Stihl setting up idle speed.

Adjustment of the carburetor of the chainsaw STIHL 230

230 STIHL in its characteristics refers to the class of semi.professional chainsaws intended for harvesting firewood at a professional level (T.e. not just saw the offships in the bathhouse, but for example for sale). Thanks to the size of the size and power of the chainsaws, it is perfect for construction made of wood and rolling trees. Due to the limited size of the tire, which is only 35-40 cm, the manufacturer is recommended to bring down trees with a diameter of not more than 30 cm. But, as practice shows, Stihl 230 copes with larger trunks perfectly.

Let’s look at the characteristics of the Stihl MS 230 chainsaw declared by the manufacturer:

- Engine volume: 40.2 cubic meters. cm;

- engine power: 2.7 liters.With. / 2.0 kW;

- idle: 2800 revolutions per minute;

- chainsaw weight: 4.6 kg;

- Tire length: 35-40 cm. / 16 inches;

- chain step: 3/8 “;

- Oil tank volume: 200 cubic meters. cm;

- Fuel tank volume: 470 cubic meters. cm;

- Sound power level: 113 dB;

According to some reports, the engine volume is 45.4 cubic centimeters. According to data from the official website of the STIHL, the value of this technical characteristics is indicated by the range from 40.2 to 45.4. Therefore, to find out the real parameters of the engine 230 Stile, I recommend watching a passport on a chainsaw, which is in configuration.

The equipment is standard. The price of 230 Stile includes the following positions:

- chainsaw;

- tire and chain;

- the key-confrontation for stretching the circuit and gas and gasoline refueling;

- screwdriver;

- Case to protect the chain;

- manual.

Features of the chainsaw STIHL MS 230

230 STIHL, like many other companies of the company, are produced by the latest technology. Let’s see the main technologies used in the production of this chainsaw:

-

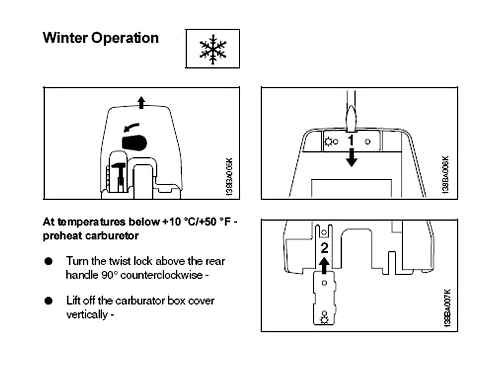

Preliminary heating of the carburetor. when working in the winter season, the chainsaw is transferred to summer mode, the carburetor is blown by heated absorbed air, thus its icing is prevented.

Adjusting the Carburetor of the Stihl MS 250 chainsaw (with a revolution meter):

Before adjusting the stihl chainsaw carburetor, it is necessary to maintain the chainsaw (cleaning the gas.rosopila carburetor, wash the chainsaw engine, replace the candle, clean the air filter, check the chain tension, adjust the idle stroke, warm up the motor).

The screws “h” and “l” (on the drowned chainsaw) wrap up to the stop, and then turn both for 1 turnover. 2. Start a chainsaw and warm up. Give a full gas and a “h” screw to ensure that the maximum engine speeds are equal to 14,000 rpm. By tachometer (by the engine speed meter). Maximum speed for adjustment keep no more than 10 seconds! 3.

STIHL MS 180 How to configure the carburetor How to Adjust Carburetor Stihl Chainsaw MS 180

How to adjust the Stihl MS 180 carburetor what revolutions min and max? Also a similar video about the adjustment on my.

Adjusting the Carburetor of the chainsaw of the Stihl 180, 170 and other low.power ones is produced by only one screw. “LD”. They are set idle speed.

The basic standard setting is as follows:

If you need to carry out an additional or other adjustment, then first you need to warm up the motor for 10 minutes. Then, if:

- idle speeds are too low. we twist the “LD” of badges until the chain begins to move, after which we turn this bolt 1/2 turn back, PHF;

- The tool chain moves at idle. slowly twist the “LD” of the PFS until it stops, after which we turn this bolt by another 1/2 turnover in the same direction.

But it is better to configure with a tachometer, not forgetting that the chain at idle should not move. Maximum turnover without the load of the STIHL 180 and 170. 13500 rpm models. Idle. 2800 rpm.

