Screwdriver charger does not charge

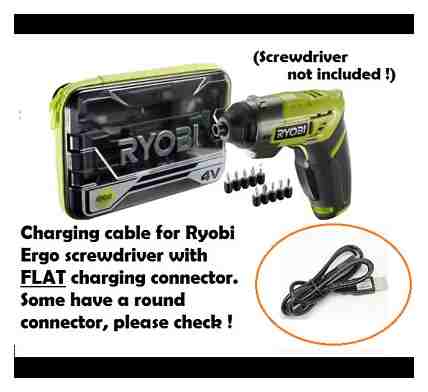

DIY 18 Volt Screwdriver Charger

Modification of the screwdriver charger 13

A screwdriver is an irreplaceable tool, alas, the discovered defect forces us to move our brains to make some improvements and make the circuit of its charger better. Leaving the screwdriver to charge overnight, the author of this video blogger AKA KASYAN discovered the heating of the battery of unknown origin the next morning. over, the heating was quite serious. This is not normal and will drastically shorten the battery life. In addition, it is dangerous from the point of view of fire safety.

Having disassembled the charger, it became clear that inside the simplest circuit of a transformer and a rectifier. Things were even worse in the dock. Indicator LED and a small circuit on one transistor, which is responsible only for the operation of the indicator when the battery is inserted into the docking station.

No charge control and auto shutdown nodes, only a power supply that will charge indefinitely until the latter fails.

Searching for information on the problem led to the conclusion that almost all budget screwdrivers have exactly the same charging system. And only expensive devices have a processor-controlled processor that implements smart charging and protection systems both on the charger itself and in the battery. Agree, this is not normal. Perhaps, according to the author of the video, manufacturers specifically use such a system so that the batteries quickly fail. Market economy, a conveyor belt of fools, marketing tactics and other clever and incomprehensible words.

Let’s modify this device by adding a voltage stabilization and charge current limiting system. Battery 18 volt, nickel cadmium with a capacity of 1200 milliampere hours. The effective charge current for such a battery is not more than 120 milliamperes. It will take a long time to charge, but it is safe.

Let’s first figure out what such a revision will give us. Knowing the voltage of the charged battery, we will set this voltage at the output of the charger. And when the battery is charged to the required level, the charge current will drop to 0. The process will stop, and current stabilization will allow charging the battery with a maximum current of no more than 120 milliamperes, no matter how discharged the latter. In other words, we will automate the charging process, and also add an indicator LED that will light up during the charging process and turn off at the end of the process.

Screwdriver device

Despite the variety of models, the general device of the screwdrivers is quite universal, and the principle of operation is almost the same. They may differ only in appearance, in the arrangement of individual parts, in the presence or absence of additional functions.

The power supply of screwdrivers can be 220V mains or rechargeable. The general design of a screwdriver includes the following elements and components:

- Housing. It is made of hard plastics, which contributes to a lighter construction and lower costs. Some models use metal alloys for increased strength. It is a pistol with a comfortable grip, when disassembled it is divided into two halves.

- Cartridge. The attachments are fixed in it, to which the rotational movement is then transmitted. Typically a three-jaw, self-clamping and self-centering device is used. Inside there is a hexagonal recess where the nozzle shank is inserted. To fix in the chuck, nozzles are inserted between the cams and clamped by rotating the coupling.

- Electrical part. Consists of a small-sized electric motor of the collector type. Mains powered devices use two-phase AC motors rated for 220V. They are started using a starting capacitor. DC motors are installed in cordless screwdrivers. Direct current comes from a battery made in the form of a set of elements combined in a common housing. The power of the screwdriver is determined by the output voltage of the battery.

- Chain elements. To turn it on, a special button located on the handle is used. Typically, pushbutton switches are paired with voltage regulators. That is, the amount of voltage applied to the motor depends on the force applied when the button is pressed. The shift lever is also installed here, which provides a reverse rotation of the shaft due to the change in the polarity of the electrical signal. From the button, the signal goes directly to the rotor through the manifold. Electrical contact is provided by graphite brushes of certain sizes.

- Mechanical parts and details. The design is based on a planetary gearbox, with the help of which the torque is transmitted from the shaft to the output spindle. The carrier, ring gear and satellites are used as additional elements. All parts are inside the body and in turn interact with each other.

An important component is the rotation control clutch, which sets a certain torque. With its help, the rotation of the shaft stops after screwing in the screw. Stopping occurs due to increased resistance to rotation. This measure prevents the breakdown of the threaded part of the screw and the failure of the screwdriver itself.

