Stihl chainsaw chain oil supply

Oil supply system

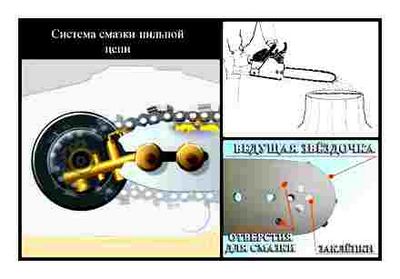

On the Stihl chainsaw, the oil supply to the chain is carried out by a special system. The patented OILOMATIC® system found on various STIHL chainsaws is an exclusive feature. Such an incredible addition can not be found in all models from other manufacturers. For this reason, more and more people choose Stihl saws. What is this system? This is a specially designed groove designed to guide oil into critical wear areas. This superior lubrication function gives the customer extended chain life with a reduced tendency to stretch.

Chainsaw not oiling? Check this FIRST! Homestead Tips

A further development of the OILOMATIC® system is the oil reservoir next to the OILOMATIC® channel. These reservoirs are filled with oil as the drive links pass the inlet of the guide bar and are emptied by centrifugal force acting on the nose of the rod. This provides more oil for distribution along the chain, groove and rails. The system protects the saw from premature wear. Simply put, it directs the oil to where it is needed. The system is available on all STIHL saw chains.

Sometimes customers may report such a problem as the chain is not lubricated on the Stihl chainsaw. This phenomenon is rare. Compared to conventional saws without a system without Ematic, STIHL controls the consumption of chain lubrication. A special system reduces consumption by up to 50%, depending on the type of wood and the cutter used. This system includes STIHL Ematic or Ematic S, STIHL Oilomatic.

For everyone who wants to know in detail about the German-made chainsaw, we offer an overview and characteristics of the Stihl 180.

Each model is equipped with a saw chain and a variable flow or reduced flow oil pump. Virtually every drop of chain lubricant is delivered exactly where it needs to be. This system reduces friction and wear and therefore extends the life of the cutter. Oil channels (funnel-shaped) in the saw chain connect the oil directly to the rivets and steps of the cutting teeth. Several recesses in which chain oil can collect are also punched into both ends of the drive links. This allows the oil to be better distributed over the sliding surfaces of the guide rods.

Stihl chainsaw: supplying oil to the chain

The Stihl chainsaw is becoming more and more popular. There are reasons for this. First of all, it is worth noting the ease of use of this device. Its lightness allows you to manipulate the saw in the most difficult and difficult woodworking. This, of course, cannot but affect performance. Stihl has earned the trust of many customers around the world and has proven its quality and reliability.

Possible problems

The oil provides protection in modern high-performance air-cooled two-stroke engines. The environmental friendliness of chainsaws and power tools has also been greatly improved with BioPlus lubricating oil (BlueAngel winner). It is a toxicologically pure oil that is not only biodegradable, but also environmentally friendly.

We also offer you to watch a detailed review of the popular Stihl 250 chainsaw model and its characteristics.

STIHL 2-cycle oils are formulated for the high temperatures and operating conditions of today’s innovative and technically advanced engines. All STIHL 2-Cycle oils contain a fuel stabilizer for a longer shelf life. STIHL recommends a 50: 1 combination of high quality 89 octane unleaded gasoline. The same mixing ratio should be used during breakage.

And what do people write about this using a Stihl saw with an oil supply system?

“Inspect clutch drum and reverse threads — inspect pump bracket. Make sure that the housing (under the threads) that holds the pump is not clogged or damaged. If so, sometimes marine epoxy can fix it. “.

“The most common reason for a system to fail is that it is blocked. You have to remove the handle. take out the screws, external plugs. You will see a hose from the tank. pull it out. If it’s broken, you’ve found the problem. Flush reservoir, hose and pump inlet “.

Stihl HP Ultra Review

Unlike conventional Stihl HP oil, HP Ultra is designed for high engine loads during operation and is recommended for use on professional chainsaws. This oil is synthetic. In order for consumers not to confuse diluted fuel, it has a green color, respectively, a ready-made mixture of gasoline with Stihl HP Ultra also has a greenish tint.

There are only two packages of this oil. This is Stihl HP Ultra 100 ml and 1 liter with dispenser.