Adjust the Stihl chainsaw carburetor, equipped with a more powerful engine, as described in previous chapters. This also applies to such the most popular models as Stihl 210, 230 and 250. For the basic setup (considered in the third chapter) “L” and “H” after twisting, they are turned back for 1 turnover.

Angle (step) of rotation of adjusting bolts during the configuration of the UPT. 1/4 turnover. Hologenic revolutions of the STIHL 210, 230 and 250. 2800 rpm models, maximum without load. 13000 rpm.

Adjustment of the carburetor of the chainsaw STIHL MS 250

How to adjust the Stihl MS 180 carburetor what revolutions min and max? As well as a similar video about the adjustment on my

STIIHL carburetor setup 230

230 STIHL in its characteristics refers to the class of semi.professional chainsaws intended for harvesting firewood at a professional level (T.e. not just saw the offships in the bathhouse, but for example for sale).

Thanks to the size of the size and power of the chainsaws, it is perfect for construction made of wood and rolling trees. Due to the limited size of the tire, which is only 35-40 cm, the manufacturer is recommended to bring down trees with a diameter of not more than 30 cm.

But, as practice shows, Stihl 230 copes with larger trunks perfectly.

Specifications

Let’s look at the characteristics of the Stihl MS 230 chainsaw declared by the manufacturer:

- Engine volume: 40.2 cubic meters. cm;

- engine power: 2.7 liters.With. / 2.0 kW;

- idle: 2800 revolutions per minute;

- chainsaw weight: 4.6 kg;

- Tire length: 35-40 cm. / 16 inches;

- chain step: 3/8 “;

- Oil tank volume: 200 cubic meters. cm;

- Fuel tank volume: 470 cubic meters. cm;

- Sound power level: 113 dB;

According to some reports, the engine volume is 45.4 cubic centimeters. According to data from the official website of the STIHL, the value of this technical characteristics is indicated by the range from 40.2 to 45.4. Therefore, to find out the real parameters of the engine 230 Stile, I recommend watching a passport on a chainsaw, which is in configuration.

The equipment is standard. The price of 230 Stile includes the following positions:

- chainsaw;

- tire and chain;

- the key-confrontation for stretching the circuit and gas and gasoline refueling;

- screwdriver;

- Case to protect the chain;

- manual.

Features of the chainsaw STIHL MS 230

230 STIHL, like many other companies of the company, are produced by the latest technology. Let’s see the main technologies used in the production of this chainsaw:

- Preliminary heating of the carburetor. when working in the winter season, the chainsaw is transferred to summer mode, the carburetor is blown by heated absorbed air, thus its icing is prevented.

- The innovative gas tank cover does not require a special key to open. The technology has been developed and patented by StiHL. The process of opening, closing passes without difficulty, and tightness, in turn, remains on top.

- Anti.Vibration system. Stihl, like Husqvarna, use a special system to reduce vibrations transmitted from tool to a person during operation. Without a similar system, with prolonged work, the human body experiences heavy loads, which over time can lead to circulatory disorders in the hands.

- Instant stopping circuit brake Quickstop. The well.known handle of the hand brake is driven by the Quickstop mechanism, which allows you to stop the operation of the Stihl MS 230 chainsaw.

- EMATIC design effective lubricant system. The system includes an oil pump with adjustable oil supply, Oilmatic chains and Ematic guide tires. The peculiarity of the system lies in the fact that the supplied oil falls only on the places where it is required, which made it possible to reduce the oil consumption in half.

Which is better Stihl 180 or Stihl 230

Sometimes in the store you can see people who choose between 180 calm and 230 calm, and not a competent seller. the consultant convinces that there is almost no difference in them and it makes no sense to overpay for a slightly larger power of 230 calm. However, this is not so, we will not conduct a full comparison in the characteristics of both chainsaws, we note only the main differences:

- The most important difference is that STIHL MS 230 has a larger engine volume, which in turn greatly increases the resource and, as a result, service life.

- The stihl 230 chainsaw is equipped with a heating system, which prevents the icing of the carburetor when working in the winter season.

- The 230th heavier than his younger brother is as much as 700 grams. Believe me, when performing easy work (trimming of branches), this difference is significant.

- Therefore, the price of Stihl MS 230 is higher.

These are the main differences and they are important. Connect all the pros and against the choice.

