What lubricant grease the screwdriver gearbox. Elimination of the detected malfunction

What lubricant grease the screwdriver gearbox?

Prof or Home Master should bother about the tool that he uses in the activities of his company. For this reason, the duration of the equipment directly depends. The power tool needs high.Quality lubrication. This will protect the nodes and mechanisms from wear. Work with all this will be significantly more effective.

Therefore, the grease for the perforator is very fundamental. It must be selected according to the features of the equipment model. Each brand develops lubricants with certain technical characteristics. Different additives included in the composition provide a variety of properties of similar products. Therefore, it must be selected in agreement with the operating criteria for the operator.

Than 150 years have passed that all additional details of the moment are removed from the door, as in the far 1851 the first time began to be used in the works of a manual punch. It was made for the needs of the mining industry and did not even have the variety of modes that of course of modern models at the moment. But even then he significantly improved the work of workers. No wonder the presented type of instrument is extensive distribution among masters of various specializations.

Since then, the tool has been subjected to significant design changes. One thing remains constant. The need for proper care. The device of the perforator is quite complicated. Some details to be rapidly wear out.

So that this does not work out, Lubrication for a perforator should own a number of properties. With the development of the submitted power tools, its additional materials were also improved. To realize how to choose a lubricant, you need to see the structural features of the equipment.

The mechanism that is able to produce the required effect on the material will appeal to an electric one in another pneumatic. Perforator has 2 main features. The power of the motor and the impact power are related to them.

Lubrication Reducer of the screwdriver DeWALT DCD734 14.4V Cordless Drill-Driver Gear Greasing

The just the indicator in watts and joules, the stronger the tool. The electrical and pneumatic type of equipment has a different device. Because, what Lubrication It is used for a perforator of each variety, the mechanism of operation of their devices will respond.

The electrical type of tool consists of a coil, core and drill. These are the elements that need lubrication. The pneumatic mechanism has a cylinder and a piston, a drill and a fight. They significantly affect the weight of the perforator.

Lubrication for the perforator Makita, Hitachi and a huge number of other manufacturers make the functions required from it. At first, it flows through the necessary details of the mechanism, preventing the friction of their surfaces one about the other. With all this, respectively, their wear is miniaturized.

Such substances have additional additives that prevent the occurrence of corrosion. The 2nd two or more fundamental feature is the washing function. When working equipment, of course, small particles of material and dust fall into the tool. They settled on the mechanism and lead to its wear.

Lubrication collects this mud and garbage and keeps them in a suspended state. When there is a lot of pollution here, the substance must be changed. There are mineral, synthetic and semi.Synthetic lubricants. The cheapest substances are made based on oil. These are mineral varieties. They rapidly lose their characteristics and require often a change.

Synthetic lubricants are expensive, but the quality of this brand is the highest. They do not often need to be changed, they provide a very benign protection of the mechanism from wear.

Disassemble and Grease Harbor Freight Impact Screwdriver (Pittsburgh)

Average in semi.Synthetic oils. They own the best than mineral varieties, properties. And to synthetic materials they do not reach little.

Each lubricant has its own appropriate features. They must certainly be taken into account. Therefore, we choose a grease for the perforator consciously. For each type, the component of the mechanism selects their variety of substance.

Lubrication for the gearbox, it has no right to be used for drill. Therefore, before purchasing lubricating materials, you need to closely study the manufacturer annotation. It is correctly indicated that from components and devices asks for processing how often it needs to be done.

Also, the manufacturer will certainly shows what substances it is allowed to create an inventory care. If you find the product recommended by the manufacturer, it is forbidden to be controlled by common rules for changing oil on various mechanisms of the perforator.

Watery oils are allowed to be used for the gearbox. They are poured in the quantities established by the manufacturer. In the case, of course, special holes. Through their butter, poured inside. The covers are locked, insulating the liquid tightly. The most popular now is Lubrication For the perforator Makita, Bosch.

For the gearbox, it is fundamentally that a mixture of such funds is watery. Some models involve the introduction of cream.Like lubricants. Alas, this is faster, the exception.

Liquid oil leaves a narrow, but strong trace of the substance on the parts of the gearbox. He is still called film. Very watery substances will not be able to maintain the monolithic coating. Dense substance makes a very dense film. It prevents the movement of the gearbox.

The most popular funds of this type are now Makita P-08361, Bosch 1615430005.

During operation, the Bur is subject to significant mechanical influences. Pressure and heating are able to rapidly disable the nozzle and their landing place. To avoid overheating, special substances are applied to Bur.

Those. Service of the screwdriver

What lubricant to use for a perforator for this purpose, you need to find out in the instrument operating manual. The manufacturer shows a list of goods applicable to grease the drill.

