What scissors cut a metal -plastic pipe. Optimal

the best scissors for cutting plastic pipes

To collect a durable, high.quality pipeline made of plastic or metal.plastic tubes, it is important to correctly connect individual elements to each other. Before connecting, the pipe must be cut according to the required sizes. The best option is the use of specialized scissors for cutting tubes. To choose the right tool, it is worth studying the rating of the best models of 2021.

To date, you can find many different scissors for cutting plastic pipes on sale. All of them can be divided into several varieties depending on the structural features, the principle of operation.

- The roller externally resembles a hook. On the inside of the scissors are movable videos. During the cutting of the pipe, it turns on the rollers, due to which the incision is created. To move or bring the cut, you need to strengthen or loosen the pressure on the spring. One of the advantages of this type of tool is the minimum pipe compression during cutting, as a result, an even cut is obtained. However, in the process of cutting, you need to use two hands.

- Precision. the simplest in design scissors for PVC pipes. To use them, it is enough to use only one hand. Suitable for cutting tubes with a diameter of not more than 42 mm. Improved models allow you to cut pipes with a diameter of up to 7 cm.

- Tool with a ratchet mechanism. They can be called upgraded roller scissors for metal.plastic pipes. The main feature of the ratchet mechanism is a more convenient work process, when cutting the tubes, you do not need to apply too much effort. Another structural feature is the presence of a wide support.

- Guillotine. This type of scissors for cutting polypropylene pipes belongs to a professional tool. They are suitable for cutting pipes with a diameter of up to 36 cm, are actively used in the installation of industrial pipelines. In the process of cutting, it is not necessary to apply significant effort, the cuts are most even as possible.

- Telescopic. A specialized tool, the design of which consists of guides, mobile carriage, rollers. The main feature of such scissors is the ability to adjust the working part for pipes of various diameters. Very often supplemented by the granular.

A separate group. battery scissors for polypropylene pipes. This is a standard hand tool that works in automatic mode. With their help, you can get clean cuts with high speed without serious effort. Most often used to lay large networks where plastic, metal.plastic pipes are used.

What to look for when choosing

Choosing scissors for PVC pipes, it is recommended to pay special attention to the following moments.

- Material of the manufacture of the blade, the angle of its sharpening. The best option is stainless steel, with an angle of 30 degrees.

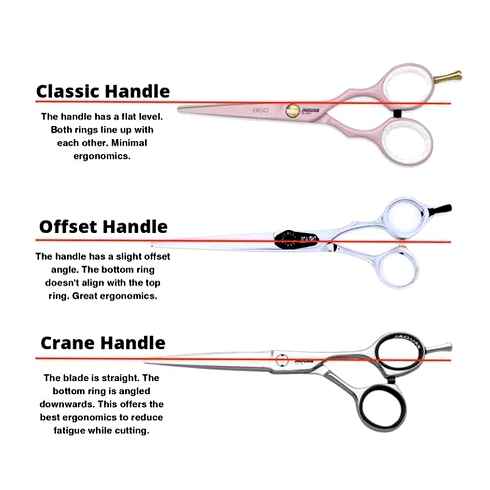

- The shape of the handles, the presence of rubber linings for more convenient work with the tool. It is recommended to try scissors before buying, hold them in your hands to determine the level of comfort when working with them.

- The mass of the tool. Affects the convenience and duration of work with scissors.

- The dimensions of the basis of the tool. The wider it is, the more even the cut.

- Type of drive. manual or on the battery.

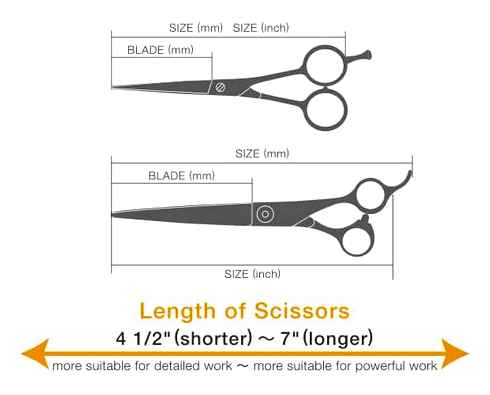

The most important parameter when choosing scissors is the maximum allowable diameter for cutting pipes. The possibilities of their use depend on this.