Carburetor adjustment

If the Stihl 230 chainsaw starts up and stalls or just works unstable, then it is time to see how things are with the fuel supply system, namely the carburetor. Most likely the reason lies in it, and it requires maintenance.

We will not dwell on this process within this article, t.to. Earlier they talked about the repair of the carburetor on the chainsaws in general and the STIHL in particular.

We recommend reading articles: device and adjustment of the carburetor on the Stihl 180 chainsaw and the second interesting article about adjusting the carburetor on chainsaws in general.

The articles raise questions of the main reasons why the saw begins to “ruin”. Detailed and detailed answers are given that will help to repair the faults with your own hands.

It is worth remembering that the chainsaw of the STIHL MS 230 is a semi.professional saw, and not a household! For this reason, it is worth carrying out periodic services, it is better to apply to a specialized service!

If for some reason you cannot contact the STIHL specialized service, and you want to adjust the carburetor of the chainsaw with your own hands, then you definitely need to watch cognitive videos regarding this issue. We present to your attention, our selection.

Adjusting the carburetor at the STIHL 230 and 250 saws is no different, so watching the video will be useful to the owners of both the other chainsaws.

Repair Stihl MS 230

The tool is quite reliable and it breaks only due to improper operation or a large amount of work, due to which the resource of the chainsaw has long been developed. One of the serious breakdowns is problems with the engine, in particular the cylinder-piston group.

Coal adjustment on the Stihl chainsaw 180

Adjustment of the carburetor of the German.made chainsaw

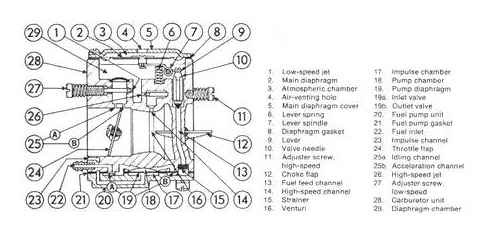

In the structure of each chainsaw there is such an element as a carburetor, the role of which is the organization of the fuel consistency to serve its engine.

But sometimes, when problems happen in the tool, it is required to adjust the carburetor of the German.made chainsaw with the positioning of the amount of fuel and air mass. Correct adjustment of the gasopil carburetor 180, idle screw on the chainsaw.

When adjusting this node in gasoline models of the series 230 or 180, it is clear to be clearly aware of the cause of the failures where they highlight:

Stihl BG 85C tune it the right way.

- gasoline deficiency in the system, accompanied by interruptions in the work of the motor;

- Excess gasoline, expressed by a huge amount of exhaust smoke and high noise;

- Scrolling the chain of the chainsaw in idle.

Now the correctness of the adjustment of the carburetor is shown in the video from many craftsmen, which presents options for repairing the carburetor of the brand 250 of the chainsaw and other contracting models.

In the database of such operations lies the control of screws responsible for the level of supply of the air fuel mixture of the saw and for the number of revolutions in the idle rotation of the engine. Self.adjusting the idle in practice. video. In the “Spit for Motors grass”, the masters help to rapidly solve this case.

We also have everything you need to work with a benzo tool where you can purchase a fishing line for a trimmer for a trimmer for grass or purchase the latest saw chain.

Carburetor setup 180. Basic steps

If there is a situation when the tool needs repairs for greater productivity and saving fuel, the carburetor adjustment with all related operations will be an indistinguishable event. And so, performing options for the carburetor system of saw 80, you need:

- Clean the fuel tank and air filters, which will provide more high.quality actions.

- Find the screws n, l and s on the carburetor.

- Using the designated screws to produce the basic options of the mixer of the stihl 180 combustible mass, performed with the motor turned off: using the annotation, set clear angles of rotation of the screws n and l, which regulate the ratio of gasoline and air, where the screw N is the screw that controls the gikler of the highest revolutions; L is the screw of small revolutions; S. a screw of accuracy of idle values. When setting the basic values, slowly crank up H and L clockwise, then return to the position by 2 turnover back.

- Turn on the engine and perform the final setting with your own hands of the STIHL carburetor. Find the largest idle speed, with a thorough of the screw l in different directions. As soon as the maximum is found, the screw is returned to 1/4 of the hours. In the event of a chain, the idle screw is returned to its full stop.

- Will perform technical verification and adjustment of acceleration and maximum speed.

