The Grass Is Wound On The Trimmer Spool

Coil with two working tendrils

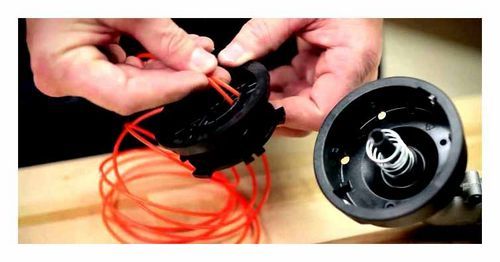

In this type of spool, you should determine the number of grooves for winding the line, lying on the inside of the spool:

- One groove. both tendrils are wound together in one groove;

- Two grooves. each tendril is wound on an individual groove.

For both cases, a line with a length of 2-3 m is taken.In single-groove reels, the line is pulled into a through hole, its ends (antennae) are folded together and aligned, after which they are wound in the opposite direction of rotation of the bobbin on the rod side. inside the arrow usually indicates the correct direction of winding. If there are fixing grooves, the ends of the fishing line are threaded through them or held with the fingers of the free hand, they are threaded into the through hole of the outer half of the bobbin, the bobbin is closed and attached to the trimmer bar.

The difference in line winding in two-groove spools is that initially a 2-5 m long line segment is folded in half (to determine the mid-bend), and the bend loop is inserted into a special groove between the grooves. Both antennae of the fishing line are wound each along its own groove, fixing the antennae and assembling the coil is similar to the above-described option with one groove.

The first execution of this procedure, perhaps, will seem long and rather laborious, but with time and experience this task will be solved much faster and easier.

The following will clearly show how to thread the line into the trimmer spool and wind it correctly. this operation is NOT difficult and with some patience it will certainly be crowned with success:

Preliminary preparation

First of all, to wind the fishing line, you need to remove the spool (bobbin, spool) from the trimmer. specific actions will depend on the complexity of the configuration and the type of the product itself:

- Small electric trimmers with a working position of the motor and coil at the bottom, as a rule, have side buttons on both sides of the bobbin. When pressed at the same time, the upper part of the spool together with the inner content for winding the line is disconnected, while the lower part remains on the trimmer. It is advisable to disassemble the bobbin on a flat, smooth place so that the spring included in the structure does NOT jump out and does NOT get lost;

- Electric and gasoline trimmers with a curved bar without the possibility of installing a knife, as a rule, have spools with special lamb: in such designs, hold the spool in a stationary position with one hand, and rotate the wing nut that fixes the Bobbin on the bar with the other hand. After disconnecting the nut, the entire bobbin is removed.

- Electric and gasoline trimmers with the ability to install a knife on a straight Bar (for example, Stihl trimmers) have a hole under the reel. To keep the rod stationary, a screwdriver or other suitable object is inserted into this hole and, with slow rotation, such a mutual position is achieved when the screwdriver enters the hole and the bobbin is fixed. After that, the coil body is scrolled clockwise (with a left-hand thread) and removed from the trimmer.

For the second and third options, the coils, depending on the design, are disassembled in different ways. In the bobbins, a lamb is unscrewed from the lamb, in the coils, the latches are pressed from the latch and one part of the coil is released from the other. If the halves of the bobbin are connected by thread, then it is enough to turn them by hand in opposite directions until they are completely unscrewed.

Coil with one working tendril

The simplest option and uncomplicated sequence of actions:

- The dimensions of the reel and the length of the original factory winding determine the recommended length of the line for winding. 2. 5 m.

- One end of the line is inserted into the fixing technological hole located inside the spool.

- The fishing line is wound on the drum in the reverse rotation of the spool in the direction of the trimmer. as a rule, on the inside of the bobbin an arrow indicates in which direction the winding is being carried out.

- A small section of the fishing line is left free to lead it out. it is fixed in a specialized groove on the inside of the bobbin, designed to hold the winding when assembling the bobbin into working condition.