They also warn the getting of dirt and dust on the work surfaces. Whenever before installing the drill cartridge, it must be treated with special material. The nozzles are lubricated, alas, not quite plentiful. The effectiveness of the work and its final result depends on the correctness of the implementation of this act.

Here, professionals recommend not saving as a lubricant. The tool may overheat another, and you will need to be repaired.

Device and principle of operation

The gearbox is an integrated gear mechanical node through which the axis of the motor-power unit transfers torque to the cartridge. Two or three gear rates are installed in the gearbox.

The design of the “household” double.Mode screwdriver includes:

- Plastic case. A small drum that is attached to the cartridge. The case itself is fixed motionless, and the shaft of the cartridge is inserted into the clamp on one of the transfer plates;

- 2 or 3 gear plates (drive). A round plate of metal, on one side of each there are 3 protrusions under the small gears. On the other side of one of them, a clamp under the shaft of the cartridge, and the other (or 2 others) has another T.N. “Planetary” gear, which rotates three small gear wheels;

- 6 or 9 small gears (three each: they can be one or different thickness). These are the so.Called “satellite” gears that are installed and rotate freely on the protrusions of the gear plates. With their teeth, they interact with the solar gear located between them and with the ring gear, which is located on the inner surface of the case;

- Ring gear. A metal ring with teeth on the inside and small protrusions on one of the rings of the external. On these protrusions and balls, she fits on the inner surface of the case.

Details are lubricated, collected sequentially and installed inside the ring gear, which lies inside the body of the body (it contains a seal with deepening into ball bearings and ledges of the gear). After that, the surface of the open satellites is closed with a metal washer, in the center of which there is a hole, which includes the engine shaft with another gear fixed on it.

During the work of the screwdriver, the gear wheel on the engine shaft rotates the upper satellites, and they, spinning around its axis and, along the ring gear, respectively, pass the movement to the next drive. Depending on the number of plates and small gears. The speed of rotation will be proportionally reduced.

As can be seen from the device of the gearbox. They are divided depending on the number of gear rates on:

Another indicator according to which gearboxes are divided is the material from which its parts are made.

The production of satellite gears uses:

- Plastic. Such structures are relatively lighter, but their reliability is lower than that of a metal analogue;

- Metal. They are durable and with proper care and lubrication will work “like a clock”.

The choice of lubrication and differences between them

Not only the user decides which lubricant for a screwdriver is better. Bosch, Makita, Metabo, Devolt manufacturing companies produce a large number of lubricants for building tools. They recently joined Russian bison and interca.

The main condition for lubrication is the absence of solid fractions in it so that this does not destroy the details of the tool. The oil should form a film that protects the elements from corrosion. And an important point. Lubricant should have a viscosity that allows it to stay on the details.

What lubrication of the screwdriver gearbox is better. The differences are their consistency. For example, a soft lubricant from metababo is used for a low rotation speed. For other parts, liquid or semi.Liquid lubricant can be used.

Than and how to lubricate the drill correctly?

For Soviet equipment, it is better than lubrication of lutol-24 not invented, and it must be laid in a gearbox and lubricated guides and gears in Soviet, and not only Soviet equipment.

Naturally before lubrication, you need to clean well and wipe the entire part (wash with a solvent, diesel fuel, gasoline!), just clean and wipe dry.

Put and put fresh lititol-24 into the gearbox and gear and collect-that is all!

Lubrication of Litol-24 will withstand high speed and fever and increased loads and friction, it is laid in the gearbox enough in large volume, as the master says-the excess will come out!, Therefore, her work is designed for a long time, and replacement actually only during repair.

In Soviet times, that people, that the technique was not spoiled by the frills. Hali that they give.

So you can treat your veteran drill with what remains of Soviet times. Even a simple solidol.

From modern lubricants for gears, you can use a shus grease (motorists know what it is), lip. Boshevsky lubricants have proven themselves well in gear.

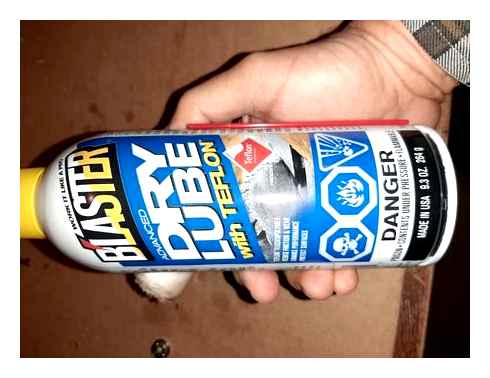

If you suddenly be lucky and come across it here

Do not miss the drill such a moment when servicing a drill: remove as thoroughly as possible, all the old grease, because there are surely there are metal particles from gears and other dirt that penetrated the tools.

There are a lot of types of drums and at purpose (drums, unstressed, mixers drills and.T.E) and by type of power, it is both manual and electric and pneumatic.

