Tools and appliances for furniture assembly

Tools for making and assembling furniture

With it we will screw in screws and mortars, and fasten the furniture accessories. Of course, you could also do with an electric drill, but this will cause some inconvenience: you will often need to monitor the length of the wire, as well as to change the screw and screwdriver bits and bits.

If you decide to collect only one table or a closet compartment, it is quite suitable and inexpensive electric screwdriver, but if you decide to seriously engage in furniture business, then take the expensive (you can use the manufacturer Makita). Although considerably more expensive, it can replace 2 or 3 cheaper tools.

But it is not necessary to chase the brand name. These are the indicators that you should pay attention to when choosing an electric screwdriver:

- A quality charger. The so-called “hour charge” will kill your electric screwdriver in a couple of months, the optimal charging time is about 6 hours;

- At least 8 power modes and a separate mode for drilling;

- Heavy, but easy to use;

- Quick-action chuck and smooth running.

Hexagonal Key for a screwdriver

Initially you may need a wrench to tighten the screws gently. You can practice with it for a while and then use a special screwdriver bit with an electric screwdriver.

Screwdriver

It is better to get a reversible screwdriver with interchangeable tips. It comes in handy not only for furniture assembly, but also for household chores. Do not spare money, get a quality screwdriver at once.

Confirmation drill

It is designed for pre-drilling holes for mortar screws.

- Makes a 5 mm diameter hole for the body of the screwdriver,

- Thanks to the additional notches, it makes an enlarged 7 mm hole under the neck of the faceplate (to avoid breaking the chipboard),

- countersinks the hole for the face plate of the faceplate (so that it sinks completely into the chipboard).

Forstner bit

You will need a 15 mm diameter drill bit for installing reamers and minifixes

Drill bit for furniture hinges

Drill bit with 26 mm diameter for shaping recesses for furniture hinges

Screwdriver bit

Bit (nozzle) under the screws is very useful when assembling cabinet furniture, in fact, replaces the “manual” hexagon.

Use an awl to make a pilot hole before drilling, to prevent the drill from slipping and to make a straight hole in the right place.

Pencil

It is needed for marking, it is better to use a pencil of medium hardness (HB).

Tape measure

Do not take a tape measure with a very wide sheet, and a length of up to 3 m is sufficient.

Corner

You will be needed for marking the Particleboard and Particleboard, as well as for holding the angle of 90 degrees, when fixing the perpendicular fasteners.

Sandpaper

The paper should be fine-grained. Needed for sanding sharp edges on end-faces Particle board or for removing sharp corners in fronts Particle board.

It performs the same functions as a hair dryer, but will be a little slower. It is useful for gluing paper or plastic edges, but not thicker than 0,5-1 mm.

An additional tool

In addition to these tools you need to prepare additional tools for the furniture collector. Among them:

- Furniture stapler. Whether used for drapery or upholstered furniture assembly, as well as in cabinet making. “Powerful” mechanical device will be able to fasten the backs or bottoms of woodchipboard drawers. The device is also used in the restoration of old furniture products that need to be draped. When choosing accessories, it is better to give preference to models with a push handle made of metal and support for adjustment. This will allow the use of staples with different sizes and parameters.

- Hexagon key for screwing in Euro screws. The tool is considered quite in-demand and necessary for fixing screws with a 6-sided slot in hard-to-reach places, which are difficult to reach with a simple screwdriver or an electric screwdriver. For the production of upholstered furniture on an industrial scale this item is not suitable, because after screwing in a couple of dozens of fasteners the hand gets very tired. Even products are made of soft materials, so that in the process of operation their edges strongly erase.

- A construction hair dryer. The device is used for gluing the PVC film on the end pieces of furniture.

- Knife jamb. Designed for trimming edges of PVC.

- Shaper. Necessary for milling the ends of parts.

Besides a set of screwdrivers and wrenches, you need to take a hammer, mallet, pliers, and measuring tools. The tool you choose should be as high quality, comfortable and accurate as possible. For more complex tasks, you can create machines for furniture with your own hands.

When you make your own furniture, it is necessary to use professional equipment, including a router. It is a specialized device with increased power indicators, which is designed for making holes and installation of built-in furniture.

