The grass trimmer carburetor does not receive gasoline causes

Fault detection

If the grass trimmer engine does not start or stops immediately after starting, if the gearbox overheats, or if during the operation of the device extraneous noises are heard and vibration is clearly felt, it is important to perform a visual inspection and identify a non-working unit.

To optimize the preparations before the repair, a simple diagnosis should be carried out and step by step checked:

- presence of fuel in the tank and grease in the main nodes;

- serviceability of the spark plug and its performance;

- cleanliness of the brushcutter’s fuel and air filter;

- clogging of the exhaust duct and breather of the device

- The quality of the fuel and lubricants used.

Weedeater 101. The two most common reasons for failure to start.

To determine if the ignition of the lawnmower is functional, you should determine if the spark plug works by testing the appearance of the spark when it comes into contact with the body of the functional device.

The spark plug itself can be replaced with a new one, pre-drying the spark plug duct, if necessary the old element is also dried, cleaned with special devices and returned to its place.

Reasons for stoppage of fuel supply

Here are the reasons why the fuel does not enter the cylinder:

- the tank is out of gasoline;

- when starting the engine, the fuel was not pumped by the primer;

- primer is defective;

- Due to a wrong inclination, the fuel system is bloated;

- the fuel system is leaking;

- the fuel system is leaking; the fuel tank vent is clogged;

- the carburetor is clogged with dirty fuel.

Out of gas

The first sign that the tank is out of gasoline is unstable operation of the engine, which for a few seconds now resets, then briefly rises the speed, sometimes “sneezes”, then stops and no longer starts.

It is not difficult to determine the cause. it is enough to look at the fuel tank. it is transparent, so you can always see the fuel level.

Most often with such a cause meet inexperienced owners of trimmers, who do not know how to determine the time of operation on one refueling. No harm to the motor trimmer for grass does not bring it, but after filling the tank with fuel it is necessary to pump the fuel through the system, if you refill the gasoline before it runs out, you can do without priming.

Failure to prime fuel when starting the engine

This reason is also typical for inexperienced trimmer users who have not yet raised this operation to the level of a reflex.

Neglecting to pump the fuel will not have any negative consequences, except concern about a possible machine breakdown, but worrying too much can lead to a breakdown of the equipment.

An inexperienced user who tries to start the engine but fails, for example, starts unknowingly to apply too much force to the starter rope and forgets to choose a free turn, which may break the mechanism.

Primer malfunction

The most common cause of such a malfunction is a hanging valve that does not close the fuel flow in the opposite direction when you press the primer button.

To reliably determine the cause without disassembling the machine, 30-50 times pull the cable of the starter with the mandatory selection of a free move, but without interruption. If this at least makes the engine “sneeze”, then the problem is really in the primer, so the trimmer needs repair.

The fuel system is leaking due to improper inclination

A fuel system choke caused by improper tilt occurs as follows:

- Changing the position of the driveshaft changes the angle of the fuel tank;

- the gasoline, following the force of gravity, tends downwards and ends up away from the suction tube;

- the air gets into the fuel system through the suction tube and after the fuel in the tube and carburettor is exhausted, the engine stops getting petrol;

- After sucking in even a small amount of air, the vacuum created by the engine is no longer sufficient to effectively move the fuel through the system, so even a return to a normal angle of inclination all leads to a stop of the engine.

Leaking fuel system

This is the most dangerous reason, because in addition to disrupting the supply of gasoline to the engine, it can lead to the ignition of escaping fuel, which is fraught with serious burns or fire.

The most common source of the problem is either a leaking seal or a damaged or dislodged hose.

Any of the defects leads to leakage in the fuel system, and the main symptom is petrol droplets and a strong odor.

The fuel tank vent pipe is clogged

Despite the tightness of the fuel system, there is a hole in the gas tank for air to compensate for wasted fuel. On the vast majority of trimmers, a hose goes through the vent hole to protect the fuel from dust and dirt.

The air speed through the pipe is slow, so dust or dirt is not sucked into it and does not contaminate the fuel. If this pipe is clogged, the vacuum created in the tank compensates the vacuum created by the piston, and fuel movement stops.

The carburetor is clogged with dirty fuel

Low-quality gasoline with a large amount of resins and various dirt can clog the carburetor channels and disrupt the operation of all fuel systems.

On different modes of operation the engine needs a fuel-air mixture with a certain proportion of air and gasoline, if the proportions are changed, the work of the engine is disturbed.

A functioning carburetor immediately reacts to changes in the operating conditions of the power unit, including an increase in load, by adjusting the amount of fuel, but clogging deprives it of this ability. The result can be a strong decrease of power and speed or a complete halt of the motor.

Lawn mower does not start: the causes of failure and how to troubleshoot with their own hands

Agree that almost any problem with the trimmer can be solved independently, without resorting to the help of specialists. When the mower does not start, the causes and remedies lie on the very surface. You only need to carry out a thorough diagnostics of the device and determine the key causes of malfunctions.