The cost of Stihl HP Ultra is almost twice the price of Stihl HP and for this reason it is less popular in our country.

What oil to choose for the chain

The best option for chain lubrication oil is BioPlus and should be chosen by those who use a chainsaw from time to time. Optimum price and quality of BioPlus make it the most popular chain oil in the Stihl range.

It is also worth remembering that BioPlus does not harm the environment, since it is made on a plant basis and decomposes in the shortest possible time, which is also important when working with a chainsaw in your own area.

Stihl HP Review

Stihl HP is a chain saw lubricant designed to meet the highest quality requirements and designed to lubricate internal engine parts during engine operation. It is made on a mineral basis and has good combustion performance (it has a low level of emission of harmful substances during combustion).

Original Stihl HP is red and sold in Stihl branded packaging.

It comes in several packaging options, the most popular of which is a one liter bottle with a built-in dispenser. You can also find Stihl HP in cans of five, ten and fifty-five liters.

The smallest package of Stihl HP, which is convenient to use in cases where you need to prepare only one liter of fuel mixture, is a twenty-gram plastic bottle.

Also, the company produces one hundred gram bottles of Stihl HP, which can be used to prepare five liters of fuel mixture.

According to the manufacturer’s recommendations, Stihl HP can be used to mix for any two-stroke engine.

The shelf life, if stored in a closed container, is 4 years.

ForestPlus

ForestPlus mineral oil for chain lubrication is a quality product that creates a reliable film on the bar and chain links, which is well retained even at maximum chain speeds.

Packaged in three types of containers, a liter bottle and cans of five and twenty liters.

ForestPlus has the lowest shelf life of the Stihl range at just three years when stored properly.

Stihl lubricant for two-stroke engines

Stihl engineers develop oils that are optimally suited for all two-stroke engines fitted to Stihl chainsaws and trimmers and beyond. Stihl’s two-stroke lubricant range includes several product options:

- Stihl HP;

- Stihl HP Ultra;

- Stihl HP S

Which Stihl oil to choose for a chainsaw

Any two-stroke engine of a chainsaw runs on a mixture of gasoline and oil, respectively, how long it will last depends on the quality and correct mixture of these components. Also, in chainsaws, it is necessary to lubricate the bar and chain, and the quality of the lubricant is not the last factor affecting the duration of use of these parts of the chainsaw. In this article, we will talk about the oils that Stihl produces and recommends for use not only on chainsaws of its own production.

- Stihl lubricant for two-stroke engines

- Stihl HP Review

- Stihl HP Ultra Review

- HP Super

- Mixing ratio

- Which oil to choose

- Stihl chain oil (overview of oils)

- ForestPlus

- BioPlus chain oil overview

- SynthPlus

- What oil to choose for the chain

- How to tell fake Stihl oil

- Output

Stihl chain oil (overview of oils)

The Stihl range of chain lubricating oils comprises three types of products:

- ForestPlus;

- BioPlus. for chains;

When working, it is necessary to use the type of lubricant that best suits the conditions and duration of work. Let’s consider each of the oils for the Stihl chain in more detail.

Chainsaw chain oil does not flow: reasons and solutions

When the saw chain is moved, a large amount of heat is generated in the groove of the tire due to friction. If oil does not flow to the chainsaw chain, it is necessary to stop work and take all measures to eliminate the malfunction of the lubrication system. The combination of heavy loads and overheating of the headset is accompanied by its accelerated wear and tear and early failure.

- Without exception, all chainsaws and their electrical counterparts are equipped with systems of the same type according to the principle of operation, by means of which the tire, the saw chain and its drive parts are lubricated.

- This unit comes standard with a reservoir from which chain oil is fed to the inlet of a fixed or variable displacement pump.

- Further, the working fluid in a metered amount enters the groove of the tire, in which the shanks of the saw chain are evenly distributed over the entire set and the working surface of the crown of the drive sprocket.

Tires of performance headsets with a length of 400 mm are completed with a driven sprocket. Periodic lubrication of the bearing is carried out individually, after 6-8 hours of operating time.

Reasons for Decreased System Performance and Efficiency

In the required amount, oil is not supplied to the chainsaw chain for several reasons. The most common failures include:

- clogging of the filter located in the oil tank;

- mechanical failure of one of the elements of the pump worm drive;

- in winter, the performance of the pumping device decreases due to filling the system with too thick oil.