- The left end of the line is passed through the hole in the outer part of the reel.

- The bobbin halves are assembled and put on the trimmer bar.

We wind the fishing line

Slowly completed disassembly of the spool-spool without losing its spare parts allows you to proceed to the main task. winding the fishing line into the reel. Technological features of the spool design and the number of working antennae determine the sequence of actions.

How to insert line into the trimmer spool? Instructions

The warranty production of the factory trimmer refueling will inevitably require line replacement. Having a very rough idea of how to thread the line into the trimmer reel on their own, beginners are reluctant to take up this business. However, with some skills, mastering this simple teaching does not present any difficulties, and the similar instruction presented below will make this process as easy as possible.

Automatic line winding to a spool

There is a type of reel in which the automatic mechanism winds itself. from the user it is enough only to correctly fill the line. The fishing line is passed through a hole on the inner part of the body, its antennae without winding are passed through the hole on the outer body, the reel is assembled, and when the winding button is rotated, the fishing line inside is wound independently. It is impossible to make the winding wrong in such a spool: the mechanism itself will determine the correct direction, since it can only spin in one direction.

Second way

Some reels have a second method of securing the cord: you can charge 2 pieces of yarn instead of one folded in half. The line is replaced according to the following algorithm.

- Before you change or load a new thread into the spool, determine how many meters it will take using the method described above.

- One end of the cord Fold into a hook.

- Find the hole at the bottom of the bobbin for fixing the line, and insert the end of the thread bent in a loop into it.

- It is required to wind the cord according to the direction of the arrow to the required level, and not exceeding the coil diameter.

- Do the same for the second bobbin compartment.

- The assembly of the head does not differ in any way from the method that was given when it was considered threading the bobbin with a piece of line folded in half.

For Shtil lawn mowers, there is a very simple and quick way to change the line without disassembling the mowing head, which you can get acquainted with by looking at this.

The ends of the cord protruding from the holes in the casing can be cut to the desired length when the part is installed in the trimmer. This can be done in two ways:

- Turned on the trimmer (when rotating, the ends of the line will be cut into a knife, fixed for THESE purposes on the protective casing)

- Cutting off the excess ends with scissors so that they DO NOT touch the casing body.

The second method is used if a large diameter cord had to be supplied, and the edging knife cannot shorten it.

In this case, it is necessary to turn off the unit (on electrical apparatus, it is imperative to unplug the plug from the socket), manually press the button located at the bottom of the part, and pull out a little line. After this procedure, the cord can again be extended due to centrifugal force, if you set the maximum spindle speed.

the lawn mower is manual. Replacing the line in the reel.

In this I show how easy and simple it is to wind the line around the reel of a hand-held lawnmower without the help of others.

The trimmer mowing head consists of several parts: a cover, a spring (not on all models), a spool with a cord and a cover.

In trimmers, 2 options for mounting the mowing head are most often used.

How to wind the line on the reel of a lawn mower

Now steep the whole coil clockwise (because the thread is left-handed) and remove it from the trimmer. Next, we disassemble the coil. It can be assembled with snaps or a twisted lamb. If the coil is latched, then press along the edges on the base of the latches so that they bend back and release one half of the coil body from the other.

We just unscrew the lamb. In addition, there may be a third type of connection of 2 halves of such a coil: with it, you need to grab the lower part with one hand, and the upper part with the other, and start turning them in the opposite directions. When disassembling such a coil, you must also look so that the inside of the spring is not lost.

Line problems

Users of trimmers, both gasoline and electric, sometimes have problems with the cord. “Advanced” Owners of mowers easily cope with difficulties in automotive products, understanding why this happens, and for beginners, these are problems that have no rational explanation. But in fact, everything is solved quite simply. The most common problems that happen with the line are as follows.