Diagnostics of the condition of the power tool

Hot surfaces of the cordless screwdriver and batteries indicate overheating of the tool. Overheating is a process that can occur in two ways. On the one hand, the screwdriver has an internal defect, but on the other hand, it is possible that it is being used incorrectly. To do this, before repairing, you need to check:

- First test current sources. electrical outlet. There are 3 ways to check. First connect another device to it and see if it works correctly. And you can also connect the tested tool to a different outlet and see if the battery is charging. Finally, check the indicators on it, such as light or sound, to make sure it is receiving electricity.

- Battery health. Sometimes the reason may not be in it, but in some separate elementary battery. This can be determined in two ways. Try plugging in the battery in a different charge and see if it charges. You can try replacing the problematic element in batteries.

- Check the charger and determine if there are any visible damaged parts. You need to pay attention to the contacts that connect to the outputs. Make sure they are not bent or broken.

- Check metal parts for corrosion or rust, which is a sign of moisture. If parts have come into contact with liquid, it may have a short circuit that prevents the battery from turning on.

- Use a voltmeter to repair battery chargers by connecting to it. Touch the contacts of the device with the probes and check that there is a reading. If they are missing, switch probes and try again. If there is still no reading, the battery is not working and needs to be replaced.

- Clean with a little rubbing alcohol and a cotton swab. Remove corrosion with fine sandpaper. Before applying test voltage to the device, make sure that the alcohol is dry and the electrical parts do not have a damp surface.

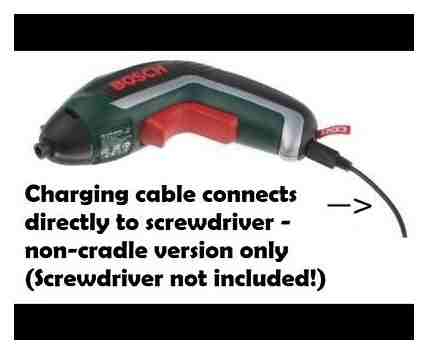

Screwdrivers are produced by a large number of firms, especially popular are Interskol, Bosch, Makita tools. They are usually extremely durable and reliable, however, individual parts can wear out. For example, when the drill does not work when the trigger is pulled. Such a breakdown indicates that the trigger (button) does not work. Replacing a trigger is a fairly straightforward operation. The battery must be removed before starting repairs to prevent injury from triggering the engine. The procedure for replacing the regulator using the example of a charger for a Bosch screwdriver:

- Remove the battery before starting work with the drill. Disconnect the two release clips on the sides of the battery and remove the battery. After removing the 12.0 V battery, put it in a safe place away from the work area. Place the equipment on a clean, level surface with the screw holes facing up.

- Find the screw that connects the two halves of the outer casing at the rear edge of the battery shaft. Use angled tweezers to remove it.

- Place the tweezers into the groove on the inside of the clip. Use your other hand to attach the drill firmly and pull upward until the clip detaches.

- Locate the eight 5.5mm screws located on the upward-facing side of the drill.

- Remove each screw with a T8 screwdriver, folding them in a safe place. After loosening all the screws, release the housing to open the motor and remove it.

- Place your finger under the metal tab and gently lift it up to release the trigger. Gently grasp the trigger assembly and gently pull upward.

- Disconnect the two wires connecting the motor to the trigger using a pair of pliers.

- Fix a faulty trigger.

Another type of repair, a Bosch screwdriver, for example, or from another well-known manufacturer is required much less often and it is better to entrust it to a service center.

Cordless screwdrivers are quite reliable these days, so in fact it is difficult to find cases of breakdown of the model with a voltage of 18 V.Lithium-ion batteries have excellent battery life and low self-discharge rates, so that tools equipped with them are constantly used in the household.

Rate this article: Share with your friends!

Charger for drill / screwdriver

The circuit outputs a voltage of 18 volts. If you charge batteries at 14.4 volts, you will need to select the charging current with a resistor.

Pulse

Analog devices take a long time to charge: 3-5 hours on average. Although for domestic purposes this is not scary. Another thing is the professional sphere, where “time is money”. Such products are worth. accordingly, there are usually two batteries in the set.

Professionals are more likely to use pulse chargers. They have an intelligent process control scheme. Full charge time is impressive: about one hour. Of course, you can make the same fast analog charger, but then its weight and dimensions will be impressive.

The well-known controller MAX713 is used. The input voltage is.25 V. The power supply is simple, so its circuitry is not here.

