment for cutting metal with a screwdriver. Benefits

- Convenient handle for secure fixation during work;

- Suitable for household and industrial use;

- It is much cheaper than a professional metal cutting machine;

- The thin cutter shaft allows you to make cuts and cuts of any shape;

- Smooth and smooth cut;

- No adjustment required, easy to use;

- Works much faster than scissors for metal;

- Cuts copper, brass, iron sheets, steel and stainless steel;

- The processed material does not deform and does not melt after cutting.

How does a cricket work on a drill for cutting metal?

The work is built on the principle of a conventional office punch. A thin cylindrical firing pin pierces a neat hole in the metal. Oscillatory movements occur at a high frequency (equal to the revolutions of the drill chuck), and when moving forward along the line of the marking, you get an even and continuous cut.

The characteristic sound during the operation of this drill bit gave the name “cricket”. Nibblers for metal “cricket” have no restrictions on the trajectory of movement.

You can cut lines of any shape. The tool (thanks to the round shape of the cutting part) can be rotated 360 ° around the cutting point.

Another advantage of the “cricket” drill bit is that it is excellent for cutting metal with stiffeners and other profile stampings.

- The first method is to repeat the plane of the profile (the operator holds the nozzle perpendicular to the workpiece, bending around irregularities). Suitable for medium bending radii.

- The second method is to cut the metal straight along the edges, without bending around the sheet profile. It is thanks to this ability that this nozzle is suitable for cutting metal tiles.

The ribs that form the shingles on the roofing sheet do not have too much level difference, but the bending occurs almost at right angles. Conventional drill bits for cutting metal in the form of scissors, such a profile will not work. And the slotted nozzle makes a cut without stopping.

The only drawback of such a tool is the relatively high loss of material. The punch has a certain diameter, so the width of the cut is the forced losses during cutting.

Usually it is a few millimeters, but nevertheless this feature must be remembered. When performing work, a large amount of metal shavings is formed. Unlike the contents of the hole punch container, these are not steel confetti, but sharp-edged crescents.

Therefore, it is not recommended to work in soft shoes, and at the end of cutting, it is necessary to immediately dispose of the metal. Another option (not very common) is self-propelled disk shears (of course, in the form of a drill attachment). There is no point in describing the principle of operation, everything can be seen in the illustration.

The bevel gear drives the upper driving disc, and the guide disc is pressed from below. It turns out, as it were, endless scissors. There are restrictions on the thickness of the metal, in addition, such scissors cannot perform a figured cut.

Any of these devices greatly facilitates the work with metal. They are not universal, so every craftsman can choose an attachment for their needs.

Drill attachment for cutting metal. mechanizing a difficult operation

How do you cut metal at home? In 90% of cases with hand scissors (we are talking about thin metal sheet). The method is unsophisticated, inexpensive, but not devoid of drawbacks.

- At the very least, making a long cut without burrs is difficult.

- Since the scissors are located along the sheet, the planes to be cut need to be spread up and down. This makes it difficult to work, not to mention the fact that the edges need to be aligned afterwards.

- If the workpiece is not flat, but with stiffening ribs (for example, corrugated board, or a figured “under tile” roof covering), it is almost impossible to make a cut with ordinary metal scissors.

It takes a lot of physical effort. If you need to cut several meters at a time, then it turns out a good workout, like in a gym. Often a grinder with a cutting disc is used for such work.

It turns out quickly, relatively smoothly and not at all physically difficult. However, the edges require post-processing and the metal at the edge is exposed to unwanted thermal effects.

If you work with sheets of profiled metal-plastic “tiles”, then the protective layer at the cut site burns out and loses its aesthetic appeal.

Progressive method. electric metal shears with vertical blades. However, this is an expensive tool that is rarely used (how often do you re-cover your roof?). Therefore, there are more practical accessories on sale: a drill attachment for cutting metal.

In fact, it is a gearbox that converts the rotary motion of the spindle into oscillatory motion. Of course, in terms of its characteristics, the device is inferior to full-fledged electric scissors.

However, a drill attachment is inexpensive, and you don’t buy a ready-made tool (scissors with a motor), which gathers dust on the shelf most of the time. There is a drill in almost every home, if necessary, it can be easily turned into a progressive cutter.

Varieties of nozzles

Classic drill attachment. metal scissors. Second name: “beaver”.

The mechanism is a shaft freely rotating in a bearing, on which an eccentric is fixed. The system works on the principle of a crank mechanism, only the other way around: energy is supplied precisely for rotation.

