tiller neva gearbox oil change

How to replace the lubricant in the gearbox?

The procedure is as follows.

- Before you start filling with new fluid, you need to drain the old.

- Place the cultivator on a raised platform. This will make it easier for you to drain the lubricant.

- You will find 2 plugs on the gearbox. One of the plugs is designed for draining, it is located at the bottom of the unit. The other closes the filler neck. The filler plug is turned out first.

- Take any reservoir and place it directly under the oil drain plug.

- Unscrew the oil drain plug carefully. The transmission oil will begin to drain into the container. Wait until absolutely all the oil has drained, after which you can screw the plug back into place. Tighten it to the limit with the spanner.

- Insert a funnel into the filler neck. Take the appropriate lubricant.

- Fill it up to the required level. Then replace the plug. Now you need to find out the level of the lubricant. Tighten the plug with the dipstick until the end. Then unscrew it again and inspect.

- If there is lubricant at the tip of the probe, do not add any more.

The procedure for changing the transmission lubricant will depend on the modification of the tiller. But basically, replacement is done after every 100 hours of unit operation. In some episodes, more frequent replacement may be necessary: after every 50 hours. If the cultivator is new, then the initial replacement of the lubricant after running in the tiller must be performed after 25-50 hours.

A systematic change of transmission oil is necessary not only because the manufacturer advises it, but also for a number of other circumstances. During the operation of the cultivator, foreign steel particles are formed in the lubricant. They are formed due to the friction of the components of the cultivator, which are gradually crushed. The oil eventually becomes thicker, resulting in unstable tiller operation. In some cases, the gearbox may fail. Filled with fresh lubricant prevents such unpleasant events and eliminates repairs. Replacing a lubricant is several times cheaper than purchasing and installing a new gearbox.

If you want your technical equipment to function for a long time and correctly, do not ignore the timely oil change. How to maintain and clean the oil filter of the motor cultivator Maintenance of the air filters of the tiller motor must be carried out according to the maintenance intervals indicated by the manufacturer or as needed, if the technical equipment is used in conditions of high dustiness. It is advisable to inspect the condition of the air filter every 5–8 hours of the tiller’s operation. After 20-30 hours of activity, the air filter needs to be cleaned (if it is damaged, change it).

What type of oil should be poured into the motor cultivator

There are many disputes about what kind of oil should be poured into the engine of a home motor-cultivator (tiller). Someone is sure that his views are correct, others deny them, but the only thing that can resolve such discussions is the manual for the unit, created by the manufacturer of the product. Any manufacturer in it prescribes a specific volume of oil to be poured, a method for measuring this volume, including the type of oil that can be used.

What all their positions have in common is that the lubricant should be designed specifically for the engine. Two types of oils can be distinguished. oils for 2-stroke engines and oils for 4-stroke engines. Both the one and the other samples are used for motor cultivators in accordance with which particular motor is mounted in the model. Most of the cultivators are equipped with 4-stroke motors, however, in order to establish the type of motor, you need to familiarize yourself with the manufacturer’s markings.

Both types of oils are divided into 2 types according to their structure. This aspect makes it possible to distinguish synthetic and semi-synthetic oils, or, as they are also called, mineral oils. There is a judgment that synthetics are more versatile and can be used regularly, but this is wrong.

The use of oils is distributed according to the seasonality of the operation of the cultivator. So, some modifications can be used in the winter season. Due to the thickening of natural elements that are susceptible to a drop in temperature, semi-synthetic lubricants cannot, along with mineral ones, be used in winter. However, the same oils are safely used in the summer season and thoroughly protect the equipment.

Thus, the lubricant is used not only as a lubricant for the components of the engine, but also serves as a medium that excellently restrains the soot produced during fuel combustion and metal particles that arise during component wear. It is for this reason that the lion’s share of oils has a thick, viscous structure. To find out what kind of oil is needed for your particular technique, carefully study the manual for the cultivator. The manufacturer specifies what kind of oil must be poured into the motor or gearbox, therefore it is recommended to follow these tips.

For example, for the Neva MB2 motor cultivator, the manufacturer recommends using TEP-15 transmission oil (-5 C to 35 C) GOST 23652-79, TM-5 (-5 C to 25 C) GOST 17479.2-85 according to SAE90 API GI.2 and SAE90 API GI-5 respectively.

