What Is Poured Into The Tiller Gearbox

By viscosity

The viscosity is determined according to the SAE J300 standard. For devices, it depends on the following characteristics:

- Unit designs;

- Features of work;

- The age of the mechanism;

- Ambient temperature.

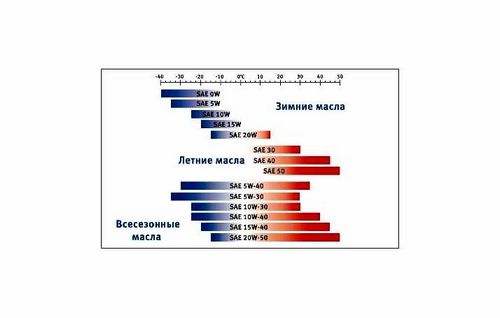

Motor oils are divided into winter and summer. Winter grades are designated by the letter W. Low-viscosity winter grades with the designations SAE 0W, 25W, as well as with intermediate values of 20W, 5W, 15W and 10W are often used. Formulations for use in the summer do not have letters in the name. They are distinguished by high viscosity and are designated SAE 20, 60, CAE 30 or 40. When using summer grades in winter, problems arise associated with starting the unit. Winter varieties in summer are NOT capable of high-quality lubrication.

Scientists have developed all-season compounds that are used for pouring into the tiller in summer and winter. Their designations are 5W-40, 10W30.

What kind of oil to pour into the tiller: is it possible for an automobile for a gearbox, in an air-cooled engine

tiller today cannot surprise anyone. He became a faithful assistant in performing work on the site and cleaning the territory. The owners of such units know that they need constant care: replacing some consumables, checking and tightening the nuts, refueling. But you still need to change the oil for the tiller.

What kind of oil to fill in Tilleri Neva

The quality of the lubricant in the tiller is gradually decreasing and becoming unusable. Along with this process, engine wear occurs. To prevent the process of wear, it is necessary to change the lubricant mixtures in a timely manner. The instructions say the recommended brand and indicate its quantity. When buying, it is necessary to take into account the level of its viscosity, the classification of quality. For Tiller Neva, you need to purchase oil in the gearbox and in the engine.

Tiller Neva is equipped with different motors. They require lubricants of different brands and manufacturers. They should be filled into the engine taking into account the viscosity and category. For example, the Tiller Neva MB-2 is equipped with an American Briggs (Bridge) engine, the MB-23 is produced on the basis of Honda engines.

If a device with a Honda engine is purchased for a land plot, you can fill it with SAE 10W-30 grade in summer and winter. For the Lifan engine, the same universal tool is suitable. Subaru produces lubricant for its equipment itself. With a Subaru engine, you need to buy grease from the same company. Her brand is Ow20. It is suitable for winter and summer engine operating conditions. Let’s fill in 5w-30 of the same manufacturer instead.

Into the Briggs engine Stratton is filled with SAE 10W-30 summer engine oil. For winter conditions, SAE 5W-30 is suitable. Its consumption is higher than that of other motors, so the level should be checked more often. If necessary, the lubricant is added to the norm.

The gearbox is an important part of the tiller. For proper operation, it is necessary to fill the Tiller Neva gearbox with good quality oil, periodically replace it. These oils include TEP-15 and TM-5. Its volume is 2.2 liters. The spent liquid in a hot state is drained through a special hole and poured fresh. These types are suitable for MB-1 devices. When replacing, the unit is installed in a vertical position, a container is placed under it for draining the mining.

If the tiller is rarely used for work, the replacement is done at least once every two years. The Neva MB-2 unit needs to be filled with TAP-15V oil; instead, you can use the TAD-17I brand.

You need to know when the oil changes. Check the level of the unit you just bought. Some tillers are sold without lubricants. If necessary, you can add oil and the run-in device within 20-25 hours. Then the replacement is done after 100-250 hours. Terms are indicated in the instructions.

What kind of oil to pour into the tiller engine

Tiller and mini tractor manufacturers prescribe engine oils for both gasoline products and diesel engines. Motors are tested at the factory. At this time, lubricants are used, which are recommended in the instructions. Some manufacturers recommend their own brand oils. Tiller Patriot is equipped with the engine of the same name and needs oil from Patriot 5W30 SJ / CF, Patriot Supreme HD SAE 30 4T.