One half of the scissors (supporting) is located on the bed, the second swinging on the axis. The movable part is connected to the eccentric, and when the shaft rotates, it reciprocates. The metal shears are mounted on the drill, and you have a complete cutting tool in your hands.

An obligatory structural element is a handle fixed perpendicular to the axis of rotation of the spindle. As the load increases, a reactive torque arises, which can turn the drill relative to the nozzle.

This nozzle is perfect for cutting sheet metal without profile bends, or with large radius waves. There are practically no burrs, it is easy to control the cutting line. Due to the short length of the cutting jaws (in contrast to hand scissors), curly cuts with small radii can be made.

Again, due to the short jaws and the absence of levers-handles, forced separation of the cut planes is not required. Moving along the line, you can perform continuous cutting of any length.

But when working with profiled sheets, especially with a small bend radius, the edge can break, if the cut is at all possible. In this case, metal shears are used.

The attachment is put on the drill, and works on the same principle: converting the rotational energy into linear energy. However, the design of the work item (called a “cricket”) is different.

Work with the Cricket nozzle

Advice from experienced craftsmen: so that the nozzle does not wedge, you need to pour the metal with soapy water.

Slitting shears for a screwdriver or drill

Popular models and their areas of application

Modern models of drill bits allow cutting sheet metal not only in a straight line. With the help of such a convenient and easy-to-use device, you can also make curly cuts, which is often required when installing roof structures, ventilation ducts, as well as gutters and other elements of the drainage system.

Using such drill bits, cuts can be made in almost any spatial position. An equally important advantage of these attachments is that they do not require preliminary adjustment.

This attachment turns the drill into an electric shear that works on the principle of cutting, not nibbling.

Among the most popular models of drill bits for metal cutting on the domestic market are the following:

- “Cricket” (from the “Enkor” company);

- Sparky NP 1.8L;

- EDMA NIBBLEX;

- ACKO YT-160A.

Cutting shears-attachment for the EDMA NIBBLEX electric drill for cutting metal and plastic

“Cricket”

One of the popular drill attachments, which are compact nibbling (nibbling) shears, is a device called the “Cricket”. This nozzle, which allows you to get a smooth and accurate cut, can be used to cut both flat and profiled metal sheets.

Scissor attachment “Cricket” is designed to operate from a pneumatic or electric drill (screwdriver) with a power of at least 420 W

With the help of the “Cricket” scissor attachment, you can cut not only a metal sheet, but also thin sheet products made of polycarbonate and other polymeric materials. In this case, the thickness of the products, for which these compact nibblers can be used, can be up to:

- 1.5 mm. for steel sheet material;

- 1.2 mm. for stainless steel;

- 2 mm. for copper and aluminum, as well as polymeric materials.

With the “Cricket” drill attachment, you can cut sheet material in the horizontal and vertical planes, as well as make internal cuts on the sheet surface.

“Sverchok” works on the principle of nibbling scissors

It should be borne in mind that in the place of the sheet from which the internal cut will be made, it is necessary to pre-drill a hole.

“Sverchok” is a good drill attachment for cutting metal tiles and corrugated board. When using this device for cutting metal, the surface of these materials does not deform, and the cut itself turns out to be smooth and accurate. The “Cricket” nozzle can easily cope with such complex tasks as artistic cutting and creating a large-diameter hole in sheet material.

Features of the use of drill bits

The attachments, with the help of which an ordinary electric drill turns into a device for cutting metal, are, in fact, a punch (cotter pin). Making numerous reciprocating movements in the inner cavity of the matrix, such a punch penetrates the metal sheet, forming a cut line on it, the width of which is 3.1 mm. When using nozzles, a point effect is exerted on the processing area, due to which the protective layers on the surface of the metal product fully retain all their functions.

The working part of the punching nozzle

Using the drill bit, you can cut metal sheets of the following thicknesses:

- made of aluminum. up to two millimeters;

- made of copper, brass, sheet iron, zinc and galvanized steel. up to one and a half millimeters;

- made of stainless steel. up to eight tenths of a millimeter.

The reciprocating movement of the punch, which is the main working body of the nozzle, is communicated by rotating the chuck of an electric drill. It should be borne in mind that such a nozzle can effectively cut a metal sheet only if it is used in conjunction with an electric drill, the chuck of which rotates at a frequency of at least 2700 rpm.

Examples of cuts with a nozzle of galvanized sheet (0.55 mm) and aluminum (2 mm)

Benefits of using drill bits

Drill bits, when compared with such a popular metal cutting tool as a grinder, have a number of advantages.

- The cut is of high quality.