Comments 41

Yesterday I disassembled the gearbox. the chain broke! Corrosion of the gearbox mechanism was found, everything that rusted was in the Tad-17 oil, I’m in shock

You can pour any transmission gearbox, pouring Lukoil TM-4 to the top of the filler plug, the one on the gearbox with a hole.

Changed oil every 3 years

8 years operational flight normal!

I have the same motor on a motor-cultivator, the first time the oil was filled with nissan SN 5w30 hydrocracking, now IDEMITSU 10w30 mineral water is filled. and so in the heat it is possible and 10w40 for example went off the HELUX.

in the gearbox, you can either motor oil 10w30 or 10w40 or a transmission, you can also TAD-17.

I always pour nigrol into the gearbox

I poured Lukoil semi-synthetics transmission into the gearbox, into the Shell synthetics 5W-30 engine

I change the oil in the spring both in the engine and in the gearbox, although I use it in the tail and in the mane twice a year. in spring and autumn!

tiller neva almost as in the photo with a 5.5 kw motor oil Tap 15 nigrol

in the motor motel synthetics

Tad-17 from the factory, if memory serves. It will flood for the entire period of operation, unless of course you are not going to drive 100 km on your MB. If the oil seals do not leak, it is possible not to change.

I always pour oil into the tiller, which is according to the instructions, why break your head 🙂

it says there. gear oil gl4 gl5 75-90

there is a lot of things written, but I’m interested in experience from life. if you have nothing to share, then don’t bother

MGB Gearbox Transmission Oil Change in a Chrome Bumper Pre-1974 Car

I just have something to share and share. the gear oil, the class and viscosity of the oil according to the instructions, according to the brand, I think Lukoil behind the eyes, I would change it once every couple of years. tad 17 is expensive. because gearbox repair will cost a pretty penny.

Filled with nigrol, grease for wagons, more than 15 years in operation.

I have Salute, pour TAD-17 into the gearbox

into the transmission. transmission)))) I filled myself with the cheapest 80V90

pour into the motor, what remains of the rushina, never bothered.

for 12 years, changed a couple of times, the engine pleases with an easy start and traction.

this tiller processes about 50 acres in cultivator mode. The first 2 years, even 10 acres of virgin soil loosened, the loads were ogogo.

look in the manual for the SAE parameters and API lei GL-5. it is especially suitable for gearboxes. the volume is also written in the manual. no manual. google to help.

according to the passport tad. but I’m pouring lukoil TM-5 80W-90 API GL-5.

How to change the gear oil on a Land Pride RCR1260

yes MAXIGEAR 75W-90 will go?

suitable, perhaps more expensive. synthetics. I filled the German tiller with the remains of the Shell Spirax S4 G SAE 75W-90.

yes MAXIGEAR 75W-90 will go?

I’m pouring mobil 75w-90

Tiller Salute 6M pour TNK transmission the most common truth a little higher than the level, in winter I do not use.

naturally transmission into the gearbox. I pour TAD

I pour the Japanese analogue of tad 17. sell from kamatsu. and in the motor 10v40 yeni oil. tiller Forte 105 e.

And what the hell does it have to change the oil in it? From the point of view of the unit, a gearbox is an eternal part. However, not such loads so that they bother with varieties of oil.

it is advisable to change the oil once a year, well, in the gearbox a little less often. in the car in the checkpoint. replacement after 70 thousand

Any technical equipment has a complex design, where absolutely everything is interdependent. If you value your own equipment, dream that it will work as long as possible, then you must not only look after it, but also buy good-quality spare parts, fuel and oils. But if you start using low-quality oil, then in the future you will encounter a number of complications and the technique may need repairs. In this note, we will describe which oils (lubricants) are suitable for a particular unit and methods for changing oils in the tiller.

