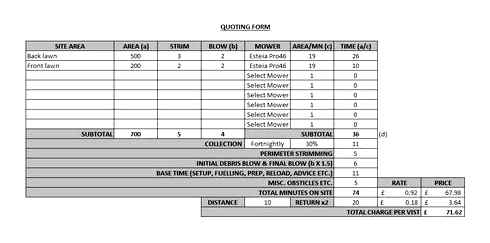

Lawn mower depreciation calculator. How Much To Charge For Lawn Mowing

How Much To Charge For Lawn Mowing Lawn mowing is the main income stream of thousands of experienced contractors across the country. One of the toughest aspects of starting a lawn mowing business is figuring out how much to charge for lawn mowing. Lawn mowing is the main income stream of thousands of experienced contractors across the country. One of […]

Read more