What can be done from a trimmer. Rules for the operation of homemade moped

What can be done from the engine from the trimmer.

Despite a fairly large number of attachments made to expand the possibilities of using a garden trimmer, home craftsmen do not leave attempts to use the latter as other devices. As a rule, this is due to the fact that the cost of acquiring factory manufacturing equipment much exceeds the price of a trimmer.

In addition, a large number of different products can be equipped with an unnecessary engine and therefore an unnecessary trimmer. For example, it can be installed on a bicycle, scooter, children’s snowmobile. In addition, the trimmer engine can be equipped with ice or motorbike, as well as reanimate the failed chainsaw.

The difficulty for a home craftsman will be only in the need to independently develop and manufacture a drive, which ensures the transfer of torque from the shaft of a power unit to the executive mechanism of a home.Made device. The design of the drive largely depends on the trimmer model.

Useful tips

Before proceeding with the manufacture of the device or its refinement, it is necessary to decide why it is needed. For example, units to remove weeds and just loosening the beds can be very different. For greenhouses it is worth choosing light models only with manual control. If the processed areas are quite large, then you should opt for options that work on fuel or from electricity.

When the cultivator is not operated for a month or more, it must be removed for storage. To do this, it is necessary to remove fuel from it, clean the surface of the engine and all other elements. It is undesirable to clean the parts of the device with strong water pressure. Metal parts must be lubricated with oil to avoid unwanted corrosion. Store the unit is necessary in a dry and nonsense room.

About how to make a cultivator with your own hands, watch in the next video.

Trimmer from a grinder

Another simple and convenient option is to make an electric garden trimmer from a grinder. In general, the assembly scheme is similar to the previous method, but with the difference that it is even easier to fix the power tool for the holder. If you remove the protective casing from the grinder in the configuration, then in this thread you can fasten the P-shaped fastener, welded independently. You can fix it on the holder by means of bolts or welding, if in the future it is not planned to disassemble a home.Made trimmer. Some craftsmen immediately weld the protective casing to the fasteners.

How to make a lawn mower with your own hands

Today, the market of electric and gasoline lawn mowers can provide a large number of different options and models. But in the case when there is no budget for a mower, but I don’t want to mow manually, then with your own hands you can do it with your own hands at home from improvised parts and materials. DIY lawn mower will allow you to significantly save money, unlike factory analogues.

Necessary materials and tools

A device such as an electric shovel with your own hands is not a matter of first necessity. But the presence of such an instrument at home will significantly save labor costs with the mowing of grass. Very simple lawn mower can be made even from an electric motor. They include the same details and functionality as the factory analogues.

Lawn mowers on an electric motor include:

Making a High-Power Electric Scooter

- An electric motor or a drive mechanism, with which nozzles rotate;

- The basis of the frame on which all the details of the mechanism will be held;

- Protective shield;

- The handle with which the mechanism is controlled;

- Load knives;

- 2-4 wheels;

- Button for turning on and off the mechanism;

- Power cable;

- A capacity for collecting grass or its removal.

It is necessary to constantly observe the safety of the work, and therefore you need to mount an element of emergency and automatic shutdown of the electric shock.

All electrocosylins have the same principle of operation. After the voltage supply to the electric motor, its shaft begins to rotate. And since knives are fixed on the shaft, they cut the grass at high speeds of the electric motor.

The choice of a suitable engine

As a motor for a lawn mower, you can use the engine:

If you need to pump out small sites, then just right there will be an engine from the old drill. It does not even need to be disassembled, just fix it in an upright position.

DIY lawn mowing from a washing machine or a Soviet.Style vacuum cleaner can be made without much effort. They have all the necessary details. The best option for mowing grass near the house is an electric motor with a capacity of 0.5 kilowatts, and the recommended number of revolutions is about three thousand. The quality of work and the mowing of the grass depends on the speed of the motor, and accordingly its blades.

The longer the knives of the device, the smaller speeds you can use it due to an increase in linear speed. But its power should increase in order to fight an increasing load.

In the event that the engine power is less than these indicators, then you need to regularly undermine the blades to obtain the desired result.