How to choose gear oil

When choosing a gear oil for the gearbox, you should be guided by the information specified in the Operation Manual for the tiller or motor cultivator. The use of oil grades that are not included in the recommended list will lead to accelerated wear of gearbox parts.

| Vehicle model | Applicable gear oils | Filling volume in the gearbox |

| Motor-cultivator MK70 | filled with Litol-24 grease, which does not require replacement during the entire service life of the product | – |

| Motor-cultivator MK100 | filled with Litol-24 grease, which does not require replacement during the entire service life of the product | – |

| Motor-cultivator MK200 | SAE85W-90 API GL-5 | 1.15 l |

| TM-5 GOST 17479.2-85 | ||

| tiller MB2 KS |

TSp-15K (80w90), | 2.2 l |

| TEP-15 (-5 ° C to 35 ° C) GOST 23652-79 (SAE90 API GI-2), | ||

| TM-5 (-5 ° C to 25 ° C) GOST 17479.2-85 (SAE90 API I-5) | ||

| tiller MB Compact |

SAE85W-90 API GL-5 | 1.15 l |

| TM-5 GOST 17479.2-85 | ||

| TSp-15K (80w90) | ||

| tiller MB2 |

TSp-15K (80w90) | 2.2 l |

| TEP-15 (-5 ° C to 35 ° C) GOST 23652-79 (SAE90 API GI-2) | ||

| TM-5 (-5 ° C to 25 ° C) GOST 17479.2-85 (SAE90 API GI-5) | ||

| tiller MB23 |

TSp-15K (80w90) | 2.2 l |

| TEP-15 (-5 ° C to 35 ° C) GOST 23652-79 (SAE90 API GI-2) | ||

| TM-5 (-5 ° C to 25 ° C) GOST 17479.2-85 (SAE90 API GI-5) | ||

| tiller MB1 MultiAGRO |

SAE85W-90 API GL-5 | 1.5 l |

| TM-5 (from 25 to 35) GOST 17479.2-85 | ||

| TSp-15K (80w90) | ||

| tiller MB2 MultiAGRO |

SAE85W-90 API GL-5 | 1.5 l |

| TM-5 (from 25 to 35) GOST 17479.2-85 | ||

| TSp.15K (80w90) | ||

| tiller MB23 MultiAGRO |

SAE85W-90 API GL-5 | 1.5 l |

| TM-5 (from 25 to 35) GOST 17479.2-85) | ||

| TSp-15K (80w90) |

What lubricant to fill in the tiller air filter?

For such purposes, it is recommended to use the same lubricant that is located in the motor sump. According to the recognized standard, the engine oil for 4-stroke engines is used in the tiller engine as well as in the air filter.

In accordance with the season and ambient temperature, it is allowed to fill the engine with seasonal lubricants of the 5W-30, 10W-30, 15W-40 classes or all-weather engine oils with the most extensive temperature spectrum.

Some simple tips.

- Never use additives or additives for oil.

- The lubricant level must be checked when the cultivator is in a level position. You need to wait until the oil is completely drained into the pan.

- If you decide to completely change the lubricant, drain it with a warm engine.

- Dispose of the grease in such a way that it does not harm the environment, in other words, do not pour it onto the ground or throw it in the trash. For this, there are specialized collection points for used motor lubricant.

To learn how to change the oil in the “Neva” tiller, see the next video.

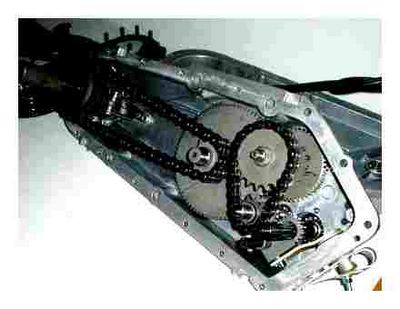

Tillers “NEVA”, as well as motor-cultivators MK100 and MK200 are equipped with mechanical gear-chain reducers housed in aluminum cases. The MK70 motor cultivator has a mechanical chain reducer in a steel case. In order for the gearbox to serve for a long time, it is necessary to regularly carry out maintenance on motor vehicles. For diagnostics and troubleshooting, please contact authorized service centers.

How much grease is required to be poured into the gearbox?

The question of the amount of transmission oil is quite fundamental. Before answering it, you will need to set the lubricant level. This is extremely easy to accomplish. Place the cultivator on a level platform with the wings parallel to it. Take a 70-centimeter wire. It will be used instead of the probe. Bend it into an arc, and then insert it all the way into the filler neck. Then remove back. Inspect the wire carefully: if it is 30 cm stained with grease, then the lubricant level is normal. When there is less than 30 cm of lubricant on it, it must be topped up. If the gearbox is completely dry, then 2 liters of lubricant will be needed.

How to change the oil in the gearbox of a motor cultivator

Maintenance of the gearbox of the NEVA MK200 cultivator should be performed every 250 hours of operation. It is better to change the oil in the gearbox immediately after the work of the equipment, since during this period it is easier to drain the oil.