How to choose scissors for cutting polypropylene pipes

We took the 7 best scissors for cutting polypropylene pipes into a review. All of them are sold in stores when distributing places took into account the opinion of experts and reviews of amateur installers.

Rating of the best scissors for cutting polypropylene pipes

| Nomination | place | Name of product | price |

| Rating of the best scissors for cutting polypropylene pipes | one | Valtec with a diameter of 40 mm | 665 ₽ |

| 2 | Rothenberger Rocut 42 TC 52000 0-42mm | 4 520 ₽ | |

| 3 | VIRAX RS-32 | 1 796 ₽ | |

| four | Ridgid 1442n | 5 535 ₽ | |

| 5 | REMS Ros P 42p | 6 650 ₽ | |

| 6 | Universal Fit 63mm scissors | 2 700 ₽ | |

| 7 | Mgf Unique 63 | 6 150 ₽ |

Valtec with a diameter of 40 mm

The winner of our rating was the available and high.quality Valtec scinals with a diameter of 40 mm. The manufacturer is confident in the reliability and durability of his product, confirming this with a 2-year guarantee. Silumine was used for the manufacture of the case, due to which it was possible to reduce the weight of the tool to 0.406 kg. On average, scissors withstand about 5000 cuts. Using the model, you can cut pipes with a reinforcing layer thickness up to 0.6 mm. The range of pipe products is quite wide, starting with polypropylene and ending with metal polyprems. The manufacturer equipped the scissors with a ratchet and a spring dilution system.

Users are satisfied with the work of scissors, they are most often bought by novice installers. The disadvantage is considered to be a cut curve on large diameter pipes.

Specifications

There are several types of cutters for metal.plastic pipes:

- Khrab cutter. Precision scissors that are suitable for cutting tubes with a diameter of up to 100 mm. Working parts. sharp metal blades. The part is fixed in the clip, the incision is performed.

- Roller cutter. A universal tool that has a C-shaped clip. Large or small videos are installed on different models. The former are suitable for cutting parts with a diameter of up to 125 mm, the latter. up to 50 mm. For cutting, you need to rotate the pipeline around your axis. The videos begin to move towards each other. Since the rollers rotate, cutting, not squeezing.

- Guillotine. Produces uniform cuts over the entire area of parts. The output is flat sections without burrs, bumps. The blade can fall through the rotation of the valve or by the principle of the pistol.

A separate type of pipeline. a mechanism with a clamp latch. The principle of operation of this instrument is similar to a roller cutter, but the workpiece is clamped from all sides, which ensures reliable retention, reduces the risk of irregularities.

Rates of the pipe (

The principles of choice

Before buying a cutter, you need to decide how to cut a metal.plastic pipe. If you need to perform several single cuts, you do not need to buy expensive tools, for this you can use a hacksaw or corner grinder. To collect the pipeline in the entire house you will need a pipeline.

- In order not to stop working because of the dull rollers or blades, you need to choose a complete set with additional working units.

- When buying tools, you need to take into account the diameter of the tube that needs to be cut.

- To facilitate installation work, you can choose a cutter with the ability to remove chamfers.

Advantages and disadvantages

The disadvantages of the pipelines include their high price, which depends on the maximum diameter.

Different type pipelines (

Manufacturers and cost

The price of tools depends on the quality, the availability of additional mechanisms, the maximum diameter of the tube cutting. Manufacturers:

- Sturm. goods of this company are suitable for beginners, lovers. Average

- WMT is a company that produces budget cutters. Average

- Ridgid, Kalde, Milwaukee. manufacturers of professional tools. Average

In construction stores, in the markets you can find cutters

Tips for choosing a suitable pipeline

Choosing a good pipeline for metal.plastic pipes, you should find out what functions, except for the main. cuts, they can possess. Some models can not only make a perpendicular cut, but also remove the chamfer of 15-30 degrees, sometimes even at the same time with a sharp. The chamfer simplifies the installation of fittings.