Classification of oil grades

To increase the service life of a gasoline or diesel engine, you need to make the right choice of engine oil. Untimely replacement thereof Reduces the life of the engine. How to choose it, in what quantity, how to pour it into the tiller. let’s talk about this in more detail.

Each mini-tractor or tiller kit includes instructions and a product passport. In the instructions, the manufacturer lists the suitable grades of fuel and lubricating fluids that can extend the life of the equipment. The engine oil performs the following functions:

- Cooling;

- Lubricants;

- Seals;

- Cleaning.

With air cooling, the grease settles on the walls of the hot cylinder. These deposits contaminate engine parts and make lubrication difficult. Therefore, antioxidant additives are present in the lubricant. They remove carbon deposits from the cylinder walls and extend the life of the tiller. Different climates require the use of different oily fluids. They differ in viscosity, composition and purpose.

Brait Tiller Oil

Different oils are suitable for tillers of different capacities and types. Chinese Tiller Bright BR-68 has a four-stroke engine, therefore it is strictly forbidden to use oil for two-stroke, as it does NOT provide sufficient lubrication.

A multigrade SAE 10W-30 grade oil that can be used at any temperature is suitable for almost all Brait devices. It is important that the oil is highly refined.

What kind of oil to fill in the MTZ tiller with a Honda engine

Tillery MTZ have established themselves as high-quality agricultural machinery, in combination with the world-famous Honda engine, they have excellent performance characteristics.

For the correct operation of the entire device, it is necessary to carry out timely technical inspection, including checking the oil level. What kind of oil to fill? For tillers Belorus 08H-09H with Honda GX 240, 270, 340 and 390 engines, oil of classification NOT lower than SG and SF is suitable, multi-grade SAE 10W-30 oil is recommended, however, under specific temperature conditions, it is necessary to select a special oil.

What kind of oil to pour into the Lifan tiller

Choosing the right oil is essential to keeping your engine running smoothly. In the instructions that come with the tiller, the manufacturer always notes which oil is needed for a given motor.

tiller Lifan needs quality oil. For four-stroke engines, it is forbidden to use oil suitable for two-stroke. It should also be free of additives.

For Lifan tiller with 6.5 HP engine The gearbox requires SAE 5W-30 oil. For most models with engines of different power (5.5. HP. 13 HP), SAE oil. 30 year old, or all-weather SAE. 10W-30.

For diesel engines

Owners of the recommended engine oil increase the service life of the unit and reduce the consumption of diesel fuel for the diesel tiller. The instructions for the diesel engine tiller indicate the following categories of lubricants:

- CA. for work with low loads;

- SV. for working with high-sulfur fuel;

- CC. for a non-turbocharged engine operating with increased loads.

Category CA reduces the amount of carbon deposits in the cylinders, but decreases the quality of the lubricant. Any lubricant is filled in the required amount. Decreasing or increasing it leads to engine seizure.

What oil is better for pouring into a tiller engine

There is a lot of controversy about which oil should be poured into a home tiller engine. Those who consider their point of view to be correct, others refute it, but only one thing can resolve these disputes. the instructions for the device, created by the manufacturer of the equipment. Each of the manufacturers in it indicates the exact amount of oil to be poured, how this amount is measured, and even the type of oil that is used.

What all their points of view agree on is that the oil should be intended specifically for the engine. Two types of oils are distinguished. oils for two-stroke engines and oils for four-stroke. Both of these options are used for chillers, depending on which engine is installed in the model. Most Tillers have 4-stroke engines, but to determine the type of engine it is worth looking at its factory markings.

Both types of oils are divided into 2 types according to their composition. This criterion allows you to distinguish between semi-synthetic and synthetic oils, or as they are also called, mineral oils. There is an opinion that synthetic oils are more versatile and can be used constantly, but this is not the case.

The use of oils is divided according to the seasonality of the use of the tiller. So, some models can be used in the winter season, and due to the thickening of natural components that are sensitive to a decrease in temperature, semi-synthetic oils cannot be used like mineral oils in winter. But the same oils are successfully used in summer and reliably protect equipment.

Thus, oil is used not only as a lubricating agent for engine components, but also as a medium that effectively retains soot generated during fuel combustion and metal fractions that appear during the rubbing of parts. This is why most oils have a thick, viscous texture.