Read how to saw a chainsaw horizontally

STIHL MS 180 How to configure the carburetor How to Adjust Carburetor Stihl Chainsaw MS 180

How to adjust the Stihl MS 180 carburetor what revolutions min and max? As well as a similar video about the adjustment on my.

STIHL chainsaw. The bolt of “LA” stops the idle speed, first on the chainsaw you need a Stihl 180 chainsaw. Repair. Classroom setting. With your own hands. What the sellers are silent about

Saw repair after 10 tanks. What the sellers are silent about.

The correctly performed setting up the carburetor system 180 will allow the maximum revolution of the chainsaw with the best productivity, when the quality of work and fuel consumption will gain the best ratio. Only idle adjustment is available to us. Not a stihl chainsaw 180? Stihl 180 on.

In the company “Sicks for Motors grass”, you can get detailed information about the independent setting of the chain saw and other benzo.tools of wood processing and vegetation, for which on the company’s website you can choose and order spare parts for motorcycles of any manufacturer, lawn mower, benzo and electric vehicles.

Checking the correctness of the Stihl carburetor adjustment

The check of the chainsaw of 260 and other episodes for the correct setting of the carburetor is performed in two stages, where 1 is carried out during the configuration of this unit, 2. during the performance of the working tasks of the benzo tool. And so, performed:

- Checking the maximum number of revolutions when adjusting the carburetor of the STIHL production motorcade. At the highest revolutions, the interruption in the ignition will be traced, which can be adjusted by a small lapel of the screw against the course of the watch. As soon as the ignition is aligned, the check is completed.

- Checking the acceleration of the chainsaw when adjusting the carburetor node of the Chinese saw. It is carried out by a smooth press of gas trigger, in which the engine must perform confident acceleration to maximum speed. Slow revolution requires a discharge against the course of the regulator L, starting from 1/8 turnover.

- Checking the accuracy of adjusting the MS 660 chainsaw carburetor or other Chinese at idle for the stability of the engine, lack of movement of the chain.

- Performing minimal manipulations in working mode with wood.

Read nozzle on a chainsaw of boat for earthwork

The same actions are permissible when servicing a bush cutter with the availability of failures in work. But if you have more global problems, you will be helped by the master “Spit for Motors grass” who will perform all actions as quickly as possible. Also, for repair situations, the online store offers the necessary spare parts as a Chinese chain for a chainsaw or elements of a piston group, ignition and much more.

The circle circle and the circle of grinding have a wide range of applications, and the circles themselves are effective and easy to use

Knives differ in the number of teeth, as well as the material of manufacture. Carburetor on the chainsaw of STIHL 180, idle setup. Adjustment. But the most important question is the grass on which we will work.

STIHL carburetor adjustment

STIHL 180 chainsaw carburetor, indiscriminately, can only be adjusted for the number of revolutions at idle. Increase or reduce fuel supply in various modes using special screws cannot. The manufacturer limits access to adjustments and does not set these screws. How to adjust the carburetor to the correct idle speed is described in great detail in the manufacturer’s instructions.

If certain malfunctions occur, and the presence of experience, you can increase or reduce the fuel supply by increasing the gap when the needle valve is opened.

To increase the feed, the rocker of the needle valve in the distribution chamber must bend up, and to reduce, down. Thereby adjust the needle and, accordingly, valve throughput.

Do not adjust your own adjustment, t. to. This must be done very accurately and with an error, it is almost impossible to return the starting position of the rocker.

How to correctly configure a chainsaw carburetor

The vast majority of models of carburetors of gasoline saws have three adjustment screws:

Installation of the desired parameters occurs by rotating these screws.

For accurate tuning the carburetor, use the electronic tachometer. It will easily determine the speed of the chainsaw engine.

The basic adjustment of the carburetor

The screws h and l must be rotated clockwise until it stops, and then turn into 2 turns in the opposite direction. This is a standard procedure for primary setting up popular chainsaw models. Other options are also possible.

Cooper adjustment

First of all, you need to find a situation in which there will be the highest idle speed, turning the screw l. When you, with the help of a tachometer, find this position, you need to turn a low.speed screw (l) by a quarter (1/4) against the direction of the clockwise. The chain of the chainsaw can rotate. If this happens, you need to unscrew the idle screw (T) against the direction of the clockwise, until the chain completely stops moving.

How to set up maximum chainsaw speeds?