As you develop your home business, you will need to purchase a circular saw or other cutting element that allows you to make accurate and precise cuts in wood blades, panels and countertops. The task of the mitre saw is to cut at an angle.

In addition to wood, this tool can also be used for cutting aluminum profiles. Support for high-speed cutting ensures accurate geometry and a smooth cut. The machined surface is devoid of chips and cracks.

Another useful accessory for the workshop is the jigsaw. It allows you to replace the electric saw with a hand hacksaw. The design is used for making angle cuts without using professional equipment.

When equipping a room for home furniture making, you need to consider a lot of factors and be consistent, buying tools as needed. It is recommended to start with simple designs and amateur systems, gradually improving your skills and craftsmanship.

Then you can go on to a more sophisticated tools and buy equipment for professionals. But since it costs quite a lot, you should assess the pros and cons in advance, and not waste money. But choosing budget items of dubious quality is also not the solution. Such a mistake often entails high costs.

Tools for assembling furniture with their own hands

In order to save money, many homeowners and apartment owners decide to do the assembly of purchased or ordered furniture with their own hands. Indeed, everything can be done on their own, but you need helpers, special tools. Website RMNT will tell you exactly what you need to assemble furniture with your own hands.

Rmnt portal. than once, we wrote about what tools will need a home handyman to perform a variety of tasks. We wrote about a set of tools for electrician, woodcarver, blacksmith, mason, gardener. Now it is time to talk about the minimum set of tools for the furniture maker, or rather, someone who has decided to become him temporarily, to assemble a hallway, closet compartment or kitchen set with his own hands.

The first thing you need to measure in order for everything to be flat, smooth, beautiful. For this you will need:

- A level.

- A pencil for marking.

- Angle, to maintain right angles, it is most often needed to install shelves.

- A tape measure for setting the diagonal of any furniture, as well as to accurately fix the bottoms of drawers and the back wall.

Undoubtedly, the most important tool is a screwdriver. With it you will quickly and reliably screw self-tapping screws, dowels, screws and other fasteners. Drill also helps to drill holes for handles, sometimes used for milling for hinges, mini-fixes and rafixes.

Important! You will need special nozzles for screws and screws, take care of their availability in advance.

A jigsaw. It is better, of course, electric. It will be needed when you need to cut a hole for the sink in the tabletop of Laminated chipboard, cut a place for the socket, to trim individual pieces of furniture.

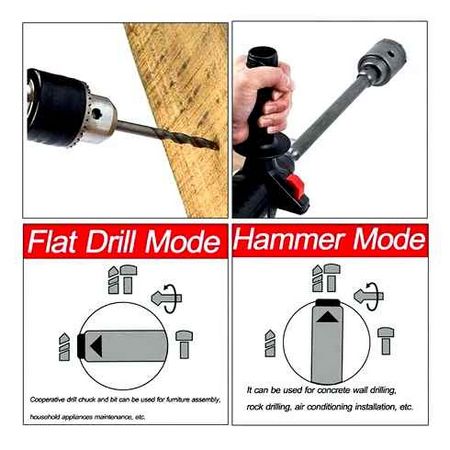

Peorator. Needed when you need to drill holes to attach bookshelves, the top row of kitchen cabinets and so on to the wall.

Hardware, staple gun. Needed not only for upholstery. 15-millimeter steel staples are used to attach the backsides and bottoms of drawers.

Screwdrivers. Most often you need flat and Phillips. Despite the fact that the mounts you will screw in a screwdriver, screwdriver comes in handy to delicately bring everything to the desired strength, adjust the door opening, tightening minifixes and rafixes.

Set of hexes. They are most often used to adjust closet doors, as well as to tighten many special furniture fasteners.

A box cutter or a jamb cutter. You’ll need it for the first phase, when you need to free the details of your future cabinets or kitchen sets from the packaging. It can then be used to trim the door sealing brushes and trim the PVC edge.

In addition, you may need:

- A silicone sealant gun, if you are installing the sink in the kitchen countertop or sealing something else.

- Clamps to clamp some parts for trimming or to fix them temporarily before fixing them.

- Pliers.

- A hammer to adjust the tight-fitting parts.

- Sliding wrench if you assemble upholstered furniture.

- Confirmative drill bit.