Oil mining drained from the tiller

What kind of oil to pour into the tiller

In the maintenance of agricultural equipment, it is important to select the right accompanying and consumables. Particularly acute, in this sense, is the question: what kind of oil to pour into the tiller. The performance of the equipment, its service life and a number of other factors that relate to a specific brand of tiller depend on this choice. Some manufacturers clearly indicate in the technical documentation that comes with the device, the recommended brand and type of oil. However, such information is not always saved, and as a result, the user of the equipment is forced to follow the basic recommendations, ignoring the manufacturer’s warnings.

What oil is better to fill in a diesel tiller

In addition to the fact that oils are divided into synthetic and mineral oils, they are also divided according to the types of fuel that the engine burns. According to the API standard, there are three types of oils. for gasoline engines, for diesel engines, as well as universal, which are suitable for devices of both categories. The first category includes oils with a two-letter marking. In this case, the first letter on the left must be S, the second can be any of the list (A, B, C, F, G, H, J). If the oil is intended for diesel engines, then the first letter on it will be different, namely. C.

Universal oils suitable for all types of engines are usually marked with a double marking, in which 2 types of devices are indicated at once through the sign /. For example, it can be SF / CC, or SG / CD.

As for a more detailed decoding of the markings, it is worth noting that the quality of all oils is determined precisely by the second symbol in the marking. The closer it is to the beginning of the Latin alphabet, the worse the quality of the oil. Thus, diesel oil with the CC marking is slightly worse in performance than the engine oil with the CD marking.

Comparative characteristics of oils

What kind of oil to pour into Tiller Neva

A feature of Neva tillers is a wide variety of modifications of the model range due to the use of various engines, respectively, from different manufacturers. Therefore, before choosing an oil for a tiller, it is worthwhile to once again revise the instructions for the engine and check which oil is recommended by its manufacturer. For the features of the tiller models and technical characteristics, read the relevant articles. tiller Neva MB-2S-7.0, Neva MB-23S-9.0 Pro, as well as technical characteristics and device of motor cultivators. Neva MK-100, Neva MK-200.

What kind of oil to fill in the tiller gearbox

Despite the fact that the gearbox, like the engine, is actively working, they require completely different types of oils for lubrication. It is not engine oil that is poured inside the gearbox, but gear oil, which provides an excellent degree of lubrication of moving parts. The amount of oil to be poured is also determined by the manufacturer, but NOT the engine, namely the device as a whole, in this case it is the tiller.

What kind of oil to fill in a Subaru tiller

One of the most popular models of Subaru engines installed in Tilleri is the Robin Subaru model. This engine is quite sensitive to the quality of the oil used, so the manufacturer recommends automobile oil for it, as well as 10W-30 according to the SAE classification. Recommended oil grade is SE or higher. In this case, the quality of the oil must be Not worse than SG. Therefore, once again, asking the question: what kind of oil to pour into the Subaru tiller, ideally it is worth giving preference to oil marked SJ or SH in case of its absence.

In the gearbox

The gearbox is the most important part, because it is he who is responsible for converting and transmitting torque from the gearbox. Careful care and high-quality oil used for the device significantly extends its life.

To replace the oil composition in the gearbox, it is necessary to perform a number of manipulations.

- the tiller must be placed on a hill. best of all on a pit.

- Then the hole for the disposal of used oil is unscrewed. The locking plug is usually located on the gearbox itself.

- After that, a prepared container is substituted for draining the spoiled lubricant.

- After completely draining, the hole must be tightly closed.

- When these manipulations are carried out, clean oil must be poured into the gearbox.

- Then you need to screw the hole plug.

The initial oil change is made after the break-in time has passed. For example, in the Energoprom MB-800 model, the break-in time is 10-15 hours, in the Plowman ТСР-820 unit. 8 hours. But the line of tillers “Oka” is designed taking into account running in 30 hours. Subsequently, it is enough to drain and fill in new oil every 100-200 hours of full operation.

How to check the level?

Checking the oil level is carried out using standard technology, to which everyone is accustomed. For this, a special probe is present in the tiller’s device, which goes deep into the unit. After removing it from the hole, at the tips of the dipstick you can see a limit strip, the level of which is equal to the level of the oil. If there is not enough liquid, then it must be topped up. On the other hand, this nuance forces you to check the entire system, since a low level of lubricant indicates that it is leaking somewhere.

In addition to the standard dipstick, some models of the tillers have special sensors that automatically indicate the amount of lubricant present. Even in the process of replacing the oil liquid, it can be used to determine how much the size of the lubricant composition has grown or its lack.

Which is better to choose?

