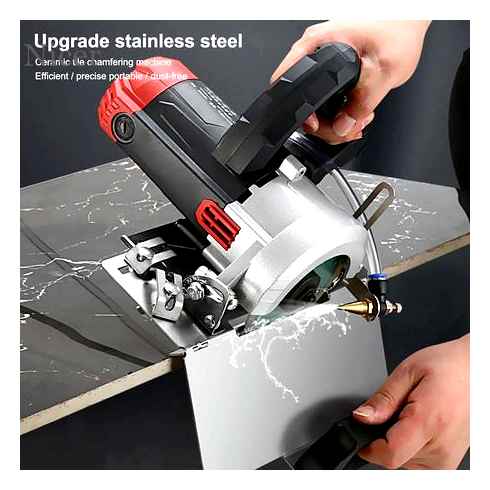

The tool for cutting tiles at 45 degrees

Tile cutters with a 0-45° angle cut

A tile cutter with a 45 degree angle of cut is designed for cutting in tiles according to specified parameters. Thanks to this function it is possible to tile internal and external corners, pipe boxes, niches of all kinds, etc.д. On the reliability and neatness of the joint line between the blanks depends not only on the attractiveness of. An even joint is easier to grout with the achievement of complete tightness, which will protect against the penetration of moisture and dust particles under the tile masonry.

Ceramic tile is one of the most popular and practical finishing materials. It is ideal for rooms with high humidity. the kitchen, bathroom, toilet. Of course, nowadays tiles are used for decorating floors in halls, on the terrace or the veranda.

Work with this material often involves cutting the tile under 45 degrees. Thanks to this design will be aesthetic and attractive.

Tile cutters can be equipped with this function:

- Mechanical. They are the simplest. To operate the mechanism does not require a connection to the network. The tile splits under the influence of a small effort of the craftsman on the cutting mechanism. Manual models are the cheapest and can be used in all conditions. Due to the lightness and compactness they can be easily moved. Usually, they are not designed for material thicker than 16 mm. Despite this, as well as the low performance, the device is popular among professionals and home craftsmen.

- Electric. The 45-degree power tile cutter is much more productive. Here, a cutting disk, often with diamond coating, does all the work. It can cut tiles of any thickness and hardness. It helps in the process of finishing facades of the house with ceramic granite and stone.

These machines have a water cooling system. It prevents the saw blade from heating up, which prevents warping and defects.

Electric models can be table and floor standing. They are easy to transport and take up little space, but do not reach the capabilities of a stationary machine with legs. Floor construction is designed for the most demanding heavy-duty applications.

The method of connecting trim without trimming

Roof strips today are often not trimmed at an angle to be then butted together, but made to butt at right angles. This method of connecting trims does not require any special trimming, which is very convenient. In addition, this method looks more modern and attractive.

If it is still necessary to undercut at an angle this or that part, it is worth stocking the chisel. the simplest device that looks like a small box. The jigsaw has slots designed for a saw or a long, sharp knife. Of course, these slots are made so that they form an even and precise angle of 45 degrees.

However, the crossbeam can have a lot of slots at once, at different angles. It is convenient, because with a single device, you can trim any part at different angles.

Available in adjustable chairs. Slots in such a chair can be adjusted, allowing the master to set exactly the angle required at the moment. In particular, it is quite easy to move the slots of such a chisel to the 45 degree position.

Now the workpiece can be trimmed elementary. Baguette, platband or plinth are placed in the jig, and then a saw is inserted into the slots, and the excess is cut off easily. The angle ends up being perfect, exactly 45 degrees.

What to do if there is no chisel? Very simply. It is necessary to make a template that will not be difficult to transfer the necessary markings on the workpieces. As a template you can choose thick cardboard or something else that will be appropriate in this case.

Using templates

If you do not have a protractor, a plane or ready-made angles, you will need to look for a suitable template. Of course, the template must have the right angle. It is attached to the workpiece and the pencil marks out the workpiece. This is one of the easiest ways to achieve the desired result.