- When using a drill bit for cutting metal, there is no need to purchase additional consumables, which significantly saves money.

- The use of such a nozzle ensures high productivity of the cutting process.

- Drill bits are highly versatile.

- Due to the fact that this tool is equipped with a special handle, it is very convenient to perform the cutting process with it.

- These attachments are suitable for both electric and pneumatic drills.

- Undeniable convenience of these attachments both in use and maintenance.

- With the help of such tools, you can make cuts in almost any configuration.

Despite the simplicity of the design of such nozzles, their use requires certain skills and dexterity from the user.

Drill bits for cutting metal: types, features, application

The need for cutting metal products arises in many situations related to construction and repair work. To perform this technological operation, special equipment of various types is used, but if it is not at hand, a drill attachment for cutting metal can help. Using such attachments and a hand-held electric drill, you can efficiently cut thin products made of various metals.

Figured cutting of metal with a punching nozzle for a drill

Types of equipment for metal cutting

You can cut a metal sheet or a more massive metal product using various equipment.

This device is also known as the “grinder”. It can be used to cut rebar, plate and other types of metal. This is the most popular equipment used for this purpose.

Metal circular saw

This saw allows you to make cuts at different angles and perform them with great accuracy. Meanwhile, when using this equipment, the resulting cuts have a limited depth and a large amount of waste is generated.

This is a high-performance equipment for metal cutting, with the help of which the processing of workpieces of a simple configuration is carried out.

Bandsaw and jigsaw

This equipment allows you to make cuts at different angles. Both the jigsaw and the band saw, due to their design features, impose significant restrictions on the size of the products that need to be cut.

This type of equipment is innovative. It allows you to cut metal with high accuracy, while the thickness of the workpiece can be up to 20-30 cm. The most significant disadvantage of this cutting method, in which the product is not subject to thermal effects, is the high cost.

As mentioned above, you can also use drill bits for cutting metal products, which are presented in a wide variety on the modern market.

Drill bits can also be used for cutting and other materials

“Steel beaver”

Another popular drill attachment that can be used to cut metal is the Steel Beaver. The principle by which such drill bits work is similar to how nibblers work. When using this device, sparks are not generated in the cutting area and no thermal effect is exerted on the metal sheet, respectively, the protective coating applied to it is not burned.

Metal cutting attachment “Steel beaver” is completed with a replaceable die and a punch

Among the technical characteristics that a drill bit of this type has, it is necessary to highlight the following:

- The efficiency of such a nozzle is ensured when the drill chuck rotates at a speed of 1500-3000 rpm.

- The maximum workpiece thickness is 1.8 mm for conventional steel sheets, 2 mm for copper and aluminum sheets, 1.2 mm for stainless steel sheets.

- The angle by which you can change the direction of the cut. 360 °.

- Minimum cutting radius. 12 mm.

When deciding which tool to choose for cutting sheet metal. a jigsaw, a grinder or a drill bit. you should first of all evaluate the tasks for which they are needed.

Drill bits are a good option for DIYers and small construction crews. When the volume of work on sheet metal cutting is small, the use of such a nozzle is the best solution. When choosing this device, you should pay special attention to the fact that the characteristics of the drill, complete with which it will be used, correspond to the characteristics of the tool itself.

The main types of nozzles for a screwdriver

On sale you can find a lot of devices that expand the functionality of the power tool. The user can get, thanks to the attachments for the screwdriver, pump, mixer, saw, polishing brush and other types of specialized equipment.

All removable devices are divided into three main groups:

- Combined nozzles.

- Tips for special purposes.

- Basic nozzles.

The working element of the handpieces belonging to the main group has the form of a cruciform or hexagonal head. Such attachments for a screwdriver are suitable for self-tapping screws of any type. They provide excellent adhesion to the fastener. In some nozzles, the heads are magnetized, which greatly facilitates the screwing process. In terms of technical characteristics and capabilities, such tips are similar to screwdrivers.

Existing types of bits for a screwdriver differ in the shape of their working part

Combined attachments belong to the category of universal attachments. Unlike the main tips, they have a working body on both sides. Each end of the combination bit has its own size and attachment system. For convenience in the process of work, the unnecessary part of the tip is simply dismantled.

Bits for special purposes are mainly presented in the form of attachments for a screwdriver for twisting wires. With their help, you can also control the depth of unscrewing and screwing in fasteners located at an acute angle.

Helpful advice! To decrease or increase the rotational speed of the nozzle, it is enough to weaken or, conversely, increase the pressure on the start button.