As mentioned earlier, there are several types of tiller oils. It is necessary to use the liquid recommended by the manufacturer of the unit. for this, it is enough to carefully study the labeling of the device and read the instructions.

In addition, each separate type of oil is divided into several types according to its chemical composition. In most cases, manufacturers try to manufacture units with the ability to use the most common types of oils. synthetic, mineral, and semi-synthetic, for example, Mannol Molibden Benzin 10W40 or SAE 10W-30.

It should be noted that this lubricant contains a friction modifier, which creates a strong film on the inner surface of the parts. This significantly reduces the wear rate of the tiller.

Another marking that should not be forgotten is the designation of the properties of oil exploitation. It also comes in several varieties. For example, category C is used for 4-stroke diesel engines and category S is used for gasoline engines.

From THIS data, a certain total can be derived. Given the engine variety, a high level of demand is directed to multigrade oils labeled 5W30 and 5W40. Of anti-corrosion oils, 10W30, 10W40 are popular.

Appointment

When buying a new tiller, the kit must contain accompanying documents, in which there are special sections with recommendations for proper care and operation. The names of oils ideally suited to the unit are also indicated there.

First of all, you should understand the basic functions of oil fluids. Liquids do the following:

- System cooling;

- Obtaining a smearing effect;

- Cleaning the inside of the engine;

- Seal.

During the operation of the tiller in an air-cooled engine, the oil liquid begins to burn, respectively, the burnt particles remain on the cylinder. That is why a smoky exhaust is formed. In addition, resinous deposits are the strongest contaminants for the rest of the tiller, due to which it becomes more difficult to lubricate the parts.

For the correct choice of oil fluid, remember that each individual composition is designed for a specific season and climatic temperature.

- The summer type of oil liquid is used exclusively in the warm season. Has a high level of viscosity. No letter designation.

- Winter oils are used during cold weather. They have a low level of viscosity. The letter designation is W, which means “winter” in translation from English. This variety includes oils with the SAE index 0W, 5W, 10W, 15W, 20W, 25W.

- A variety of multigrade oils is more popular in the modern world. Their versatility allows you to fill the engine with fluid at any time of the year. It is these lubricants that have a special index in the general classification: 5W-30, 10W-40.

In addition to seasonality, oils are divided by composition. They are:

- Mineral;

- Synthetic;

- Semi-synthetic.

In addition, all oils differ in the performance requirements of 2-stroke and 4-stroke engines.

The price of the issue, of course, is high, but the reaction of the unit lies in its long service life.

Tiller oil: which is better to fill and how to change?

Buying a tiller is a pretty serious step that should be prepared in advance. For the long-term operation of the unit, it is necessary to carry out timely preventive work, if necessary, replace parts and, of course, change the oil.

In the engine

The primary oil change in the internal combustion engine occurs after 28-32 hours of operation. The next replacement can be done NOT more than 2 times a year. in summer and winter, even if the unit has been idle for some time. To start the replacement process itself, it is necessary to prepare special attributes. a funnel and a container for draining the spent liquid.

At the bottom of the engine there is a hole with a cap through which old oil can be drained. In the same place, a container for draining is substituted, the locking cap is unscrewed, and the waste liquid is drained. It is necessary to wait some time for the residues to completely drain out of the engine system. Then the plug is screwed into place, and fresh oil can be poured.

Its quantity must be identical to the drain. If it is not possible to make a measurement, it is better to look at the technical data sheet of the unit, where the required number is indicated in grams. After new oil has been added to the engine, the level must be checked. To do this, just use a special probe.

This instruction is a general guideline for both two-stroke and four-stroke models. specific information on how to change the oil fluid in the tiller is better viewed in the instructions for a particular unit.

How to change?

Anyone can change the lubricant in the tiller, but if there are any doubts, it is better to contact a highly qualified specialist. The procedure for updating with oil liquid in any model of chillers is NOT different from each other, whether it is an Enifield Titan MK1000 instance or any other motor from the Nikkey line.

Thanks to the above nuance, the warm spent mixture easily flows into the container placed below. After the used oil is completely gone, you can start the replacement process.

First you need to Unscrew the breather plug, drain the remaining used oil and, if necessary, change the additional oil and air filter. Then you need to fill in fresh liquid and return the plug to its place. Pour new oil carefully so that it does not get on other parts of the system, otherwise an unpleasant odor will arise.

Can I use car oil?