The resulting charger for the screwdriver “is distinguished by intelligence and ingenuity.” It checks the voltage and turns on the boost charge mode. The battery is ready in about 1-1.5 hours. The scheme allows you to choose:

- charge voltage;

- Battery Type.

It shows the value of the resistor (R 19) for switching modes and the position of the jumpers. Using the proposed drawing, you can repair the breakdown. The financial issue will become an additional incentive. Saving at least twice.

Self-charging lithium-ion batteries

Sometimes for old models of the tool it is impossible to purchase a new charger and you need to revise or make a new one yourself. For Ni-Cd and Li-ion lead acid batteries, an 18 volt screwdriver charger circuit is required. The main features of this versatile source are:

- DC voltage.

- Automatic shutdown when fully charged.

- Maximum current 5 amps, batteries can be charged normally.

- Fully customizable mode according to battery specifications.

- Low cost.

- Optimal wiring diagram. No special parts required, they are all standard and easily accessible.

- LED indicators for monitoring cut-off and charging status.

- Suitable for garages and home use.

This multipurpose fixture is a 5 amp constant voltage source, however, additional DC circuitry between the input power source may be required to charge less current.

Sony Xperia XZ1 Charging Port Repair Guide

The battery may overheat during deep charging, which should be protected by automatic temperature controller circuitry or fan cooling. List of parts for DIY screwdriver repair:

- Resistors.

- Capacitors.

- Simistra.

- Zener Diodes.

- Reducer.

Schematic diagram

The purpose of power tools is primarily to make our daily work less tedious and routine. In the home, an indispensable assistant in the repair or disassembly (assembly) of furniture and other household items is a screwdriver. Autonomous power supply of the screwdriver makes it more mobile and convenient to use. The charger is a power source for any cordless power tool, including a screwdriver. For example, let’s get acquainted with the device and the circuit diagram.

For circuit diagrams of chargers for 18 V screwdrivers,

Standard charger circuit for 18 volt screwdrivers

Almost all screwdrivers operate on batteries. The average battery capacity is 12 mAh. And in order for it to always be in working order, a constant recharge is needed. This requires a charger specific to each type of battery. However, they differ greatly in their characteristics.

Currently, they are producing models for 12-18 V. It is also worth noting that manufacturers use different components for chargers of different models. To figure it out, you should familiarize yourself with the standard circuitry of these chargers.

Types of chargers

There are many types of chargers for cordless screwdrivers on the market, differing in the principle of operation, price and a number of other parameters. There are 2 main groups of such devices: analog and pulse. Analog ones are equipped with built-in or external power supply.

Using a specialized microcircuit

The versatile MAXIM MAX713 ICs are commercially available that provide good charging characteristics for 18V devices. They charge both NiMH and NiCad batteries. At the same time, fast charging mode is available. Such a microcircuit monitors the state of the battery and, if necessary, reduces the current strength. At the same time, after the end of charging, the microcircuit almost does not consume current. It is capable of interrupting charging. A 1A block is enough to provide the required voltage.

Types of batteries used

Most often, the following types of batteries are installed in screwdrivers:

- nickel-cadmium;

- nickel metal hydride;

- lithium ion.

Nickel-cadmium batteries are not often installed in screwdrivers. They charge in fast mode, their price is not high. These batteries have a high load capacity. Their positive qualities also include the ability to give energy even when working in subzero temperatures.

Nickel-metal hydride batteries have better performance than nickel-cadmium batteries. Their self-discharge rate is much lower. In addition, such batteries do not have a memory effect. They are considered to be more environmentally friendly and safer. do not contain toxic cadmium.

Lithium-ion batteries have low self-discharge and high capacity. They do not withstand deep discharge and temperature rise. Most often they are installed in professional models. With overheating, there is a high probability of an explosion or leakage of the battery, and with a deep discharge there is a possibility that the original capacity will not be restored.

The positive qualities of lithium-ion batteries include the absence of a memory effect and the ability to work in freezing temperatures. Often these batteries are equipped with chargers that have a microcontroller that prevents overcharging. This increases the service life of the device. The only clear drawback of lithium-ion batteries is the high price.

Analog with external power supply

This type of device also has a simple structure. It is a set including a charger and a power supply unit. The charger has the following components:

- transformer;

- diode bridge;

- capacitor;

- rectifier.

At the output, it provides 18 V. The device is controlled by a small controller board, the size of which does not exceed a few centimeters. These appliances do not include a heat dissipating system. This leads to their rapid breakdown due to overheating. The disadvantage of chargers with an external power supply is the need for a prolonged connection of a screwdriver to it.