Features of the use of trimmers

A trimmer that mows grass with a fishing line can be used near: houses and other buildings, fences and hedges, trees and shrubs, beds and flower beds, row spacing in a garden plot.

Such a convenient, and most importantly, effective device like a trimmer exists in several variations:

- Petrol;

- Rechargeable;

- Electric.

Line consumption directly depends on the frequency of use of the device and the scale of the work performed. The more grass is cut and the more often it is trimmed with the trimmer, the more active the line is used. And, accordingly, the faster it will end. In this regard, the question arises: how to thread the line into the trimmer spool?

Not everyone knows the answer to this question. But the winding of the line on the reel plays an important role in the trimmer operation. For the device to function properly, it is very important to properly wind the new line onto the reel. How to change the line for a trimmer, and will be discussed in this article.

How to wind the line onto the trimmer spool. We master step by step

There is a type of reel in which the automatic mechanism winds itself. from the user it is enough only to correctly fill the line. The fishing line is passed through a hole on the inner part of the body, its antennae without winding are passed through the hole on the outer body, the reel is assembled, and when the winding button is rotated, the fishing line inside is wound independently. It is impossible to make the winding wrong in such a spool: the mechanism itself will determine the correct direction, since it can only spin in one direction.

Also, the scythe heads may have different devices: with automatic line feed, semi-automatic or manual. In the first case, in order to lengthen the working ends of the thread, it is necessary to slightly lower the speed. And when you add them again, the line will come out automatically. For semi-automatic devices, you need to click on a special button located below.

To find out how to wind the line on the trimmer reel, you need to carefully examine the mowing part of the device or look in the tool passport. The fact is that, depending on the refueling method, the trimmer coils are quick-charging and collapsible. For the former, everything is very simple. You DO NOT have to remove and disassemble anything, you just need to find holes for the fishing line, thread it through both ears and wind the required number of turns, and cut off the excess.

But on the second option it is worth dwelling in more detail, because the coil will have to be dismantled and disassembled.

- First, make sure the trimmer is off, and if you are using a lawn mower, be sure to Unscrew the candle.

- Remove the mowing head from the trimmer and disassemble it. To do this, press all the way on the latches located on the head body and remove the cover.

- Cut off the required amount of fishing line, and make the ends sharp. It will make the job easier.

- Place one end of the line in a special clip located in the center of the reel.

- Wind the string in the direction of the arrow indicated on the cap, while holding the string firmly with your finger.

- Leave a free end 12-15 cm long and attach it to the slot on the spool.

- If the mowing wheel in your trimmer is two-piece. Repeat the last 4 steps. At the same time, wind the line into the free section. And fix the end on the other side of the coil.

- Return the structure to the mowing head and through special slots Pull out the free ends of the line.

- Close the head cover and assemble the trimmer. Your braid is ready to go again.

At first glance, threading a line into the reel of a tool is not easy. But it is enough to carefully study this process. and in the future all the necessary actions will be performed without any difficulties.

It is worth reading this guide to find out how to tuck the line into the trimmer. The step-by-step instructions given below take into account the peculiarities of the coils of different types of trimmers, therefore, it is applicable to any tool.

- The line spool is the bottom end of the trimmer. First of all, of course, you need to remove this head from the device. To do this, you need to fix the rod (or, in other words, the shaft) on which the coil is attached. It is required to fix it in such a way that it does not scroll. The easiest way to do this is by placing a kind of stupor (preferably metal) between the shaft threads through a special hole. When the shaft is fixed, the spool can be unscrewed.

- At this stage, you have to remove the bobbin from the head, on which the fishing line is attached. To do this, you need to disassemble the head into elements. To do this, you must first find a retainer on its body. It is located on the circumference of the product and is like a button. When the latch is found, you need to press it firmly. Keeping the latch pressed, you must return the head cover clockwise. Then you need to remove the cover and remove the bobbin.

