Shelves for tools in the garage with their own hands

Garage chores. Step 5 Shelves in the garage

The next step in garage setup is the shelves.Shelves in the garage, as you know, not much happens. over, my garage is not big, and after insulation the internal volume became even smaller. Plus, I wanted to do everything inexpensive and without unnecessary gestures, such as cutting angle and welding.

In general, from the mass of options available on the Internet, I decided to do the shelves, using brackets to mount cable trays. Quick, not exactly cheap, but cordial.On the back wall and up to the middle of the side wall I decided to make wide shelves. 40cm, and the other two sides narrow. 30 cm.Through my friend Khabarovsk I bought 16 brackets of this type (Of course for safety I should have taken more brackets and put them more often than every meter, but took as much as took):

They were wrapped in 4 pieces. in polyethylene. Minimum batch, by the way was 4 pieces.

The length of these brackets is 32 cm. They are great for all types of shelves (30cm and 40cm wide.). As the shelves themselves were bought wooden furniture boards. Expensive of course, but of high quality.

I fixed the brackets to the wall with two anchors. I can use 8 mm anchors, but better 10 mm. 10 mm anchors are more reliable, hold more load and are perfectly sized. Just note that to put a bracket on the anchor bolt, you need to unscrew the nut completely, put the bracket on the stud and screw the nut. The 8 mm diameter anchors with a “dupel” easily fit into the hole of the bracket.

The distance between the brackets is about 1 meter.

Some of the shelves that didn’t have enough brackets, I additionally reinforced with steel corners I bought at the Level store. Corners themselves are reinforced with small stiffeners that do not let them bend or unbend.

The angle brackets are of course worse than the brackets, because they are shorter, but they perform their function.

Next, I screwed the shelves to the brackets with self-tapping screws.In one place, where because of the difference in the width of the shelves a step was formed, made a shaped scribing with an electric jigsaw. It’s nicer and safer. There is no sharp angle.

But it was either my hands or the level in general, in the corners of the shelves did not match in height.

Actually, it does not matter because the shelves do not form a single surface. I decided to leave room in the corner to put there long boards, tubes and other long objects.

To hang clothes, I bolted a coat rack with hooks.

At the entrance to the right (if you look from the entrance) of the leftover OSB (12 mm) and brackets from the bookcase built another shelf for sundries. Again there is a place to put a can with beer when you close the gate.

Remains to organize all the junk on shelves.But there’s still a long way to go. So that’s it for now

We make shelves in the garage with their own hands: practical tips, recommendations

The main purpose of the garage is to store cars. However, this does not prevent car owners from using it for other purposes: storage of preservation, tools, household appliances, unnecessary things, car parts. Over time, piles of household goods accumulate in the room. The garage is slowly turning into a chaotic dump, the space is becoming less and less. This is a sign. it’s time to competently organize the space, by installing shelves in the garage. They will allow you to rationally place things, save usable space, improve the interior of the room.

Garage with a convenient storage system, when everything in its place

Racks in the garage with their own hands to make quite simple. You need to prepare the tools, buy some materials, free up a few hours of work. In this article we will consider a detailed instruction, some tips, recommendations for the arrangement of such a structure.

Features

Having at its disposal a garage, each of its owner should from time to time bring order in it, removing unnecessary and systematizing what will come in handy in the work. In order for this process to have maximum productivity, racks should be installed in the room.

It is fundamentally important for a garage to have sufficient size to freely put a car or make repairs. If something is in the way of these activities, it should be removed.

The availability of shelving is a very important factor for a number of reasons, among which are:

- the presence of chaotically located things prevent free passage of the car in and out of the garage;

- The abundance of things arranged haphazardly and throughout the garage does not allow you to quickly find what you need;

- Having a large number of things out of place increases the risk of fire and will make it difficult to extinguish due to the scattered arrangement of substances that can ignite;

- The lack of storage system makes the garage look cluttered and messy, not everyone will be happy to be and work in it.

Using shelving can solve all these problems, making the room a comfortable environment. You don’t have to bring your garage into perfect order, but every thing should have its own place, then there will be more order and it will be easier to find the right thing.

For the car enthusiast, garage shelves are also needed to store wheels, tires and other car parts. They usually have a considerable size, so their haphazard storage will not allow a rational use of working space. Garage owners often love their car so much that they spend all their free time in the garage, so everything in this room should contribute to a comfortable work.

