What disk to saw laminate circular. Place No. 2: A cut with a curved blade

How to cut a laminate: we select a suitable cutting tool

In order to properly lay the laminate on the floor, you need to be able not only to connect laminate panels, but also to cut them correctly. Otherwise, “fit” into the area of the room, as well as observe the traditional chess pattern will be impossible. Since you can’t take laminated boards with your bare hands, cutting them can be entrusted to one of the manual or electrical tools.

The main characteristics that should have a tool for cutting a laminate at home is:

The last point, the meaning of which is not to spoil the type of laminate board after cutting, for most home masters is a decisive. However, its meaning is still exaggerated. In any case, chips up to 5 mm in size on the finished coating will not be noticeable. defects on the edge of the panels will be hidden behind skirting boards.

So, which tools are most suitable for cutting laminate?

Tool Electricity

The best result in the cutting of the laminate can be achieved by applying an electrician for this purpose. This is an easy, very convenient tool to use, to which any master-novice will quickly find an approach. Even a woman or a teenager. The cut with an electrician is performed at increased speeds, which avoids damage to the structure of the wood.fiber plate. If you act quickly, confidently, then the cut will turn out to be almost perfect.

The main thing in the use of an electrolobian is the choice of files. A modern tool is usually originally supplied with special files for cutting laminate. They are distinguished by a special shape, step and method of wiring teeth. However, ordinary metal files for metal will also cope with this business. narrow, with small teeth.

In order not to damage the decorative surface, the fishing line for cutting is applied (pencil or chalk) on the wrong side of the laminate board. It is laid on the table (chair) by the wrong side up so that the part that is planned to be cut is in limbo. With one hand they fix the laminate lying on the table, and the other quickly cut off the excess part.

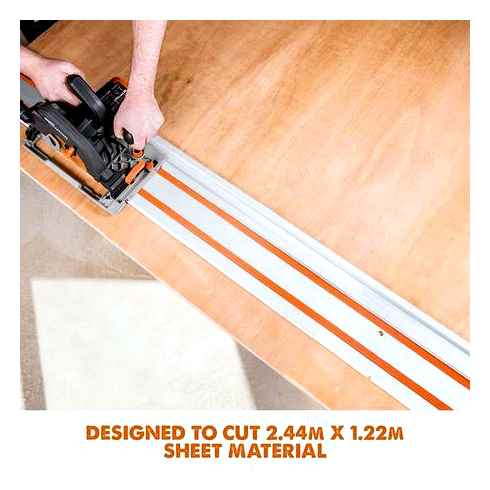

Circular saw tool

A neat cut along the edge of the laminate can be obtained using a circular saw with a metal disk. Working with a circular saw is more difficult than with an electrician, so it requires some skills. If you have them, then you can cut the laminate quickly, exactly, almost without chips.

The laminate board is laid on the hard surface with a pattern up, fixed. You need to cut carefully, with a little pressure, moving the disk along the drawn line, trying not to slow down in one place.

Angle.grinding machine tool (angular grinder)

Corner grinder. a convenient tool indispensable in the box of a home master. You can cut almost everything, including laminate. For a beautiful edge, without cracks and chips, when cutting, you need to turn the laminate board with the front surface. At the same time, metal disks, concrete or ceramic tiles are used.

Disadvantage of using corner grinding (and circular saw too!) can be called a large amount of dust that will be released during laminate cutting. Also, this action may be accompanied by the smell of a burning tree. Therefore, you need to do a harsh on an open balcony or on the street.

Khspovka tool

Laminate can be successfully cut with a conventional hacksaw on wood. But this will have to spend strength, because its teeth are quite large and will bite into the laminate, and not to cut it. Smaller teeth in a hacksaw for metal. it must be used for sawing.

Scabbard is very often used for cutting with small volumes of work. In construction teams, this method is not applied, due to increased time costs and complexity.

Laminate cutter tool

A cut for a laminate, on the contrary, allows you to make cutting at a professional level. Most often, this tool works according to the type of guillotine. a knife, which, with the help of a handle, is lowered to the surface of the laminate and cut it. The cutter acts easily, without chips and noise. For its use, you do not need to use strength and have skills. Perhaps this is the easiest tool in operation, which allows in any conditions to get an excellent result.

