What disk to saw laminate with metal locks. Fabric for metal

Is it possible to cut a laminate with a hacksaw on wood

It is impossible to lay the floor with whole sheets of laminate. There is always a need to saw a laminate to obtain the required size. Therefore, in order to avoid excessive consumption of the material, it is better to determine the list of devices and tools for neat and non.waste disperses of the panels at home before starting work.

A feature is that the cut of the material is carried out directly at the installation site. At the same time, it is very important to achieve a qualitatively even cut and not spoil the panel.

The entire laminate cutting tool can be divided into two categories: manual tool and power tool. The advantages of the first category are the versatility of application and affordable price. The use of the instrument of the second group, despite the higher cost and dependence on the connection location to the mains, can significantly accelerate and facilitate the process of installing the coating.

The use of any tool from the list given with appropriate experience will allow you to get a high.quality and neat slice. A general or unified recommendation than cutting a laminate at home, which equipment or device does not exist in a particular situation. Each master, on the basis of personal practical experience, knowledge and professional training, has his own preferences and “chips”. It is important to take into account that in any of the selected methods, one should be guided by popular wisdom: “Measure seven times, cut off once”.

Hacksaw

Let’s start with the simplest and affordable. manual wood or hacksaw saw. This is a hand tool that is in almost every house. The hacksaw requires the use of physical efforts and can be used when cutting a small amount of material. On a large volume its use is not effective. At the same time, the choice of hacksaw with large teeth can lead to the destruction of the decorative surface of the coating lamellas. To prevent such consequences, it is better to use a hacksaw with small teeth or a hacksaw for metal.

The hacksaw is not the main tool for cutting laminate in professionals due to low productivity, large physical costs and the danger of damage to the decorative layer of the panel. But in some cases with small volumes, when it is impractical to use an electrician or corner grinder, a hacksaw may be useful.

A direct alternative to a hacksaw is an electric saber’s saw. Now the market is a large selection of such a tool. However, the electric saw will not add much to amenities and speeds in work. Therefore, in our review we will not dwell on it in detail.

The electric jigsaw is a convenient, simple and very productive tool. In most cases, it occupies the first place, thanks to the convenience of circulation, accessibility in operation and efficiency of use. Therefore, when searching for solutions to the problem, than to cut a laminate at home, many of the users opt for it.

Typically, a set with a jigsaw includes several paintings designed for processing a tree or laminate. If you do not have them, you should take care of the purchase in advance. Lamite on an electric laminate has a special shape and a small step of the teeth. Look for the appropriate marking on the packaging. The use of a wrong file will lead to the appearance of chips on the edges of the cut. Therefore, it is better to cut the panels with a special file for a laminate jig. If you could not find one, you can use the canvas for the metal, but the productivity of the work will be slightly reduced.

An important advantage of an electrician over other types of tools is the ability to make not only direct cuts, but also curved. This is very relevant if necessary to put a laminate floor in the places of passage of pipes and communications. Under them, the jigsaw will easily cut through the grooves and suckers.

The circular saw allows you to get a more even cut of laminate than an electrician, and at the same time much faster. However, working with such a tool requires great attention and is much more dangerous. Therefore, it is recommended to use the circular saw only to those who have skills and experience with a similar tool, or familiarized themselves with the order of work by watching the video.

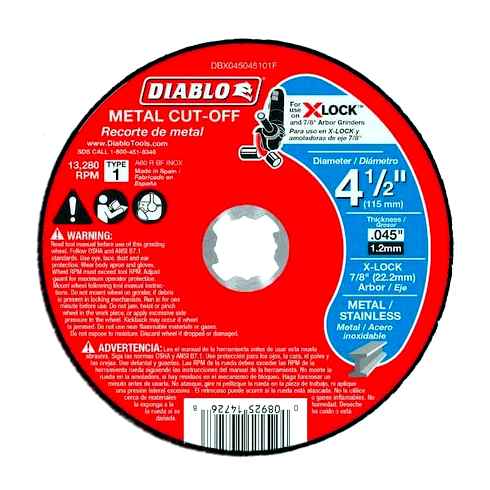

As in the case of a jigsaw, a disk intended for this procedure should be installed for sawing a laminate on a circular saw. The cut is made by the front side up with smooth movements in the longitudinal or transverse direction.

