What can be done from a chainsaw chain

Materials and tools

Saw making

First, we need to erase 2 rivets on the chain on a grinder,

We make holes in it with a hot nail, 4 in each for strength,

We pass them through all the holes as shown in the photo.,

I hope you enjoyed the homemade product, bye everyone!

- Self-made cars 325

- DIY furniture 269

- Home Ideas 145

- Homemade products for summer residents 557

- Fisherman, hunter, tourist 113

- Construction, repair 263

- Self-made from unnecessary things 790

- For radio amateurs 406

- Homemade light 130

- Homemade machines 81

- Homemade Tools 285

- Welding machines 44

- Homemade light 130

- Home Master 305

- Homemade products for business 94

- Homemade products for the holidays 312

- Homemade products for animals 57

- Homemade products for sports 21

- Homemade products for children 284

- Computer homemade products 98

- Home doctor 37

- Experiments and Experiments 33

- Helpful Hints 121

We make a simple and inexpensive sandblasting gun from a plastic bottle in a couple of minutes.

Small alteration of the balloon, which will help speed up the process of changing car wheels.

A simple device from a disposable medical syringe that can be used in everyday life for various

How to convert an electric screwdriver from old nickel-cadmium batteries to lithium at home.

Making a simple conditioner from two plastic bottles and a fan.

Smokehouse. which can be made from a gas cylinder in the country.

Ancient chainsaw chain.

Every time, when mowing in new places, we come across on the way as not reinforcement, so bricks and a new knife is transformed into a piece.

What Can Be Made From An Old Chainsaw Chain

Russians have long been distinguished by their own ingenuity. Even the most primitive objects, with the use of imagination and resourcefulness, of course, transform into a work of art or some desired object.

How to make your own saw from a chain

sdelaysam-svoimirukami.ru chain saw

Going on a long journey, fishing with an overnight stay, hunting, or just rest, many fishermen, hunters and tourists load a small chainsaw into the luggage of the car. Most often it is a small lopper to cut a biscuit into a stock of firewood. And what about long-distance hiking enthusiasts? You can’t put a chainsaw in a backpack, even a small one. it will simply replace all the other accessories necessary for a hiking trip. And the prospect of carrying excess weight, even if the thing necessary for the hike, does not cause much optimism. Of course, there is always room in a backpack for a small hatchet, but there are times when you need a saw. For example, sawing off a piece of thick log that will burn all night. The dry, resinous trunk of a fallen coniferous tree is unusually hard and can be baled with a small hatchet all night long. No bonfire needed! In this case, the chain from this very chainsaw will help us out, from which we will make a chain saw. With its help, you can quite easily and quickly saw through a trunk with a diameter of up to 20 centimeters. It takes half an hour to make such a saw. I had, among other things, junk in the barn, a torn chain from a chainsaw, from which I made a chainsaw.

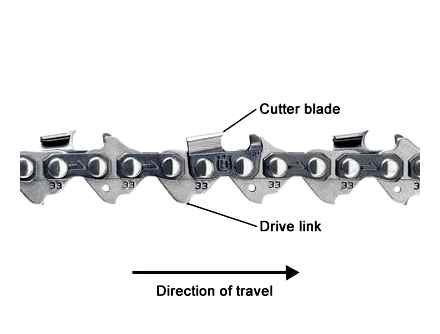

Of course, you can make it from a new chain, but, in my opinion, a saw from a new chain will not be so effective; it has too wide, not sharpened teeth and it is not developed. it will be harder to wield it. On the old chain, all the teeth are already, as a rule, thin and sharpened, which is very convenient for this type of saw.

Hand saw from a chain from a chainsaw test homemade

Hey! I will show you how to make a saw from a chainsaw chain Purchase ready-made course here Group.

2.4. Prepare the chainsaw engine by removing the bar and chain. Leave the other parts intact. Keeping the motor in the body will make it easier to attach to the scooter platform.