It is strictly forbidden to use engine oil in chillers. Unlike a car engine, a Tiller has certain principles of lubrication and an appropriate temperature regime for operation. In addition, tiller engines have certain features. These include the material of construction from which it is made, as well as the degree of forcing. In many cases, these nuances are incompatible with the characteristics of automotive oils.

How much oil to fill in the tiller gearbox?

If you have a question about the amount of oil to be poured in, you should follow a simple algorithm:

- the tiller should stand on a flat surface with wings parallel to the ground;

- A wire with a length of 70 centimeters can act as an oil dipstick;

- When bent, the wire should resemble an arc in shape;

- The wire is pushed into the tank to the bottom to control the oil level.

If the lubricant is 30 centimeters of wire, DO NOT top up any more. If it is dry, you need to fill in at least two liters of grease.

Oil change algorithm in Tilleri

Before introducing a new lubricant, it is important to clean the gearbox of the used compound.

Change the lubricant immediately after using the equipment, before the oil has cooled down. You can quickly change the oil with your own hands according to the following scheme:

- the tiller is installed horizontally;

- Two plugs are installed. Through one, the already used composition is drained, the second is used to fill in new oil;

- The lubricant filling cap is unscrewed. A wide container is installed under the drain hole;

- The drain cover is unscrewed to drain all the used oil;

- The drain cover is screwed up to the stop with a spanner wrench;

- The funnel is inserted into the filling hole and new oil of the appropriate brand and temperature is added;

- The lid is screwed on. With a special probe, you can check the amount of the poured product.

For details on the specifics of the replacement procedure, see the introductory.

If the equipment is operated under normal conditions, the oil in the gearbox is changed once every hundred hours of tiller operation. When working around the clock, replacement is done every fifty hours. This will prevent various breakdowns of agricultural machinery.

Tiller reducer

Reducer Acts as one of the most essential assembly systems in the tiller. With its help, the torque is transferred from the engine to the wheels through a V-belt transmission. The gearbox also controls the speed change and the movement of equipment.

What kind of oil to fill in the tiller gearbox?

How well and durable the tiller gearbox will serve depends directly on the quality and characteristics of the oil.

When purchasing a lubricant, it is worth considering the advice of the tiller manufacturers. It is also worth paying attention to the price of oil. Cheap tools DO NOT guarantee good gearbox performance.

It is worth noting the following types of oils according to Labeling on the market:

- SAE. An excellent composition for work with frequent temperature changes. A number is indicated before the letter W. this is an indicator of the minimum temperature at which the lubricant is poured;

- ASEA. The most popular universal products. These figures depend on the conditions in which the equipment can work;

- API. Are in the Highest Demand. They serve as a good lubricant, regardless of the type of gearbox and the conditions of use of equipment.

Before using the oil, it is definitely worth Reading the instructions of the tiller manufacturers.

| Mark Tiller | Tiller gear oil type |

| Neva MB-2 | Transmission oil TEP-15 (-5 ° C to 35 ° C) GOST 23652-79, TM-5 (-5 ° C to 25 ° C) GOST 17479.2-85 according to the international viscosity classification system of engine oils SAE90 API GI- 2 and SAE90 API GI-5, respectively. Filling volume 2.2 liters |

| Neva MB-1 | Transmission oil in accordance with GOST 23652-79 (TAD-17I, TAP-15V, etc.). |

| MKM-3 Mobile-K (lander) | TAD. 1711 GOST 23652-79. Can be filled with SAE 90, SAE 75W / 90 according to API GL-4, GL-5 classification. Refueling 1 liter |

| Salyut-5 fireworks 100 |

TM 5-18 (TAD17Y) |

| Belarus 08N-09N | In summer (above 5 ° C) Motor oils M-10V2 or M-10G2 GOST 8581 (duplicate. Motor oil M-bz / 10V GOST 10541) In winter (below 5 ° C) Motor oil M-8G2, GOST 8581 (can be replaced with M-4 s / 6v1 GOST 10541) |

| MTZ.05 | M-8B1, M-8V1, M-8G1, according to GOST 10541-78 |

| cascade MB6 cascade MB6-62 |

Transmission oil according to GOST 23652-79 Transmission oil GOST 23652-79 or aircraft type MS-20 GOST 23652-79 |

| Ugra NMB-1 | ТСn-10 GOST 23652-79 or other type, which corresponds to SAE 80. 85W API: GL3. GL4 |