- A tight spring is placed between the bobbin and the head. It needs to be put aside for a while so that it does not interfere with the winding process. Before proceeding with the step of winding the line, it is necessary to inspect the bobbin. If there are remnants of old fishing line on it, they must be removed. When the bobbin is cleaned, you can start preparing a new bobbin.

- Here is a previously prepared skein of new fishing line, you need to measure and cut off six (maximum. seven) meters. Keep the bobbin close at hand.

At this point, the key stage actually begins, which this article is devoted to.

The required amount of line has been cut off. Now you need to carefully examine the bobbin in order to understand what type it belongs to. It depends on how the line is to be wound on it.

There are two types of bobbins. In general, they differ slightly from each other. Regardless of the type, the coil is divided into two sections. upper and lower. In the first type, the dividing face does not close into a ring and has a depression.

In the second type, it is solid, but near it there are small through holes on the sides on both sides. The method of winding the thread should be studied depending on which of the above types the coil belongs to.

- The previously prepared six-meter segment must be bent in half. Best of all is inaccurate in the middle, and in such a way that one half is longer by about fifteen centimeters.

- Then the place of the fold must be inserted into the recess in the dividing face. One half of the line should be at the top of the reel, the other half at the bottom.

- Now you can start winding directly. You need to wind in the direction in which the arrow points to the bobbin. When winding, you need to keep the threads so that they are NOT intertwined and the upper half winds up in the upper part of the spool, and the lower half in the lower part. Each half should have about fifteen centimeters free from the end.

- There are small indentations (or, in other words, grooves) in the upper edge of the bobbin for securing consumables. The ends of the threads must be inserted into these recesses so that they are fixed one opposite the other.

- The final step of threading the consumables into the tool. the ends attached to the bobbin must be threaded into the Corresponding holes in the trimmer head.

- That’s all. The winding process is complete. Now all that remains is to assemble the head into a single whole. The spring fits neatly back between the bobbin and head. Then you need to insert the bobbin into the head and press them together.

- It is recommended that the free ends of the thread be pulled out more. To do this, you need to take turns pulling the ends of the consumables so as to remove them from the grooves of the bobbin. You can make sure that the cutting element is removed from the retaining grooves by trying to pull the threads a little. they should freely exit through the holes in the head.

- Presses the bobbin down, you need to put the cover over it. The cover must be screwed to the head so that all the grooves on their bodies are aligned and the bobbin remains fixed between them.

- And finally, the very last action. the head is screwed back into place at the bottom of the tool.

- A previously prepared segment of six meters in length is required to bend exactly in the middle and cut. Thus, two segments of the same length are obtained.

- Make a small “hook” at one end of each line. To do this, it is necessary to bend a couple of centimeters from the edge and fix it for a short time so that the “hook” did not unbend.

- Then one segment is taken. The hook is inserted into the through hole at the top of the bobbin.

- Now you can proceed to the key stage. winding. The direction in which to wind is indicated by an arrow pointing to the bobbin. It is important to make sure that the line is wound strictly within the upper part of the reel. It is not necessary to wind the thread to the very tip. that’s the end About fifteen centimeters should remain free.

- In the upper edge of the spool there are small recesses (so-called grooves) for fixing consumables. The free “tail” whine must be inserted into one of THESE recesses.

- The top of the coil is loaded. Now you need to do the same procedure with the bottom. Take the second piece of thread. The “hook” is threaded through the through hole at the bottom of the bobbin.

- After that, you can start winding the line (within the lower compartment). And for this segment, you also need to leave about fifteen centimeters free from the end. This remaining “tail” must be inserted into the grooves opposite to the one into which the end of the first segment is inserted.

The subsequent actions for this type of coils are exactly the same as those described for the previous type in paragraphs five to nine.

This is how the line in the trimmer spool changes. Nothing complicated in the commenting process. And already after several refuelings, all actions will reach automaticity.