In order to change the oil in the gearbox of the motor cultivator, you should perform the following steps:

- Set the cultivator to a vertical position

- Place a container of at least 2 liters under the gearbox

- Unscrew the breather plug, clean it from dirt

- Unscrew the oil drain screw, drain the oil from the gearbox

- After draining the oil, screw in the oil drain screw with gasket and tighten the screw. Dispose of oil at a waste oil collection point.

- Fill in fresh gear oil of 1.15 liters of the appropriate grade and operating temperature through the hole for the breather plug

- Screw in the breather plug.

Changing the oil in the tiller neva gearbox

Share your experience, who pours what kind of oil into the gearbox and how much? thank.

Repairs and malfunctions

If necessary, repair work will require a complete analysis of the mechanism. A complete cleaning with lubricant drainage is also required beforehand. Only after that the unit is disassembled and visually inspected with checking the details. If there is a need to replace a part, then you will have to buy a native element or an analogue, which is provided for this model of the Neva.

- spring or clips are damaged. After replacement, adjustment is made;

- the switching system has out of order. The screws are loosened and, after engaging the first gear, they are tightened again;

- oil began to ooze. Oil seals are being replaced;

- jammed. Chain change required;

- there is no transmission fixation. Replacing the fork brush.

It should be borne in mind that most problems can be avoided if you constantly carry out a full inspection and technical inspection. It is also important to remember and not violate all prescribed operating conditions.

Multiagro

Reducer Multiagro is a special version of the mechanism, which was patented specifically for the Neva. It has a number of features:

- the number of gears has been increased;

- the gear ratio is increased, which makes it possible to increase thrust with a small expenditure of power;

- wheels (right and left) are separated, which is necessary for the minimum size of the radius when cornering. This allows for a significant increase in maneuverability;

- resistance to higher loads by means of a more powerful body, which is reinforced with stiffening ribs in the inner side of the body;

- the body part is sealed with a special silicone-based sealant;

- the shape is streamlined, which reduces the resistance during tillage.

All these features allow the tiller to get additional features that are often inaccessible to competitors.

This gearbox was made specifically for the tiller neva

How to change the oil seal

The oil seal can be changed in a simple way. This is necessary if oil starts leaking. Old elements are pry off with a screwdriver, after which new ones are inserted.

Experts recommend, after removing the old oil seals, to clean the entire surface, which will affect the duration of the subsequent elements.

What are the tiller gearboxes: varieties and purpose

There are two main options for the engine used in the Neva. gasoline and diesel. The electric type is rarely used. The gearbox does not change its purpose from this. By type, mechanisms can be of various options:

- chain. There is a chain of metal character, with the help of which the stars are scrolled. There is a bolted connection. Among the advantages are convenient operation and reverse function;

- gear-worm is used for vertical crankshaft. Features include a high level of performance and minimal noise. Made from different alloys. Steel and cast iron can be used;

- in the belt version, a rectangular or V-shaped belt is used instead of a chain. The belt strip is fixed with pulleys, in which there are grooves;

- the gear version depends on the design, which can be either angular or straight. The gear itself is mounted on shafts and has the shape of a cone or cylinder. This type of gearbox is rarely used as it is difficult to maintain. Most often installed on professional-type equipment, as it has high power.

There may also be homemade options that combine different types.

Important! All gearboxes, regardless of their purpose, must receive high-grade and high-quality oil for lubrication, since wear gradually occurs.

How to change oil

Most often, the oil change rate depends on the engine and its performance. Changing the oil in the gearbox can be done in conjunction with changing the engine lubricants. It all depends on the type of engine:

- Robin Subaru. First replacement process after 20 hours of working procedure and then every 100 hours.

- Honda and Lifan. 20 hours, and then after 6 months.

- Briggs Stratton. 5 hours. Subsequently, a regular check is carried out after 8 hours. A complete replacement process must be carried out every 50 hours of operation.

Important! The established standards for motors may differ for the gearbox, since everything here will depend on the intensity of work. The best option would be to completely change the transmission oil every 50 hours, as well as after downtime or repair work.

- the technique is placed vertically without even a slight tilt;

- the breather is unscrewed and cleaned;

- after unscrewing the screw, the oil is drained into a container of at least 3 liters;

- the screw is returned and tightened;

- oil is poured;

- the breather closes;

- the efficiency of the equipment is checked.