The chisel for cutting pipes with your own hands

The use of a template is not too convenient. you have to make a cut on the mowing line, holding the angle grinder by weight, which leads to large errors. If you have a welder, you can make a simple jig. guides for the disc of the angle grinder, not allowing it to go sideways.

To do this, use a previously made template, in the side of which is drilled a hole and weld the nut. When working, a homemade jig is put on the profile, a bolt is screwed into its nut and the device is pressed against the profile surface. the angle grinder with a disk on metal to make a cut, slightly pressing a disk to the side surface of the device. It is clear that with prolonged work, the edges in the jigsaw gradually grind down, and although the process occurs simultaneously on all edges, over time there will be some inaccuracies. It is therefore better to make the device from hard, wear-resistant metal to increase its service life and obtain a more accurate tool.

Why it is better not to use 45° boring on outside corners

Why are we on the outside corners do not perform zasazhivkuyu under 45 °, and set them to the profiles? This question may arise from many craftsmen. For some reason, the use of all kinds of profiles is considered a low indicator in the work of the master. In this case, we have, as you can see, all around the perimeter of the room there is a glass frieze. Unlike the main tile, it has a pattern on the opposite side, on which the adhesive is applied. If we had done a 45° trim of the entire tile and these friezes, we would have gotten this angle of adjacency:

Then this whiteness can not be restored to its former color by anything. no paint, no grout. So the technically correct thing to do here is not to make any overlaps, and install profiles of stainless steel. They give the room a more advantageous look.

In conclusion I can say: always have a professional technical approach in any case without any prejudice.

Buy tile cutters in F.ua

Wondering where to buy tile cutters? Our online store offers a wide range of products of this group at affordable prices. Tile cutters only from reliable manufacturers and well-known brands.

In Fotoce you can make an inexpensive qualitative purchase for any purse with a real cost from 36 UAH. and up to 30903 UAH., as well as take a loan or installment.

Constant updating with new models, including 2022. Each product card contains the necessary characteristics that include equipment, technical information, a detailed description, photos and feedback from our customers. Frequently updated articles and informative video reviews. will help you choose exactly what you need. It is possible to buy cheap tile cutters as F.ua provides great discounts, sales and promotions.

Call our consultants for a line for a trimmer. and you can find out the terms of delivery, warranty or get more detailed advice from our specialists.

Tile Cutter

Here we are talking about professionals who are engaged in similar work on a permanent basis. The two most popular are the two models of the company Feida:

Despite the fact that they are made by Chinese companies, they have a high quality and precision cutting.

With their help, absolutely any angle of the tile that will be needed for laying is made. Most often it is 45 degrees and is popular.

Also among the companies distinguished by reliability Einhell and Proton.

A lot of problems arise when working with wavy tiles, when the tile cutter touches the glazed part. It becomes scraped and “torn”, which noticeably spoils the appearance. The tile work will usually be done by professionals. After all, no one will buy expensive equipment for personal use. Such work is carried out very rarely:

When ordering a service from a construction firm, it is best to clarify its status and experience in this area beforehand. Not uncommon cases where a large number of tiles are “destroyed”. Every nuance is worth to spell out in advance in the contract, so that later there will be no problems in the proceedings.

The quality of the cut at 45 degrees with a professional tile cutter can be noticed by everyone at once. In addition, the work is carried out in a short time, which allows you to begin laying tiles almost immediately. Such a design of tile corners will be appreciated by every owner of the room where the tiles will be glued.

Using sandpaper

This material is most often used to conceal the inaccuracies of preliminary work, when the glaze is damaged or there are chips. In addition, there is another option of using sandpaper.

Instead of using a professional tool and the necessity to save the glaze layer, the cut on the face is made with a glass cutter. After that, on the back side an angle grinder notch in the shape of “V” is made, which must be made across the entire width of the tile. All that remains is to break the element, and the remaining work is completed with sandpaper.

Some craftsmen try to reduce the cost of the work, using only ordinary sandpaper. In this case the corner grinding of tiles under 45 degrees is done by yourself, watching the condition of the clay and the glaze itself. If you overdo it, the damage will affect the tile, therefore, you will have to spend money to buy a similar material. Significant importance will also play the coarseness of the sandpaper itself, which should vary.