Corner grinding machine or in the airplane grinder of the “corner grinding” for cutting the laminate is used quite often. This is a simple tool for applying. A disc of pure wood cuts is installed on it, which can easily cut the laminate panel.

For many, the corner grinder is associated with a sharp metal. But this power tool has great opportunities and a wide range of sizes and capacities, which allows it to be attributed to the category of a universal tool. A certain part of the masters do not make another decision when the issue of choosing cutting tools arises. they prefer to cut a laminate with a corner grinder, since it is with its help that they cut almost all materials.

Important! Before the sharp workpiece, laid and fixed with the front side up. Cut should be smoothly, without strong pressure, clearly in a straight line. For cutting laminate, you need to use a saw wooden disk with a clean car.

While working with this tool, a large amount of dust and the unpleasant smell of a foul tree forms. Therefore, when choosing a corner grinder, it is not recommended to perform the work indoors: for this it is better to go to an open balcony or on the street.

Outwardly the cutter resembles a guillotine equipped with a sharp knife. When you need to make a decision on choosing the right tool, a cut for laminate is usually not the first offer, since a wide range of users is not known about this narrowly professional tool, despite its effectiveness.

- Noiselessness;

- High speed of work;

- Lack of dust;

- Do not need experience and skills;

- High cut quality.

TOP 5: Best Saw Blade for Laminate Flooring 2022

Important! Work by a cutter is possible only in the transverse direction.

Construction and stationery knife

Most often, a construction or stationery knife for cutting a laminate can be used in situations where you need to adjust or cut a small fragment of the board. You can also use a construction knife if it is necessary to cut off a fragment of the laminate, and there is no other tool at hand. To do this, you need to cut the decorative layer on the marking several times with strong pressure (completely cut off the fragment as a saw), until a deep trace remains on the surface. Next, you need to put the handle of the hammer or other emphasis under the fishing line for the trimmer for the cutter and break off the piece, pressing on the far edge. The cut can be cleaned with the same knife or skin.

Features of the laminate cutting process

Each type of tool for laying and cutting the laminate at home should meet the following criteria:

Of course, the best tool for cutting a laminate is an electrolobian. It is universal, convenient, can cut lamellas along, across and with rounding, does not require special skills, is easy and not expensive. It is only important to choose the right file.

One of the popular types of flooring of residential premises is laminate. This material consists of several layers, each of which performs a certain functional purpose. When laying such a coating, it is necessary to fit and cut the panels in order to efficiently and technologically advanced installation.

How the laminate works

Laying the laminate only by whole parts is almost impossible. Laminate lamps are most often made rectangular shape. On the surface of the planks there is a thin film made of resin, which protects the laminate from various kinds of influences and damage. Under the protective layer is a layer with a shade, where the formation of a picture goes, which externally looks like a tree of various types.

Next is a layer of wood-based stove, which increases stiffness indicators. The latter is a layer of melamine, thanks to which the laminate is resistant to moisture. As a result, it turns out that in thickness such a coating will be about six to twelve centimeters

If you saw such products, then it is very important to carefully make the edge. Otherwise, curved chips may form, which will need to be compensated by valuable centimeters of the coating

It may also be necessary to replace the elements with a malfunction with new.

In order not to throw away valuable pieces of coating, which is quite expensive, it is better to prepare tools in advance that will make it possible to make even sections. Thus, you can protect yourself and immediately styling without spending additional resources.

It is important to make only even sections. otherwise you can greatly ruin the coating, which will affect the expenses

Drill saws for cutting

Today it is just indispensable. construction, as well as woodworking. You can’t do without such a motorized device. Saws, as well as appropriate laminate cutting discs today are in great demand.

Discs are classified depending on the work on the work. So, to work with lamellas, use a special device for boards.

!