If only three phases were found in the farm, then the start.Up capacitors must be added to this design. They must correspond to the engine capacity. Drawings of lawn mowers from a grinder or other starting materials can be easily found on the Internet or specialized literature.

Types and principle of work of cultivators

The principle of operation of the cultivator is simple: the element that loosen the ground begins to work after the mechanical part of the device is launched. Depending on the external size, engine power and performance, cultivators are divided into three types: light, medium and heavy equipment.

- Light equipment is used in small areas with soft soil (flower beds, greenhouses).

- Medium severity is used on clay soils.

- Heavy equipment refers to universal equipment. It can be used for any soil.

Cultivators are of different types: disk, rotational, lap and milling. In terms of functioning, they can be: manual, with electric drive and working on gasoline, as well as trailed, hinged, process one or more rows.

See also: vacuum spraying. The principle of operation and the technology of vacuum plasma spraying. The most common vacuum spraying methods. Iono vacuum spraying and the principle of its work. Vakuu process

When processing a land plot, everyone chooses the model you need. Hand cultivators are good in that they can be made independently with minimal cash costs.

Advantages and disadvantages

Each cultivator, regardless of whether it is manual or electric, has its pros and cons of.

- Manual cultivator. Easy to use and much more conveniently shovels, compact. Does not load the lower back. The soil loosens well, does not melt the roots throughout the site. But this technique will not cope with the unlucky land, as it has low performance. It is better to use it in small areas, such as flower beds or greenhouses.

- Electric cultivator. Light and compact equipment working from the network. Simple in maintenance. The lack of equipment is an electric cord. It can interfere during operation, and due to its length there is a limitation in the processed area. Has low power and small soil processing depth. Not intended for hinged equipment.

- Gasoline cultivator. Thanks to hinging equipment, it has many functions. Does not connect to electricity, so it can move throughout the site. Suitable for processing small territories. Weighs much more electrical equipment. It is difficult to care for it, and fuel is required for refueling.

Snowmobile or snowfall

On the basis of the Trimmer motor, you can redo it with a self.Propelled vehicle for a snow.Covered flat terrain or a simple snowbreaker (motorized sleigh) for steep descent from the mountain.

Self.Propelled guns. A frame structure, including:

The frame is made of welded spars, on which racks of 30×30 cm are welded and cross. A steel pipe with a diameter of 14 mm is taken as a drive shaft. Skiing-musculoskel. Moving the snowmobile occurs with a screw or chain transmission.

Block: 6/7 | Summer characters: 515Source: https: // spacmahina.Ru/gazonokosilka/samodelki-az-trimmera.HTML

Boat motor

By simple transformations, the trimmer, if necessary, can be turned into a motor for a small rubber or plastic boat. As a rule, the whole refinement comes down to the manufacture of a rowing screw and install it instead of a mowing unit. At the same time, you need to pay special attention to compliance with safety requirements, which will save the boat body intact and eliminate the possibility of injury to the user. The process of refinement of the trimmer is described in detail in our article.

How to build a 60MPH MOBILITY SCOOTER #1-Frame

So, above the manufacturing methods from the garden trimmer of the most popular tools in the household were given. As you can see, the process is not super.Complex, but requiring not only enough extensive knowledge in electrical engineering and great experience in performing locksmiths and installation work, but also many diverse tools. The main thing is to observe safety precautions.

Cultivator from a trimmer

If you have to process the soil in the country all year round, then, without a doubt, the converted trimmer to the cultivator will become a real assistant in this difficult matter. Immediately you need to make a reservation and say that you can purchase ready.Made nozzles for a trimmer for soil processing, but you can, like us, engage in their independent manufacture.

First, it will demand to prepare all the necessary material with tools:

- A piece of sheet metal with a thickness of 3 mm, but it is possible a little more. The base for the knives of the cultivator will be cut out of the metal;

- Thick metal wire (katanka), which will subsequently be cut into pieces, is flattened and welded to a piece of metal;

- Corresponding tools for the manufacture of cultivator knives. First of all, this is a grinder, a welding machine, some fitting tool, of course, a hammer, and t. D.