For accurate alignment, two versions of the material to create a bevel of 45 degrees is suitable:

The first numbers will be used as a rough adjustment of the tiles, and the second, to create a really smooth and high-quality surface as much as possible. Only after that you can put the tiles on the corner, without fear, criticism from the outside. If you follow the requirements and recommendations from the experts when making 45-degree cuts, there will be no questions about how to design the corners of the tiles. In the end, you can even say that you got a tile without corners.

For more clarity, you should watch the thematic videos, a selection of which we made just below.

Recommendations for correct tile trimming at an angle of 45 degrees

Cutting tiles at an angle of 45 degrees should be carried out so that the disc of the angle grinder or tile cutter did not reach the glossy surface of the tile about one millimeter. This means that only the clay itself should be cut. That is, only the clay is cut, which acts as the basis of the finishing material. This is due to the fact that this technology helps to make the cut more accurate. When cutting a tile all the way through, there is an increased chance of damaging the glossy surface and causing scratches. Such a defect will be impossible to correct, so you’ll have to throw the tile away or accept its not the most aesthetically pleasing appearance.

In some cases, trimming tiles under 45 degrees forces the master to cut right through the glaze. In this case, experienced craftsmen know a few ways to avoid damage to the glossy tile coating.

In the first place it is recommended to simply cut the tile exactly according to the given dimensions. After that you can begin to grind the received edge at the desired angle. As a result, the obtained cut will be even, neat and beautiful. True, in order to do it right you will need to score a hand. Therefore it is recommended to practice a little on a broken or damaged tile in order not to spoil a lot of finishing material later.

In addition, the edges of the tile can be processed with sandpaper for maximum smoothness and flatness.

Masters also use the method of trimming the corner from the factory edge. At the same time, they hide all the undercuts made by the angle grinder or tile cutter under another tile.

Also : How to drill tile: proper hole drilling

In any case, taking into account the latest trends in bathroom design and kitchen decoration, craftsmen and designers prefer the technology of cutting tiles at 45 degrees than corners. So if you want to create a really comfortable and modern interior, then you have to work a little harder in order to master the technology tile trimming at a certain angle.

Cutting at 90 degrees

To cut evenly across a round pipeline or metal profile with a rectangular cross-section, use a sheet of ordinary paper. They wrap the workpiece so that the edges of the paper sheet coincide, and then it is fixed on the part with tape or glue. Angle grinder draw a thin trimmer line near the edge of the paper sheet, and then gradually deepen it until it is completely cut out.

Metal profile or round tube can be sawed with a template, putting on them evenly cut element with a large inner diameter.

Collar cutter

To obtain the branching of metal pipe lines in the form of T-pieces, a collar cut-in is used, for which it is necessary to cut the edge of the circular tube adjacent to the walls of the other at right angles. To implement the method, proceed as follows:

- cut the edges of the workpiece at right angles with the previously mentioned method.

- On the round end face marker mark four equidistant points located at angles of 90 and 180 degrees to each other.

- Measure the size of the circumference, the resulting diameter divided by 3. From the two diametrically located points the resulting distance is postponed, and then these points are connected to the other two points with a smooth arc, conducting a line for the trimmer with a marker.

- According to the markings make a cut with an angle grinder and separate semicircular segments, after which the part is ready for welding. In case of small inaccuracies in the conjugation, it can be sealed with a sledgehammer by placing it on the round surface of another element.

Tile trimmers

For making figured cuts, you need pliers. In fact, they do not cut the tile, but break off small pieces from it. Because of this, the line for the trimmer is uneven and requires additional sanding.

The tile cutters are designed for making material for mosaics. They began to be used later for ordinary repairs. Pliers in general similar to the usual, but on the bottom they have a diamond roller, and on top of the so-called “jaws”.

To obtain a round notch, a marking is made, and then small pieces are selected. If you need to make a straight cut, you should first use a roller cutter on the glaze. Then you put the roller under the bottom and the jaws on top. When you press the handles, the tile breaks along the line.