The grass mowing head is a cylindrical body in which a spool (bobbin) is inserted with a fishing line (cord) tucked in it. This design can be installed on both gasoline and electric trimmers. The heads differ in the way of threading and feeding the cord and are of 3 types.

- Automatic. Cord feed is performed after the user Decreases engine RPM. Although the automatic line feed is convenient if large volumes of work are performed, there is one drawback in such bobbins. a high whine consumption.

- Semi-automatic. The use of this type of heads does not require the user to perform complex manipulations. The principle of their operation is designed in such a way that the cord lengthens automatically while the apparatus is operating at full speed. It is enough to lightly hit the ground with the trimmer head (this removes the blocking of the cord), and the line is pulled out of the bobbin due to centrifugal force, after which it is cut to the required length with a knife located on the protective cover.

- Manual. To lengthen the cord, the device must be stopped, after which the line is pulled manually.

Line winding algorithm

Depending on which trimmer model is used, the type, thickness and length of the line are selected. The diameter of the cord can be from 1.2 to 4 mm. It is not difficult to guess that the thicker you fill the cord, the harder and thicker grass it is able to cut.

There are 3 ways to find out which line diameter you can use on your mower.

- View information on the thickness of the cord in the instructions for the device.

- Look at the bobbin itself. It can contain information about the possible diameters of the line.

- Insert the line into the outlet. If it easily passes into it, then a cord of this diameter can be used.

Noise level

In some options, designers install special sound-absorbing nozzles, but you have to pay extra for them.

Algorithm of actions

Before winding the line correctly on the trimmer spool, follow these steps:

- Block the cutting shaft with a stupor;

- Remove the coil by pressing the button or two small clips (they are located on opposite sides of the shaft)

- Pull out the bobbin carefully (there is a spring inside the spool, which may be lost after removing the bobbin)

Bobbin with spring, spool free and ready to rewind new line

- Free the block from the remnants of fishing line and grass, if they got there;

- Measure the required length of the working thread and cut it off (usually a 6 meter line)

- Fold the thread in half and in the middle Place inside the spool.

Further actions depend on the type of bobbin.

Picking a cord

There are general rules for choosing a line for a trimmer.

- If the petrol grass trimmer is equipped with an engine power less than 500 V, choose a working thread with a thickness of 1.3 mm.

- For motor over 1000 V Use a 2 mm cord.

- If the work shaft is bent, a 2 mm thread will do. For straight line. 2.4. 3 mm.

- When choosing a fishing line, consider the cross section. For young and thin grass Use a spiral cord. If there are less thickets of weeds, Install a line with a serrated section. Rectangle thread Use to give your lawn a flat surface, but this thread is NOT strong. To clear difficult thickets Use a circular line with internal wire.

Better not to change the line to metal wire. Doing so can damage the instrument as well as injury if it bursts.

First option for double bobbin

- Insert the line fold into the special groove located in the dividing rib. One half of the segment is located at the top of the structure, the other half is at the bottom.

The thread is attached to the edge of the bobbin. Rotating in the direction of the arrow winds the line around both discs. After winding, loose ends remain

- Wind the thread along the arrows indicating the direction of rotation so that the upper part remains at the top, the lower, respectively, at the bottom.

- Leave 15 cm from each edge.

- Find the whining grooves on the bobbin and insert the remaining pieces into them.

- Assemble the trimmer head so that the free areas of the line fall into the holes of the working shaft.

- Insert the bobbin into the head, the spring has previously returned to its original place.

- Press the bobbin against the head and pull the ends of the line out. Check how the free sections of the cutting thread move. They must rotate the shaft freely, without jerking.

- Place the cover on the bobbin. Check the alignment of the holes in the case. After all the grooves are aligned, fix the cover.

- Replace the head in its original place.

Second winding option

- Cut the measured piece of thread in half.

- Before threading the line into the trimmer spool, bend one of the ends of each piece and press firmly to form a hook.