To change maximum speed, you need to interact with the screw N. If you tighten the screw, the turns will become higher, and if you unscrew it, below. As a rule, the largest allowable engine speed varies in the range of 11500-15000 per minute. If you try to work with an even larger number, the problem with the ignition will begin. In this case, the screw is slightly unscrewed.

Acceleration check

If you press on the gas.speaker gas button, the engine should increase the number of revolutions. This should happen fast enough. If the tool is slowly gaining momentum, you need to unscrew the screw L slightly, no more than 1/8 turnover.

When the setting is completed, you need to re.check the operation of the chainsaw at idle. the engine should work properly and the circuit should remain motionless. If the engine is unstable or the circuit moves, you need to repeat the adjustment, lowering the stage of the base setting.

The nuances that need to be remembered in the setting process

Do not unscrew the low.speed screw (l) too much in relation to the high.speed screw (n). This will cause the ingestion of a lunch mixture (too much air regarding gasoline). As a result, the piston will be dry during operation and begin to heat up hard.

It is best to remember the initial position of the carburetor screws in order to leave yourself the opportunity to install factory settings again if the saw suddenly does not start or it will work unstable.

Setting up a chainsaw is an important, but not the most difficult procedure. If you follow the instructions and do everything right, the tool with a adjusted carburetor will be optimally configured, will be able to work with high efficiency and last you for a long time.

Power system: improper fuel mixture

Two-stroke engines are designed to work from a mixture of gasoline with butter, which is necessary to lubricate the cylinder-piston group. The lack of oil will quickly disable the tool and lead it to major repairs.

In gas tools of different manufacturers, the ratio of oil to gasoline is 1:40 or 1:50. This proportion cannot be violated in any case. If the oils are poured more than the necessary, this will lead to the shift of the compression rings of the piston. They will tightly fly in their grooves, and the motor will lose compression and power.

The exception is only the mode of running the tool. In this case, the mixture is made 1:25 and it is used for a short time, with a minimum load.

Signs of an excess of oil in gasoline are as follows: the chainsaw stalls, abundantly smokes, does not develop power.

Stihl chainsaw stalls: reasons

If the tool is turned off immediately after starting, then there was a breakdown of a device or part. To determine the reason, the mechanism is tested independently or in service workshops. Sometimes the reason that the mechanism starts poorly is the improper service of the saw:

- insufficient volume of gasoline;

- poorly cooked fuel mixture;

- poor lubrication quality;

- muffler clogged by combustion products;

- unresolved carburetor;

- air filter obstruction;

- Piston or cylinder malfunction.

When pressing gas

Speaking units work at idle, but the motorcycle stalls when the gas is pressed, t. to. The load rises. The tool is heated before use, driving off the engine at idle for a minute. If this is neglected, then the motor stops after pressing the pedal. Other reasons can be:

- a clogged or unresolved mixing unit of fuel fuel;

- The clogged air filter does not give the desired air flow when the load is increased;

- a contaminated gasoline filter does not miss the required amount of the mixture;

- the wall of the cylinder and the piston rubs.

Low octane fuel number causes the brake, t. to. This circumstance does not allow the motor to achieve the required power when increasing the load.

At idle

Violation of the functionality of the fuel unit system leads to an air leakage. In this case, the unit stalls at idle and does not hold their number. An additional suction reduces the air pulse to the fuel pump and passes through the membrane of the pallet or crankshaft oil seals. Diagnosis is made by vacuum.

The stopping of the engine is on the cold for other reasons:

- The candle channel contains an excess amount of combustible mixture;

- A gap is not adjusted between the tip of the candle and the high.voltage cradle;

- Failure of power supply.

Check the seals, pouring gasoline into the crankcase, the leak is visually visible. So, the engine does not work at idle, and at a high frequency, leaky oil seals will lead to jamming of the bearings. In the case of elements, they are replaced with new ones and sealing.

At full speed

Sometimes the engine stalls after normal operation

To establish the cause, pay attention to related circumstances:

- The motor stalls in the middle of work for no apparent reason. The starter is in a fixed position and does not turn. So, the tool is jammed and requires urgent repair.

- During normal operation, the power is reduced in a short time and the engine stops, the cylinders are overheated. The situation indicates the occurrence of an air suction under the rubber pipe between the carburetor cylinder, possibly due to the gap. Air impoverishes fuel, it requires replacing the pipe.