Most of the tools we’ve listed are just necessary to assemble cabinet or upholstered furniture quickly and effortlessly. We’re sure you can manage by following the manufacturer’s instructions, as well as through handheld and electric helpers.

What tools you need to assemble furniture

Principle! If you only deal with carpentry work occasionally, a small, cheap model is completely sufficient for you. If you want to make furniture items your own business, it is better to buy an expensive model with good functionality.

- Hexagonal screwdrivers for screwing them in gently.

- Screwdriver. According to the opinion of professionals, a reversible model with interchangeable bits is the balanced option. A high quality screwdriver with good bits is not only needed for furniture construction, but also for repair work.

- Drill bits 4.5, 7.5 and 10 mm across.

- Screwdriver. It is used for preparatory drilling of holes for mortars. The normal version is a 5 mm across hole. Additional notches allow you to drill extended holes up to 7 mm.

Principle! With the help of drill bit also countersinking of holes for the faceplate of the screwdriver for the full penetration into the chipboard. This is an indispensable tool for assembling furniture made of particleboard.

- 15 mm Forthner drill bit. This tool is needed when making furniture with your own hands to make holes for the installation of minifixes and rasteks.

- Drill bit for furniture hinges with a cross section of 26 mm.

- Concrete bit.

- Dagger, for piercing before drilling work. This prevents the drill from slipping.

- Medium-hardness (HB) pencils for markings.

- Tape measure. completely sufficient for three meters.

- Corner. To be used for checking the perpendicularity of fasteners, also for marking when working with chipboard and particle board.

- Fine sandpaper. Grinding sharp edges on chipboard ends or removing sharp corners on facades made of chipboard is a great sanding solution.

- Iron (it is occasionally substituted with hair dryer). used for gluing cardboard or narrow plastic edges.

What tools are needed for assembling furniture with their own hands

Hi there! Even if you are not a professional furniture maker, but rather an amateur, you may still be interested in a tool for assembling furniture.

Buying furniture, in extremely rare cases it comes already assembled. Basically, these are the elements of the design that need to be combined with each other. This is how to buy items of upholstered furniture, kitchen furniture, cabinet furniture, etc. In front of you a set of parts and fixtures. It does not matter if it is made of particle board, laminated particle board, solid wood or even natural wood.

In the arsenal of the furniture maker there is always a certain set of tools that allows you to save on the services of assemblers from the store, and create everything with your own hands.

If you want to do the assembly yourself, then you will need to assemble a certain set to make ready-made structures. Something you already have at home, other components are easy to buy in Ikea or similar stores. All tools, which can be useful during assembly, conditionally divided into marking and assembling (fixing).

Measuring tool for furniture making

At all stages of making furniture with their own hands will need a measuring tool. Even if you just want to assemble the finished furniture IKEA. you can not do without measurements.

- Markers and pencils. Markers are taken of different thickness, mainly alcohol, which are easily erased when there is no need in the marker.

- Measuring tape and square. It is worth responsibly treat the choice of this measuring tool and give preference to those options where there will be no doubts about the accuracy of calibration.

- The awl. With the help of an awl and a pencil is convenient to mark places for screwing screws and holes for mortars, shelf supports and other fasteners.

- Level. Strictly speaking, this tool for making furniture with their own hands will be needed only at the very initial stage. measurements. To properly develop a design project built-in closet, it is important to consider the curvature of the walls and the difference in the horizontal and vertical planes. You will also need a spirit level to install the assembled modules.

- Furniture templates and jigs. Prefabricated furniture guides for marking holes for runners, hinges, handles and other fixtures greatly simplify the process. After all, in fact, all connecting holes in furniture are applied in the same way, according to the well-known “system 32”.

Furniture templates for marking furniture parts can be purchased ready-made.

Or make your own hands from thick cardboard, remnants and scraps of thin plastic, fibreboard, HDF.

Necessary tools for furniture making

Of the variety of joinery tools, the tools of choice are those for screwing, drilling, cutting and measuring.

In a set for his own workshop include the first steps only necessary. it will be enough to make your own furniture:

For quality and uncomplicated work, the list of mains or cordless tools is as follows:

The tool does not have to be cordless electric.

Cordless models are well represented in today’s range.

In the process of gaining skills and moving on to more complex tasks, the list can be gradually expanded.