The process of manufacturing a cultivator from a trimmer will best be divided into several separate stages. At the first stage, you need to prepare the base from a piece of sheet metal. For these purposes, two circles must be cut from a steel sheet with a diameter of 25-30 cm. Then you need to cut the wire into pieces, no more than 10 cm long, and flatten the ends on it. The large length of the cultivator knives will create a strong load on the trimmer, as a result of which the internal combustion engine may fail.

As soon as the wire is ready to be welded to metal circles. 3-4 pieces of wire are enough for the effective lift of the earth. Exactly the same operation is carried out with the second circle of metal. After homemade mills for the cultivator are ready, they can be attached to the trimmer.

Just an ideal option in this case will be a reverse thread and a welded tube with a nut on home.Made cutters. In this case, the nozzle simply wraps up on the shaft of the trimmer, so the alterations of the tool will be reduced to “no”. If an electric trimmer is used for the manufacture of the cultivator, then a fairly long extension cord will need to be provided, which would be enough for the entire processed area.

What can be done from a trimmer: useful homemade

The easiest and cheaper for yourself to make a lawn mower from a trimmer. The trimmer is already designed to mow small vegetation, but unlike the lawn mower you have to carry it all the time in your hands, which causes a lot of inconvenience. Having made a simple but effective device, it will quite turn out to facilitate this overwhelming burden.

So, to remake a trimmer to the lawn mower, it will be enough to use a metal frame made of steel wire and two or four wheels. If you need a full.Functional lawmaker from a trimmer, then it is best, of course, to install four wheels on a metal frame.

Also, the necessary elements of a home.Made lawn mower are protection, handles and control buttons. As for the knives, you can completely abandon them and use standard “trimmer” accessories for mowing grass, which is the trimmer line. The trimmer itself, as it becomes clear, is installed on top of the frame, at a certain height from the ground.

10 Smallest Vehicles With Powerful Engine ▶1

Thus, you can easily and simply redo the trimmer into a lawn mower with minimal financial investments, seriously modifying and improving the most popular to date, a manual tool for the care of a lawn.

What to make from the engine from a trimmer

First of all, you need to make a frame for the engine. To do this, take a metal sheet with a thickness of at least three millimeters. The size of the frame is selected based on the length of the knife, but the maximum width of the lawn mower rarely exceeds sixty centimeters. Thus, you need to cut a square of metal with a side of 50 or 60 centimeters. In the center of the square you need to make a hole under the engine. The flange engine is attached to the frame with a shaft down. If the engine is with ears, then you need to weld additional mounts to the frame.

Such a frame can be made from boards or plywood, but the metal is still preferable, since it is less susceptible to deformations. The casing is designed to protect the engine shaft from garbage and scraps of grass. The simplest casing can be made of a metal canbank. Complex options will have to tinker. If the finished casing is high, it will protect the electrical mechanism of the lawn mower. If not, then to protect connections with a wire, you need to make another casing.

The casing is put on the engine shaft. Next, the sharpened knife is put on and the entire mechanism is fixed with a bolt. Next, the wheel is attached to the frame. To do this, corners with holes drilled in them should be launched on the frame. The diameter of the wheels is selected so that the knife passes at a height of five to seven centimeters above the ground. If the knife drops below, it is likely that it will get stuck in the ground. The grass is crushed at a larger height, not cut.

Regardless of what the handle is made of, it needs to be straightened up by the growth of the one who will most often use the lawnical mower. Usually the optimal handle length is about 90 centimeters. The final stage of operation. The connection of the power cord. Do.It.Yourself electric lawn mower is ready, you can test it in your own summer cottage. In order to protect against cut grass, a mesh is attached over the lawn mower.

The second option is to make a frame of a special curved shape. This technique described the assembly of the lawn mower to the standard form. Options. A lawn mower made of a drill, on which a wide knife is fixed instead of a drill. At the same time, the drill itself must be attached to the frame with the handle. The advantages of such a home.Made lawn mower are that you do not have to fool the head with the connection of the cord. The drill mechanism is used. Secondly, such lawnmands can be used to cut grass under the trees and off the borders.