The drills are also different in power, in terms of the number of revolutions that it can “give out”.

Manufacturers are different, many manufacturers produce their lubricants and recommend using only them.

In any case, in order to lubricate the drill (its gear) to it (gearbox) must be reached.

There are also a lot of options, perhaps your drill must be “split” into two parts (I’m about the case, we unscrew the screws of the body mounting).

It is not necessary to disassemble it to components.

They removed the old lubricant (although this is not always done) carefully cleaned of the old lubricant (conveniently with a rag) laid a new one, in general, everything, there are no difficulties here.

Albina always lubricated its “ancient” Soviet drill with Litol-24, there was no thought to switch to something more “advanced”, the lubricant satisfied completely.

The choice of lubrication and differences between them

Not only the user decides which lubricant for a screwdriver is better. Bosch, Makita, Metabo, Devolt manufacturing companies produce a large number of lubricants for building tools. They recently joined Russian bison and interca.

The main condition for lubrication is the absence of solid fractions in it so that this does not destroy the details of the tool. The oil should form a film that protects the elements from corrosion. And an important point. Lubricant should have a viscosity that allows it to stay on the details.

What lubrication of the screwdriver gearbox is better. The differences are their consistency. For example, a soft lubricant from metababo is used for a low rotation speed. For other parts, liquid or semi.Liquid lubricant can be used.

The reasons for overheating of the equipment

Many home masters have a question about how to use a perforator so that the body of its gearbox does not overheat. First of all, you should find out the cause of too intense heating. One of these reasons can be too much lubrication in the inside of the gearbox, which also negatively affects the performance of the device.

The reason for the intensive heating of the perforator gearbox may also be that an insufficient amount of lubrication comes to its internal details. This can happen in cases where the perforator is used for too long in detection mode.

Through this hole in the perforator body, the lubricant is periodically laid during operation

Another common reason for the overheating of the device is that the holes for which the air is supplied to the punch electric motor are clogged. In such cases, it is necessary to carefully clean the perforator of dust and transfer it for a while into a normal drilling mode. When working in such a sparing mode for about half an hour the temperature of the gearbox body should decrease.

What lubricant grease the screwdriver gearbox?

Screwdriver, like another mechanism, needs to maintain and care. Sometimes users forget about such a simple procedure as lubricating the details of the tool. This article will tell you what grease to grease the screwdriver and how to do it right.

A typical design of a screwdriver

There is nothing complicated in the device of the screwdriver. The main thing, with the subsequent disassembly of the instrument, remember the position of the details:

- Frame. Often it is made in the shape of a pistol. This is due to the convenience of operation and the ability to work at different angles. The case itself is made of plastic. It costs inexpensively and has a slight weight.

- Cartridge. Since the screwdriver is used for twisting and drilling, a cartridge is installed on it. Depending on the model, it can be quick.Collapsible or selfless. It is located at the end of the spindle wound on the thread.

- Adjustable rotation clutch. So that the screwdriver does not overheat during operation, the rotation clutch with adjustment is installed on it. In the case of excessive effort on the tool, the rattle is triggered and the cartridge stops working.

- Engine. All models of screwdrivers are equipped with engines. It can be brush and brilliant motors. The engine is a hollow cylinder, inside which there is a rotor and magnets. The rotor stands on small brass supports. On the rotor itself, around the circle, grooves are located. They have a wire with increased permeability. In collector engines, the brushes are made of graphite or coal. There are no brushes in the biases.

- Gearbox. An important mechanism of screwdriver. Located in a separate building. Planetary gearbox is a few gears, which have a total axis of rotation. Many are interested in which gearbox is in a screwdriver and what material is made of. In inexpensive models, many details are made of plastic, which is fraught with a quick failure. In professional units, the gearbox and other elements are completely metal. This significantly reduces the risk of breakdown.

The reasons for overheating of the equipment

During operation, the screwdriver may overheat. If you do not stop work in this case, then the tool may fail. There are many reasons for overheating, but there are basic:

- Electricity changes or incorrect batteries;

- High load on the tool;

- Strong wear of brushes on the engine;

- Fan failure;

- Unsatisfactory lubrication of bearings or shaft skew.

The choice of lubrication and differences between them

Not only the user decides which lubricant for a screwdriver is better. Bosch, Makita, Metabo, Devolt manufacturing companies produce a large number of lubricants for building tools. They recently joined Russian bison and interca.

The main condition for lubrication is the absence of solid fractions in it so that this does not destroy the details of the tool. The oil should form a film that protects the elements from corrosion. And an important point. Lubricant should have a viscosity that allows it to stay on the details.

What lubrication of the screwdriver gearbox is better. The differences are their consistency. For example, a soft lubricant from metababo is used for a low rotation speed. For other parts, liquid or semi.Liquid lubricant can be used.