Drill

The drill is a basic component of any workshop for furniture making.

An electric drill with impact function and an electric screwdriver are sufficient for the first steps.

Availability of such additional options will save on the purchase of a torch and an electric screwdriver.

If capabilities allow, then the best choice is a cordless electric drill.

Essential Tools & Tips For Assembling Furniture (from a Tasker) NEW Tool Update

Thanks to the impact mechanism to work with hard surfaces, produce assembly and installation of built-in or cabinet furniture.

You can use the variable speed control to adapt the RPM to your needs: drilling for metal or wood, tightening screws, or the pulse or impact function.

An electric screwdriver

Electric screwdriver. it is also one of the main specialized “tools” carpenter for assembling and manufacturing furniture.

Functions include installing furniture fittings, screwing and drilling.

Modern models are equipped with a pulse and impact function, and the introduction of battery technology allows you to organize a convenient work process even in the absence of electricity.

Quick-change chuck allows you to change accessories in the blink of an eye to perform various operations.

Two torque speeds are just as useful.

Working time depends on battery capacity.

When choosing an electric screwdriver, you should pay attention to the presence of two batteries. a spare power supply will not interrupt the work during recharging.

Jigsaw

Electric jigsaw. this tool allows you to cut shaped furniture and its parts with high precision.

- sawing blades;

- Making cutouts for built-in appliances;

- size matching;

- Curved or rounded catches, etc.д.

The jigsaw mechanism is designed to adjust speeds and change the inclination of the cutting blade.

Special saws are used for metal work.

Grinder

Grinder intended for stripping and leveling the surface or mowing the cut line.

It’s great for removing varnish, old paint or pretreating the substrate before painting.

Measuring tools

Measuring tools for self-made furniture:

hand tool

Hand-held tool for the first experiments in furniture production compares favorably with electric counterparts in terms of cost, but loses in performance.

However, some models are nowadays indispensable.

It is used for upholstery furniture and installation of thin walls of organite, plywood, etc.

Accessories and consumables

One of the important tools for furniture making is a workbench.

The work table should be equipped with a vice and a clamp to securely hold the elements.

Of the working tools you will need the following set:

- drill bits for wood for holes with a diameter of 20 to 130 mm; for metal and wood, with a diameter in the range of 2-12 mm;

- Forstner drills for drilling non-boring flat holes, such as for hinges;

- Drills with extra hard tip for concrete, brickwork.

What it is

In talking about what tools a furniture maker needs, I left out such an important thing as a work jig. I can not say that it is an element of the first necessity, but without it to solve some tasks is much easier and faster.

Furniture conductors are fairly simple mechanical devices. They are needed to simplify and speed up the drilling process of various holes. Using such an object, you can make a hole according to the markings and with optimum accuracy and the required angle of inclination. It is actively used in the process of assembling furniture, in various carpentry tasks. The conductor is well suited for use in the home, since it can always be made with one’s own hands, or one can purchase a small tool for personal use.

It is essentially a template for holes with different diameters. The main part of the tool is presented in the form of a bar of rectangular shape, made of durable material. There are holes on the bar.

Many models have additional adjustment and locking mechanisms, so as to make working with the conductor easier. If you want or need, you can make the tool with your own hands. And sometimes the result is not worse than Cheiron.

Using the conductor the drill moves in a given direction and creates a hole of the required size. The material is drilled at a right angle of 90 degrees. Some models allow you to adjust the angle or they initially have a certain slope. Avoiding deviations is very important when working with thin materials, end pieces of doors and walls. Correct angles are difficult to achieve by hand. Often there are a lot of rejects, you have to waste unnecessary material.

The conductor is designed for drilling all materials used in furniture production, including wood. Particleboard and fibreboard.

If you need to perform a lot of identical holes on different parts, or perfectly even make them along a single mowing line, the conductor will be just an indispensable tool.

The furniture fitter’s professional tool

In the life of everyone there are situations when it is necessary to use a tool, in this situation it is furniture assembly. A good tool is the quality of work and its speed, and the level of a professional can be determined by the tool he works with A set of tools in capable hands becomes a means by which any furniture installation is facilitated so much that it turns into almost a pleasure to do the work.