The advantages of the shelving unit are its small size. Often such designs are located by the wall, they can have fixed or removable shelves, allowing to adjust their height if necessary. Open design allows you to quickly find the desired item, because it is in plain sight.

If the rack is made of durable materials, you can also place heavy parts, a car engine or something similar on it.

If we consider the types of racks, then today there are four options:

How to Make a Custom Tool Organization Board

Stationary racks are installed once and attached to garage walls. They are sturdy and reliable and can withstand a lot of weight. The prefabricated type can be bought for a specific garage, based on the dimensions. It is not difficult to assemble it, and it is possible to put it in any convenient place and set the individual height of each shelf.

Mobile shelves are distinguished by the presence of wheels, on which the rack can be moved to any convenient location. The rotating version is good for small tools that need to be easily accessible.

When selecting racks, you need to choose those options that will fit the specific room, and use it to the maximum extent, raising the shelves to the ceiling and placing them along the longest wall. It is important not to choose a rack with wide shelves, so that the garage had room for both the car and the owner, who should easily and quickly enough to get to any objects of interest to him.

Kinds of material for shelves in the garage

Shelves for tools in the garage with their own hands are made of different materials. The most practical options: wood, metal, plastic and any combination thereof.

Wooden structures are made stationary non-dismountable, assembled using nails or screws. The products are lightweight, easy to assemble, but can withstand a small load.

Heavier, but more reliable metal construction. Stationary shelves made of metal are made by welding. It is possible to make a mobile design, connecting the frame with bolts. It can be dismantled or transformed if necessary. The disadvantage of the product is the lack of rigidity due to the presence of backlash. In order to make the storage system more stable, it is recommended to attach it to the wall.

Often a mobile shelf unit is assembled from a bend with a peoration and the frame is completed with shelves made of wood or metal. Storage systems are installed with the use of hooks mounted on crossbars and slots on racks. The advantage of the design is the ability to rearrange the horizontal elements to the desired height. But they do not cost cheap.

To install the product you will need the shelves themselves, vertical struts and horizontal bars. To increase the rigidity of the framework and compensate the side load from the rear side additional diagonal wooden or metal fasteners are installed. Metal angles are screwed or welded together.

It is important to decide on the materials already at the stage of the project. The length of the span between the uprights depends on the stiffness of the materials used. The shelf must not sag under the load. The optimal length is 1.5 m.

The choice of materials for the frame and horizontal flats depends on the expected load. For example, in order to complete the product with racks for storing wheels in the garage, the frame is made of profile. Angular or rectangular section is suitable.

Materials

In addition to selecting the design, it is necessary to decide on the material for making shelves in the garage.

Wooden shelf in the garage

Shelves in the garage with their own hands can be made of the following building materials:

- natural wood. Pine is mainly chosen, but sometimes hardwoods are used;

- plywood. Board made by gluing together several balls of veneer. The most commonly used is moisture-resistant plywood;

- blockboard. Material made of natural wood slats glued together along the length and width. The strength of such material is not inferior to wood;

- wood. chipboard (chipboard) or wood-fibre board (wood-fibre board). Chipboard. the cheapest construction material. One of the negative qualities of chipboard is that it deforms under prolonged exposure to heavy loads, in addition, it is very sensitive to the humidity in the air. At high humidity Wood chipboard loses its shape (swells) and crumbles.

In addition to wood and composite materials, metal is also used to make shelves. Metal shelves from the profile have higher functional properties. If treated with special corrosion inhibitors, they will generally last for decades.

Keep in mind that you need a welding machine to work with metal products.

After choosing the design and material, let’s proceed directly to the consideration of technologies for the manufacture of shelves for the garage with their own hands.

Assembling metal and wooden structures

Plan to make a wooden or metal shelving, shelves with their own hands. half the battle. It will be necessary to realize the conceived, build your dream, embody it in wood or metal.

Home-made items are often assembled without proper attention, performing it in a hurry, so “homemade” designs, for all their merits, look nondescript, worse than the factory ones. Iron frame before installation is finally adjusted, sharp edges are sanded, preparations for future painting are made. As a method of installation, welding, bolted connections. anything that will provide the necessary rigidity. are suitable.