Tips for lubricating the screwdriver gearbox and tool care

What lubricant to use for a screwdriver. Old school professionals will best answer this question. In addition to modern lubricants, many still use time.Tested Litol-24. It can be bought in any profile store and it will cost inexpensively.

- Before lubricating the gearbox, it must be cleaned of old lubricant, dirt and at the same time rinse the rest of the elements. It is better not to touch the bearings. After cleaning, wipe all the details dry. Do not rinse the gearbox with gasoline, solvent and other caustic liquids.

- After all the manipulations, grease the gearbox with fresh grease and place in the case. When a screwdriver is turned on, the remaining lubricants may seep. There is nothing wrong with this. Excess oil can be removed with a napkin or a rag.

- The screwdriver itself requires no less care. For the tool to work for a long time and without breakdowns, it should be kept clean. After work, the unit needs to be cleaned from dust with a rag or soft rag.

- It is unacceptable to get into the screwdriver of moisture and water. Store the tool in a dry room. You can not throw a screwdriver, and you should also try to protect the batteries from shocks. In the case of a network unit, make sure that there are no bending and twisting cable.

- If during operation there are problems in the tool, power elements or charger, it is advisable to stop the work. With serious breakdown, it is better to contact the service center. It will save time and finances. Minor malfunctions can be settled yourself without resorting to the help of specialists.

Results

What grease for a screwdriver to choose, how to use it. All the information can be obtained in specialized centers. Friends can give good advice. You can learn more about lubricants for a screwdriver from reviews and user reviews.

Tips for lubricating the screwdriver gearbox and tool care

What lubricant to use for a screwdriver. Old school professionals will best answer this question. In addition to modern lubricants, many still use time.Tested Litol-24. It can be bought in any profile store and it will cost inexpensively.

- Before lubricating the gearbox, it must be cleaned of old lubricant, dirt and at the same time rinse the rest of the elements. It is better not to touch the bearings. After cleaning, wipe all the details dry. Do not rinse the gearbox with gasoline, solvent and other caustic liquids.

- After all the manipulations, grease the gearbox with fresh grease and place in the case. When a screwdriver is turned on, the remaining lubricants may seep. There is nothing wrong with this. Excess oil can be removed with a napkin or a rag.

- The screwdriver itself requires no less care. For the tool to work for a long time and without breakdowns, it should be kept clean. After work, the unit needs to be cleaned from dust with a rag or soft rag.

- It is unacceptable to get into the screwdriver of moisture and water. Store the tool in a dry room. You can not throw a screwdriver, and you should also try to protect the batteries from shocks. In the case of a network unit, make sure that there are no bending and twisting cable.

- If during operation there are problems in the tool, power elements or charger, it is advisable to stop the work. With serious breakdown, it is better to contact the service center. It will save time and finances. Minor malfunctions can be settled yourself without resorting to the help of specialists.

Properties of consistent gear lubricants

The standard characteristics of thick oil oils for the punch reducer are not suitable. Close parameters have only compounds for automobile CV joints.

Some properties are generally unique, since the gearbox mechanism not only works under large variable loads. When the shock mechanism is operating, spontaneous squeezing of the lubricant from the contact zone.

Requirements for the composition

- Adhesion should be so high that with any load between the details there remains an oil film.

- A high water resistance indicator is required. Perforators can work in conditions of high humidity. When cooling, reduced pressure occurs in the gearbox, atmospheric air together with fluid vapor is sucked in.

- When water hits, the emulsion should not form.

- Since the gearbox heats up greatly during operation, the lubricant lifts from the temperature. In this case, the basic properties should be restored after cooling. The heated composition should also not lose the main antifriction parameters.

- High dropproof temperature is required. Otherwise, the rotating gear under the influence of centrifugal forces will dump the grease from the surface of the teeth.

- Small cement (stone) dust enters the gearbox. The composition of the lubricant is selected so that the abrasive particles are connected and removed from the intensive friction zone. When using good oil, dirt is always on the walls of the gearbox, and not inside the gears.

- Since the gearbox body is made of aluminum alloys, and gears and bearings made of alloy steel, anti.Corrosion properties should be equally suitable for both metals.

The same properties (with the exception of the temperature of the drip and indicators of adhesion) should be present in liquid compositions. In the airtight crankcase of the gearbox, adhesion of grease is not required: liquid oil during operation constantly washes all parts of the mechanism.

How to grease the screwdriver gearbox. Lubrication of a screwdriver. Equipment and tools

Professor or home master should troubles about the tool that he uses in the activities of his company. For this reason, the duration of the equipment directly depends. The power tool needs high.Quality lubrication. This will protect the nodes and mechanisms from wear. Work with all this will be significantly more effective.