Features of polishing tips for screwdriver

After processing the product with a polishing pad, its surface becomes perfectly smooth. For this, an end disc is used, which removes the microscopic top layer of the material. This ensures that the thickness of the product does not change.

Drill bits for various purposes for work in the home workshop

Make CUTTER From Drilling Machine ( Metal, Wood & Marble )

The main types of accessories for cutting, grinding, polishing and other tasks. Accessories for working with metal, plastic, wood.

The screwdriver attachments for polishing various surfaces have a stop disc with fasteners for fixing the polishing material. This element is held by a threaded tip. Since the tool shaft can rotate both to the left and to the right, you can find accessories on the market with connections of the corresponding type.

During operation, the polishing disc on the attachment wears out, so it should be periodically replaced with a new one. Replaceable products are thin (only a few millimeters). They are usually made from polyurethane. Although there are other options. from felt or wool of natural or artificial origin.

There are options for polishing tips for a screwdriver made of felt or wool

Some types of tips can be used to polish car body and glass, as well as products made from polycarbonate. In the process of work, such nozzles must be kept parallel to the surface to be treated.

The main types of polishing and grinding attachments for a screwdriver

The polishing and grinding attachments for the screwdriver are a large group of removable accessories, including many varieties. In this category, you can find handpieces for different tasks:

- polishing metal, wood and glass surfaces, as well as varnished products;

- cleaning products made of metal from corrosion and remnants of old paintwork;

- grinding wood and metal surfaces.

Thanks to the huge variety of screwdriver attachments for grinding, you can choose the tips for operations that cannot be done with standard methods.

Varieties of screwdriver attachments for self-tapping screws in tape

To fix the screws with a screwdriver, not only bits, but also tapes can be used. They are part of the automatic fastener feed devices. Such attachments make it possible to speed up installation work by about 2-3 times. The advantage of using them is that the master does not need to take a new self-tapping screw every time and install it on the bit.

To fix self-tapping screws, not only bits, but also tapes can be used

Manufacturers produce two types of drives with a tape feed mechanism for self-tapping screws:

- Removable tape attachments for a screwdriver. if necessary, such a tip can be removed and additionally screwed on the self-tapping screw. This option is in high demand among consumers, although it is not without its drawbacks. The fact is that the attachment must be bought together with a screwdriver.

- Stationary mechanisms. in this case, the attachment together with the screwdriver is a one-piece structure. Such a tool belongs to the category of narrowly targeted and can only be used with tapes.

Tape screwdrivers are battery and mains. Devices that plug into an outlet cost half the price. However, they are completely dependent on the power supply and are not so convenient to use, since the hanging cord creates certain inconveniences. This is especially true when installation work is carried out on the ceiling.

Helpful advice! To increase the efficiency of polishing, the disc of the attachment must be lubricated with a special polishing paste.

There are two types of drives with a tape feed mechanism for self-tapping screws: stationary and removable type

The main types of angle adapters for a screwdriver

Angle adapters allow you to unscrew and tighten fasteners in hard-to-reach places. Such nozzles greatly simplify the work, because the tool can be held perpendicular to the surface, and the screws can be screwed at an angle, both to the left and to the right.

Angle adapters make it easier to work in tight spaces

Taking into account the technical characteristics, as well as the functional purpose, there are two types of angle nozzles for a screwdriver:

- flexible;

- tough.

Flexible design attachments use flexible coupling to change the direction of the torsion axis. Outwardly, the device looks like a drill used in dental clinics for dental treatment. The removable tip consists of a flexible shaft that connects the work bit to the chuck of the screwdriver. This type of attachment makes it easier and faster to work in hard-to-reach places where you need to unscrew the screws.

Note! Flexible angle attachments for a screwdriver are not suitable for fasteners that are made of strong alloys.

Rigid adapters are short attachments that mechanically change the direction of the axis of rotation. Unlike the previous version, the cartridge of this device is much stronger. Rigid adapters allow mounting and dismounting of fasteners from either side. Such attachments are usually used in professional screwdrivers, the motor of which is designed for high loads and strong vibrations.

There are two types of screwdriver angle bits: flexible and rigid

Characteristics of screwdriver rivet bits

Traditional one-piece rivets are rarely used. Many professionals prefer to use a welding machine. However, not every master has such equipment in his arsenal, and also has the skills necessary to work with it. In this case, the best option would be a rivet attachment, which is installed on a screwdriver.

Screwdriver bits for rivets can only be used on models with a reversible drive

Such attachments can be used on electric and cordless tools to install nut-type rivets and other fasteners with a core.