Since this cutter is used exclusively for the laminate, it makes sense to buy it only with professional styling. For the decoration of several rooms of the apartment, this option is considered impractical.

Tool building knife

An ordinary building knife can also be used for laminate cutting. For example, if you almost finished the flooring device, it remains to cut one board, but suddenly a corner grinder broke. There are no other tools at hand, and the cut should be done urgently. Then a construction knife will come to the rescue. Put the ruler on the front side of the laminate board, draw a deep cut on it with a knife. Holding the board on one side of the cut, press on the second side. The laminate should be broken, just like ceramic tiles under the influence of tile cutter.

Types of tool cutting tools

By virtue of its structure, the laminate is well sawn by wood tool and is extremely simple to process for masters of different levels: from professionals with many years of experience to beginners.

A feature is that the cut of the material is carried out directly at the installation site. At the same time, it is very important to achieve a qualitatively even cut and not spoil the panel.

Turning to specialists with the question of how to cut a laminate quickly and efficiently, you can get various tips. After all, each master has its own criteria for selecting tools, their own characteristics and knowledge of technology, experience and natural ingenuity. For one it is important to work with an easy and mobile tool, for the other, the issue of connecting to a power grid or manual execution is important. However, everyone converges in one opinion: laminate cutting should be performed qualitatively, providing an ideal cut.

The entire laminate cutting tool can be divided into two categories: manual tool and power tool. The advantages of the first category are the versatility of application and affordable price. The use of the instrument of the second group, despite the higher cost and dependence on the connection location to the mains, can significantly accelerate and facilitate the process of installing the coating.

When choosing how to cut a laminate, you can count up to seven tools:

- hacksaw;

- electrician;

- circular saw;

- corner grinder;

- special cutting;

- construction knife;

- and even an ordinary clerical knife.

The use of any tool from the list given with appropriate experience will allow you to get a high.quality and neat slice. A general or unified recommendation than cutting a laminate at home, which equipment or device does not exist in a particular situation. Each master, on the basis of personal practical experience, knowledge and professional training, has his own preferences and “chips”. It is important to take into account that in any of the selected methods, one should be guided by popular wisdom: “Measure seven times, cut off once”.

Consider briefly the purpose and principles of the work of each type of tool for cutting the laminate.

Hacksaw

Let’s start with the simplest and affordable. manual wood or hacksaw saw. This is a hand tool that is in almost every house. The hacksaw requires the use of physical efforts and can be used when cutting a small amount of material. On a large volume its use is not effective. At the same time, the choice of hacksaw with large teeth can lead to the destruction of the decorative surface of the coating lamellas. To prevent such consequences, it is better to use a hacksaw with small teeth or a hacksaw for metal.

Tip: Before proceeding to the saw, a painting tape should be glued to this place, which will protect from the formation of chips at the site of the cut. At the same time, it is recommended to lay the board with a facial coating up.

The hacksaw is not the main tool for cutting laminate in professionals due to low productivity, large physical costs and the danger of damage to the decorative layer of the panel. But in some cases with small volumes, when it is impractical to use an electrician or corner grinder, a hacksaw may be useful.

A direct alternative to a hacksaw is an electric saber’s saw. Now the market is a large selection of such a tool. However, the electric saw will not add much to amenities and speeds in work. Therefore, in our review we will not dwell on it in detail.

Electric

The electric jigsaw is a convenient, simple and very productive tool. In most cases, it occupies the first place, thanks to the convenience of circulation, accessibility in operation and efficiency of use. Therefore, when searching for solutions to the problem, than to cut a laminate at home, many of the users opt for it.

To use an electrician does not need special training or long.term skill, everyone can successfully cope with it. The result will be of high quality, the cut will be even and perfectly smooth, given that the tool works at high speeds. The main thing in its use is the correct selection of a laminate file.

Typically, a set with a jigsaw includes several paintings designed for processing a tree or laminate. If you do not have them, you should take care of the purchase in advance. Lamite on an electric laminate has a special shape and a small step of the teeth. Look for the appropriate marking on the packaging. The use of a wrong file will lead to the appearance of chips on the edges of the cut. Therefore, it is better to cut the panels with a special file for a laminate jig. If you could not find one, you can use the canvas for the metal, but the productivity of the work will be slightly reduced.