That’s why Lubrication for the perforator is very fundamental. It must be selected in coordination with the features of the equipment model. Each brand develops lubricants with certain technical characteristics. Different additives included in the composition provide a variety of properties of similar products. Therefore, it must be selected in agreement with the operating criteria for the operator.

The history of the development of technology

Than 150 years have passed that all additional details of the moment are removed from the door, as in the far 1851 the first time began to be used in the works of a manual punch. It was made for the needs of the mining industry did not have the variety of modes that of course of modern models at the moment. But even then he significantly improved the work of workers. No wonder the presented type of instrument is extensive distribution among masters of various specializations.

Since then, the tool has been subjected to significant design changes. One thing remains constant. The need for proper care. The device of the perforator is quite complicated. Some of its details are variations to wear rapidly.

So that this does not work out, Lubrication for a perforator should own a number of properties. With the development of the submitted power tools, its additional materials were also improved. To realize how to choose a lubricant, you need to see the structural features of the equipment.

Perforator device

A mechanism that is able to produce the required effect on the material, you will like electrical or pneumatic. Perforator has 2 main features. The power of the motor and the impact power are related to them.

The just the indicator in watts and joules, the stronger the tool. The electrical and pneumatic type of equipment has a different device. Because, what Lubrication It is used for a perforator of each variety, the mechanism of operation of their devices will respond.

The electrical type of tool consists of a coil, core and drill. These are the elements that need lubrication. The pneumatic mechanism has a cylinder and a piston, a drill and a fight. They significantly affect the weight of the perforator.

The main properties of lubrication

Lubrication for the perforator Makita, Hitachi and a huge number of other manufacturers make the functions required from it. At first, it flows through the necessary details of the mechanism, preventing the friction of their surfaces one about the other. Here, respectively, their wear is miniaturized.

Such substances have additional additives that prevent the occurrence of corrosion. The 2nd more fundamental feature is the washing function. When working equipment, of course, small particles of material and dust fall into the tool. They settled on the mechanism and lead to its wear.

Lubrication collects this mud and garbage and keeps them in a suspended state. When there is a lot of pollution here, the substance must be changed. There are mineral, synthetic and semi.Synthetic lubricants. The cheapest substances are made based on oil. These are mineral varieties. They rapidly lose their characteristics and require often substitution.

Synthetic lubricants are expensive, but the quality of this brand is the highest. They are not necessary often to change, they provide very benign protection of the mechanism from wear.

Average in semi.Synthetic oils. They own the best than mineral varieties, properties. But in addition to synthetic materials, they do not reach slightly.

For what parts the lubricant is suitable?

Each lubricant of course has its own appropriate features. They must certainly be taken into account. Therefore, we choose a grease for the perforator consciously. For each type, the component of the mechanism selects their variety of substance.

The lubricant for the gearbox is not able to use the drill. Therefore, before purchasing lubricating materials, you need to closely study the manufacturer annotation. It is correctly indicated that from components and devices asks for processing how often it needs to be done.

Also, the manufacturer will certainly shows what substances it is allowed to create an inventory care. If you find the product recommended by the manufacturer, it is forbidden to be controlled by common rules for oil substitution on various mechanisms of the perforator.

Lubrication for the power tool Makita, amendment in the description.

Subscribe, support the project. Financial support for amendments: 181490-7.

Gear lubrication screwdriver DeWALT DCD734 14.4V Cordless Drill-Driver Gear Greasing

Often during operation Uncharacteristic ringing sound. How to disassemble lubricate.

Gearbox

Liquid oils are allowed to be used for the gearbox. They are poured in the quantities established by the manufacturer. The case has special holes. Through them, oil is poured inside. The covers closed, insulating the liquid tightly. The most popular today is Lubrication For the perforator Makita, Bosch.

For the gearbox, it is important that the consistency of such funds is liquid. Some models involve the use of cream.Like lubricants. But this is rather an exception.

Liquid oil leaves a thin, but strong trace of the substance on the parts of the gearbox. It is also called a film. Too liquid substances will not be able to maintain the monolist of the coating. Dense substance creates too dense film. It prevents the movement of the gearbox.

The most popular means of this type today Makita P-08361, Bosch 1615430005.

The drill of the instrument

When working, the Bur is subject to significant mechanical influences. Pressure and heating are able to quickly disable the nozzle and their seat. In order to avoid increased overheating, special substances are applied to the bur.

What lubricant to use for a perforator for this department must be found in the instrument operating manual. The manufacturer indicates a list of products suitable for brown lubrication.

They also prevent dirt and dust on the working surfaces. Each time before installing the drill cartridge, it must be treated with a special material. The nozzles are lubricated, but not very plentiful. The effectiveness of the work depends on the correctness of this action and its final result depends.