- Insert the resulting thread hook into the hole. Wind the sewing thread in the direction indicated on the bobbin case.

- When 15 cm remains of the original length, stop winding. Insert the remaining section into the groove.

- Wrap the line on the bottom of the body in the same way.

- Assemble the bottom of the trimmer, put the bobbin in place.

In a spool consisting of one section, the working thread changes in the same way. Unwind 15 cm from the finished piece, make a loop and fix it in the groove. The line is wound in the direction of the arrow. After the end of the process, the remaining end is fixed on the coil cover.

Tool feeding methods

The Trimmer provides 3 ways to feed the line:

- Manual;

- Semi-automatic;

- Auto.

This is what 3 types of trimmers look like

In the first case, the thread is pulled at the ends after stopping the tool.

In the second, wire feed starts after unlocking. To do this, you need to lightly hit the head with the soil.

In automatic devices, the mechanism works independently after starting the engine. This option is convenient for performing a large amount of work. Disadvantage of the machine. it requires a long length of thread.

Petrol trimmer

Small mobile devices for cutting grass and young branches, consisting of a bar, motor, cutting part and a handle are called a trimmer.

The device without a trimmer is simple, it is easy to disassemble, if necessary

There are electric and gasoline modifications. The former do NOT refuel, but they depend on the length of the cord. The latter do NOT work suspension from the presence of electricity, anywhere in the garden or vegetable garden.

Petrol trimmers are lighter and less expensive than lawn mowers. They cope with grass and shrubs, so such mowers are used in everyday life and on an industrial scale. For convenience, the technique provides belts that are worn on the shoulder. Thus, the stress on the arms and back is reduced.

How to wind the line on the trimmer spool. detailed instructions

Is the trimmer cutting thread used up and needs rewinding? Don’t be in a hurry to panic. There are several ways to wind the line around the trimmer spool. The choice of method depends on the bobbin design and tool model. We understand the details of the process.

The trimmer can have several attachments to work with different types of vegetation

Varieties of benzotrimmers

Trimmers are distinguished by indicators:

- Power;

- Engine’s type;

- Cutting element;

- Handle configuration;

- Fuel filling method;

- Noise level.

Depending on the power, tools are of household, industrial, mixed, universal type. Lawn mowers are a separate type. They are the most powerful of all types of gasoline trimmers.

Option

To remove the trimmer head, you will need to completely disassemble it.

- To remove the cover that covers the inside of the head, you must press on the latches (latches) located on both sides.

- After removing the cover, you will see a spool that needs to be removed from the body. Some spools have a spring under the bobbin, which must be carefully pulled out to avoid losing it in the grass.

- When you remove the bobbin, you will see a slotted screw for a Phillips or flathead screwdriver in the center of the case. It is possible that there may be a hex bolt or a nozzle “star”.

- Using a screwdriver, selecting the required bit (bit), it is required to Unscrew the bolt (counterclockwise).

- After removing the fasteners, grasp the body of the part and, swing it in different directions, Remove it from the gearbox shaft.

How to remove and disassemble a coil

Before starting the process of changing the cord, it becomes necessary for trimmer users to remove and disassemble the coil. Let’s see how to do it.

The trimmer mowing head consists of several parts: a cover, a spring (not on all models), a spool with a cord and a cover.

In trimmers, 2 options for mounting the mowing head are most often used.

How to change the line to the trimmer

The trimmer is the most common machine used for cutting grass and small bushes. This device is distinguished by its simplicity in service, simple operation during operation, and due to its low weight, even women can handle it. It is no secret that the correct selection of cutting tools is required for high-quality performance of work on mowing grass. As the latter, special cutting attachments (discs, knives) or trimmer heads with a fishing line inside are used in trimmers. Nozzles and line are expendable tools, but if the knives can be sharpened, then when the line is used up, it must be replaced. In this article, we will tell you in as much detail as possible how to properly replace the fishing line.