Do not forget to follow the instructions for changing the oil

This is a standard lubricant change plan.

It should be borne in mind that, according to standard recommendations, the frequency of change is regulated in the following order:

- running-in. 30-35 hours;

- simple. 1-2 years;

- working process. 150-200 hours.

These parameters are set for workflow without increased tiller load. In the case of an enhanced operation, it is better to change the oil every 50 hours of operation, which will allow the entire lubrication system to not clog. This will increase the chances of a full-fledged work without breakdowns.

What kind of oil to fill

It is necessary to fill in oil together with the lubrication of all parts, as well as with an oil change in engines.

Important! Different types of oil are poured into the engine and gearbox. Transmission oil is poured into the Neva gearbox.

What kind of oil to pour into the tiller’s gearbox and how much depends on various nuances, including the season of operation.

Engine oil is poured into the engines, which must not be poured into the gearbox.

The choice of oil depends both on the season in which the work is performed and on the data specified in the operating instructions.

According to Tiller models, transmission oil is distributed according to GOST:

- TEP-15, TM-5;

- TAP-15V, TAD-17I.

This is a standard that is spelled out in accordance with the corresponding GOST 23652-79.

Oil for Tiller Neva must be of high quality and from a good manufacturer. this is a prerequisite.

It is worth considering that each oil is used only in the allotted period. For example, TEP-15 is used in the summer. The minimum temperature limit is –.5 degrees. If the temperature is lower, then you will have to use TM-5, which has a minimum of 25 degrees of frost. The specified oils are also used in various modifications.

How much oil to fill in the gearbox

How much oil to fill in by volume depends on the intensity of work, since in this case the lubricant is consumed faster or slower.

The standard volume of the required level is 2.2 liters.

The gearbox has a control hole with a bolt. If you unscrew it, then oil will pour out. In this case, you will need to top up it until it flows. After that, the control bolt is tightened and the filler cap is closed. All residues of lubricant are removed from the surface with a dry cloth.

Important! Lubricant must always be available and filled. You cannot work without this. If necessary, the level can be checked with a dipstick.

When checking with a dipstick, it is necessary to wait until the equipment has completely cooled down. Otherwise, the level will be shown higher than it is.

If the level is not constantly monitored, then the gearbox may need to be repaired in the future.

Gearbox device

The tiller gearbox allows the use of additional equipment, which receives revolutions from this particular mechanism. The device itself and the principle of operation are similar to elements of other models.

Important! When assembling the Tiller Neva gearbox, the structural features and the device must be taken into account first of all, since if the arrangement is incorrect, the mechanism will not work.

The device is responsible for the rotary transmission that goes from the engine to the wheel system and additional attachments. It turns out that there will be no movement without a mechanism, since it is a control tool for the rotational number, speed and direction of movement.

The mechanism has an element for gear shifting. It is located in the upper case. The lever includes the 5th position in its location. When pressed with a fork, the clutch is disengaged from the clutch. If the lever is released, the fork reverses back.

In this video, you will learn how to change the oil:

Moto Guzzi Breva 750 Gearbox & Bevel Drive Oil Change

To slow down the technique, the drive is connected to the right-hand axis. The torque is generated from a sprocket located near the input shaft. If the lever is pressed, then the left sprocket engages, which leads to a low gear. For top gear, the handle is set to the limit.

All design features are required to know when correcting breakdowns and malfunctions.

How to choose gear oil

When choosing a gear oil for the gearbox, you should be guided by the information specified in the Operation Manual for the tiller or motor cultivator. The use of oil grades that are not included in the recommended list will lead to accelerated wear of gearbox parts.

| Vehicle model | Applicable gear oils | Filling volume in the gearbox |

| Motor-cultivator MK70 | filled with Litol-24 grease, which does not require replacement during the entire service life of the product | – |

| Motor-cultivator MK100 | filled with Litol-24 grease, which does not require replacement during the entire service life of the product | – |