In this article we will consider popular causes of breakdowns of benzocosa, ways to detect them. Here are the recommendations for repair at home. To make the process easier to understand for those who are new to this business, we provide illustrative photos and detailed video instructions.

complex causes of mower failure

If the step by step algorithm for troubleshooting did not produce a result, and your grasshopper still does not start or stops, it is worth inspecting the carburetor and the engine itself. A clogged carburetor can be one of the causes, unstable operation of the tool. Three main problems can be distinguished here:

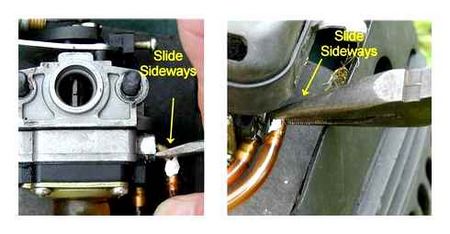

- Clogging of channels or jets. This can be cleaned with special washes or with a powerful compressed air jet from a compressor. Do not use needles and wire, as it can damage the cross sections;

- Wear carburetor gasket. The solution is to replace the faulty gasket;

- Tightness problem. An ordinary household tonometer can be used to check this figure, replacing the gauge on it with a suitable. Watch the readings: if they do not change. everything is fine, and if the pressure starts to fall, it means that some part of the carburetor is faulty. You’ll have to find it and replace it with a new one.

If everything is okay with the carburetor, the gasoline trimmer for grass may not start due to the wear of the piston group. If you find chips, scratches or scrapes on the piston or cylinder, replace them. Piston rings must be checked. A slight play of the piston when rocking the connecting rod is an indication that it is time to change the rings. This procedure is best left to the professionals at the service center.

Why the grass trimmer does not start: causes of malfunction and ways to fix them

It’s time to cut the lawn and the mower isn’t working? It’s scary to even imagine how you can keep your lawn in perfect condition with a hand tool, especially when you haven’t had to do it before. If the grass trimmer does not start, the reasons may be many, but most of them you can fix yourself.

You don’t need any special tools or specialized knowledge. A little courage and free time to read this material. and the grass trimmer will not need to take to the master.

In this article we will tell you how to determine what is preventing the start, give instructions on how to repair each component and recommendations on how to avoid problems in the future. For illustration there are some pictures and video, where the most widespread breakages are explained.

Reasons of fuel supply stoppage

Here are the reasons why the fuel doesn’t go into the cylinder:

- Out of gasoline in the tank;

- When starting the engine, you didn’t pump fuel with a primer;

- The primer is defective;

- fuel system is leaking due to improper tilt;. fuel system is leaking

- fuel system is leaking;. fuel system is leaky;

- the gas tank vent is clogged;

- the carburetor is clogged with dirty fuel.

Running out of gasoline

The first sign that the tank is out of gasoline is unstable operation of the motor, which for a few seconds then resets, then briefly rises the speed, sometimes “sneezes”, then stops and no longer starts.

It is not difficult to determine the cause. it is enough to look at the fuel tank. it is transparent, so you can always see the fuel level.

Most often such cause is encountered by inexperienced trimmer owners, who do not know how to determine the time of operation on one fill-up. It does not do any harm to the grass trimmer motor, but after filling the tank with fuel it is necessary to pump the fuel through the system, but if you refill the gasoline before it runs out, you can do without pumping.

When starting the engine did not pump the fuel primer

This reason is also typical for inexperienced trimmer users who have not yet raised the operation to the level of a reflex.

Neglecting to pump the fuel will not have any negative consequences, except worries about a possible machine breakdown, but excessive worrying may result in a machine breakdown.

For example, an inexperienced user who tries to start the engine and fails to do so, begins unknowingly to apply too much force to the starter rope, forgetting to select the free stroke, which may lead to a breakdown of the mechanism.

Primer malfunction

The most common cause of this malfunction is a hanging valve that does not shut off fuel flow in the opposite direction when the primer button is pressed.

To determine the cause of this condition accurately without disassembling the machine, pull the recoil starter 30-50 times, making sure to choose a free move without interruption. If this leads to at least “sneezing” of the engine, then the problem is really in the primer, so the trimmer needs repair.

The fuel system is leaking because of the wrong inclination

Fuel system choke caused by improper tilt is as follows:

- changing the position of the drive shaft changes the angle of the fuel tank;

- the gasoline tends to go down and is carried away from the suction pipe by the force of gravitation;

- air through the intake tube enters the fuel system and after the fuel in the tube and carburetor is exhausted, the engine stops getting gasoline;

- After sucking in even a small amount of air, the rarefaction created by the engine is no longer enough to effectively move the fuel through the system, so even a return to a normal angle of inclination all leads to the engine stop.