Important! Marking is performed from the wrong side of the panel. For cutting a jigsaw, it is necessary to lay the workpiece on a flat clean surface with a decorative side down. So the teeth of the files less damage the panel during the cut.

An important advantage of an electrician over other types of tools is the ability to make not only direct cuts, but also curved. This is very relevant if necessary to put a laminate floor in the places of passage of pipes and communications. Under them, the jigsaw will easily cut through the grooves and suckers.

A circular saw

The circular saw allows you to get a more even cut of laminate than an electrician, and at the same time much faster. However, working with such a tool requires great attention and is much more dangerous. Therefore, it is recommended to use the circular saw only to those who have skills and experience with a similar tool, or familiarized themselves with the order of work by watching the video.

Features of the laminate cutting process

Starting to lay a laminated floor, you need to know not only how to cut a laminate at home, but also how to use tools correctly. Among the main determining moments regarding the features of working with laminate, the following can be noted:

- Large efforts should not be used when cutting laminate;

- With a poorly cut, the board should be laid by the damaged side under the baseboard;

- To obtain the perfect cut, the workpiece should be placed downward when working with a corner grinding and a circular saw or upside down when an electrician;

- Before the rez, check the calculations several times in order to prevent damage to the materials;

- Figure cuts should be performed using a template for measuring bends, gluing construction tape into the place of cutting.

Features of the laminate cutting process

Starting to lay a laminated floor, you need to know not only how to cut a laminate at home, but also how to use tools correctly. Among the main determining moments regarding the features of working with laminate, the following can be noted:

- Large efforts should not be used when cutting laminate;

- With a poorly cut, the board should be laid by the damaged side under the baseboard;

- To obtain the perfect cut, the workpiece should be placed downward when working with a corner grinding and a circular saw or upside down when an electrician;

- Before the rez, check the calculations several times in order to prevent damage to the materials;

- Figure cuts should be performed using a template for measuring bends, gluing construction tape into the place of cutting.

Instead of a resume

Each type of tool for laying and cutting the laminate at home should meet the following criteria:

- be sure to be serviceable;

- be convenient to use;

- have little weight;

- ensure the quality of the work assigned to it;

- It is inexpensive.

Of course, the best tool for cutting a laminate is an electrolobian. It is universal, convenient, can cut lamellas along, across and with rounding, does not require special skills, is easy and not expensive. It is only important to choose the right file.

Follow our tips, and the chosen cutting tool will make the laminate laying process simple and high.quality.

How can you cut a laminate at home

Depending on the thickness and material of the laminate board, you can use several options for cutting tools that are probably available in a home workshop. The idea to cut a laminate using only the strength of the hands is good if you need to repair or replace one or two lamellas. In other cases, it will be extremely difficult to do without power tools.

The traditional set, with which you can accurately and neatly cut the laminate, looks as follows:

- Manual hacksaw with a canvas for cutting metal;

- Circular saw in manual or desktop design;

- Guillotine cutter in a floor or desktop version;

- Construction grinder for cutting reinforcement or corner grinder;

- Renovator or vibration cut;

- Electric jigsaw;

- A special knife for cutting wood.fiber slab.

Important! Not all of the listed materials and tools are equally good for cutting a stove from pressed chips and wood fiber. In addition, the quality of the cut depends on the experience and the ability to handle the tool.

The easiest option is to make a special cutting knife for cutting laminate. The design of the blade differs from the stationery and ordinary knife by the presence of 2-3 teeth on the front edge. Such a cutter is usually made from an old wood saw, the cutting edge is pulled from the opposite sides. In order to cut the laminate, it is necessary to attach a carpenter, apply a fishing line for a cutter to a cutter to a lamella. After that, the film is cut out with an ordinary knife, and then the square is changed to the locksmith ruler, and the rest of the laminate is cut through the laminate with a cutter.

Vinyl cut knife

The fishing line for the trimmer cut is not too smooth, but at the same time there are no chips and paper fringe on the edges.

Cutting the laminate with guillotine

The tool is largely similar to a cutting knife. The design of the tool is presented in the photo below.

Universal tool for any type of laminate

The cutting part is fixed on the steel frame. a stand, and the cutter itself can rotate around the hinge at the end of the device. The fishing line for the trimmer of the cut is flat and flat, but the material, especially on the edges, can be deformed due to a large pressure on the surface of the laminate. In order to cut it with guillotine, it is not necessary for special preparation. The cutter is usually used for cutting vinyl slabs and lamellas.