How To Buy The Proper Chain For A Chainsaw

Unscrew the centrifugal clutch from the crankshaft. The power from the motor will be transmitted by means of the sprockets and bicycle chain. A trivial problem is the fact that you cannot suspend the working engine with a stationary scooter, you also have to raise the rear wheel off the ground in order to start it. It is also possible to keep the coupling and use a chain that matches the sprocket on the coupling flange. If your chainsaw has a two-stroke engine (you have to add oil to the gasoline), then keep the centrifugal clutch. Rolling off a slope without a clutch will result in the combustion of the engine, because the engine will have to run without being lubricated with a consistency of gasoline and oil.

Bolt the other stars to the rear axle of the scooter. For you, this is easier said than done. painstakingly choose a scooter, realizing that you will need to modify the rear wheel mount, and also install stars at this address.

How To Put A Chain On A Chainsaw Properly

Place the motor on the back of the scooter platform to make sure the stars are on the same lane.

What can be done from a chainsaw chain

Receive one most read article by mail once a day. Join us on and

If the house has a chainsaw, then there must be additional chains. To create our homemade product, you just need one unnecessary chain. It should not be old or stupid, otherwise it needs to be “brought to life”: sharpened and well lubricated. The chain must be open. We will make a compact hand saw out of it.

Basically, all you need to do to create a saw is make the right handles. You can make them from any available material. Of course, it is better to approach the process responsibly and make high-quality handles right away. For this, it is best to use a wooden pole and metal reinforcement. From the latter, it is necessary to cut out the core-holders for the handle using an angle grinder.

In each core, using an angle grinder, we make a small cut along the length and supplement it with a hole for a nail (rivet), which will hold the chain. The handle is recommended to be processed with sandpaper and a file, as well as covered with protective compounds. It will be pleasant to keep such, and most importantly, she will not be afraid of dampness and moisture.

Using a hand chain saw is very easy. We grab a piece of wood with a chain, grab the handles, make an emphasis with our foot and begin to pull. It is easier to work with such a saw than a single hand one. Even thick enough pieces of wood can be cut in this way. On a fishing trip or a picnic, such a tool will be indispensable, and it will come in handy in the country.

Want to know even more interesting things? Then read about how to sharpen a chainsaw chain with a drill: a visual instruction. which will help with solving a difficult task.

Did you like the article? Then support us, press:

Light weight and solid power in combination with compact dimensions allows this “lumberjack’s dream” to be aggregated with an ice drill and a bicycle, a sawmill and a winch.

Interesting homemade products from a chainsaw with their own hands can be made by anyone who confidently works with a welding machine, an angle grinder, and, if necessary, can stand up to a lathe.

In this matter, knowledge of the basics of design and drawing will be very useful, since accuracy of all sizes and build quality are the main conditions for the normal functioning of a unit powered by a chainsaw.

Without going into technical details, we will consider options for the most interesting designs using it.

The first thing that comes to mind when you think about what can be made from a chainsaw is using it as a sawmill. Many developers had to dissolve the logs onto the timber with this tool.

In this case, the log lies motionless and is carefully sawn along its entire length without wobbling and oblique seams. If you equip such a mobile carriage with four lifting screws, then you can accurately set the thickness of the sawn timber.

A light home-made snowmobile from a chainsaw is more complex in design than a sawmill, since here you need to take out the gas, clutch, and also take care of the shock-absorbing suspension of the supporting frame.

To increase traction, a “traction” gear is placed on the drive shaft of the caterpillar, the diameter of which is larger than the size of the chain saw drive sprocket.

The steering gear is usually not a problem, since it is taken from a regular bicycle or scooter and modified so that the central axis moves the rods that turn the skis. The engine power of the snowmobile must be at least 5 horsepower, so for this purpose it is better to use the Ural chainsaw.

The winter line of home-made vehicles will be supplemented by a snowmobile from a chainsaw, which is structurally simpler than a snowmobile. They are driven by a large-diameter propeller that directly rotates the gasoline engine.