In the latter case, the drive and all pump parts operate under increased loads, initiating serious mechanical damage.

Self-help troubleshooting feature

A full-fledged self-repair of chainsaw chain lubrication, under all equal conditions, requires knowledge of the interaction of all elements of the system, the availability of tools and locksmith skills.

Restoring the operating parameters of many chainsaws involves partial or complete dismantling of the component equipment. To carry out complex repairs, it is better to use the capabilities and technical potential of service workshops.

Parts with stripped threads and damaged spline joints, as well as non-separable structures that complete the lubrication system of the popular Stihl 180 chainsaws and other models of the same type must be replaced.

If, when the tank is filled, oil does not enter the headset structure, the reason should be sought in the pump itself. Dismantling and disassembling the mechanism will help identify faulty parts and eliminate the malfunction by replacing them.

Checking the system for oil output and performance

Contamination of the oil filter manifests itself as a significant decrease in pump performance. It is not difficult to check this parameter. To do this, hold the headset of the saw operating at working speed over a clean sheet of paper.

By the density and size of the oil strip, one can confidently judge the state of the system and the complexity of the upcoming repair.

There is no definite answer to the question why the repaired lubrication system works, but oil does not go to the chain in the right amount. The reason for the failure may be mistakes made during assembly, failure of standard adjustments, discrepancy between the density and viscosity of the selected composition to the declared characteristics.

Oil starvation of the headset is possible when installed on a household saw with an unregulated pump of a longer productive tire, which is equipped with professional-grade chainsaw equipment.

Advantages of high-class oil pumps

The maintainability of collapsible pumps is sufficient to restore the unit’s performance at home.

The gears of the pump drive of budget chainsaws are mostly polymer. Proprietary variable capacity models, advanced in terms of technical equipment, are equipped with drive mechanisms made of non-ferrous metals. The cost of such systems is compensated by an economical, up to 50% consumption of working fluid.

Signs of a malfunctioning lubrication system

The correct choice of consumable lubricant and flawless operation of the system contribute to full lubrication, effective cooling of the saw equipment and full depletion of its resource.

There are several external signs that the chain on the chainsaw is not lubricated. First of all, these are:

- constant oil level in the tank;

- increased engine load;

- accelerated wear of the cutting edges of the saw links;

- characteristic smell of overheated wood.

In the simplest version, the cause of oil starvation can be the clogging of oil channels with sawdust. This drawback is typical for budget headsets that do not have convenient access to problem areas.

The specifics of the repair of Chinese chainsaws

A significant share of the imported chainsaw range is made up of Chinese-made chainsaw equipment. Many models copied with more or less success from the best European designs.

The main advantage of Chinese products in the budget segment is a high level of interchangeability of spare parts, assemblies and systems. To repair Chinese chainsaws, in some cases, you can use accessories from models of other manufacturers that are identical in power and purpose.

Chainsaw chain lubrication system

To supply oil for lubricating the chainsaw chain, a special pump is used in the tool, which is dosed, depending on the number of engine revolutions, supplies lubricant to the saw bar.

The system uses oil to lubricate the chainsaw chain, which has increased adhesion properties, this is necessary to evenly distribute the oil around the entire perimeter of the tire and keep it on it even at high chain speeds. Let’s take a closer look at the oil supply system implemented in modern chainsaws.

Lubrication system malfunctions and how they are eliminated

The main malfunctions of the oil supply system on a chainsaw can be divided into two main types, these are general malfunctions inherent in all chainsaws and individual ones, which may differ depending on the type of pump and worm gear installed on a particular model. Let’s start sorting out faults in order.

It is prohibited to use the chainsaw if the chainsaw is not lubricated. This adversely affects the tire, drive sprocket and chain, and can also result in serious repair costs.

Principle of operation

The main unit of the system is the pump. The principle of its operation is as follows. With an increase in engine speed, a gear mounted on the main shaft drives the pump shaft through a worm gear. In turn, the rotation of the shaft creates a certain pressure in the oil line, which forces the oil to move along it towards the tire.

The end of the oil channel is located at the point of contact of the tire with the tool housing, where there is a longitudinal groove, on which, when the tire is installed, its oil channel falls.