| Eyes MB-1D1 (2) M | Transmission oil TAD-17I, TAP-15V and others in accordance with GOST 23652-79 |

| Celina MB | From the factory in tillery gear oil “RAVENOL” EXP SAE 80W-90 API GL-5 Can be filled with SAE 90 GL-5 gear oils |

| Tarpan | Transmission oil TAD-17I or analogues of the SAE 90 SAE 75W / 90 type API GL-4, GL-5. |

| Favorite MB. 3, MB. 4, MB. 5 | TAD-17i or MS-20 |

| agate | TAD-17I; MS-20 |

| motor Sich | Lubricating oil TAD17Y, Tap-15V, TEP-15, TSP-15K, TSL-14 in accordance with GOST 23652 |

| Vario | oil 80W90 |

| Patriot garden | oil 85W90 |

| Zubr | TAP 15 oil |

Features of the tiller reducer device

In each tiller unit, the design includes certain details. They differ slightly in different types of gearboxes.

In detail, the mechanism consists of the following parts:

- Covers and pulleys;

- Shifting forks and wasps;

- Bearings;

- Lever of regulation and switching;

- Input shaft bushings;

- Shaft block;

- Intermediate shaft gears;

- Washers and oil seals;

- Double row chain;

- Left and right axle shafts;

- Double stars;

- Asterisk block;

- Clutches;

- Input shaft;

- Bracket and springs;

- Clutch forks.

You can take a closer look at the structure of this node in the diagram. The tiller gearbox is quite complicated, but following the diagram, you can easily cope with its dismantling and reassembly.

The following steps are taken:

- The reducer is completely removable;

- The screws are loosened, the protection covers are removed;

- The input shaft sleeve is removed very carefully, the fork and lever are dismantled;

- The input shaft is removed together with the gear;

- The shaft sleeve and chain are removed;

- The shaft block is dismantled together with the sprocket;

- The intermediate shaft is removed together with the gears;

- Clutch with left and right axle shafts are removed.

After all THESE actions, you can get the reducer for analysis. At the end of the repair, it is reassembled.

What are the tiller gearboxes. varieties and purpose

The tiller design is quite diverse. Modern units are equipped with the following types of gearboxes:

- Tiller angle gearbox. It is the connecting piece between the engine and transmission. Such a mechanism is distinguished by good characteristics and availability, therefore it is actively used by farmers of small and large lands. The corner model can be modified, making it much more productive;

- Reducing gear for tiller. With the help of this type, the engine load increases and its speed decreases. These gearboxes are among the most reliable and multi-tasking ones, since they consist of durable steel parts and a high-quality cooling system. This technique is highly efficient regardless of workload;

- Reverse gear. This type of reverse rotation is the presence of reverse. The mechanism is installed between the bevel gears, namely on the main shaft. But the gearbox cannot boast of high performance, it has a low speed;

- Gear reducer. This mechanism is installed on heavy tiller models. With its help, torque is transmitted to the wheels of equipment. The gearbox is highly reliable and has a simple design. But maintaining such a mechanism is extremely difficult;

- Worm. This is a gearbox with a special screw, there is also a gear worm wheel. All used spare parts are high-strength, the technique is efficient and durable. A gearbox of this type is very relevant due to the presence of the angular speed by reducing the type and the torque of the highest type. Even a homemade gearbox will allow the machinery to work with little noise and a smooth ride. Before implementation, it is worth paying attention to gear ratios.

Each type of gearbox with its own Distinctive characteristics. You should pay attention to them during the selection and installation of the mechanism.

How to replace oil seals with Tilleri?

If there is an oil leak, the oil seal must be replaced. The algorithm for replacing this element is performed according to the following scheme:

- The cutters are removed from the shaft, dirt and oil residues are completely cleaned;

- The bolts are loosened on the cover that protects the gearbox. The tight-fitting lid is tapped with a hammer;

- The worn-out oil seal is pulled out and the place under it is carefully rubbed;

- At the edges, the new oil seal is sealed with a sealed agent. The part is installed and the cover is screwed on.

Disassembly and replacement of the oil seal Takes a minimum of time. Then, before introducing the tiller, you need to make sure that the used sealant is completely dry.

The above recommendations and algorithms are suitable for the following brands of equipment: Neva MB-1 and MB-2, Cascade, Farmer, Oka. After that, you can independently perform simple steps to change the oil and oil seals.

How it works?