Cord breaks

If the line breaks frequently, this may be due to the following reasons:

- Stones, small branches and other solid obstacles come across in the grass;

- Users are mowing the grass right next to the fence, and if it is mesh, it cuts off even faster “antennae”;

- Poor cord quality (it is recommended to purchase a quality one)

- The outlet holes in the mowing head are worn out, which causes the line to be erased on the sharp edges of the bushings and break off (a complete replacement of the part will be required).

Second way

Some reels have a second method of securing the cord: you can charge 2 pieces of yarn instead of one folded in half. The line is replaced according to the following algorithm.

- Before you change or load a new thread into the spool, determine how many meters it will take using the method described above.

- One end of the cord Fold into a hook.

- Find the hole at the bottom of the bobbin for fixing the line, and insert the end of the thread bent in a loop into it.

- It is required to wind the cord according to the direction of the arrow to the required level, and not exceeding the coil diameter.

- Do the same for the second bobbin compartment.

- The assembly of the head does not differ in any way from the method that was given when it was considered threading the bobbin with a piece of line folded in half.

For Shtil lawn mowers, there is a very simple and quick way to change the line without disassembling the mowing head, which you can get acquainted with by looking at this.

The ends of the cord protruding from the holes in the casing can be cut to the desired length when the part is installed in the trimmer. This can be done in two ways:

- Turned on the trimmer (when rotating, the ends of the line will be cut into a knife, fixed for THESE purposes on the protective casing)

- Cutting off the excess ends with scissors so that they DO NOT touch the casing body.

The second method is used if a large diameter cord had to be supplied, and the edging knife cannot shorten it.

If a charge was made to whine into the mowing head, but the length of the protruding ends of the cord is insufficient, then they must be lengthened before starting the machine. this applies to the head with manual adjustment. However, there are cases when using a semi-automatic mowing head, when, due to the insufficient length of the protruding ends of the cord, they do NOT automatically lengthen. In this case, it is necessary to turn off the unit (on electrical apparatus, it is imperative to unplug the plug from the socket), manually press the button located at the bottom of the part, and pull out a little line. After this procedure, the cord can again be extended due to centrifugal force, if you set the maximum spindle speed.

No cord feed, coil does NOT spin

An automatic or semi-automatic head should feed the line without stopping the machine. But if She does not come out, then the reasons may be as follows:

- The line in the reel is not wound correctly, because of which the latter does NOT spin;

- The cord is not wound evenly, and the thread can get stuck between the turns (the thread should be wound neatly, turn to turn, without distortion)

- Too short ends of the thread come out of the holes, as a result of which there is not enough centrifugal force to extract them, and the line is NOT fed (it is recommended to always adjust the length of the cord by pulling it slightly before starting the unit)

- The line is stuck together (will be discussed later).

What can be used instead of fishing line

Many users of trimmers ask themselves the question: what can be used to replace the default cord used in this kind of machines? Begin unsafe experiments by installing metal or copper wires, metal ropes or strings, and ordinary fishing line in the mowing head.

If you install a metal cable instead of a fishing line, the trimmer turns into a dangerous device Not only for the user, but also for those around. This fact is explained by the fact that during the operation of the unit, the steel cable will gradually be triggered, its ends will unravel, and small pieces of wire will scatter in different directions at high speed.

And if you accidentally hook your or someone else’s leg while working with a steel cable (wire), then a strong and deep tissue incision, and in some cases amputation of your toes, is guaranteed. The manufacturer does NOT use nylon for THESE purposes in vain, since it is light and strong enough, and when it comes off it does not fly far away and cannot cause injury.

Of course, you can use fishing line in the trimmer instead of the standard one, but this will add extra trouble to you, since it wears out quickly, tears, mows slowly and is NOT suitable for cutting tough grass. In addition, when carrying out work, a lot of time is lost to replace the broken tool more than once.