It’s time to change the lubricant in the Ushm gearbox

It turns out to find and buy a lubricant for a gearbox of a corner grinding machine (Ushm) in provincial stores is not so simple. But, to replace the thickened and contaminated lubricant. What to do? Information on the Internet is very scarce, therefore I had to collect bitches and this is what was collecting.

The viscosity (penetration) is indicated by numbers after the abbreviation NLGI, which is deciphered as: National Institute of Plastic Lubrices National Lubricating Grease Institute. There is a whole institution in the USA that is engaged in anything other than lubricants.

Visibility is selected depending on the tool:

DRAS, perforators, lobe, where the gearbox has low rotation speed-NLGI-2.

Light punch and shock drills. Class NLGI-1, in consistency very soft.

Ushm, circular saws, motorcycles. Class nlgi-0, half-liquid in consistency.

Heavy perforators, junk hammers. Class nlgi-00, in consistency is liquid.

For Ushm reducers, tool manufacturers and not only produce lubricants, but there is not always the opportunity to purchase them.

If you do not find a special lubricant, you can use for example,

They already have the necessary additives and they have the right “zero” penetration.

If this is not there, take a consistent lubricant for rolling bearings with a viscosity of NLGI-2 (30 grams) and transmission oil TM-5 (GL-5) (60 grams) in a ratio of 1/2 and mix well. Such lubricants already contain the necessary outfit, antioxidant, anti.Sympathetic, etc. Additives. GL-5 transmission oil was created mainly for hypoid programs.

The use of solidols, lithols, industrial oils is not recommended. Litol is very thick, viscosity of NLGI-3 and in its composition has only oil thickened with lithium soap without any additives like I-20A oil, as the letter “speaks” the letter “.

It is good to use lubricants with the content of molybdenum sulfide mos2. It has many positive properties:

Very low friction coefficient (from 0.03 to 0.06);

A wide range of operating temperatures from.185 ° C to 450 ° C;

Performance in vacuum and radiation;

Resistance to corrosion, alkaline solutions, salt, smelter and sulfuric acid;

Hyundai H1 Grand Starex. Диагностика ходовой на трясучке

Levels the surface, smoothing micronerings;

Therefore, you can use SHRUS-4 lubrication, Shell Gadus S2 V220AD, etc.

2.5 parts of the oil are needed for 1 part of the CVA. Such a mixture during idle is relaxed over time, but there will be constant mixing in the Ushm.

The amount of lubricant should not exceed 1/2 of the gearbox volume. No need to apply to capacity. It will climb out of all the cracks and the gearbox will be very hot.

Duplicates were not found

You say correctly. The gearbox rarely dies first.

The approximate parameters of the Ushm are known, so you can do as mechanics-profiles with machine-building formations: the gear lubrication of the parameters will go on, the sites of sellers of lubricants for gearboxes are found and they take the right.

It would be necessary to replace in the Chinese drill a lubricant with normal, otherwise the gear nozzles are very, as if they had not been added or the lithola was drinking.

Most likely this gearbox was already a cunt and both details of the joints want to replace. Check the bearing too, there is a chance for replacement both on the head.

The jamming of the gearbox for Ushm does not threaten nothing. But you can tear it out of your hands. There is little pleasant. Medicine will come out of at least 2 orders of magnitude more than the replacement of two serial pieces of iron, moreover, sold.

Just bought a drill. 4 holes for 8 mm in metal 30 mm drilled. Noise immediately. So, there is still a chance to save a lubricant.

But the fact that? Well, the male will flow out. But percent up to 80 of the volume of the head if you fuck, it will not even notice. 50 percent of filling is usually normal.

I wrote about this in the article. “no more than 1/2”. From a large number, the gearbox begins to bask hard.

Unobvious moment: the gearbox is very warm not from lubrication, but from a large amount of lubrication. Bearings can be an example. The most important condition for ensuring the normal temperature regime of the bearing is the degree of filling with lubrication of the cavity of the bearing. The lubricant should take 2/3 of the cavity of the bearing at a rotation frequency of up to 1500 rpm and 1/2 of the volume at a rotation frequency of more than 1500 rpm. If there is too much lubricant in the bearing, the bearing overheats from high hydraulic friction. Overheating leads to increased wear of the bearing and loss of lubrication properties. The same with the gearbox. The more lubricant, the more work is done in a thick environment to push it, drag and chat (in simple words).

The plus is the heating of the electric motor from the excess load to overcome the lubrication resistance. This is physics and chemistry.

An experiment on this topic was conducted by Evgeny from Belgorod on YouTube. Channel “Evgeny Belgorod” The name of the video. “This is the top of idiocy. Do not do this with your grinder “

What lubricant to lubricate the gearbox grind

Bulgarian in the household the desired and useful tool. With the help of this device, you can engage in professional activities, or you can carry out repairs at home. The effectiveness of the operation of the grinder depends on the quality of care.