The fuel system is leaking

It is the most dangerous reason, because besides the disturbance of gasoline supply to the engine, it can lead to the inflammation of the leaked fuel, which can cause serious burns or fire.

The most common problem is a leaking gasket, or a damaged or dislodged hose.

Any of the defects leads to the suffocation of the fuel system, and the main manifestation is a drop of gasoline and a strong smell.

The fuel tank vent pipe is clogged

Although the fuel system is leak-tight, there is a hole in the gas tank for air to compensate for the wasted fuel. On the vast majority of trimmers, a hose runs through the vent, this protects the fuel from dust and dirt.

The speed of air movement through the tube is slow, so dust or dirt is not sucked into it, thanks to which the fuel is not contaminated. If this tube is clogged, the resulting suction in the tank compensates the suction created by the piston, so the fuel stops moving.

The carburetor is clogged with dirty fuel

Poor-quality gasoline with large amounts of tar and various dirt can clog carburetor passages and disrupt operation of all fuel supply systems.

In different operating modes the engine needs an air-fuel mixture with a certain proportion of air and gasoline, if the proportions change, the engine operation is disturbed.

A faultless carburetor immediately reacts to changes in the operating mode of the power unit, including an increase in load, by adjusting the amount of fuel, but a clog deprives it of this ability. The result can be both a strong drop in power and rpm, or a complete stop of the motor.

Why the gasoline grass trimmer does not start

Gasoline grass trimmer does not start for various reasons, so it requires a step-by-step diagnosis.

Fuel tank (fuel quality)

Remember, always check the presence and quality of fuel before starting your machine. In this case, do not be greedy and save, as well as “smart” about the amount of added oil. It is necessary to do everything according to the enclosed manual, because if the piston group fails, its replacement will cost about 70% of the total cost of the grass trimmer. Use only as much fuel as you can use during the actual job. The remaining gasoline in the tank after some time loses its properties and can harm the engine. Therefore, do not prepare the mixture in large quantities. If the mower does not start well, try draining the “old” fuel from the tank, and refuel with a freshly made mixture.

Important! Filling the machine with fuel of unknown origin is fraught with negative consequences. Gasoline should be of good quality, bought at a gas station and its brand should be at least Ai-95.

Spark plug and spark plug passage

So, you have changed the fuel, but nothing has changed, and the grass trimmer still does not start. In this case, it is worth checking the spark plug channel: whether it does not get covered with combustible mixture. Users often turn the choke to the “OFF” position when starting the engine and then leave it in the “ON” position after starting, and then the engine stalls. Next, the attempt to restart the engine leads to the fact that the gasoline floods the spark plug, and the start becomes impossible. To diagnose and correct a possible problem with the choke, do the following.

- It is necessary to unscrew the spark plug, wipe it well and dry it. When installing the plug in the engine cylinder, it must be dry.

- Drain the fuel which has accumulated in the combustion chamber. This is done through the hole where you unscrew the spark plug.

- if there is soot on the electrodes, remove it with either a fine file or a nail file.

- Don’t forget to adjust the gap between its electrodes before putting the part back in place. The gap on the spark plug should be 1 mm. A coin may be used as a feeler gauge to check the gap.

- Next, reassemble the unit, read the start-up instructions and try to start the engine again.

If the internal combustion engine does not start, you will need to check the spark. To do this:

- unscrew the spark plug;

- put the high voltage wire cap on it;

- touch the metal part of the spark plug to the cylinder head (a socket wrench can be inserted to make contact) as shown in the illustration below;

- pull the starter cord so that several revolutions of the engine happen.

Normally there should be a spark between the electrodes every time the piston is pumped. If there is a spark, then the cause of the fact that the ICE does not start, you need to look in other parts of the machine.

For a better understanding of how to test the spark plug, you can use this video, where the test is shown on the example of the lawnmower “Union”.

If there is no spark, then first check the cable that connects the spark plug to the coil. perhaps the cause is in it. You can test it with a tester. If you find a broken wire, you will need to replace the ignition cable.

Also, if the spark is lost, there may be a problem with the ignition coil (magneto). The picture below shows what the coil (magneto) from the Patriot gasoline grass trimmer looks like (Patriot).

To rule out malfunction, you will need to use a tester to check the grass trimmer’s magneto, namely its primary and secondary windings. The primary winding resistance should be between 0.4 and 2.0 ohms. If the device shows 0. it means that there was a short circuit in the winding, and if infinity. it is a clear sign of a circuit breakage. Resistance on the secondary winding should be within 6 to 8 kOhm.

On some coils it can be as much as 15 kOhm.