| Motor-cultivator MK200 | SAE85W-90 API GL-5 | 1.15 l |

| TM-5 GOST 17479.2-85 | ||

| tiller MB2 KS |

TSp-15K (80w90), | 2.2 l |

| TEP-15 (-5 ° C to 35 ° C) GOST 23652-79 (SAE90 API GI-2), | ||

| TM-5 (-5 ° C to 25 ° C) GOST 17479.2-85 (SAE90 API I-5) | ||

| tiller MB Compact |

SAE85W-90 API GL-5 | 1.15 l |

| TM-5 GOST 17479.2-85 | ||

| TSp-15K (80w90) | ||

| tiller MB2 |

TSp-15K (80w90) | 2.2 l |

| TEP-15 (-5 ° C to 35 ° C) GOST 23652-79 (SAE90 API GI-2) | ||

| TM-5 (-5 ° C to 25 ° C) GOST 17479.2-85 (SAE90 API GI-5) | ||

| tiller MB23 |

TSp-15K (80w90) | 2.2 l |

| TEP-15 (-5 ° C to 35 ° C) GOST 23652-79 (SAE90 API GI-2) | ||

| TM-5 (-5 ° C to 25 ° C) GOST 17479.2-85 (SAE90 API GI-5) | ||

| tiller MB1 MultiAGRO |

SAE85W-90 API GL-5 | 1.5 l |

| TM-5 (from 25 to 35) GOST 17479.2-85 | ||

| TSp-15K (80w90) | ||

| tiller MB2 MultiAGRO |

SAE85W-90 API GL-5 | 1.5 l |

| TM-5 (from 25 to 35) GOST 17479.2-85 | ||

| TSp.15K (80w90) | ||

| tiller MB23 MultiAGRO |

SAE85W-90 API GL-5 | 1.5 l |

| TM-5 (from 25 to 35) GOST 17479.2-85) | ||

| TSp-15K (80w90) |

Gearbox malfunctions and repairs

Like any other technique, tillers can also fail. If the problem lies in the gearbox, you need to disassemble and repair it. Often the breakdown turns out to be insignificant and you can easily cope with it yourself.

First, you need to thoroughly clean this part from dirt and oil residues, which will also need to be drained. All parts must be inspected and checked for damage. If something is out of order, it needs to be replaced. Use only new elements that are suitable specifically for your Tiller Neva model. Also, do not forget to add oil after assembly.

Some common gearbox failures:

- broken spring or clips. They need to be replaced with new ones and then adjusted;

- in the switching system, the settings are lost. You need to loosen the screws, turn on the first gear, tighten the screws back;

- oil oozes through the shaft. Most likely the reason is the cuff, which is worn out. It needs to be replaced with a new one. How to replace oil seals? It is enough to remove the old ones by prying them with a screwdriver or other object and install new ones;

- jamming appeared. Perhaps this is due to an open circuit. It needs to be replaced with a new one;

- cannot commit the transmission. The reason is that the fork brush is worn out, so it needs to be replaced.

These are the main and most common gearbox failures. It is very important. if you cannot fix the breakdown yourself, then you should seek professional help.

How much grease is required to be poured into the gearbox?

The question of the amount of transmission oil is quite fundamental. Before answering it, you will need to set the lubricant level. This is extremely easy to accomplish. Place the cultivator on a level platform with the wings parallel to it. Take a 70-centimeter wire. It will be used instead of the probe. Bend it into an arc, and then insert it all the way into the filler neck. Then remove back. Inspect the wire carefully: if it is 30 cm stained with grease, then the lubricant level is normal. When there is less than 30 cm of lubricant on it, it must be topped up. If the gearbox is completely dry, then 2 liters of lubricant will be needed.

How to change the oil in the gearbox of a motor cultivator

Maintenance of the gearbox of the NEVA MK200 cultivator should be performed every 250 hours of operation. It is better to change the oil in the gearbox immediately after the work of the equipment, since during this period it is easier to drain the oil.

In order to change the oil in the gearbox of the motor cultivator, you should perform the following steps:

- Set the cultivator to a vertical position

- Place a container of at least 2 liters under the gearbox

- Unscrew the breather plug, clean it from dirt

- Unscrew the oil drain screw, drain the oil from the gearbox

- After draining the oil, screw in the oil drain screw with gasket and tighten the screw. Dispose of oil at a waste oil collection point.

- Fill in fresh gear oil of 1.15 liters of the appropriate grade and operating temperature through the hole for the breather plug

- Screw in the breather plug.

Do I need to fill and change the oil in the air filter of the motor cultivator?

In the vast majority of situations, it is enough just to slightly saturate the air filter sponge with machine oil. However, air filters of certain modifications of tillers are in an oil bath. in such a situation, lubricant should be added to the level marked on the oil bath.