When buying such a device, it is necessary to pay attention to the number of teeth and the angle of their inclination, the geometry of sharpening, as well as the recesses between the teeth.

A small number of teeth. an option for working with chip plates and wood. The average amount is suitable for massive wood and soft metals. Large. used exclusively with a very powerful device, so it is not advised to use it for soft flooring.

It is the sharpening geometry that will affect the cleanliness of the cut and the efficiency of work. Available varieties. flat, trapezoidal, as well as alternating. The angle of inclination also affects the quality. Flat sharpening is better to use for quick cuts, the universal version is suitable for any tree.

There are also professional discs with special teeth from hard alloys. They have hardness, high strength, as well as resistance to destruction. This guarantees high performance, long service and excellent quality of work.

Laminate cutting by means of saw

Unlike the wood-steering plate, lamellas amenable to manual sawing. Here you can safely use any option with small cloves, because it is such a tool that will not leave a backbone on the edges.

! Even if there are any damage to the end part, they later hide under the baseboard, which means they will be invisible to the eyes.

So, how does the process happen? The procedure looks as follows:

- Put the laminated board so that its front part “looks” upward. This will become a guarantee of the high quality of the frontal part of the edge;

- Try not to press the saw for cutting the laminate in the process, because this will lead to the breakdown of the edges of the processed laminated bar.

Drill saws for cutting

Today it is just an indispensable tool for repair, construction, as well as woodworking. You can’t do without such a motorized device. Saws, as well as appropriate laminate cutting discs today are in great demand.

Discs are classified depending on the work on the work. So, to work with lamellas, use a special device for boards.

! When buying such a device, it is necessary to pay attention to the number of teeth and the angle of their inclination, the geometry of sharpening, as well as the recesses between the teeth.

A small number of teeth. an option for working with chips and wood. The average amount is suitable for massive wood and soft metals. Large. used exclusively with a very powerful device, so it is not advised to use it for soft flooring.

It is the sharpening geometry that will affect the cleanliness of the cut and the efficiency of work. Available varieties. flat, trapezoidal, as well as alternating. The angle of inclination also affects the quality. Flat sharpening is better to use for quick cuts, the universal version is suitable for any tree.

There are also professional discs with special teeth from hard alloys. They have hardness, high strength, as well as resistance to destruction. This guarantees high performance, long service and excellent quality of work.

Electrician and features of working with it

Electrician is the most preferred type of tool, since using it you can get a high.quality smooth saw that does not have chips on its surface, burrs and other damage.

Important! When working with a thin laminate, you can use an inexpensive jigsaw, with its help you can cut wood with a thickness of up to 7 mm. To saw more laminate with a larger thickness, a more serious tool with a capacity of up to 750 watts will be required and

The jigsaw allows you to quickly and efficiently cut the laminate

If this kind of work is carried out on a regular basis, then it is better to immediately purchase a more expensive, but reliable tool. The table below shows the average cost of electrician as of July 2018.

Table 1. The average cost for lobes

Choose a file

To obtain an even and smooth cut at the end of the laminate laminate, it is not enough to purchase a high.quality tool. the result depends on the correctly selected file. Some manufacturers complete the tool with several varieties of files. It may happen that it is not necessary to purchase an additional file for working with a laminate. it will be complete with the tool.

From others, the characteristic features are distinguished by a laminate file. Form, step, wiring of teeth and the material of the canvas must be taken into account when buying a file. So, the laminate files from the well.known manufacturer Vosch are flexible and durable, since a bimetallic canvas is used for its manufacture.

Bosch Lamin Lamin “Special for laminate”

By and large, if for some reason it was not possible to find a file with a marking that says that it is designed to work directly with a laminate, you can choose another, having small teeth and thin canvas. The result can be obtained different:

- A saw with a wide canvas allows you to get a high.quality rectilinear cut.

- For a curly or curved cut, a thin canvas of the file is chosen.

- The neat edge on the front side of the lamella will turn out if the cut is carried out from the outside.

- To carry out an even cut floor with the front side, choose a file with the back of the directed teeth of the file.