Despite the fact that the St. Petersburg plant “Krasny Oktyabr” produces a wide range of Neva tillers, differing in power and configuration, the gearbox in all THESE devices is arranged according to a single general scheme. According to the principle of operation The gearbox used is of the gear-chain type, where the change in rotation speed is carried out due to the interaction of a system of gears of different diameters and with a different number of teeth, which are either in direct contact with each other, or are connected by a chain transmission.

This design combines the device used on the tillers with the gearshift mechanism of the bicycle. deceleration of rotation is achieved by transferring the transmitting chain to the gears with a large diameter. The only difference is that in the gearbox, in addition to the gears located on the same axis, separate gear links are also used, which make it possible to vary the speed and direction of rotation over a wider range, as well as transmit rotation simultaneously to the wheels of the tiller and the equipment used on it.

The entire system of chains, shafts and gears of the Neva tillers’ reducers is housed inside a strong sealed case made of aluminum. Lubrication of rotating parts is carried out by filling the product with oil (this principle of structure is called “oil bath”).

The gear shift lever, as well as other elements for controlling the gearbox are brought out, which greatly facilitates its adjustment. There are 5 positions in total. When the lever is pressed, the fork connected to it disengages the rotation transmitting clutch from the gears. When shifting the lever, the fork moves the clutch to the desired position. When you release the lever, the clutch engages with the desired gear system and the fork returns to the home position. In standard operation, rotation is transmitted through a gear located near the input shaft of the device.

Finally, extending the lever all the way to the end results in an overdrive, allowing for higher travel speeds.

The dimensions of the gearboxes used on the products of the Krasny Oktyabr plant are 23 × 30 × 61 cm, and their weight without oil does not exceed 18 kg. The volume of the oil sump used to fill the device with oil is 2.2 liters.

The diameter of the shaft transmitting rotation from the device to the wheels is 30 mm.

Basic rules for performing work

Any work on disassembly and assembly of the gearbox, as well as on its maintenance should be carried out in a pre-prepared workplace with all the necessary tools. It is imperative to ensure the cleanliness of the workplace, which will prevent dust, dirt and debris from getting inside the mechanism. It is advisable to carry out all work in clean work gloves, which will provide both protection for hands from injury and dirt, and protection of gearbox components from unwanted debris and dust.

Carefully monitor the condition of the tool used. there should be no visible damage, especially cracks. Failure to do so will result in dangerous injury.

Before disassembling the gearbox, drain the oil. After that, you need to thoroughly clean all parts of the device from possible contamination.

Typical breakdowns and their repair

The most frequent breakdowns of the device are as follows.

- Oil flow through the output shaft. To eliminate this problem, it is necessary to change the oil seals installed in the gearbox. To replace them, you need to purchase new ones, dismantle the ones installed in the gearbox with a screwdriver, and then install new oil seals in their place. This will help strengthen the tiller, the power of which is reduced due to constant oil leaks from the gearbox.

- If there is a shift shaft leakage, then you may have added too much grease to the gearbox. Therefore, it will be enough to drain the excess oil and check if this helped in troubleshooting. If leaks continue, replacing the oil seals will help.

- Open circuit, which leads either to jamming, or to the impossibility of operating the device in SEPARATE gears. For repair, you need to replace the broken chain with a new one.

- If the gearbox does NOT transmit torque in any of the installed gears, it is most likely that one of the gears has broken. After disassembly, you need to find a broken sprocket and replace it with a new one.

- If the gears do not shift, you need to check the condition of the fork, bushing and thread of the gear knob, and then replace the damaged element.

Appointment

The possibilities of regulating the speed of rotation of the shaft of an internal combustion engine are limited by the available operating modes, therefore, in motor technology (from chillers to cars), devices are traditionally used that make it possible to change the speed of rotation transmitted from the engine to certain structural elements.

If a gearbox is used for this purpose in cars, then gearboxes are traditionally installed on Neva tillers, which allow controlling the rotation speed, torque and direction of movement. It is to this element that the wheels of the device are connected, and various attachments that require connection to the engine (for example, cultivator cutters, mower blades, brooms, and so on).

How to choose spare parts?

Pay particular attention to the type of oil you intend to fill in the gearbox.

The following brands of transmission oil are best suited for devices used on Neva tillers:

- TEP-15;

- TM-5;

- SAE90 API GI-2;

- SAE90 API GI-5.

How to change the tiller reducer chain “Neva”, look in below.