What type of oil should be poured into the motor cultivator

There are many disputes about what kind of oil should be poured into the engine of a home motor-cultivator (tiller). Someone is sure that his views are correct, others deny them, but the only thing that can resolve such discussions is the manual for the unit, created by the manufacturer of the product. Any manufacturer in it prescribes a specific volume of oil to be poured, a method for measuring this volume, including the type of oil that can be used.

What all their positions have in common is that the lubricant should be designed specifically for the engine. Two types of oils can be distinguished. oils for 2-stroke engines and oils for 4-stroke engines. Both the one and the other samples are used for motor cultivators in accordance with which particular motor is mounted in the model. Most of the cultivators are equipped with 4-stroke motors, however, in order to establish the type of motor, you need to familiarize yourself with the manufacturer’s markings.

Both types of oils are divided into 2 types according to their structure. This aspect makes it possible to distinguish synthetic and semi-synthetic oils, or, as they are also called, mineral oils. There is a judgment that synthetics are more versatile and can be used regularly, but this is wrong.

The use of oils is distributed according to the seasonality of the operation of the cultivator. So, some modifications can be used in the winter season. Due to the thickening of natural elements that are susceptible to a drop in temperature, semi-synthetic lubricants cannot, along with mineral ones, be used in winter. However, the same oils are safely used in the summer season and thoroughly protect the equipment.

Thus, the lubricant is used not only as a lubricant for the components of the engine, but also serves as a medium that excellently restrains the soot produced during fuel combustion and metal particles that arise during component wear. It is for this reason that the lion’s share of oils has a thick, viscous structure. To find out what kind of oil is needed for your particular technique, carefully study the manual for the cultivator. The manufacturer specifies what kind of oil must be poured into the motor or gearbox, therefore it is recommended to follow these tips.

For example, for the Neva MB2 motor cultivator, the manufacturer recommends using TEP-15 transmission oil (-5 C to 35 C) GOST 23652-79, TM-5 (-5 C to 25 C) GOST 17479.2-85 according to SAE90 API GI.2 and SAE90 API GI-5 respectively.

How to replace the lubricant in the gearbox?

The procedure is as follows.

- Before you start filling with new fluid, you need to drain the old.

- Place the cultivator on a raised platform. This will make it easier for you to drain the lubricant.

- You will find 2 plugs on the gearbox. One of the plugs is designed for draining, it is located at the bottom of the unit. The other closes the filler neck. The filler plug is turned out first.

- Take any reservoir and place it directly under the oil drain plug.

- Unscrew the oil drain plug carefully. The transmission oil will begin to drain into the container. Wait until absolutely all the oil has drained, after which you can screw the plug back into place. Tighten it to the limit with the spanner.

- Insert a funnel into the filler neck. Take the appropriate lubricant.

- Fill it up to the required level. Then replace the plug. Now you need to find out the level of the lubricant. Tighten the plug with the dipstick until the end. Then unscrew it again and inspect.

- If there is lubricant at the tip of the probe, do not add any more.

The procedure for changing the transmission lubricant will depend on the modification of the tiller. But basically, replacement is done after every 100 hours of unit operation. In some episodes, more frequent replacement may be necessary: after every 50 hours. If the cultivator is new, then the initial replacement of the lubricant after running in the tiller must be performed after 25-50 hours.

A systematic change of transmission oil is necessary not only because the manufacturer advises it, but also for a number of other circumstances. During the operation of the cultivator, foreign steel particles are formed in the lubricant. They are formed due to the friction of the components of the cultivator, which are gradually crushed. The oil eventually becomes thicker, resulting in unstable tiller operation. In some cases, the gearbox may fail. Filled with fresh lubricant prevents such unpleasant events and eliminates repairs. Replacing a lubricant is several times cheaper than purchasing and installing a new gearbox.

If you want your technical equipment to function for a long time and correctly, do not ignore the timely oil change. How to maintain and clean the oil filter of the motor cultivator Maintenance of the air filters of the tiller motor must be carried out according to the maintenance intervals indicated by the manufacturer or as needed, if the technical equipment is used in conditions of high dustiness. It is advisable to inspect the condition of the air filter every 5–8 hours of the tiller’s operation. After 20-30 hours of activity, the air filter needs to be cleaned (if it is damaged, change it).