Cutting laminate corner grind

This is one of the most successful tools used for cutting and cutting building materials. High speed rotation of the cutting circle provide the highest quality of laminate cutting. In order to cut off the part of the laminate panel, it is enough to lay the material on the edge of the table or workbench, fix it, and with a slight effort to smoothly perform the incision along the marking line. Thanks to huge power, you can cut the laminate any thickness.

With one hand you can cut only if there is a special support heel

Top 5 Best Saw to Cut Laminate Flooring in 2021

Note! Corner grinders cannot be cut on the basis of PVC. In this case, the fishing line for the trimmer of the cut is uneven, the plastic is paid and follows from the contact zone.

You can cut a soft wood panel with almost any cutting circle. It is best for cutting a laminate with a corner grinding laminate is suitable for a disc with a diameter of 110-125 mm and a thickness of 0.8-1.5 mm. Various kinds of diamond and nitride-based circles on a metallic basis cope with the task a little worse.

In order to cut a laminate, a small machine with a capacity of 300-500 watts is enough. In the presence of a certain experience, the incision can be performed even with one hand.

Cutting the laminate with a jigsaw

The popularity of the electrician is very great, it is used to cut out all kinds of lumber, plastic and even thin.leaved metal. There are several options for hacksaw paintings for materials for materials of various density and hardness. Usually this is a short titanium blade with sharp teeth, for metal tooth metal is 1-1.5 mm, for soft wood and plastic, the size of the cutting edge increases by 2 times.

Electricity is a convenient tool if you need to cut the cutting very quickly, as they say, “on the fly”. But a seam or a fishing line for a cutter of cut after using a jigsaw is not the most even. over, if you use a canvas with teeth of high altitudes and cut at low speed, then the cutting edge is strongly “shaggy” of laminate material.

Be sure to use guide devices

Therefore, in order to cut the laminate with a jigsaw without chips, you must adhere to the following rules:

- You can cut the laminate only in an inverted state, the front part on the table or the supporting surface of the workbench;

- If the back side is very soft, then the top line is best glued to the usual tape. The tape does not interfere with the movement of the teeth, while maintaining the edges of the incision whole;

- Cutting speed is selected individually. Typically, for soft materials, high speeds are chosen when minimal supply of the canvas.

Another condition is that you can’t cut the laminate with an electrician on weight, there must be a hard support, both for lamellas and for the sole of the jigsaw. In addition, if the width of the laminate is more than 15 cm, then it is necessary to use the guide bar, which is attached to the tool case and provides smooth and uniform movement during the cutting process.

Based on the above, we can conclude that there is a wide variety of tools for cutting the coating.

You need to choose depending on the size of the room and financial capabilities.

For example, specialists who professionally engage in laying coatings should be armed with special equipment. However, those who want to make the installation of housing, can do with cheaper decisions.

If you do not have special equipment, it is not necessary to purchase it. you can cut off the laminate using a hacksaw

The primary task of the installation of the laminate is to avoid the occurrence of chips and cracks. In this regard, it is important to properly calculate everything.

You can make a cut of laminate almost using any equipment with a cutting part. It is important to do everything gently. It is worth selecting a tool based on skills, planned volume of work and means.

The most optimal solution for cutting coatings is an electric jigsaw, since this tool is universal, and certain skills for working with it will not be required.

If there are any doubts about laying and cutting the coating from the laminate, then it is best to trust professionals. There is a risk only to spoil the material, which will greatly affect the means.

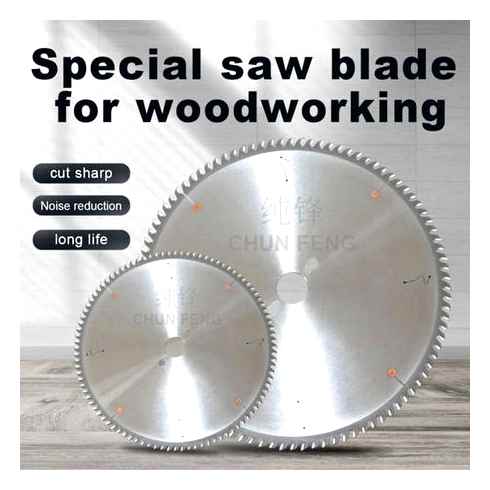

Types of Circular Saw Blade

Vinyl laminate cutting

Type of lamellas, which will be used during installation, determines in most cases the necessary tools for cutting. If it is planned to lay the coating on their own without the use of the help of professionals, then it is worth taking a closer look at the laminates of soft types.