When used during minor repairs, it is enough to put the screwdriver to charge overnight. The charge received by the Chinese screwdriver will last for 3-5 hours, depending on the quality of the battery, and more powerful devices of the Zubr brand and other manufacturers will be able to work for at least 1-2 hours.

Chargers for charging the screwdriver

- Types of chargers

- Analog with built-in power supply

- Analog with external power supply

- Pulse

- Types of batteries used

- Homemade charging devices

- Two-transistor circuit

- Using a specialized microcircuit

- Charging the screwdriver without charger

Often, the charger for the screwdriver supplied with the device is of poor quality, therefore it breaks down after a short period or does not charge quickly. To eliminate this problem and extend the life of the screwdriver, you can purchase a charger with suitable characteristics or make it yourself.

Two-transistor circuit

At home, you can quickly make a charger using the KT361 and KT829 transistors. The value of the charge current will be corrected by the KT361 element. The current will then be supplied to the collector, which should be equipped with an LED bulb. In addition, the first transistor controls the operation of the KT829 element.

The principle of operation of such a device is extremely simple. An increase in battery capacity causes a decrease in the charge current, which leads to a gradual fading of the LED. The moment of charge is fixed by measuring the voltage. The required caliber is set on a variable resistor of 10 kOhm. To check the indicators, you need to install a volt-ohm meter on the terminals of an unconnected battery.

Analog with built-in power supply

A screwdriver with a built-in battery is not able to work for a long period. After the battery is discharged, the device must be connected to the network to complete the work.

The operation of an analog device equipped with a built-in power supply is not complicated. The charging works as a stabilizer. It operates on a compensatory basis. Excess energy can be dissipated by generating heat. Heat dissipation in the device is provided by a copper heat sink connected to the microcircuit.

The output transformer built into the charging is capable of lowering the voltage supplied from the network from 220 V to 20 V. Then, by means of a dioxide bridge, the current is rectified, which enters the capacitor, and then the stabilizer KR 142EN. Here the voltage drops to 12 volts.

Resistors are additionally installed. These simple chargers are cheap, they are not equipped with automation, so the user must control the process and duration of battery charging. They often break due to overheating.

Use of BC847 transistors

The charger circuit for the BC847 screwdriver is quite simple. The specified elements are used most often by the “Makita” company. They are suitable for 12 mAh batteries. In this case, the microcircuits are of a three-channel type. Capacitors are used with double diodes.

Directly triggers are used of an open type, and their current conductivity is at the level of 5.5 microns. A total of three transistors for charging 12 V are required. One of them is installed at the capacitors. The rest in this case are located behind the reference diodes. If we talk about voltage, then 12 V overload charges with these transistors are capable of carrying 5 A.

14 volt chargers

The charger circuit for a 14 V transistor screwdriver includes five pieces. Directly, the microcircuit for converting current is only suitable for a four-channel type. Capacitors for 14 V models use impulse capacitors. If we talk about batteries with a capacity of 12 mAh, then tetrodes are additionally installed there. In this case, there are two diodes on the microcircuit. If we talk about the charging parameters, then the current conductivity in the circuit, as a rule, fluctuates around 5 microns. On average, the capacitance of the resistor in the circuit does not exceed 6.3 pF.

Directly loads of charging current at 14 V can withstand 3.3 A. Triggers in such models are installed quite rarely. However, if we consider the Bosch brand screwdrivers, they are often used there. In turn, in the “Makita” models, they are replaced by wave resistors. In order to stabilize the voltage, they fit well. However, the charging frequency can vary greatly.

Charger circuit for a screwdriver. Electric circuit of the charger of the screwdriver

Many modern screwdrivers operate on a rechargeable battery. Their capacity is on average 12 mAh. In order for the device to always remain in working order, a charger is needed. However, in terms of voltage, they are quite different.

Nowadays, models are produced for 12, 14 and 18 V. It is also important to note that manufacturers use various components for chargers. In order to understand this issue, you should take a look at the standard charger circuit.

Chargers for Bosch screwdrivers

The standard charger circuit of the Bosch screwdriver includes a three-channel type microcircuit. In this case, the transistors are of the pulse type. However, if we talk about 12 V screwdrivers, then transitional analogs are installed there. On average, they have a bandwidth of 4 microns. Capacitors in devices are used with good conductivity. The chargers of the presented brand have two diodes.