A set of files on a laminate with a back tooth

How to work with a jigsaw

The following rules will allow when cutting a laminate to get a high.quality cut and simplify the cutting process itself:

- In the process of sawing laminate boards, the tool should have maximum speed.

- The cut is made on the intended line at a time. If you slow down the course of the cutting element or suspend the work, then small irregularities, chips and other damage can form on the surface of the cut.

- When cutting the laminate, the pendulum mechanism of the tool is disconnected.

Before sawing the laminate, a fishing line for a cutting trimmer is marked on its surface

Important! Many laminate manufacturers give information on the packaging on how it is recommended to cut the lamellas. on the front or back side.

To calculate the number of laminate on the room, use a special calculator. You will find it in our article.

Cutter

This is a professional tool that is quite expensive and is used by masters whose work is related to large volumes of laminate laying orders. Such a tool is a supporting structure on which a very sharp blade is fixed. The trimming of the board occurs at one time by the type of guillotine.

Using such a device, cutting can be carried out in different directions. along or across the lamella, while the length of the cutting element has a decisive effect on the quality of the cut along the lamella.

table 2. The principle of operation of the device

There are no traces of the cut on the front side of the lamella, and on the back, if necessary, the torn edges are polished with sandpaper.

What may be needed when laying a laminate? Look for an answer in a special article. You will find everything there: from the tool to the instructions for independent styling.

Kryazuvka for metal

Unlike a cutter, a hacksaw is the cheapest and most affordable tool for cutting a laminate. Khfevka in the farm of each homeowner and it can be used if necessary to trim a small amount of laminate. The simplest hacksaw stands from 200.

The use of a hacksaw is justified in dots at the facility of electricity

In the process of cutting the laminate using this tool, it is necessary to adhere to the following recommendations:

-

The tool should be ready to work. the metal canvas is securely fixed and the force of its tension is checked.

The tension of the canvas is regulated by a special screw on the saw handle

The disadvantage of such a tool when performing this particular type of work is the complexity of the process and the need to have a skill. Laminate is dense material, so you can practice on a board or plywood similar in structure.

A circular saw

The high cost and the availability of professional skills in working with this tool, put it on a par with a cutter. The result when pruning the laminate by the circular saw is very high quality.

The tool will be divided into professional and household. The first variety has additional elements: a rack, a supporting structure and a clamp for a reliable fixation of the panel.

It is clear that the cost of household models is lower than for professional. But it is also recommended to choose them starting with the average price category. a cheap tool is not practical and will not last long.

Table 3. Average cost for circular saws

An important role is played by the right choice of disk. Its size should be from 16 to 20 cm with a canvas thickness of not more than 0.2 cm. The disk must have 48 teeth.

The peculiarity of cutting with a circular household saw is that it must be kept smoothly, smoothly pushing forward without sharp jerks.

Cutting process. lamel must be securely fixed

The laminate in composition differs from wood, so has its own characteristics when working with it.

How to cut a laid laminate

Very often, when flooring, a situation arises when it is required to align and cut the ends of the laminate in the direction of laying the lamellas. The situation is complicated by the minimum distance from the wall to the end surface. Typically, the gap does not exceed 10-15 mm, which is too little so that the laminate can be cut using a hand hacksaw or an electrician. In this case, they resort to the use of the renovator.

In order for the fishing line for the cutting trimmer to turn out to be even, ladies laid must be loaded with an additional oppression. These can be books, sandbags, sports inventory. This must be done in order to avoid lifting the material during trimming.

Can only be cut off only with a lateral emphasis

If you need to cut the protruding ends of the lamellas in the center of the room, for example, under the arrangement of the transition from the laminate to tiles, then parallel to the cutting line additionally laid a metal profile, you can use an aluminum corner or a long metal locksmith ruler. They will serve as a guide support for the cutting edge of the renovator.

Tips for professionals

Of all these models, the renovator looks the most attractive. It can be considered as a real alternative to a hacksaw or cutter. If you are talking about cutting a laminate on the floor with an area of 50-80 m 2. then the power of the tool will clearly not be enough. To lay the floor in an ordinary one.room apartment, you can do with an ordinary hacksaw. If you engage in the installation of the laminate professionally, then the best option would be to purchase a desktop machine with a set of circular saws of various sections. To repair the coating, it will be enough to make a knife-cut.