I have long understood that the quality work of any tool and mechanism requires the mandatory.Service. Bulgarian lubrication for a grinder is a product that allows the tools to provide a full protection against negative effects.

Readers will agree with me that many do not know what lubricant to use for the gearbox of the grinder. People do not have the idea of what principle the composition is selected and what to pay special attention to. All these nuances will be considered in the presented article.

General rules for replacing a lubricant

The main Ushm module is a gearbox. It is this part of the grinder that experiences the maximum load. The block includes different elements that contribute to rotation. Once in the tool case, the substance reduces friction. The compositions used for the Ushm gearbox allow reducing the temperature indicators that occur during operation.

During the work of the grinder, the mixture for lubrication is gradually scattered within the body. After a while, the substance begins to dry, and lumps are formed in the work. These pieces collect particles of dust and metal, therefore, a quick replacement of the oily composition is needed. Sometimes the problem occurs due to high temperature. The lubricant heats up, flows out, and the gearbox is left without a protective mass. It is important to replace it in a timely manner.

Lubrication for the gearbox Golarka. Which one to choose?

Angle.Grinding machines (Ushm) are widely used in people who love to craft and carry out various repair and construction work at home. Such tools allow not only grinding various surfaces, but also cut stone, metal, plastic and other materials. Ushm. Reliable tools that require competent maintenance during operation, in particular. Timely lubrication replacement. Let’s talk about the choice of lubricant for the gearbox and Ushm bearings.

In the Bulgarian, the main node, which during the operation of the tool is subjected to the greatest loads, is a gearbox, which is a design of scobed gears. During the operation of the Ushm, the rotor creates a rotational moment transmitted to the working tool through a small gear to a large gear. High.Quality lubricant for the grinder reducer significantly reduces the heating temperature, friction power inside the tool and reduces the wear of its parts.

Lubrication reduces friction of the parts inside the gearbox

The bearing of a grinding machine also needs periodic lubrication, especially the supporting bearing of the spindle of a large gear. For this, it is necessary to use only high.Quality, reliable compositions recommended by manufacturers of the Bulgarians. Experts recommend using oils with the following technical characteristics:

- Viscosity up to 800 PA C;

- Strength of more than 120 Pa;

- The temperature of the drop is more than 120 ° C;

- Lack of mechanical impurities;

- Resistance to corrosion processes;

- The ability to retain firmly on the details of the grinder;

- High temperatures resistance;

- Water.Repellent properties.

When choosing lubricants, it should be borne in mind that two types of bearings are used in a modern grinder. For the electric motor and for the gearbox. For them, it is necessary to use different compounds, since bearings differ from each other in different working conditions.

For foreign stamps of Ushm, it is recommended to use specialized compounds designed specifically for such a power tool. Most often, manufacturers of Bulgarians recommend using lubricants on which there is such a marking-MOS2 NLGI 2 ISOL-XBCHB 2 DIN 51825-KPF 2 K-20. The following information can be obtained from this marking:

- MOS. An indication of the additive material used (number 2 is molybdenum);

- NLGI2 is a viscosity class, here it is the second;

- ISOL-XBCHB 2-confirms the compliance of the materials with the ISO standard;

- DIN, KPF, K-20-confirms compliance with the German quality standard DIN;

- Figures 51825 mean that the material is classified as “k”.

This marking confirms the highest quality of the material, but such lubricants are very expensive. You can buy high.Quality oil is much cheaper, each manufacturer of the Bulgarian creates its own special lubricant, the use of which will extend the life of Ushm and guarantees the excellent work of the tool. On the market you can find compositions from Makita, Bosch, Hitachi, Redverg, Metabo, Intercker and many others.

Manufacturers insist that when servicing the tool, it is necessary to use their own lubricants. The use of the composition of another brand can cause guarantee for refusal.

Given the high cost of grease for power tools from foreign manufacturers, in some cases it is easier to use domestic analogues. In recent years, Russian manufacturers have been actively creating universal compositions of the highest quality that are not inferior to Western samples and suitable for a variety of tools. In addition to gearboxes and bearings of the Bulgarians, they can be used for drifts and perforators.

Among all the domestic lubricants presented on the market are most popular among consumers, thanks to the best ratio of price and quality, the products of Nanotek Metalplak Electra are used. This company produces a number of high.Quality materials that can be selected to lubricate the nodes of any tools.

Tips for lubricating the screwdriver gearbox and tool care

What lubricant to use for a screwdriver. Old school professionals will best answer this question. In addition to modern lubricants, many still use time.Tested Litol-24. It can be bought in any profile store and it will cost inexpensively.