Also, pliers are very useful if you need to cut a trimmer line of less than 5 mm from the tile. Other tools will not cope with such a task. It is better to use a construction level, so that the masonry does not go askew on the wall.

Cutting tiles with the glass cutter

The glass cutter is part of the cutter and handheld tile cutter. It can also be used separately from these tools.

Cutting tiles with a glass cutter is carried out according to standard rules:

In order to ensure that the line for the trimmer turns out even, you can make a household machine. For this purpose, 2 wooden bars are used: on one tile is laid, and the second is pressed. The glass cutter is carried out along the line of contact of the upper bar with the tile.

When you need to cut a tile at a 45 degree angle?

Tile trimming. that’s what professional tile trimmers call cutting tiles at the right angle. It is needed to form a beautiful joint of ceramics in the design of exterior corners:

- Boxes for utilities.

- Ventilation shafts.

- Niches, window sills.

- Square, rectangular columns.

- Overhangs.

This preparation of the ceramic material is also necessary when laying diagonally.

Sawing at an angle of 45 degrees is used when working with any tiling material, including mosaics, porcelain tiles. Installation of plastic corners for decorating outer corners when laying material without trimming is rarely used today, because it reduces the aesthetic perception of the design.

The price of tile filing at an angle of 45◦ depends on the quality and properties of the material, its dimensional parameters. Professional craftsmen include this service in the estimate of the work, as it takes a lot of time, requires cutting equipment, as well as the skills to work on it.

Professionalism of a tiler. a key condition for obtaining an even edge for ceramic joints, therefore, invite only experienced craftsmen with qualification for tiling.

What tools are needed for cutting tiles at a 45° angle?

To perform a quality cut on a tile, you can use the following tools:

- An angle grinder is a simple, but skill-intensive tool for machining ceramics at home.

- Electric tile cutter. with its help, you can achieve a perfectly smooth cut, without jagged edges. Working on it is much faster and easier than with other cutting tools.

- Glass cutter. used when it is necessary to cut a small amount of tiles. Labor-intensive, requires time, skill, and additional processing.

Disadvantages of the angle on the tile, sharpened at 45 degrees :

The corner becomes more vulnerable to impact. Especially if located on the aisle. It is enough to catch the slope with an empty metal bucket so that a piece of the emptied corner on the tile flew away. Increases the labor intensity of work, and hence the price.

To catch such a corner can be anything, even a harmless belt buckle of a trouser belt:

Opinion of masters about tile filing on the angle at 45 degrees.

To prepare the angle of 45 on the tiles can also be done with an angle grinder. Lots of dust. The wrong quality. But really. The main thing is cheap and always possible.

It is especially important to mark the correct angle when laying decorative stones. Often the corner elements for such products are not provided or are not available. Cutting stone at an angle of 45 degrees is the only way out of this situation.

Angle on the decorative stone under 45 degrees.

All the pros in one appendix

The master quickly (an hour after the call) came with all the tools, immediately said there were not enough crosses and they need to dokupit (without experience it is impossible to say) finished laying tiles for 1 day. Came the next day, grouted the joints. I was satisfied. I recommend the master. more

Good day to all! I want to write and recommend these guys who at least direct minimum time (14 days) have made repairs in the apartment 35kv.м. This dismantling of floors and walls, construction and screed, laying ceramic granite all plumbing and electrical engineering all you can say from scratch. Я. more

Tilers, Ceramic tiling, Tile work, Tile handling, Tile laying (walls), Tile laying (floor), Tile cutting, Tile cutting in porcelain tiles, Drilling holes in tiles

Was quick to respond. Was at the site the next day. Contracted to install porcelain tile with a slope towards the shower tray. He didn’t limit me in choosing materials, gave recommendations, and calculated the material volume. Well, I bought Ukrainian tiles in Leroy. Batch number matched on all. more

We had to fix the defects of the previous workers. It took a long time to choose a specialist so as not to make a mistake again. And to our luck Akmalzhon responded. I wish there were more such specialists. Removed the crooked mosaic in the shower room, leveled the floor, waterproofed and tiled. Fast.