Vinyl tiles should only be cut on a desktop machine-cutting machine. Manually or in any other way to cut it off evenly and gently. The plastic is quite viscous, and the high.speed tool will simply melt and deform it.

Advice! When selecting the tool, you do not need to experiment, remove protective parts, clips and casings. This will not simplify the task of cutting the material, but can dramatically increase the injury hazard of the process.

How to cut a laminate at home

In order to accurately and neatly cut the lamel, it is necessary to adhere to two main conditions. First of all, you need to correctly mark the fishing line for the cutting trimmer. Only carpentry are used for these purposes. No segments using laser rays and decrees mounted in an electrician or renovator cannot be used.

The second condition is the low speed of the cutting tool. The stronger the cutting edge presses on the material of the laminate, the stronger the teeth deviate from the direction of movement. Productivity increases, but the surface quality is reduced by many times.

If you cut the material with a corner grinder or a disc saw, you will also need to maintain a constant effort on the tool. This is the only way to cut equally exactly along the entire length of the panel.

How to choose a hacksaw?

Often during the laminate layout work, they resort to the help of such a popular tool as a hacksaw

However, for effective and quick sawing of panels, you need to choose its correct model. Of course, if you have others, you can use a hacksaw on wood. But in this case, the process will be time.consuming, since the hacksaw on wood has large teeth. Due to these features, the hacksaw will not carefully cut the canvas, but to dig into it.

The most optimal option will be the choice of scabbard for metal. It has small cloves and is able to cut the panel smoothly.

10 Amazing & Useful Angle Grinder Disc !!!

However, it is worth remembering that the help of a hacksaw for metal should only be resorted to with small volumes of work. Unlike power tools, this one takes more time on the sawing and requires great effort, so professional builders do not use a hacksaw for these purposes.

Introduction

In this article we do not invent a bicycle and do not teach you to saw any materials. Naturally there are actions that do not change over time and technology. To cut any material is not difficult for anyone, this event is not laborious and simple. But to choose how to cut a laminate, and how to do it correctly, you still need to observe some nuances. It is likely that when sawing, you can damage the boards of laminate. chips and cracks will appear and the coating will lose its attractiveness. If you are not sure that you can cope with the task without difficulty, we advise you to contact professionals. They already have a certain qualification: they will do everything in a short period of time and without damage to the material.

Laminate boards are easily sawing, we remind you that a laminate is a pressed structure covered with an acrylic resin or melamine film. This laminated surface is able to deform and break off if it is improperly exposed. Therefore, it is important to correctly approach the choice of the tool in order to saw off the unnecessary part of the laminate.

To correctly follow the technology of laying the laminated coating, it will still have to saw the laminate. Drink along the element, you need to endure the distance between the laminate and a 10 mm wall to the wall of the board, this will prevent the appearance of the creak of the laminate, which we talked about in another article. Fortunately, progress gave us a wide selection of tools for sawing any material, but not everyone is suitable for the laminate. Nevertheless, the better to cut the laminate is these tools:

- electric jigsaw;

- “Corner grinder”;

- Any hand.saw on wood;

- Kryzuvka for metal;

- Special laminate cutting tool.

Before any action with sawing off the mother, it is worth it to measure everything once again and mark. I saw the place, mark on the back of the board with a pencil using a square. If you cut you on the front side of the laminate. stick a masking adhesive tape and make a mark on it. Also take into account the width of it, it has different tools for all tools.

Do not rush to immediately take on the tool, as in any other business, in the cut of the laminate there are subtleties and nuances, we will talk about them in separate.

§ one. Sawing laminate with an electric jigsaw

Use an electrician to cut the laminate the most effective and quick way. With a certain dexterity, cutting the laminate with an electrician, will not take much time. To do this, select a special wood on wood with small teeth. Electricity should work at high speeds, and it is necessary to move it smoothly. These rules prevent the appearance of chips and torn edges.