Triggers in devices are used only for 12 V. If we talk about the protection system, then only open transceivers are used. On average, they are capable of carrying a current load of 6 A. In this case, the negative resistance in the circuit does not exceed 33 ohms. If we talk separately about modifications for 14 V, then they are produced for 15 mAh batteries. Triggers are not used. In this case, there are three capacitors in the circuit.

Application of the LM7805 regulator

The charger circuit for a screwdriver with an LM7805 regulator includes only two-channel microcircuits. Capacitors are used on it with a capacity of 3 to 10 pF. Regulators of this type can most often be found in models of the “Bosch” trademark. They are not suitable directly for 12 V chargers. In this case, the negative resistance parameter in the circuit reaches 30 ohms.

If we talk about transistors, then they are used in models of a pulse type. Triggers for regulators can be used. There are three diodes in the circuit. If we talk about modifications to 14 V, then tetrodes are suitable for them only wave type.

Scheme for the Skill model

The Skil screwdriver charger circuitry includes a three-channel IC. In this case, the models on the market are presented at 12 and 14 V. If we consider the first option, then the transistors in the circuit are of the pulse type. Their current reducibility is no more than 5 microns. In this case, triggers are used in all configurations. In turn, thyristors are used only for charging at 14 V.

Capacitors for 12 V models are installed with a varicap. In this case, they are not able to withstand large overloads. In this case, the transistors overheat rather quickly. There are three diodes directly in the 12V charging.

Scheme for the model “Makita

The charger circuit of the “Makita” screwdriver has a three-channel type microcircuit. There are three transistors in total in the circuit. If we talk about 18 V screwdrivers, then in this case the capacitors are installed with a capacity of 4.5 pF. Conductivity is provided in the region of 6 microns.

All this allows you to remove the load from the transistors. Directly used tetrodes are of open type. If we talk about modifications for 14 V, then the chargers are available with special triggers. These elements allow you to perfectly cope with the increased frequency of the device. At the same time, they are not afraid of online jumps.

Charging circuit

The standard electrical circuit of the screwdriver charger includes a three-channel type microcircuit. In this case, four transistors for the 12V model are required. In terms of capacity, they can be quite different. In order for the device to cope with the high clock frequency, capacitors are attached to the microcircuit. They are used for charging both impulse and transient types. In this case, it is important to take into account the characteristics of specific batteries.

Directly thyristors are used in devices for current stabilization. In some models, open-type tetrodes are installed. They differ in current conductivity. If we consider modifications for 18 V, then there are often dipole filters. These elements allow you to easily cope with network congestion.

Battery types

There are three types of tool batteries:

- Nickel Cadmium (NI-Cd). The older generation, which is still equipped with household screwdrivers. Affordable price, good ratio of size and capacity (rather compact), keep a charge in an inoperative state for a long time. The disadvantage is the memory effect. If recharged without a full discharge, then “information” about an incomplete volume is accumulated, it interferes with giving a charge until the real resource is exhausted.

- Nickel metal hydride (Ni-Mh). Improved analogue of nickel-cadmium batteries with cleaner production technology. Although the memory effect is present, it is weaker. The main disadvantage is that they are quickly discharged during storage.

- Lithium-ion. The most advanced type, which is gradually replacing other types in the segment of professional / semi-professional electric hand tools. High capacity, almost complete absence of “memory”, durability, low self-discharge in storage mode. The only drawback is the high cost compared to other analogues.

Important! The price of a 2 Ah nickel-cadmium can is approximately twice the price of a lithium-ion can.

What to do if the screwdriver battery does not charge

Cordless screwdrivers are more convenient to use than cordless ones. They are distinguished by their mobility, independence from the presence of an outlet “at hand”, the length of the cord. The only drawback is that you need to monitor the charge level for timely recharging. But not all types of batteries allow you to do this, and at the most inopportune moment the screwdriver stops working. And unfortunately, there comes a time when the battery stops charging.

Why the screwdriver battery does not charge. causes and elimination

The reasons for the absence or low level of charge, as well as ways to eliminate the malfunction, are different:

- There is no contact between the terminals of the charger and the battery. This is a consequence of the fact that the memory plates are bent. Gently fold back the plates, returning to working condition.

- Oxidation of terminals or dirt adhering to them. Contacts are cleaned and wiped with alcohol.

- Failure of one of the “cans”. Disassemble the battery pack housing by removing the cover (unscrew the screws or remove the latches). Call each jar with a tester for voltage or discharge current. With tension it is easier. it is either there or not, but this method does not always work. The discharge current is measured at a load resistor. in a faulty can, it is an order of magnitude lower than in a working one. After diagnostics, the faulty jar is separated from the serviceable ones, and a new one is installed in its place, exactly of the same type, and with the same polarity orientation relative to the rest of the elements.