- Before lubricating the gearbox, it must be cleaned of old lubricant, dirt and at the same time rinse the rest of the elements. It is better not to touch the bearings. After cleaning, wipe all the details dry. Do not rinse the gearbox with gasoline, solvent and other caustic liquids.

- After all the manipulations, grease the gearbox with fresh grease and place in the case. When a screwdriver is turned on, the remaining lubricants may seep. There is nothing wrong with this. Excess oil can be removed with a napkin or a rag.

- The screwdriver itself requires no less care. For the tool to work for a long time and without breakdowns, it should be kept clean. After work, the unit needs to be cleaned from dust with a rag or soft rag.

- It is unacceptable to get into the screwdriver of moisture and water. Store the tool in a dry room. You can not throw a screwdriver, and you should also try to protect the batteries from shocks. In the case of a network unit, make sure that there are no bending and twisting cable.

- If during operation there are problems in the tool, power elements or charger, it is advisable to stop the work. With serious breakdown, it is better to contact the service center. It will save time and finances. Minor malfunctions can be settled yourself without resorting to the help of specialists.

Tips for lubricating the screwdriver gearbox and tool care

What lubricant to use for a screwdriver. Old school professionals will best answer this question. In addition to modern lubricants, many still use time-tested lititol-24. It can be bought in any profile store and it will cost inexpensively.

- Before lubricating the gearbox, it must be cleaned of old lubricant, dirt and at the same time rinse the rest of the elements. It is better not to touch the bearings. After cleaning, wipe all the details dry. Do not rinse the gearbox with gasoline, solvent and other caustic liquids.

- After all the manipulations, grease the gearbox with fresh grease and place in the case. When a screwdriver is turned on, the remaining lubricants may seep. There is nothing wrong with this. Excess oil can be removed with a napkin or a rag.

- The screwdriver itself requires no less care. For the tool to work for a long time and without breakdowns, it should be kept clean. After work, the unit needs to be cleaned from dust with a rag or soft rag.

- It is unacceptable to get into the screwdriver of moisture and water. Store the tool in a dry room. You can not throw a screwdriver, and you should also try to protect the batteries from shocks. In the case of a network unit, make sure that there are no bending and twisting cable.

- If during operation there are problems in the tool, power elements or charger, it is advisable to stop the work. With serious breakdown, it is better to contact the service center. It will save time and finances. Minor malfunctions can be settled yourself without resorting to the help of specialists.

Home workshop: how to repair a screwdriver gearbox?

Any tool, regardless of the model and brand, sooner or later undergoes breakdowns. Scrolls are no exception: individual parts and nodes wear out over time, and without proper care or under force majeure may refuse.

The main functional load during the operation of the tool is distributed through the gearbox between the engine and the cartridge, so if something happens to the gearbox, the work will become. In order not to spend money on the services of the repair service, it is enough to use the advice of the masters to restore the work of the unit yourself.

What is the principle of the planetary gearbox of the screwdriver?

The planetary gearbox at the drill, as in other mechanical devices, is designed to reduce or increase after transmission from rotation of the twisting moment, reduce the load on the input shaft of the engine and increase the load on the output.

Gearboxes maintenance tutorials l Episode #2 l Lubrication (English subtitles)

- The solar gear, which is located in the center of the planetary gearbox, is driven by the rotating shaft of the engine.

- Several (minimum) gear gears are driven from the solar gear, the gear ratio is already changing.

- From the gears around the solar gear, the rotation is transmitted to the coronal gear, which closes the mechanism and transfers rotation to the output shaft.

- Then a repeat of operation is possible if it is three.Speed.

- So at the output we get a different speed and power.

The advantages in the use of such gearboxes are the durability of the tool with increasing its power due to gear ratings.

The principle of operation of the planetary gearbox is a decrease in revolutions included in the gearbox and the transformation of their decrease into power traction. In general, as a conventional gearbox.

The little gear turns large because of this, the turns decrease, but the traction force on the shaft of the large gear increases directly in proportion to the reduction in speed.

Only in an ordinary gearbox, a small gear spars the larger one itself without intermediaries, and in the planetary through planetary gears, their number can be different 2-3-4-5-6 or more.

That is, a small lead gear does not apply to a large driven.

Now what is it for, and in order to unload the teeth and a large and large gear, since in the planetary gearbox of teeth that transmit the load at times more than the usual, respectively, and they will withstand more together more!

Therefore, it can be used for the manufacture of such gearboxes cheaper and light in processing materials, such as plastic, and working in the planetary gearbox, they will withstand a sufficient load, having served enough time without wearing out without wears.

The planetary gearbox, among other things, is more stable and sparing bushings and bearing, since the load is distributed throughout the gearbox in it, and not since the usual one from one contact side.

That’s why they use such gearboxes in screwdrivers to provide good craving and effort with not bulky details.