The laminate bar must be fixed with the front side down on a solid surface. You can put on a stool and lean your knee. If a file with the direction of the cloves is used, then the laminate bar should lie up the decorative side.

How to trim the mounted laminate?

It happens that it is necessary to make a trim of a laminate, which have already been mounted on the floor. For an inexperienced person, this may not be easy.

If you believe the reviews, then the most optimal way in such circumstances will be the use of corner grinding. As experienced users advise, an angular grinder with a diamond spray disk is best suited for such work

When doing all the actions, it is important to be very careful and not forget to change the position of the tool, not very acting on it. Do not forget that you always need to keep your finger on the button in case of loss of control

You can also trim the laminate already laid on the floor, however, it is more difficult to do it

In addition, you can apply not such a simple tool, but it is safer. a cutter. There are special cutters that are used for wood work. just this is best for cutting the laminate. As professionals say, the cutter needs to make two parallel cuts with a width with a chisel. After that, you need to select a cut panel using a chisel.

You need to unscrew the protective casing so that it is possible to get to the space under the wall, and then carefully cut off the unnecessary. This method is not the most convenient, but it does not require disassembling the coating

There is also such a tool as a renovator. The equipment is a corner grinder, which can cut in places with difficult access. Such equipment is expensive, but you can always order a tool from China for about thirty dollars.

Why chips appear

Before cutting a laminated wood-brown slab or laminate using an electrician, it is advisable to understand why chips are formed when cutting out sheet material. And the answer here is simple: everything lies in the design of the electrician, or rather in the design of the files.

So, in the process of cutting, the saw receives return movements (up and down). And if, when the saws move along the teeth (usually down), chips are practically not formed, then when the tool moves in the opposite direction, the teeth seem to tear the upper layer of the material, thereby forming an unpleasant chip. That is why you can observe an almost ideal cut on the bottom of the laminated wood-bearing plate and cuts with chips along its upper edge.

Geometric parameters of the cutting edge

With a careful examination of the paintings, we note that they have various geometric features of the sawing surface, differ in teeth and wiring. Increase in the divorce of teeth leads to an increase in the width of the cutting line

The work is performed quickly, and its quality is reduced. There are the following types of nozzles for an electrician:

- Milling saws having a classic wiring. Each subsequent tooth is bent in the opposite direction. This makes it possible to produce rapid sawing of material with low quality. Allows you to saw a tree of different densities, plastic products and a color.

- With a wave.like wiring. Smoothly bending several teeth in one direction is carried out, then a similar amount deviates in the opposite direction. The sawing edge has the shape of a wave. This is the equipment for a laminated woody stove, wooden, plywood and plastic products, as well as color metro.

- Polished saws with classic dilution. Dental breeding and their grinding are done. This allows you to perform high-quality cuts of wooden products, wood-fiber slab and wood-based stove of structures.

- With conical grinding. Teeth are not divorced, but their grinding is carried out. Designed for laminate, wood and polymer structures. Allow you to make a thin neat section.

Each of the above nozzles has its superiority to perform the tasks of a narrow direction.

Manual hacksaw: work nuances, safety precautions

If the front of the work is small-one or two rooms-and there are no electric cutting tools, a manual hacksaw is quite suitable. A handmade sheet should have very small and frequent teeth.

The scabbard for metal is best suited, since the laminate is solid, very durable, pressed material, and it is difficult to cut with a conventional tool with large and rare teeth.

The laminate board is sawn on the front side, and so that the chip and chips do not form, the painting tape must be glued along the sawing line. An accurate fishing line for a trimmer for a ruler or a square is drawn on top of the tape, according to which the material will be sawn.

Will greatly facilitate and accelerate the process of electrical.burning, and the quality of the cut will be better. Using an electric or hacksaw for metal, you can make angular cuts in the laminate, but for rounded cuts (for example, under a pipe or column of the arch), such tools are not suitable for.

For the cut, the board must be laid on the desktop so that the fishing line for the trimmer of the saw is located from the edge of the table at a distance of at least 20 mm.