In a similar way, you can make a gas mower from a chainsaw. For him, you need to prepare a special frame frame, for example, cook it from pieces of pipe. Next, move the chainsaw engine to it. There are both drawings on the network and a video on fastening knives to such a lawn mower. Due to the engine power, the gas mower from the chainsaw copes even with a small shrub.

How to make a home.Made snowmobile from a walk.Behind tracker on tracks

Four wheels are installed inside the caterpillar. Когда происходит движение они катятся по транспортерной ленте, с закрепленными грунтозацепами. The caterpillar drive is carried out by a chain from the motor, special leading stars, through the driven shaft. They are removed from the “Buran”.

The engine is taken from the usual walk.Behind tractor, the power of which is 6 liters.With. You can’t accelerate quickly on it. A soft suspension of skis and caterpillars was removed because the snowmobile is intended for driving loose snow. This design was simplified and reduced by the mass of the snowmobile.

Making caterpillars for snowmobile

Consider the process of making a caterpillar. Plastic water pipe 40 mm, cut 470 mm long. They will be made blanks for dirt drives. After that, each of them is cut along the equal parts of the circular saw.

Soil.Bearing are attached with furniture bolts to the conveyor tape

When the caterpillar is made, it is extremely important to maintain the same distance between the soil. Otherwise, “rising” on the teeth of the leading star will occur, as a result of which the caterpillar will slip and slide from the rollers. To drill holes for fasteners in the conveyor tape, a conductor was made

To drill holes, a wood drill that has special sharpening was used

To drill holes for fasteners in the conveyor tape, a conductor was made. To drill holes, a wood drill that has special sharpening was used.

This conductor allows you to drill six holes in the conveyor tape simultaneously to attach three caterpillar soil. Leading stars (2 pcs), an inflatable rubber wheel (4 pcs), closed bearings No. 205 (2 pcs) were also purchased.

The turner made a support for bearings and the leading shaft of the caterpillar. The snowmobile frame is made independently. For this, square pipes are used 25×25 mm. The hinged axes of the rotation of the steering wheel and skis are in the same plane and on the same line, so an uncertain steering rod without ball.Tips was used.

Easy bushings are made quite easily. A water clutch is welded to the front transverse beam of the frame, the internal thread of which is 3/4 inches. There are entangled pipes with outdoor thread. The bipods of the rack of skis and steering traction welded the bipods to them. Corners are installed on the skis, which serve as a mount to the rotary stance of the snowmobile. A metallic incision is made from below to better control the snowmobile while driving along the rolled snow or nest.

We make a motorized car

From a conventional bicycle, home masters managed to make a more practical vehicle. They rearranged the engine from motorcycles on it. At the same time, options are practically implemented both with a gasoline engine and with an electric motor.

Required tools, materials and details

Electrical engine It feeds on a bicycle from the battery, which, depending on the power of the unit (it is taken 0.35-1.2 kW), is enough from 30 minutes to 2 hours.

To remake a bicycle are used Two- or four-stroke gasoline engines. The last option consumes less fuel and is not so noisy during operation. The recommended power is from 1.5 liters.With., And the best option 2 l.With. When using a motor with a smaller parameter, the motorcycle bike will barely go or will not be able to move at all at all.

Rotational movement from an engine operating on gasoline to a bicycle wheel occurs using use belt or chain transmission. Because of this, you will need to make the following details:

- Metal suspension in the form of a frame with sides to fix the motor on the bicycle frame;

- The driven and leading pulleys or stars for attaching to the engine and wheel, respectively.

For the implementation of the project, you will need to choose Suitable gearbox. After installing the pulleys, choose a belt of the desired size.

The dimensions of the frame under the engine depend on its dimensions. The suspension itself to the frame of the mototalosyped is fixed:

The last option in strength is the best if the welder is good. If the design of a bicycle frame allows, then The suspension is replaced with a clamp, which fix the engine. This fastening option is more practical. The method of fixing the motor should be comfortable, reliable and allowed to quickly remove it if necessary.

Doing all the work with your own hands in the presence of an old, functioning trimmer, bicycle and a small set of tools will require the executor of time, as well as patience.