With wood is easier to work with. it is fastened with nails, self-tapping screws of the required length, angles. It is better to drill holes, taking into account the material’s propensity to splintering and splitting. For wood, treatment with compounds that prevent rotting and combustion is a prerequisite. The chosen method of assembly must guarantee:

Given the above nuances, building a shelving unit is not as difficult as it seems at first. If, of course, correctly plan and provide for as many little things as possible, which in the future may affect the course of work.

What are the materials for making garage shelves?

The first step is to choose what material you want to use. What the shelves will be made of, will affect the construction of the structure, the principle of attachment. Metal or wood shelves are considered the most common.

Metal shelves

This type of shelving is mainly made using stainless steel corners and sheets. Such shelves have both positive and negative sides. Let’s take a closer look at them.

Table Positive and negative sides of metal shelves

ability to be used for a long period of time;

The stability of objects placed on the shelves;

the ability to withstand heavy and bulky objects;

the inability to attach to walls built of thin or porous material;

Wooden shelves

Work on wooden shelves does not require the garage owner skills to work with welding, and therefore the presence of a welding machine, and therefore goes much easier. In addition, the very options for creating garage shelves from solid wood or similar materials (chipboard, fiberboard, shields) are much more. The shelves are fastened with a frame or metal profile.

On how to make a shelving unit from wood with their own hands, you can read in our special article.

Table Pros and cons of using wooden shelves

neat finished products, pleasant to look at;

the possibility of attaching products to the walls of any material;

Deformation of materials in service from the interaction with moisture;

In addition to the above materials, there are less popular, but functional options. For example, often wooden or plastic shelves are added to the metal frame, thereby the construction becomes more reliable, but inexpensive.

Also, the shelves can be created from quality plastic that can withstand a lot of weight and is resistant to warping. This material is easier to care for and easier to install.

However, if we talk about garage conditions (especially if the room is not heated in winter), the best option is to put it metal shelves. They will last for decades and will not have any problem withstanding almost any weight. Accordingly, shelves made of metal are often preferred in cases where it is necessary to store heavy and rigid objects. For this purpose metal will serve better than any other material.

When working with metal, it must be coated with a rust preventative, while wood must be painted with paints that protect the material from humidity and temperature variations. Otherwise, the boards can begin to rot, they can change their shape and lose their integrity. Also wood can be infested by pests.

When choosing the material, it is very important to understand how many things will be stored on them, what weight and what will be used to secure the work of welding or nailing. There is no single correct way of making this product.

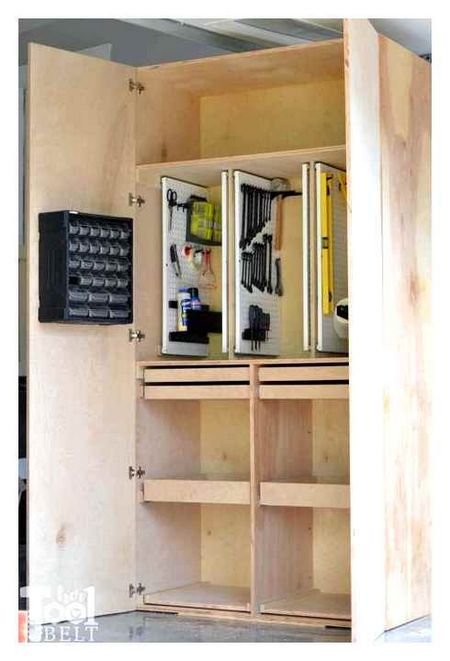

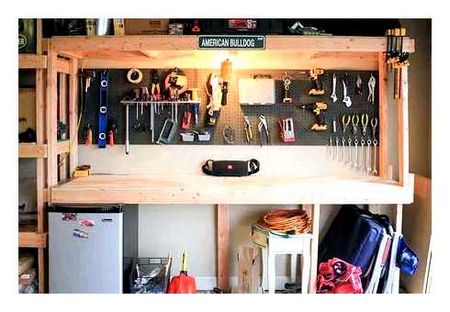

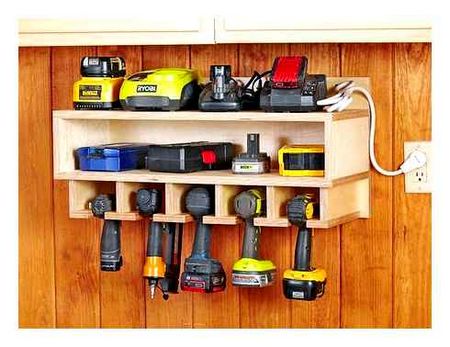

Shelves for tools in the garage with their own hands

Every craftsman knows how important it is to arrange his workplace correctly. It is necessary to enjoy the work, and therefore the environment itself should be comfortable, practical and thoughtful. In the context of the arrangement of the workshop, every detail matters, here everything depends not only on what kind of work you plan to do, but also on your personal preferences, your vision and understanding of convenience and practicality.