Air filter

If your lawnmower does not start well or immediately stops after starting, you should pay attention to the air filter, because it may be clogged, as a result of which air does not enter the combustion chamber and the fuel does not ignite. To see if the filter is the problem, remove it and try starting the engine. If it works, it means the cause is found. Filter must be replaced or well washed and dried before installation. In case you find oil in the air filter, it should be washed with gasoline, squeezed well and dried for at least 2 hours before installing it in place.

If, however, with the air filter removed, the unit still does not start, it is recommended to check the fuel filter.

Fuel filter

This filter cleans fuel from possible impurities. If it is clogged, no gasoline enters the cylinder, and, consequently, the unit does not work or cuts out after starting. The fuel filter is located on the end of the intake hose, which is inside the fuel tank. To get to the filter you need to remove the plug with the tubes coming out of it.

If you remove the plug, the intake hose may disconnect and remain in the tank. Remove it with tweezers.

Next, remove the old fuel filter from the hose and put a new one on it, purchased in advance. You can also clean the fuel filter if you do not have a new. The filter should be secured to the hose with a spring clip.

Install the intake tube on the plug and insert the latter into the tank.

It should be noted that in some models of trimmers, the intake hose is not on the plug, but inside the tank. it can be pulled out with a tweezers or a hook bent from a wire.

The breather

The breather is a check valve, which is designed for equalization of pressure in the gas tank. If it is clogged and does not let air flow toward the tank, then a vacuum is formed inside the fuel reservoir, and the fuel stops flowing into the carburetor. To check the valve, remove the hose that goes from the tank to the carburetor. If there is no petrol coming out of the tank, it means the breather plug is clogged.

Trimmer users often wonder where the breather pipe is? The valve is usually located on the fuel tank lid and looks like the following picture.

Cleaning the breather valve is easy: take it apart and wash all the components. In some chain saws this valve may be located directly on the fuel tank. You can not find it at once, because it is hidden from sight under the starter housing. This breather can be cleaned with an ordinary needle.

The outlet channel

The reason that the grass trimmer has significantly lost power, and when you try to increase the engine speed, it picks them up slowly, is often a blockage of the exhaust duct, through which the exhaust gases exit the combustion chamber.

It is necessary to remove the muffler so that the inside of the cylinder does not get soot. Next, clean the exhaust duct from carbon deposits.

This has to be done very carefully, avoiding fouling the combustion chamber.

After this procedure, weak machine power and slow RPM of the mowing head will no longer frustrate you.

Insufficient compression

If the compression is insufficient, then to start the engine, in most cases, will not work. To check the compression, you can use an automobile compressometer.

- Unscrew the spark plug from the ICE cylinder.

- screw a compressometer in its place.

What compression should be? Normally, compression should be at least 8 kg/cm2. Although even at 8 kg/cm2 some engines do not idle and shut down because the fuel is not sufficiently pumped. In case your petrol mower does not pump more than 8 kg/cm2, you will have to check the cylinder, piston and rings.

You may also notice poor compression from a loose carburetor. Check to see if it is loose. If so, tighten the fasteners holding it well. Also, if the carburetor is loose, you may notice gasoline dripping from the carburetor when it is running.

The gasoline grass trimmer carburetor device

Adjusting the brushcutter carburetor is a process that must be mastered for the grass trimmer to work fully. Grass trimmer is a completely uncomplicated device, which can break only in a few places and require mechanical repair or replacement of the part. Adjusting the device of the carburetor of the float-type brushcutter may require the knowledge of certain subtleties. Nuances due to the model and the specifics of its functioning will ensure a clear mode of mixing and feeding the fuel mixture.

Having excluded the mower filters malfunction, as discussed in a previous publication, it is necessary to make a check of the breather. The breather valve is a part that is responsible for normalizing the pressure in the tank. When the fuel gradually goes from the tank to the carburetor, the pressure increases (vacuum is created). To discharge the vacuum inside the tank, the breather is used. a kind of valve that is located on the tank lid of the tool. The valve has a filter element that filters the air that enters the tank.

Over time, the filter becomes clogged and causes a vacuum in the gas tank. Banal, but in 30% of cases the grass trimmer failure, in the form of inability to start, is associated with a clogged breather. The breather valve on the trimmer can be cleaned and the tool can continue to be used. To make sure that the grass trimmer malfunction is caused by the breather is as follows:

- Unscrew the cap of the gas tank

- If when unscrewing, there will be a bleeding of air, then we can already assume with 100% certainty that the breather plug is out of order

- Screw in the lid and start the lawnmower engine. If the grass trimmer starts, but stops after a while (when the amount of fuel in the tank is reduced), it is necessary to clean the breather plug

The breather plug can be cleaned with a normal sewing needle. Many people don’t even know about this important detail, so they often don’t understand what to do when the lawnmower engine won’t start. Answering the question of the impact of the breather plug on the start of the engine, we must say that it has a direct impact. Excess pressure in the tank prevents the fuel flow to the carburetor, so the engine does not start.