He is not gaining momentum

A lot of mechanism systems are involved in launch, so the loss of the stiHL chainsaws after operating at idle may become a consequence of various factors. Confident work of idle and interruptions in the motor with a load can arise for the following reasons:

- engine resource development;

- wear, deformation and corrosion of the piston group;

- malfunction of the ignition or candle coil;

- Balance of carburetor screws.

If the tool does not develop speed, then the conductivity of the hole in the lid of the tank for fuel is disturbed. The emergence of a vacuum does not give the right amount of fuel, because the engine does not gain the required power. The revolutions are reduced when the carbon monoxide is accumulated in the muffler, it is difficult to remove gases from combustion.

Does not drop in momentum

The tool quickly reaches the maximum speed, and the power is not reduced. This situation is explained by the fact that:

- the throttle does not work due to the weakening of the spring or traction element;

- periodically refuses the tooth controller;

- There is no corkscrew on the axis of the throttle;

- The carburetor was clogged;

- The fuel hose and a filter of gasoline are functioning incorrectly.

stihl fs 90 r carburetor adjustment

Adjustment

With adjustments to Stihl 180, everything is simple, there is one screw with which you can slightly adjust the idle passage.

Rifles l and h, as on other chainsaws, there is no 180th carburetor. This is done so that the inexperienced user does not twist what should not be twisted and, accordingly, does not harm the chainsaw.

The Germans of course invented well, but sometimes, especially after replacing the piston group and the installation is not original, idling disappears on the chainsaw. If there was an opportunity to adjust the fuel mixture, then this problem would be solved in a couple of seconds, and so you have to climb into the main camera and regulate the position of the needle.shaped rocker.

Malfunctions and repair

STIHL 180 chainsaw carburetor requires both initial and periodic adjustment. You can find out about its need by the following signs:

- Problems with the engine, for example, it does not start or immediately stalls after the start of work. Most often, the reason is the use of poor.quality fuel mixture.

- Fuel consumption and exhaust increase. Exhaust gases are becoming larger due to incomplete combustion of fuel. Most often this problem may occur due to oversaturation of fuel.

Other breakdowns may appear, for example, blockage due to damage to the air filter or the formation of scale. The reasons may be due to the fact that with a long.term simple in the fuel tank, gasoline remains. This is due to the fact that fuel is exhausted, which spoils the device.

Regardless of the reason, the carburetor repair will be required, which is most often reduced to adjustment. The method of performing this procedure depends on the chainsaw model, but you can adhere to general principles.

How to remove a carburetor from a chainsaw

Before adjustment, you need to remove it from the stihl chainsaw. For this you need:

- Turn the lock to the left to remove the lid.

- Remove the filter, why unscrew two nuts that hold it. For simplicity of work, it is recommended to use special screwdrivers with suitable nozzles.

- Remove all the rods, including the carburetor lever.

- Remove the carburetor, and then disconnect the fuel hose.

It is recommended to remember the location of the parts so that then you can put the carburetor in place and there are no extra fasteners left or there are no distortions and cracks.

How to clean

In the event that the chainsaw stalls at idle, it is necessary to disassemble the part and clean it. First of all, this applies to cleaning the additional filter. This part is a net. To get to her, you need:

- Take the largest lid.

- Remove the membrane located under the lid.

- Clean the net, which is located in the recess. This must be done extremely carefully, since the net may fall out. To clean the copper wire for cleaning. Additionally you need to rinse and blow all the channels. The last procedure is necessary if gasoline does not enter the carburetor.

How to setup

The adjustment of the Carburetor of the Stihl 180 chainsaw is carried out to improve the performance and saving of fuel.

- Clean the fuel system, including the tank, from the remnants of a mixture of gasoline and oil. Blow out air channel and filters.

- The tuning of the carburetor of the chainsaw is performed using b, l and s bolts. The bolt controls the nozzle, provides maximum speed. Bolt L performs the same function, but provides minimum turns. Screw S is responsible for the accuracy of idle speed. This procedure must be performed when the engine is turned off.

- It is necessary to adjust the carburetor on the chainsaw by the task of the corresponding angles of rotation of the first two bolts. You can set basic values as follows. Turn the first two bolts slowly in the direction of the clockwise, after the stop to return back to two turns.

- Turn on the engine and adjust the ignition on the stihl chainsaw and its carburetor finally. To do this, you need to find the highest blast speed by turning the bolt L in different directions. After this maximum is found, the bolt must be returned by a quarter of the course. In the event that the chain begins to move, the engine needs to be stopped.