The groove is necessary to ensure the supply of oil to the tire, regardless of the chain tension of the chainsaw. Simply put, no matter what position the tire is in at the time of operation, oil through the groove will get onto it.

Further, a chain is included in the lubrication process, on the links of which, depending on the model of the chain, there is either a groove or a hole through which the oil is accelerated throughout the tire. With an increase in engine speed, the oil flow rate also increases.

Some models of chainsaws are equipped with pumps that additionally have a flow rate adjustment, and if necessary, the amount of oil supplied by the lubrication system can be increased or decreased.

This function is quite convenient, since it allows you to save money and not waste extra oil.

Troubleshooting

After it has been determined that oil is not being supplied, further diagnostics is possible only if the oil system is completely removed. Of course, changing the filter helps in some situations, but this is very rare.

Access to the oil pump of some models of saws is possible only after complete disassembly, therefore, if you do not have the skills to repair gas powered tools, it is better to entrust the repair to professionals.

How to remove the pump

The oil pump is installed on the right side of the bottom of the housing, in the same place the oil line from the chainsaw tank is connected to it. To remove the pump, you will first need to free the saw from the handle, for this the rear handle of the unit is unscrewed and the throttle control rod is disconnected. At the next stage, you need to remove the plugs of the shock absorbers of the handle and, using a powerful slotted screwdriver, squeeze them out of their seats on the handle.

After the handle is removed, the body of the chainsaw is turned upside down. The hose coming from the oil tank to the pump will be visible immediately. It must be removed from the seat.

The pump itself is removed with an M5 screw and a wide washer. The screw length should be approximately 45-50 mm. A washer is put on the screw and it is screwed into the pump (the inside of the pump is threaded). Further, as the screw is screwed in, the stop from the washer will force the oil pump to rise along the thread. Thus, the pump is removed from its seat. Before starting work, we recommend that you read the article on how to disassemble the Stihl 180.

For a better understanding of the pump removal process, you can watch the video below. In the video, the SC master shows in detail how to remove the oil pump from a chainsaw, and also describes the main malfunctions of the supply system.

The Stihl 180 oil pump is a very high quality and reliable part, therefore it is necessary to change it only as a last resort, when all other elements of the system have already been checked.

After the pump is removed, it must be cleaned and blown out. As a rule, the main breakdown of an oil pump is its blockage. By removing it, the pump can be reinstalled.

Replacing the pump is only required if it is not possible to remove the blockage.

How to repair a chainsaw

To repair a chainsaw, you need to familiarize yourself with its internal structure, the operation of all mechanisms, and study the lubricant supply system. When the chainsaw is running, the following problems may occur.

Leakage of oily fluid is common.

Possibly, the tightness of the fastening of hoses is broken. To solve this problem, you need to disassemble the tool, replace the hoses. If parts are missing, you can degrease the old hose and its seat. Install self-tightening clamps in the place where the hose is connected to the tube. After this, the tightness will be restored.

Sometimes the oil filter gets clogged. It needs to be cleaned periodically. The oil supply is repaired only if the chain is dry. This usually happens due to clogged channels. They must be thoroughly cleaned. This phenomenon is very common.

When it is difficult to start a chainsaw, and sometimes it is simply impossible, it is required to diagnose the device. The spark plugs and air filter are checked first. All parts must be dried well before reinstalling.

Chainsaw fuel system: 1. fuel filter, 2. carburetor, 3. manual pre-priming pump.

If there is fuel on the spark plugs, we can talk about its excess. The main cause of this problem is poor carburetor adjustment or improper starting. The fuel supply valve may be closed. To fix the breakdown, you need to make sure that there is enough fuel in the gas tank, check how well the combustion chamber is functioning. If the candles have become unusable, they must be replaced.

The fuel supply may have stopped due to a clogged breather. A vacuum forms in the gas tank, which blocks the fuel supply. This phenomenon occurs when the channels are clogged, the carburetor is poorly tuned and the air filter is clogged. These malfunctions require repair of the valve, which equalizes the pressure during petrol supply. The breather is cleaned with a sharp needle.

To adjust the carburetor, you need to find the optimal rpm value. To do this, it is necessary to turn or, conversely, unscrew, the adjusting screws. Such adjustment should be carried out exactly according to the instructions for repairing the Stihl chainsaw.

The filter mesh is cleaned in the carburetor, all channels are blown through, the operability of the membrane is checked, no ruptures are allowed.