Construction assembly sequence

To independently collect a bicycle with a engine working on gasoline, you will need, in addition to the materials and details considered, also:

- Controller;

- Cable for adjusting the operation of the motor;

- Fuse;

- Exhaust pipe welded by welding;

- Sleeve;

- Washers;

- Bolts;

- Chain tensioner.

The assembly of a mototalosip is carried out according to this algorithm:

- Put on the rear bicycle wheel asterisk;

- The engine is fixed with a clamp (with an asterisk on the shaft) on the frame behind the seat or on the trunk, if the design features of the bicycle allows, otherwise you will need to choose another convenient place for this purpose;

- Put on the chain on the stars of the wheel and motor;

- Attach the tensioner;

- Regulate the stretch of the chain;

- Fix the handle of gas;

- Stretch the cable to the engine;

- Fix the fuel tank;

- Mount the carburetor.

The Worlds Most Powerful Chainsaw STIHL MS 881- Our Biggest Sponsor Yet

For the purpose of personal safety During the operation of a motorcycle system, the braking system is modernized, the wheel tires are changed to non.Slip products, check the integrity and stability in the movement of the created structure. After the entire structure is assembled, it is tested, having previously examined the shortcomings.

What can be done from a trimmer: useful homemade

The easiest and cheaper for yourself to make a lawn mower from a trimmer. The trimmer is already designed to mow small vegetation, but unlike the lawn mower you have to carry it all the time in your hands, which causes a lot of inconvenience. Having made a simple but effective device, it will quite turn out to facilitate this overwhelming burden.

So, to remake a trimmer to the lawn mower, it will be enough to use a metal frame made of steel wire and two or four wheels. If you need a full.Functional lawmaker from a trimmer, then it is best, of course, to install four wheels on a metal frame.

Also, the necessary elements of a home.Made lawn mower are protection, handles and control buttons. As for the knives, you can completely abandon them and use standard “trimmer” accessories for mowing grass, which is the trimmer line. The trimmer itself, as it becomes clear, is installed on top of the frame, at a certain height from the ground.

Thus, you can easily and simply redo the trimmer into a lawn mower with minimal financial investments, seriously modifying and improving the most popular to date, a manual tool for the care of a lawn.

What can be done from the engine from the trimmer. Machines, welding, metalworking

Each fisherman was thinking about replacing the engine of the magazine with an alternative engine. He learned to create from lawnmands, gasoline pumps and even screwdrivers, since their cost is several times lower than the price of the finished sample. The most suitable option is a trimmer, as this device is equipped with all the necessary elements and mechanisms.

What can be done

There are several possible options for modifying a trimmer for an engine for a swimming device.

Option No. 1. A very simple method, but it requires additional financial costs.

You will need to purchase this data:

- Clip for attaching the device to the transit of the boat.

- Rowing screw screw. You can buy a ready.Made set via the Internet, because in stores such a product may not be. The kit includes a special stainless steel drive, as well as universal adapters for a flexible shaft trimmer, which allows you not to worry about whether they do not correspond to your model.

The attachment for the trimmer is indicated in the instructions. The installation will take about half an hour.

Option No. 2. For refinement, you need a corner from a crusher, a screw that can be cut from a stainless steel sheet, as well as seals and bearings for fasteners for fasteners. This method allows you to get maximum speed, despite the small step of the screw. In the field settings, the device requires additional adjustment, which is performed using pliers.

Option No. 3. This method is performed as much as possible manually. Consider this in more detail on the example of gasoline pumps with a two.Stroke engine of 25 cm. A device weighing 4.5 kg and 700 watts is equipped with a curved leg. The trimmer with this power allows you to move the boat at a speed of about 5-7 km / h.

Engine installation on a bicycle | Assembly of Motovelosiped Motax Lampa

New equipment from the company MOTA. Motovelic! Installation engine on Motax Lampa bicycle. Assembly

Motokosa boat motor.

I bought an interesting device for myself, two in one: motorcycles (trimer) and a motor for a boat!