- Conduct a technical check. In particular, you need to determine the maximum number of revolutions, check the acceleration and stability of the engine at idle, as well as the correspondence of these parameters to the basic values in the instructions. The quality of the mixture for verification should be the highest.

What if the chainsaw does not hold idle speed?

Coaling problems are considered constant satellites of chainsaws. The prerequisites that could lead to swallows at the time of launch and scrolling the chain during operation can be several, the main of which:

- littering of air and gasoline filter;

- low.quality fuel mixture or its improper preparation;

- malfunctions of the incendiary module;

- carburetor, the settings of which ceased to correspond to the load on the saw;

- motor elements deformed or rust.

Consistently perform a number of actions:

- wash the fuel hose or replace it with new,

- Clean the aerofilter that could clog with sawdust and particles of dirt. Modern aerofilters are reusable, they can be washed with the addition of a detergent, completely withdrawing from the saw building;

- Check gasoline and motor oil that can be of poor quality or simply not suitable for working with this saw;

- Test candles and carburetor.

The elimination of one or more possible malfunctions usually returns the saw of its former force.

Why is a chainsaw is not gaining momentum?

Launching is a complex multi.level process in which almost all the system life support systems are involved. That is why the fact that Motopila loses turns, turns on with interruptions and confidently feels exclusively at idle, it is worth considering from different sides.

- A faulty motor. its motorcycle resource could be developed, and the piston rings and the cylinder. to worry, deform, or even succumb to corrosion;

- The fault of the ignition or the coil itself is out of order. as a result of this, the spark necessary for ignition of the fuel mixture is not formed;

- The carburetor screws are urged, as well as a number of reasons that could disable it.

Husqvarna sawing carburetor adjustment.

For the run.in mode, so that the parts are received in sufficient quantities, the tuning of the Husqvarna chainsaw carburetor is made in such a way that the maximum speed is 600–700 rpm. Below working. If there is no way to install the working maximum frequency in the tachometer, you should not change preliminary settings with a screw H. Exceed the value of the maximum number of revolutions by the manufacturer prohibited. If, after the adjustment is completed, when operating the engine at idle, the saw chain moves, you should turn the screw t counterclockwise forced to stop it completely.

For accurately adjusting the saw, at least 10 minutes should be warmed up, installed on a flat surface. The tire should be directed in the opposite direction from the person conducting the setting. At the initial stage, the highest value of the idle frequency should be detected. For this, the screw l is smoothly rotated first from left to right, then vice versa. When the maximum speed was found experimentally, it is necessary to turn the screw L counts on the time to a value of 1/8 to a quarter of full turn.

The idle stroke is tuned with a jacket with a marked letter t. It must be rotated from left to right until the chain starts moving. Then smoothly serve in the opposite direction until the rotation of the chain stops. The screw h is considered to be established correctly if the noise of the saw at full gas without load remains small. If the exhaust is too smoky and the saw is very noisy, the mixture is too rich. You need to turn the jackpot h clockwise before installing the right sound. How to correctly configure the carburetor, you can watch on the video below.

Partner and stihl chainsaws, their adjustments.

In STIHL chainsaws and partner, air and gas proportions are set in the mixture. When the screws are weakened, the mixture is enriched, the speed increases. Screwing leads to the impoverishment of the mixture and, accordingly, a decrease in engine speed.

Setting up the carburetor of the chainsaw partner on idle is carried out by a screw T (stihl, it sets this adjustment with letters LA). The basic commissioning of the tool is done at the factory during final tests. In most cases, the carburetor was adjusted to feed a slightly more enriched fuel mixture than optimal. The settings installed by the manufacturer must be saved in the first few hours of operation, during the period of the run-in. After that, a thinner adjustment can be carried out, although this is not necessary, the saw will work normally and on the basic settings.

A tachometer is required for the subtle regulation of the carburetor, in addition, technical documentation will be needed to carry out work in strict accordance with the requirements of the manufacturer. The best decision would be to entrust the jewelry tuning of fuel equipment to specialists.

If you still decide to regulate it yourself, you should start with the screw L, after which they go to the jick H, after which they expose the blank rotation T (or LA. if it is STIHL saw).