It should be noted that screwdriver attachments for rivets can only be used on those tool models where there is a reversible drive. These fixtures are designed for mounting aluminum or steel fasteners, the diameter of which is in the range of 2.4-5 mm. They can also be used to install sleeves made of non-ferrous metals, the diameter of which does not exceed 25 mm.

If a battery-powered screwdriver is used to install the rivets, you need to ensure that the battery voltage does not exceed 12 V. The installation process itself is not particularly difficult, and the attachments are compact enough to be stored together with the screwdriver in one case.

Varieties of attachments for a screwdriver for grinding

There are more than ten varieties of screwdriver tips that you can use to sand the surface. Removable attachments of this type consist of a rod on which the abrasive material is fixed:

- sandpaper;

Screwdriver attachments for grinding consist of a rod on which an abrasive material is fixed

- hard abrasive;

- stiff fabric such as felt

- brushes.

The most popular among the craftsmen are the following types of removable handpieces:

- Plate. these products can be rubber or plastic. Equipped with fixed and adjustable pins.

- End. made of hard and soft materials, can have various shapes (drum, washer, cone).

- Cup. brush attachments for a screwdriver with brass or metal fibers, as well as tips with soft foam or felt filling.

- Disc. removable devices with soft padding or bristles made of brass or steel wire.

- Drum. an emery belt is used as an abrasive, suitable for processing holes and end zones of glass products.

- Serrated. consist of several elements covered with sandpaper. Used for processing surfaces with complex geometry.

There are many varieties of screwdriver grinding tips

Note! If you wish, you can use a compact screwdriver with a face bit for processing jewelry. The nib is so precise that it allows you to sand fine details on precious metal jewelry.

For cutting tiles

Another name for this drill bit is cricket. The set can be used both for smooth surfaces and for profiled iron sheets. The advantage of this cutter is the ability to create an even cut, without burrs and irregularities.

The cricket drill attachment is convenient to use for:

- cutting thin-sheet products;

- cutting out parts from metal sheets.

Since its application does not depend on the spatial arrangement, you can easily cut a horizontal and even vertical sheet.

Milling cutter

In another way, this nozzle is called a roller cutter. It is designed for processing wood and metal products:

- a roller cutter replaces a file;

- significantly speeds up the grinding process;

- eliminates defects.

One set can include cones of different shapes, thus, for each specific situation, you can choose the most suitable nozzle. Some of them outwardly practically do not differ from the drill.

Varieties of drill bits for cutting metal

Who has not encountered the need to cut a metal part during repairs? Among the craftsmen, most likely there is no person who would refuse a powerful portable instrument. In most cases, it is used:

- grinder disc;

- milling installation;

- scissors for cutting metal.

But the modern market for power tools does not stand still, and now there is a drill attachment for cutting metal.

Scissors attachment

Of all the nozzles presented, this one is the least similar to a drill. It turns the drill into an electric shear, not a nibbler. They work on the principle of a straight cut, cutting through metal with sharp edges using mechanical force. This is a rougher method for cutting metal and plastic. Such scissors perform only a straight cut, it is very difficult to change its direction during operation.

This set is more suitable for cordless tools.

Using a drill

It’s no secret that a drill can be used not only as a drill, but also as a multifunctional tool. There is a whole range of different devices that facilitate the work of the worker.

- a cutter for metal for a drill avoids monotonous manual work with a file;

- a scissor attachment for a drill provides the ability to cut metal sheets and elements;

- a drill attachment for cutting metal tiles, in turn, helps to accurately cut sheet metal roofs at any angle.

Working with this kit requires some skill, but over time you will realize the benefits of this method.

Let’s take a closer look at each option.

What are the attachments for?

Various types of cutters, as a result of repeated repeated movements, cut metal with a matrix. As a result, durable metal lends itself to processing. Thus, we cut, punch holes or grind a metal surface. Point impacts allow you to work accurately without disrupting the structure of the elements. In addition, the natural protective layer of the product is preserved.

Using nozzles, you can act on the following metals:

- 2mm aluminum plates;

- copper, brass, iron, zinc and steel elements;

- galvanized parts with a thickness of 1.5 mm;

- stainless steel 0.8 mm thick.

Metal crowns

In addition to the basic tips, there are other devices, for example, a metal crown. This is a special drill designed for making wide holes. Its use is due to the need to lay communications. The downside of a metal crown is its roughness: the edges of the hole made require additional processing. It is in such cases that the roller cutter comes into play.

The set of crowns can include both simple and diamond-coated edges. They can be used to drill concrete floors and thick metal sheets.