Due to its complex mechanism, work with the carburetor must be carried out carefully and in perfect cleanliness. His normal and good work depends on it.

To achieve the correct operation of the chainsaw, you need to constantly look after it. It requires constant cleaning of the air filter, lubrication of the chain, and always with new, fresh oil.

When the tool is removed for long-term storage, it is necessary to drain all gasoline and remove the oil for lubricating the chain. In this case, the chainsaw will work without breakdowns for a long time.

Main characterizing points

Stihl chainsaw chain lubrication system consists of:

- guide rail;

- saw chain;

- oil pump.

The oil supply by the pump has a special regulation. Chainsaw chain lubrication occurs constantly during machine operation. Therefore chainsaw chains have a long service life.

During operation, the chain requires a constant supply of lubricant. Its continuous supply must be ensured. This is required by the design of the device. During the operation of the chainsaw, the oil leaves the groove of the tire, instantly absorbed by the sawdust.

For this reason, the chain is lubricated automatically. Some chainsaw chains are equipped with a system that regulates the exact amount of lubricant supplied. The cheapest devices are equipped with a hand pump, which is powered by a drive located on the handle.

Circuit diagram for checking the operation of the chain lubrication system.

A special oil has been specially developed for good lubrication of the chain. After work, it quickly decomposes, so there is no violation of the ecological system. You can also use oils of the brand:

Transmission lubricant is absolutely not suitable for work. In winter, it freezes, as a result, the oil system clogs up, you have to completely clean it.

In winter, chain lubrication requires special attention. Branded oil “M-20” thickens in severe frost and resembles petroleum jelly. Therefore, to work in winter, it is necessary to lubricate chainsaws with special winter oil, which has a more liquid consistency.

It is not always possible to purchase such a lubricant. To solve the problem, diesel fuel is mixed with oil, the viscosity is lowered. However, if the previously filled oil remains in the crankcase, then the addition of diluted oil will not have a positive effect, the system channels will remain clogged. There is only one way out. heating the chainsaw in a warm room.

If the chain oil does not solidify too much, you can try to melt it by running the saw at low idle.

Chainsaw chain lubrication system

Each chainsaw, regardless of its model, brand, and class, has approximately the same structure. It consists of several important units, including the lubrication system. Without the latter, the work of the power unit is impossible. Due to the functioning of the forced lubrication system of the tool chain, the risk of severe wear is reduced, which is guaranteed under conditions of constant friction of the carved element against the guide bar, inevitable heating. When lubricating the chain mechanism, friction is softened, the operator of the chainsaw needs to repair this element or replace it completely.

Breakdowns and are able to eliminate them

Considering the types of malfunctions in the lubrication system, two categories can be distinguished:

- general breakdowns found in all types of power units;

- individual, which depend on the type of pump, on the features of the worm-type transmission, on the other structural features of a certain chainsaw.

Important! If the lubrication system does not work, it is not recommended to use the saw. This will damage not only the chain, but also the guide bar, as well as the main sprocket, which leads to the need for a large investment in the repair of the device.

“Symptoms” of a faulty lubrication system:

- the chain mechanism is dry, pale, there is no shine;

- the chain stretched quickly after installation;

- the guide rail heats up, its paint melts;

- the oil remains in the same volume in the tank, despite the intensive use of the tool;

- the cutting efficiency of the chain is significantly reduced.

All this indicates a malfunction of the lubrication system or its functioning intermittently.

How can I check this node? It’s simple.

- Dismantle the side tire.

- We start the tool.

- We gradually increase the speed, observing the end of the oil line.

If a consumable arrives, then the reason for the problematic operation of the lubrication unit, most likely, lies in a clogged filter, which can be cleaned or replaced with a new one. If possible, after this manipulation, the supply of consumables is regulated.

If the consumable does not arrive, then additional diagnostics need to be carried out, since, most likely, the problem is more serious.

Please note that it is not always necessary to dismantle the tire to check the lubrication system. Alternatively, the end of the tire is directed to the side (use a chock) from the direction of the cut, maximizing the speed, keep the tire (its end) 10 centimeters from the chock. You will see the corresponding stains when the oil is fed.

What is the principle of this node?

The heart of the unit is a pump, consider the principle of its functioning.