If necessary, you must quickly find the right tool, as well as the necessary parts or spare parts at a particular time. One of the key elements in any workshop is special shelves and racks: spare parts, equipment accessories, tools and all kinds of fasteners like bolts, screws, nuts, etc. are placed on them.п.

In general, it may seem that the shelf is a simple and even primitive piece of furniture, but this is a misconception. A good and practical tool shelf can be a fairly complex design that combines convenience, practicality and a certain elegance.

Just look online at the design of garages and other workshops: note the photos of shelves for tools. a variety of designs will pleasantly surprise any craftsman. How in this variety to choose or better make it yourself. that’s what we will talk about in this article.

Racks in the garage. With their own hands. Economy version

Racks in the garage. With my own hands. economical variant. Greetings to all! In DAS’s blog. Slightly off topic, but dobretzo how to store you need.

Today, my friends, I will tell you how to make a shelf in a garage from the profiles and OSB. Why the economy version? It’s simple! I went the opposite way. First I bought OSB, then adjusted to the size of the shelf. Let’s start!

Went to the “Epicenter” and found OSB with a discount. The thickness of 6 mm, the size of 2500×1250. Two sheets together with a sawing cost me 1200 Sawed 1250×500. We have 10 sheets.

Since I was finishing the shelving on the other side of the garage, there were 8 sheets left over for this side.

On a wall we draw the size of a rack taking into account call of a shelf of 25 mm on a profile.

To do the project we will need: 1. Dowel nail 40 mm. 2. Screw with a drill bit for profiles. Popularly known as “seeds” or “fleas”. 3. Metal screw 30 mm. And of course the tool: Drill, electric screwdriver, jigsaw, metal scissors, pliers, tape measure. Gloves are a must! And all the little things at hand.

Profile: 1. CW-50 50x48mm. 2. UD-28 28×27 mm.I had:CW 8 pcs. x 100 = 800 (taking into account the height of the basement 2 meters).UD 12 pcs. x 43 = 530 (including 5 cm. for installation).Screws. Bought at 400 with plenty to spare. I bought 400 pcs., But by weight, not in boxes.

Next. Fasten the profiles to the wall, according to the drawn scheme, with dowel nails. The distance between the dowels is 30-40 cm.

Install the vertical uprights. To make sure the dimensions are correct, we insert the horizontal profile for the shelf. Fix the shelves “with seeds”, where possible, necessarily with an offset.

To the deck, in my case it is plywood, with wood screws.

Bed for the shelf. For structural strength, we put the central profile, the vertical bar in the center. Profile is cut to 25 mm from each side for fastening to the uprights.

That’s how we attach it to the vertical uprights. Important! After you have screwed it down, bend the sharp edges with a hammer!

Jigsaw the corners of the shelf. The distance to the horizontal profile is 25 mm. on each side.

Before fixing the shelf, we mark the center of the transverse profile. Fix the shelf with metal screws. Spacing 15-20 cm.

Go higher. The profiles on the wall can be cut to size.

The first row is ready. For the weight load. It’s holding me, my weight is 96 kg.

The case is not complicated, but monotonous. Just need the screws. Helped by electrical assistants.

The second row of shelves is ready. It gets hot.

Finish! On the second day after the start, four hours a day.Here’s a little more detail. Since I was missing one shelf, the far bottom one, I used particle board from a former cabinet.And on to the sawing. The outermost shelf is one centimeter too long after it’s sawn. less. That’s why the horizontal profile under the shelf needs to be shifted inward.

On shipping. If you remove the rear seats and fold down the front, 3-meter profile fits easily under the glove compartment.

Everyone have a good weekend rest! Maybe someone could use it and like it. Button at the bottom!