Important! The most difficult part of changing a can is soldering the cans into a battery. At the plant, spot welding is used, and for DIY repairs, a soldering iron is often used. During operation, it is important not to overheat the battery, you need to work quickly.

There is another reason for the lack of charge, but it is characteristic only for nickel-cadmium batteries. the memory effect has worked, and the battery does not charge, although its resource has not yet been exhausted. In order not to bring it to this, it is important to carry out the charging correctly.

Tacklife SDH13DC Advanced 3-Position Cordless Screwdriver with LED Lights Review

How to charge the battery correctly

When buying a new tool with a nickel-cadmium or nickel-metal hydride battery, the battery is fully discharged and charged (pumped over) three times before use. When using a screwdriver, the battery is not charged until it is completely discharged. Then the pumping is repeated periodically as a preventive measure.

Important! To avoid downtime, you need to have a spare battery.

When the full charge is reached, the Ni-Mh and Ni-Cd batteries are disconnected from the network (for lithium-ion batteries, this is done by the controller). During a long break in work, the battery is removed and stored separately from the screwdriver.

With careful handling, following the manufacturer’s instructions, the battery will work for a long time and will not require early replacement. And minor repairs can be done by hand.

Useful video reviews of smartphones and other gadgets on our Youtube channel

Problem: The laptop battery has stopped charging

It happens that a device that used to charge normally stopped doing it at some point. The laptop is working and the battery is connected correctly but not charging. This is confirmed by the absence of an inscription when you hover the mouse over the battery status icon in the tray. There are three ways to solve the problem.

Problem: Laptop battery is connected but does not fully charge

The problem is manifested as follows: the battery is charged, but does not reach 100%, i.e. does not fully charge. The operating time of the device from one charge is sharply reduced. For example, it worked up to 4 hours, and now it works only 40 minutes.

Diagnostics of programs on a laptop

If the diagnostic utility shows no significant wear on the battery in step 1, then the battery is probably not the direct cause of the drop in battery life. The culprit for the fast discharge may be some program you recently installed that runs in the background and prevents the processor and Wi-Fi chip from going into economic mode.

Open the Task Manager by pressing CtrlShiftEsc and analyze the CPU usage of background programs. Sort applications in the list by CPU usage and watch for a while. Removing unnecessary programs running in the background will increase battery life.

Method 1. reset battery settings in BIOS

- Disconnect power. Unplug or unplug the AC adapter from the device.

- Take out the battery. In models with a removable battery, and there are most of them, for this it is enough just to turn the device over and push back one or two locking devices that hold it.

- Press the power button and hold it in this state for about a minute.

- Insert the plug of the power supply into the laptop and connect it to the mains. In this case, you do not need to install the battery in place yet.

- Turn on the laptop and enter its bios. To do this, at startup, press the key or their combination indicated in your user manual. Typical solutions: Del, F12 or F2.

- Reset the settings to the preset value, Restore Defauts, and save the bios settings, Save and Exit.

- Turn off the laptop by holding the power button for 5-7 seconds.

- Turn off the power supply again and replace the battery.

- Insert the charging plug and plug the power supply into an outlet.

- We turn on the laptop in the usual way.

If the method worked, then we should see a message from the system by hovering the mouse over the tray icon: the battery is connected and charging.

What to do if a new battery won’t charge

A much more difficult situation is when only the installed new battery on the laptop does not charge at all. To get started, we advise you to do the bios reset operation described above.

What to do if the laptop battery does not charge?

When there are problems with charging, many ask the question. “why is the laptop connected but not charging?” and rush to replace it with a new one. Yes, the battery is a consumable item. It is designed for a limited number of charge / discharge cycles, and over time, the capacity becomes much less than the nominal value indicated by the manufacturer. However, the charging problem will not necessarily be solved by replacing it. In this article, we will look at the three most common problems and tell you what to do to solve them.

Check the battery status

You can check the battery status with the free Battery Health program for iOS or the standard Battery Care utility in devices running Windows 7 and 8.

Three main parameters of battery health are important to us.

- Declared nominal power. This is the capacity of the new battery when it just left the factory.

- Maximum power. This is the current capacity value.

- Battery wear percentage. The larger this value, the higher the need for replacement.

The problem of not reaching the required level of charge is also solved by calibration.