- As soon as the engine speed increases, the gear of the main shaft with the help of a worm drive makes the pump shaft work.

- When the pump shaft is operating, pressure is created, which is transmitted to the oil line, which pushes the oil towards the tire.

- The end of the lubrication channel is located at the junction of the crankcase of the power unit and the guide rail, where the longitudinal groove is located. The last is the lubrication channel.

What is the function of the groove? It supplies oil to the guide bar, no matter what the chain tension is. This is a guarantee that the oil gets on the tire even when it is in a non-standard position at the working moment.

Do not forget that the chain mechanism is involved in the lubrication process. Depending on the design features, the chain has holes or grooves through which the lubricant is distributed over the bar. Oil will flow to the tire faster as the engine rpm increases.

Certain models of the tool have pumps that can be additionally adjusted (the operator will be able to adjust the pump capacity, depending on the amount of work and the operating conditions of the saw). If necessary, the oil supply is reduced, if it needs to be increased, an appropriate adjustment is made.

Be sure to read the article, which presents the feature of supplying oil to the Stihl chainsaw chain. The system may differ depending on the brand of the chainsaw.

The main advantage of this function is the ability to save consumables. By the way, if you are interested in what kind of oil to pour to lubricate the chainsaw chain, choose what is recommended by the manufacturer of your power unit.

What is a forced lubrication system?

Stihl chainsaw lubrication system and this unit in other power units are an identical unit, which depends on the speed and number of revolutions of the chainsaw heart, engine. Oil is supplied to the carved element, or rather to the tire, is dosed. This is possible due to a special pump.

The chainsaw chain lubrication pump transfers a consumable with high adhesion characteristics to the saw headset. You need to use only consumables of this quality, since only it, even at maximum speed of the chain mechanism, can be evenly distributed throughout the tire.

Lubrication system device

The chain saw chain lubrication system, taking into account the manufacturer of the tools, may differ slightly in design features, in the parts used to create this unit. At the same time, the features do not affect the system connection diagram, as well as the total number of parts used.

The main components include:

- oil reservoir located in the engine crankcase;

- tank filter (element located directly in the tank);

- an oil line that looks like a small diameter hose made of high quality rubber;

- the pump itself can be considered the heart of this node;

- feed force from the engine to the heart of the worm gear assembly (worm-type transmissions).

In some works of powertrain repair specialists, the guide rail is described not just as a saw headset, but as one of the components of the lubrication system. Why is that? This can be explained by the presence of special holes in this tire through which oil is supplied. By the way, the chain itself can be considered a participant in the transportation of lubricating consumables, since this mechanism also has parts related to the distribution of oil.

What to do if there is no oil supply?

As we have already found out, it is necessary to carry out additional diagnostics. For this we disassemble the lubrication system. Please note that in some saw models this is possible when the tool is completely disassembled. So, just in case, arm yourself with the proper repair tools. If you do not have experience in parsing a saw, entrust this business to a professional.

When the lubrication system is disassembled, you can find one of these failures:

- the oil hose is torn off (sometimes visible with the naked eye during a preliminary study of this part of the unit), which needs to be replaced;

- there is no thread of the shaft where the oil pump is located (you need to attach, replace);

- damaged thread of the main pump gear (a new one is installed);

- there is no corkscrew of the main shaft (this problem is often observed with Homelite chainsaws), which can be solved by installing the original corkscrew, a nail in place (ideal in size, if there is a need to cut it);

- clogged line, this is solved by blowing (mechanically or with the help of compressed air, sometimes the wire helps);

- clogged filter element (clean or replace).

How To Fix A ChainSaw If It Won’t Oil The Bar And Chain. Video

Please note that for some Stihl power units (for example, for the MS 180 model), the pump cannot be disassembled, but it will periodically clog up. In this case, it is washed with gasoline or, if necessary, completely replaced.

Chinese saws often “suffer” from the sheared grooves of the main gear, through which the force is transmitted.

Another common problem, again typical for Stihl products, is the leakage of the line. You need to look for the problem at the point where the oil line that goes from the reservoir enters the equipment case. Such a breakdown is indicated by oil leaks at the bottom of the power unit. In order to remedy the situation, the handle is dismantled, the hose is removed, cleaned and degreased, then the seat is treated with sealant and the hose is reinstalled. After that, the lubrication system should start working normally.