At home, the process of sawing soft types of laminate, for example, on the basis of a cork will not represent a particular difficulty. These types of coating have increased resistance to wear and water protection. In addition, such a laminate quickly fits.

To cut these types of coatings, you do not need to use any special tools. You will need a simple ruler, pencil and knife. The cutting line for the trimmer of the incision should be indicated with a pencil and then just walk with a knife. Then you just need to bend the laminate. It is also possible to make incisions in the form of figures. for this you can use ordinary scissors.

Nevertheless, in order to cut other types of panels with numerous layers, where there is a particularly strong wood fiber or wood-piece plate, a special tools may be needed.

How to trim the mounted laminate?

It happens that it is necessary to make a trim of a laminate, which have already been mounted on the floor. For an inexperienced person, this may not be easy.

If you believe the reviews, then the most optimal way in such circumstances will be the use of corner grinding. As experienced users advise, an angular grinder with a diamond spray disk is best suited for such work. When doing all the actions, it is important to be very careful and not forget to change the position of the tool, not very acting on it. Do not forget that you always need to keep your finger on the button in case of loss of control.

In addition, you can apply not such a simple tool, but it is safer. a cutter. There are special cutters that are used for wood work. just this is best for cutting the laminate. As professionals say, the cutter needs to make two parallel cuts with a width with a chisel. After that, you need to select a cut panel using a chisel.

You can use the jigsaw. You need to unscrew the protective casing so that it is possible to get to the space under the wall, and then carefully cut off the unnecessary. This method is not the most convenient, but it does not require disassembling the coating.

There is also such a tool as a renovator. The equipment is a corner grinder, which can cut in places with difficult access. Such equipment is expensive, but you can always order a tool from China for about thirty dollars.

Tips for professionals

Of all these models, the renovator looks the most attractive. It can be considered as a real alternative to a hacksaw or cutter. If you are talking about cutting a laminate on the floor with an area of 50-80 m 2. then the power of the tool will clearly not be enough. To lay the floor in an ordinary one.room apartment, you can do with an ordinary hacksaw. If you engage in the installation of the laminate professionally, then the best option would be to purchase a desktop machine with a set of circular saws of various sections. To repair the coating, it will be enough to make a knife-cut.

Vinyl tiles should only be cut on a desktop machine-cutting machine. Manually or in any other way to cut it off evenly and gently. The plastic is quite viscous, and the high.speed tool will simply melt and deform it.

Advice! When selecting the tool, you do not need to experiment, remove protective parts, clips and casings. This will not simplify the task of cutting the material, but can dramatically increase the injury hazard of the process.

Cutting a laminate at home is no more difficult than a lining or a finishing downtime. In order to work with lamellas, you do not even need to purchase some specific devices or devices. It is quite possible to do with what is in a home workshop, unless, of course, you can work with a saw or circular machine.

Discuss the article on the forum

Noise.insulating linoleum: types and installation rules

Laminat Ritter: reviews of professionals, collections, laying rules

Quartz-vinyl laminate: what is it, photo and manufacturers rating

Berry Alloc Laminate: Buyer reviews and laying rules

Norwegian laminate Alloc: Customer Layers and Reviews

How to choose a carpet for a bedroom, living room and a children’s room

Hacksaw

This is the easiest tool, which, in principle, can be cut off the laminate. But the wood hacksaw is not suitable for this purpose. Its large teeth will make the cuts decomposed and torn, and you will have to spend too much effort. Case with small teeth are more suitable for these purposes, but still, this is far from the perfect way.

You can use a manual hacksaw designed for cutting metal products. She will practically leave no traces after herself, but the work will be long and tedious. If you need to cut several panels, then this method can be used. If there is a large amount of work, then you should choose a more effective tool.

Corner grinder

Almost every man has this popular tool. And it can be used universally, including for the cut of laminate. But not everything is so simple here. It is important to choose the right cutting disk. If you use an ordinary cut.out disk designed for cutting metal, then nothing good will come out. The room will be filled immediately with caustic smoke, after which the work will need to be temporarily collapsed. And this is logical, because the cuts are designed only for metal.