Tile joint treatment, Tile installation (floor), Tile cutting, Tile removal from floor

There was an urgent order for tiles in the bathroom and toilet. He responded promptly and the next day came with a partner and proceeded to work. Did everything very quickly and efficiently, took all wishes into consideration, and went around all the hard spots. Left behind clean, tidy, and neat. more

Tilers, Tile laying (walls), Tile cutting, Drilling holes in tiles

Repair of the bathroom was carried out perfectly! First we discussed the scope of work, stages and cost, the final price coincided with the original one. Nicholas was always in touch, on all matters promptly communicated with us, clarified details If there was a lack of some materials, Nicholas. more

Ceramic tile laying, Processing of joints between tiles, Tile processing, Tile laying (walls), Tile laying (floor), Tile cutting, Cutting tiles, Drilling holes in tiles

Cutting tile at 45 degrees: how to do it best?

Tile cutting technology at 45 degrees allows you to aesthetically tile any exterior corner when finishing walls with ceramic finishing materials. At the same time it allows you to get rid of the need to purchase and then use special decorative corners, whose appearance can negatively affect the overall design of the room. Plastic and metal corners. it’s not only unaesthetic and unfashionable, but also not practical. Given this fact, it is worthwhile to understand how the trimming of tiles under 45 degrees and what recommendations should be observed in this case.

The technology of grinding the ends at 45 degrees eliminates the need to use decorative corners when finishing exterior corners. Thanks to this it will be possible to create an aesthetic appearance of the wall. Such corners have a neater and more stylish appearance than those trimmed with corners. Agree, it is much more interesting than overlapping tiles or inserted plastic.

Disadvantages of trimming tiles to form outer corners

When using technology for grinding the edge of the tile or porcelain tiles at an angle of 45 degrees there is a thinning of the edge of the finishing material. As a result, its edge becomes very fragile and susceptible to destruction under external physical influences. Therefore, the use of this technology is not allowed for finishing steps and exterior walls in areas with high traffic. In such cases, it is recommended to use special decorative plastic or metal corners.

Technology of cutting a tile on 45 degrees

Working technology of cutting a tile at an angle

When filing tiles at 45 degrees, two main requirements are met: the slope is made as accurate and precise as possible, and 0.5-1 mm of the edge on the front side with enamel is left unsharpened and is scraped by hand.

To meet the requirements of the technology, the work is divided into two steps. At the first one you remove the main excess from a tile with diamond discs, at the second one. the edge is brought to the maximum evenness.

At home, trimming performs with a vice and angle grinder, with the ability to adjust the speed within 1000-2000 rpm, and replaceable attachments (diamond circles, turtles and sanding discs for grinding tiles). If you need to saw a large number of products can not do without the tile cutter. a universal cutting and grinding machine, eliminating errors fixation and the risk of the cutting disc to the side.

How to perform the work with a hand tool

When using angle grinders, the work is carried out sequentially:

- The workpiece is clamped in a vice perpendicular to the edge.

- A disc with a diamond coating is put on the angle grinder.

- The reverse (clay) side of the tile is ground with a disc at an angle of 45 ° or slightly sharper, not reaching the edge of the enamel by 0.5-1.5 mm. The exact value of the indentation depends on the tile texture and thickness of the enamel, on products with a relief or wavy protrusions do it a little more. Throughout the entire step the angle grinder works at minimum speed.

- The bevel is scraped. Tooling depends on the skill of the employee and the budget, if possible at this stage uses the same angle grinder with a diamond wheel or belt sander. As an alternative to diamond wheels are grinding discs with sandpaper on velcro, and a belt sander. wooden blocks with sandpaper.

In the absence of experience in performing such work, the last step is recommended to perform by hand, with a gradual reduction in the grain of abrasive nozzles. Particular attention requires products with dark glaze or texture relief, their factory edges are left untouched if possible and only lightly sanded with sandpaper. To avoid errors, the required distance can be marked with a pencil.