A position in both directions is searched for a position in both directions, in which the speed of rotation at idle will be maximum. After this point is found, it is required to turn out the screw l at 1/4 turnover. If at the same time the chain continues to move when the motor operating at idle, the screw t (la) slowly diverges until the circuit stops.

After setting up the maximum speed, their frequency value is checked by the tachometer. If the speed at the maximum does not correspond to the values indicated in the documentation, the adjustments are repeated. If at maximum speed the mixture turns out to be too rich, there is too much smoke from the muffler, with a poor mixture, it makes a screeching sound and the engine is warmly warming. The adjustment ends with the installation of idle. the situation is considered correct if the engine works exactly at a minimum of revolutions and the chain is worth it. The installation of idle can be viewed on the video presented below.

Malfunctions and repair

STIHL 180 chainsaw carburetor requires both initial and periodic adjustment. You can find out about its need by the following signs:

- Problems with the engine, for example, it does not start or immediately stalls after the start of work. Most often, the reason is the use of poor.quality fuel mixture.

- Fuel consumption and exhaust increase. Exhaust gases are becoming larger due to incomplete combustion of fuel. Most often this problem may occur due to oversaturation of fuel.

Other breakdowns may appear, for example, blockage due to damage to the air filter or the formation of scale. The reasons may be due to the fact that with a long.term simple in the fuel tank, gasoline remains. This is due to the fact that fuel is exhausted, which spoils the device.

Regardless of the reason, the carburetor repair will be required, which is most often reduced to adjustment. The method of performing this procedure depends on the chainsaw model, but you can adhere to general principles.

How to remove a carburetor from a chainsaw

Before adjustment, you need to remove it from the stihl chainsaw. For this you need:

- Turn the lock to the left to remove the lid.

- Remove the filter, why unscrew two nuts that hold it. For simplicity of work, it is recommended to use special screwdrivers with suitable nozzles.

- Remove all the rods, including the carburetor lever.

- Remove the carburetor, and then disconnect the fuel hose.

It is recommended to remember the location of the parts so that then you can put the carburetor in place and there are no extra fasteners left or there are no distortions and cracks.

How to clean

In the event that the chainsaw stalls at idle, it is necessary to disassemble the part and clean it. First of all, this applies to cleaning the additional filter. This part is a net. To get to her, you need:

- Take the largest lid.

- Remove the membrane located under the lid.

- Clean the net, which is located in the recess. This must be done extremely carefully, since the net may fall out. To clean the copper wire for cleaning. Additionally you need to rinse and blow all the channels. The last procedure is necessary if gasoline does not enter the carburetor.

How to setup

The adjustment of the Carburetor of the Stihl 180 chainsaw is carried out to improve the performance and saving of fuel.

- Clean the fuel system, including the tank, from the remnants of a mixture of gasoline and oil. Blow out air channel and filters. performed using bolts n, l and s. The bolt controls the nozzle, provides maximum speed. Bolt L performs the same function, but provides minimum turns. Screw S is responsible for the accuracy of idle speed. This procedure must be performed when the engine is turned off.

- It is necessary to adjust the carburetor on the chainsaw by the task of the corresponding angles of rotation of the first two bolts. You can set basic values as follows. Turn the first two bolts slowly in the direction of the clockwise, after the stop to return back to two turns.

- Turn on the engine and adjust the ignition on the stihl chainsaw and its carburetor finally. To do this, you need to find the highest blast speed by turning the bolt L in different directions. After this maximum is found, the bolt must be returned by a quarter of the course. In the event that the chain begins to move, the engine needs to be stopped.

- Conduct a technical check. In particular, you need to determine the maximum number of revolutions, check the acceleration and stability of the engine at idle, as well as the correspondence of these parameters to the basic values in the instructions. The quality of the mixture for verification should be the highest.

The cost of repair work and replacement of the carburetor

If there is no experience of repairing parts of the Stihl chainsaw, it is better to entrust this to specialists. The price depends on the complexity of the repair and the region. The average values are as follows:

- Diagnosis of gasoline saw. 300;

- Replacing the carburetor. 300;

- complex service (the complex includes flushing, installation and adjustment). 1000;

- external cleaning unremarking. 300;

- adjustment. 300;

- Board of carburetor and engine. 2000;

- Hermeticization of the pipe. 200.

Regular tuning of the carburetor allows you to increase the efficiency of the chainsaw and reduce fuel costs. At the same time, it is recommended to accurately observe the technology or entrust work to specialists.