It is also not the best option that is a disk designed to cut concrete. He will not only fill the room with smoke, but also leave behind uneven edges.

It is permissible to use a wood disk having a teeth. Only work should be very neat, since the teeth are very large.

Laminate cutting with a construction knife

On the shelves of any construction store you can find a extending household knife with replaceable blades. Using this tool, you can process almost any material, including ensure laminate cutting.

For this type of work, a powerful knife with crashing heads made of high.quality steel will be required. It is better to carry out cutting work using a building corner or a previously fixed steel line. Simultaneously with a strong press, the master leads the cutting edge of the knife along the marking, providing even cutting without chips. If the floor element is too thick, then the procedure must be repeated several times until one part of the part is completely separated from the other.

Drilling holes using a drill or screwdriver

Drilling equipment is also necessary when cutting laminate floors, since quite often the board needs to be laid around the heating riser or other pipes for communications. For the correct performance of this type of work in the panel, it is necessary to drill a hole using a conventional drill or screwdriver.

A feature of drilling is a large diameter of the hole, for the device of which you need to use a special tree expander. It is a milling tip with a landing rod suitable for a standard tsang drill. It is better to have a set of such expanders in stock, since the master may have a task to increase the already drilled hole.

To work with a laminate, it is not at all necessary to have a powerful drill. the simplest tool with minimal characteristics is enough. Battery screwdriver will also quickly cope with such a task.

It should be remembered that immediately after the laminate device, the installation of skirting boards will be required, which in most cases are attached to the brackets, previously fixed to the wall using dowels and screws. So, drilling equipment will be indispensable in the nearest related work on the finishing of the room.

How to saw a laminate are tried by users

Andrey, 22 years old. I live in a one.room apartment, I decided to put a laminate in a room on an old parquet. I have not yet acquired the instrument. I took a hacksaw “Piranha” in the store with a hacksaw with teeth step 15 per inch. High.quality sharpening, even after laying continues to cut well, does not leave chips. He saws along and down without problems, the blade does not clamp, but manually adjust the last panels in width still energy.intensive.

Pavel, 44 years old. On his old electrician installed a T101BIF file to cut a laminate without chips. The bimetallic canvas copes well with sawing the panels along and across. Laid a laminated coating in a private house on the ground floor 10 mm thick (33 class). The entire area, not counting the bathroom, was about 60 square meters. m. The saw did not break, even at the very end I sawed perfectly. Only positive emotions remained.

Peter, 48 years old. I liked to use a special laminate cutter. A guillotine with a curved blade cuts panels with a minimum noise, which in the apartment is very important. During work, a lot of fine dust is not formed, only large waste remains, which are easy to collect. The machine is suitable for straight cuts in width, length and at an angle. There are no large chips when cutting. Due to a large lever, you do not have to make a lot of effort.

Alexander, 52 years old. I tried at home to cut a laminate with a corner grinder with a diamond segmented disk on concrete. It saws quickly, it turns out an even edge, you don’t get tired when working. The only thing that is very dusty is very small particles that fly throughout the room. I cut it on the street, since I live in a private house, it is not a problem to go out.

Oleg, 29 years old. Of the power tools, only a circular saw was at home. I used a wooden wood disk with carbide attacks “Zubr” for cutting. Chose with 48 teeth. Prepared a convenient table from black boards. Laid a laminate with a thickness of 8 mm, set the depth of cut to this size, taking into account a small output of 1-2 mm. There is no much experience with power tools, so he cut along and across the guide to make the edges even.

Comparative table with parameter assessment

We will evaluate the listed tools for working with a laminate according to some characteristics. To do this, make a table with conventions:

When evaluating, we will use the five.point system.

| Tool | CHR | Kr | Cf | BSh | Kr |

| Electric | 5 | 5 | four | 3 | four |

| Manual cut | four | 2 | 5 | 5 | 5 |

| Corner grinder | 5 | 3 | four | 3 | four |

| A circular saw | four | 2 | 5 | 3 | 5 |

| Wood hacksaw | four | 2 | 3 | four | 3 |

Additionally! The purity of the cut of laminated panels is important, but in most cases small chips and irregularities at the site of the cut are easily closed with floor skirting boards.