For refinement, you need a corner from a crusher, a screw that can be cut from a stainless steel sheet, as well as seals and bearings for fasteners for fasteners

How to make a motor for a boat from a trimmer: methods and advice

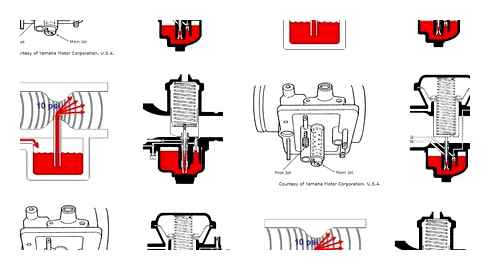

The presence of a boat makes rest or fishing on any pond, whether it is a river, a lake or even a sea, a more pleasant and fascinating event. Despite the fact that many types of inflatable boats that are often used by vacationers in freshwater reservoirs are equipped only with oars, if desired, you can independently make a motor from a trimmer. Most of modern trimmers used to cut lawns are an excellent basis for making a home.Made motor for an inflatable boat, which is characterized by a relatively small weight. Given the trimmer’s mechanism, the basis of the task for any person who wants to make an engine for a boat is a transformation of the lower nozzle intended for mowing grass into a full.Fledged screw with blades.

Any modern trimmer has almost all the necessary parts to turn it into an engine for a boat, including a fairly powerful engine and a bar, including a shaft transmitting torsion. Thus, to convert the trimmer into a full.Fledged boat motor, it must be equipped with a screw with blades, a suspension on the mines and, of course, replace the handle of control. For the manufacture of a home.Made motor for the boat, a trimmer with a two.Stroke engine, the declared power of which is at least 700 watts, will be quite enough. Such trimmers are compact and their weight usually does not exceed 5 kg. If you need a more powerful motor for the boat, it is better to take a four.Stroke trimmer as a basis. In addition, the second important point in converting a trimmer into a motor for an inflatable boat is the fastener of a protective structure that will not allow damage to the blades when they touch the bottom or clue of various garbage and algae.

So, to start turning the trimmer into a full.Fledged motor for an inflatable boat is worth replacing the lower nozzle for mowing grass with a curved bar, as this is the most difficult moment. First of all, you should remove the bobbin with a trimmer line from the trimmer and unscrew the nut available on the bar, which will be needed in further work. Next, you should carefully cut the nut with a saw on the metal to get two, but smaller. After that, you need to carefully remove and remove the plastic gas button. Given that, as a rule, at the end of the rod, a sliding bearing is installed, not roller, it will need to be cut, and as neat as possible. Sliding bearing is represented by an ordinary bronze sleeve. Before carrying out this manipulation, it should be removed from the main pipe-stank, which is in it flexible and deedwood ramparts. Last of all, from the pipe-stamp, you need to carefully remove the plastic tread.

After all the necessary elements are neatly extracted from the “darling” of the curved bar, you should choose a duralumin straight tube that will replace it. A bronze sleeve is carefully impressed into the new straight bar, and then a flexible shaft and a plastic tread is installed. Next, you need to make a screw from the usual strip of duralumin, the thickness of which should be at least 2 mm. The size of the duralumin sheet should be 100×30 cm. Then a drawing of the future screw is applied to the paper, and in its center you need to make a rounded hole corresponding to the diameter of the shaft. The finished pattern should be moved to a duralumin sheet and cut a screw along it. The finished screw must be put on any even horizontal surface and gently bend each of the 2 blades under the bend upward. It is best to bend the blade by about 10 mm. If the duralumin screw bends poorly it needs to warm it up and bend the edges of the blades with pliers.

On a new bar, with all the necessary elements installed in it, a standard nut is put on, on which the screw is fixed. On the outside, the screw is fixed by the second regular nut. To improve the appearance of the screw, you should cover the standard nut with a conical elastic Band, which can be purchased in any car shop. Further, instead of the previously removed overlay with the gas switch, the usual switch of the bicycle speed switch should be installed. Then you need to make a ring nozzle that will cover the screw, preventing it from being damaged on stones or wind up algae. The nozzle is a long sheet of a metal sheet, the width of which should be about 15 cm, bent into a circle and fixed with bolts, with fasteners extending from it. The protective nozzle is attached with clamps directly to the bar. The trimmer motor is last fixed on the boat mines with a clamp.