In practice, the installation of a conventional line is justified if the user is going to mow the grass near the fence, especially if he is from the netting. In this case, in order to protect the standard, and sometimes expensive, line from wear and tear, it is changed to a fishing line, which is not a complaint. Usually, in order to change the line to the line, it must be selected The greatest thickness. 2-3 mm.

Option

In this embodiment, the head is screwed onto the gearbox shaft. To remove it, you need to fix this shaft. To do this, in such trimmers, for example, in the Huter and Champion devices, a hole is provided through which you can insert either a thin screwdriver or a metal rod.

So, to remove the bobbin, follow 2 easy steps.

- Insert a screwdriver into the hole and lock the shaft.

- Grasp the head body and start turning it clockwise. Torque in this direction follows because the thread cut on the shaft is left.

The line is flying out

The reason that the cord unwinds after starting the unit may also be due to the weakening of the spring inside the head. In addition, there are times when the mowing head flies apart when the machine is turned on, and the spring installed in it is lost. Inexperienced users do NOT notice the absence of a spring and assemble this unit without it. Therefore, the cord does NOT hold, and under the influence of centrifugal force flies out.

How to properly wind the line on the trimmer spool?

Despite the fact that gardening equipment has been used for quite some time, it is still a novelty for some owners of private houses. That is why there are often questions about how to properly wind the line on an electric or gasoline trimmer.

This is essentially a simple operation, but all its stages must be performed correctly in order to achieve the desired result. over, in the operating instructions, only a few manufacturers provide an answer to this sore question. Explore the article and find out how the line winds around the trimmer reel.

The procedure for winding the line on the trimmer spool

First of all, you should know that trimmers have different working attachments. The reel can be designed for different lengths and thicknesses of the line. this point should be taken into account when purchasing consumables.

So how does the line load into the trimmer reel? All work is divided into several stages:

- First you need to disassemble the trimmer head.

- Unscrew the nozzle by rotating the drum to the right.

- Press with your fingers on the two latches located on different sides of the tap holes and remove the top cover of the nozzle. You can pry off the cover with a screwdriver. This should be done carefully: reels with automatic line feed have a spring that can forcefully throw the cover along with all the contents of the reel.

- Remove old line scraps.

- Now you need to find the middle of the line. To do this, unwind it to the required length (for example, 10 m), cut and fold in half.

- Hook the middle of the line into the existing groove or insert it into the hole specially designed for this. And start winding. The direction is indicated by the arrow, which is usually marked on the trimmer reel body (usually against the rotation of the drum). Some models have a double-sided reel: in this case, the line should be wound in different directions: one end in one direction, the other in the other, while the loop of the line must be inserted into the dividing slot in the middle.

- Leave loose ends of the line about 20cm each. Later they will need to be fixed in the recess.

- And finally, the last step will be the assembly of the drum. Reinstall the washers and spring. On the top ring of the reel there are two notches where you need to tuck the antennae of the fishing line. Thread them through the holes and place the spool in the drum, trying to tighten the line without displacing the spring.

- Place the drum cover on top and close it with your fingers. The latches will snap into place with a distinctive click.

When you turn on the trimmer, excess line will be cut off by the trimmer blade.

As you can see, winding the line on the trimmer reel is not difficult: the main thing is to do everything right. And here are some more tips that will come in handy when choosing a fishing line, winding it and subsequent work:

- The line comes in a variety of thicknesses and cross-sections. The best option for winding is the “native” line for this model;

- Never use fishing line or metal cables for the trimmer. This replacement may seem effective, but it is very dangerous. Jumping off a working trimmer, the cable can seriously injure Not only the lawnmower himself, but also those around him;

- The line is cut when the trimmer is in contact with hard objects. Try not to allow this, otherwise you will have to stop each time, turn off the device and rewind the line on the reel;

- Use regular line for cutting lawn grass and braid line for coarse weeds. It is more durable and will not constantly cut.