The same should be known for those home inventors who would like to make a backpack-type helicopter out of a chainsaw. Such a machine will require not one, but at least two engines operating in a coordinated mode.

This vehicle is most often made for the sake of principle, and not for practical use. The main driving force of its creator is the desire to test his strength as a mechanic and to prove to others the original use of this cutting tool.

The basis for the design usually becomes the old grandfather’s chainsaw Friendship and no less ancient bicycle, with which you can carry out any experiments on altering the frame for mounting the drive.

The transmission of power here is carried out through a gear pair by means of a bicycle chain, and the start of such a homemade product resembles preparation for cutting firewood.

Less common are more advanced models based on a mountain bike equipped with reliable brakes and shock absorbers. Such a moped from a chainsaw is equipped with a gearbox with a gear ratio of 18: 1 and a variator gear, which allows you to comfortably ride it at the speed of a regular bicycle.

This option for using a chainsaw is quite simple, since here the task is to transfer torque from the saw motor to the propeller. A homemade boat motor does not need to install a transmission. For him, you will need to make a reliable adapter on a lathe from the drive gear of the saw to the propeller shaft. The propeller can be used from a standard outboard motor.

It is difficult to make a full-fledged uniaxial tractor from a chainsaw due to the lack of power and tractive effort. But many home craftsmen managed to build a light motor-cultivator on its basis.

The design of such a machine is very simple: a motor rotates a pair of gears and transfers an increased tractive effort to one drive wheel.

The chainsaw motor does not care what it is turning. the cutting chain or the auger mechanism of the snow blower. It all depends only on the design abilities of the creator and his ingenuity.

Using a STIHL chainsaw with a power of about 3 kW, you can easily build a good device for clearing loose snow from an area. To simplify the design, some craftsmen refuse to install wheels using conventional sled runners.

The most daring inventors have long been eyeing the possibility of using a chainsaw as an engine for an aircraft. However, this instrument is not strong enough for airspace exploration. Therefore, no one has yet succeeded in making a knapsack helicopter out of one chainsaw.

This device is useful not only when building a fence or foundation from screw piles, but also during winter fishing, when dozens of holes have to be drilled in thick ice.

A motor winch is a very useful device, because with its help you can not only easily pull out a stuck car, but also raise a heavy load to a height, pull a boat on land or move a cut tree.

The marching power plant is assembled on the basis of the Ural or Druzhba chainsaws. It consists of a frame, an engine with a gear reducer, a control panel, a generator and connecting electric cables.

Beavers are serious competitors to the chainsaw in the wild, which, in addition to self-sharpening teeth, have other advantages)

Confirmation that the craftsmen manage to make a unique, practical and beautiful product is a knife from a chainsaw or motorcycle chain. The product really amazes with its originality and pattern similar to Damascus steel. The practical use of a chain knife is real in any conditions.

Preparatory work

In the package version of making a knife from a chain, the product is suitable for various mechanisms: a motorcycle, a car, a bicycle or a chainsaw. Having decided on the manufacturing method, it is necessary to prepare the tools and materials:

- anvil, two hammers. large and small;

- oven or forge;

- vice, angle grinder with disks for various purposes;

- tetraboric acid (borax);

- Hydraulic Press;

- grinding machine;

- welding machine, steel chain;

- high carbon steel plate;

- engine oil and a container with water;

- drill, wood block, epoxy glue;

- masking tape, sandpaper of various grains;

- impregnation for the handle from natural oils.

The tools and materials are professional. From the very beginning, it was sounded. work for experienced craftsmen. Beginners should not try this material. You need to start experimenting with simple blanks.

Instructions for making a knife from a chain

A distinctive feature of the batch forging process is the work with multiple metal plates. Having everything you need, you need to start the primary forging of the blade:

- Cutting wheel on an angle grinder, cut the chain into several pieces of the same length. Having folded them into a single shape, using welding, “grab” to obtain a solid workpiece.