It is hard to believe, but today a furniture collector, armed with a high-tech tool kit, does what previously a team of craftsmen could hardly do. Particularly popular cordless screwdriver, which saved the collector from hard and tedious manual work, and with modern measuring tools furniture assembly has become more accurate and of higher quality.

In complex modular systems, quality furniture assembly is not possible without the use of specialized tools. To perform work on installation, hinging, fitting furniture are used: cordless tools, power tools, measuring tools, hand tools. Let’s look at the characteristics of the tool, and in the assembly of which modular furniture systems needed:

Cordless drill. electric screwdriver

Basic tools. It is desirable to have two batteries and a fast charger. Batteries power in volt (6, 9, 12, 14, 18), capacity (operating time) in Ah (1.4, 2.0, 2.4, 3.0 ). An electric screwdriver usually has two torque speeds. For a chuck we use a magnetic holder with BIT set, drills. furniture assembly screwdriver

Peorator

Auxiliary tool, for hanging furniture elements, accessories. Often attached when installing kitchen furniture and built-in cabinets, when drilling in concrete. There is a percussion mechanism inside the drill that produces the percussion itself. So, all you have to do is put it against the wall, press the release button and the screwdriver will do the rest. Specialized drills, augers, core bits are used.

Impact drill

The drill is inherently multifunctional. Used for drilling holes in furniture panels, countertops, drilling walls. The drill has a chuck speed regulator, percussion mechanism. We drill wood and metal at high rpm. At low speeds use as a screwdriver. Shock-type device is used when drilling walls. Perfect for cabinet and built-in furniture assembly.

Jigsaw

The jigsaw has found its place in the kitchen furniture assembly, sawing worktops, making cutouts for the sink and stove hob, it can change the parameters of cabinets, etc.д. Used for built-in furniture, for panel trimming. Equipped with speed regulator and blade tilt. Jigsaw blades (saws) available in many sizes and the ones with the smallest bevel are used for cutting furniture panels. Saws for metal.

Circular saw

The circular saw cuts kitchen countertops, recessed furniture, large size furniture panels. Indispensable tool for installing furniture made of panels Woodchip board according to the customer’s measurements. Use specialized discs when cutting Chipboard or Fibreboard, to reduce splintering.

Sanding machine

In furniture assembly the tool is used for surface finishing after sawing the furniture component. Aligns trimmer line, removes chips. In most cases, it is used as a supplementary tool with a jigsaw and circular saw. The machine is used for restoring furniture. Also for removing lacquer or for sanding wooden surfaces before painting.

Electric clipper

Found use for upholstery upholstery upholstery upholstery upholstery upholstery upholstery upholstery. Can be used to install hardwood boards, such as the back of a cabinet.

Circular saw

The tool has proven itself in the sawing of furniture elements for corner mouldings, stringboards, skirting boards. Large saw blade speeds result in an almost splinter-free cut. Installation of stationary office partitions mitre saw cuts aluminum profile.

Chisel

The handheld equivalent of a mitre saw. Used to cut decorative pieces of furniture into corners, such as furniture for installing cornices (walls, uprights, kitchens).

Set of hand tools

Furniture assembly and installation with hand tools: Set of screwdrivers Hammer and mallet Set of chisels Set of hexagonal wrenches Knife

Measuring tool

Measuring tools are indispensable for installing furniture. Measuring tape, rulers, angles for marking in furniture components. A level to level the furniture. Laser measuring tools are used to measure rooms for furniture installation more accurately.

Wiring detector, metal detector

Auxiliary tool for checking walls when drilling. Detects live wiring, metal, wood. Indispensable when hanging shelves on plasterboard walls. Finds metal channels, and some models also find wooden beams.

Furniture assembly safety when using tools.

During the operation of modern professional electric tools, if used incorrectly, there is a threat to the health of the person using it. The tool is capable of causing considerable injury to the operator as well as to the observer. It follows that the tool should be used by adults who understand the safety rules. Think through your work in advance, prepare your workplace. Always wear close-fitting clothing and eye protection. Keep children, bystanders and animals at a safe distance from your work station. Read and follow the tool manufacturer’s instructions. Use the tool when you are in good physical and mental condition and ready to go. Do not work with unserviceable tools or damaged tool parts.