- A bar is welded to the resulting rectangle for ease of holding. After warming up the furnace, we put the workpiece in it and heat it up to 1100-1200 ° С.

- Metal, having reached a bright red hue, take out and sprinkle abundantly with brown. This will allow you to more reliably fasten the pieces of the chain together and get rid of voids in the links. We send to the oven for further heating.

- We take out again, sprinkle with brown and quickly move to the press. With its help, we gradually squeeze the workpiece from all sides. We monitor the temperature, the part has cooled down. again into the oven. The process performed by the press will help get rid of voids in the workpiece and weld it with forge welding into a monolith.

- Having made sure of sufficient welding, flatten the workpiece into one plate with a large hammer. Cool the product in air, cut the bar with an angle grinder. And with the same tool, we halve the plate.

- Between the resulting halves we lay carbon steel, sprinkling the layers with brown. Gently “grab” by welding, return the bar to its place. We put it in the oven and heat it to a bright red hue. Having taken out the plates, we forge it with a large hammer. The plates must be welded together by forging.

Then we forge the workpiece like ordinary knife steel. This method will provide excellent cutting properties of the blade. In Damascus steel, a multilayer forging method is used, thanks to it, unique patterns are formed on the blade. In the described case, they will manifest themselves due to the structure of the chain.

The choice of material for forging a knife

In machines and devices for various purposes, chains are used to transfer mechanical forces to related units. She carries a lot of physical activity. A chain made of durable alloys is capable of withstanding. A blade made of such metal will amaze not only with the beauty of the pattern, but also with its practicality.

The manufacturing process is not an easy one, you need to be patient. Work experience in metal forging is also required. Bicycle or car chains have different metal compositions. Depends on the tested load of the “donor” used.

Professional knife makers advise using a high-alloy plate gasket between two chain covers. A kind of “sandwich” is welded by forge welding, and a bag of metals will result in excellent cutting qualities and aesthetic appeal of the product.

The trick: welding a cutting edge made of knife steel to a chain blank will upset the blacksmith in the final form and reliability of the blade. The batch option is definitely preferable. He will be discussed in this article.

Blade shaping and finishing

Thanks to forge welding, the resulting package must be forged like ordinary knife steel. We heat the workpiece, forge the descents and the rise of the blade to the nose. The inner insert will come out into the cutting edge as required. The final stages are:

- After the workpiece has cooled, cut off the bar. Clamping it in a vice, mark and cut out the shank using an angle grinder. The part is ready for processing on a grinding machine. We bring descents to the finishing line along the entire length of the blade. the article will help: “how to make descents on a knife”.

- On a grinding machine, you should walk over the entire surface of the product. removing carbon deposits. It is necessary to make a cutting edge and pre-sharpen the knife.

- The process of hardening the product is mandatory. Professionals advise to carry it out in oil and water. Having heated the blade to 800-900 ° C, it is completely immersed in oil for 2-3 seconds, removed and immersed in water for a couple of seconds. The product will acquire the required hardness and will be able to withstand heavy loads.

- The blade needs to be tempered in a furnace with a temperature of 200 ° C for 2 hours. We leave to cool in a natural way. At the end of the process, you need to go over the entire blade with fine sandpaper.

- We deduce the cutting edge depending on the further purpose of the blade. And we sharpen it, useful “how to sharpen knives on a machine.” For the manifestation of the chain pattern, it is necessary to etch the knife in a solution of ferric chloride 5% for 20 minutes.

It remains to mount the handle. In this case, the choice fell on the rider type. A hole is drilled in a wooden block in accordance with the shank. Wrapping the blade with masking tape for safety. Epoxy glue is stirred, poured into the hole made, and the blade is inserted with its tail. We leave the product to dry for a day.

The article: “how to make a handle for a knife” will come in handy. Then we grind the handle to the desired shape, saturate it with special oils. We grind the blade to a shine. We polish the handle. The knife from the chain is ready. The most time-consuming process was the primary forging, as was originally foreseen. Experience and perseverance, in such work are necessary.