Roller pipelines can reserve a groove. irregularities and roughnesses that spoil the appearance of the cut and operational indicators.

A good tool will be equipped with a special nozzle for removing a grata. It resembles the surface of the file, put on instead of a disk rotating blade, and the cut is processed according to the same principle as cutting. by turning the device around the pipe.

The blade can dull and, most often, this happens at the most incorrect moment, when the work is in full swing and I do not want to sharpen the sharpening of a pipeline at all. In this case, it will be very useful such an element of standard configuration as a spare video. The sharpened “reserve” will always help out in an emergency situation.

Manufacturers conduct hundreds of tests and create many prototypes that allow you to create a pipeline with an ergonomic handle when each finger is “in its place”, and the work does not cause discomfort

Ergonomicity. this criterion is one of the fundamental when choosing a manual pipeline for metal.plastic pipes. The tool that you will use often and in large volumes should be comfortable, lie well in your hand and not slide. Work is carried out with one hand, while you should not feel fatigue.

Preparatory stage

The preparatory stage involves stripping tubes from irregularities. To do this, it is more convenient to use a connecting clutch. After that, you can start cutting a metal.plastic pipe.

Cutting technique

You can not use tools not designed to cut metal.plastic. They can damage the material, leave irregularities, burrs. You also can not try to bend the pipe with your hands. To do this, use the pipe.

When cutting, you cannot make great efforts. It is important to control the process so as not to damage the part. The marks of future cuts can be left with a pencil or marker. You can not use sharp objects for this.

Technical features

Yourself, without certain skills, you can cut tubes with a diameter of up to 30 cm. If the dimensions are larger, you need to seek help from experienced installers. It is not recommended to cut parts in hot weather under direct sunlight. The material is heated, the cut mark will shift to the side.

It is important to read the technical passport of parts in advance if it was issued when buying. If it contains more plastic than metal, work must be carried out quickly. If the metal is larger, you need to choose a tool that will have the least friction. After cutting, the tube must be wiped with a damp cloth to remove dust, garbage.

If there is no pipeline under your hands, you can use a knife with an Sergey sharpening. You need to lubricate the blade in advance with machine oil, check its sharpness.

Due to the improved technical characteristics, metal.plastic pipes are very popular. To cut them, you can use an angular grinder, a knife for metal, a sharp knife or a pipeline. The latter option is preferable, since the sections will turn out to be even, without burrs. In addition to this, you do not need to spend too much effort.

How to choose a pipe for pipe from plastic

When choosing a pipeline, you should rely on the expediency, volume of work, the purpose of the tool and your material capabilities. A pipeline is a professional tool that requires skills.

What pipelines are recommended for certain work:

- One.time wiring of metal.plastic. scissors or guillotine pipeline.

- Installation of communications with a diameter of up to 50 mm of any plastic networks. scissors or guillotine manual tools.

- Installation of plastic. communications from 50 mm diameter. roller pipe cutter.

- Installation of large diameter networks or areas in hard.to.reach places. chain pipe cutter.

note! If you opt for an expensive tool, while not having a locksmith of 4-5 categories, then in case of its breakdown, the manufacturer will not take responsibility for a spoiled pipe cutter.

Types of tools

There are several varieties of pipelines for metal.plastic. The tool may differ in terms of action, cost, cut quality.

Manual and electric

A manual type pipeline requires an application of muscular effort. Such a tool is convenient for its autonomy, small dimensions, the lack of a binding to an electric network or charging the battery.

How to execute a chimney pass through a roof from a metal tile with your own hands

It is perfect for household tasks, however, for large volumes of performance of this tool, it will clearly not be enough. In addition, a hand.made pipeline will not cope with large.section products and thick walls.

If metal.plastic pipes must be cut constantly and in large quantities, it is worth paying close attention to electrical models. The role of man here is minimized. You just need to apply a mark onto the pipe, fix the product so that the marks in the observation window and on the pipe coincide, and start the cutting process. The cut is guaranteed to turn out even and smooth.

Of the disadvantages of devices of this type, we note the high cost, relatively considerable dimensions and dependence on the availability of power source (battery or a standard power supply).

Classification by type of cutter

The cutting mechanism of the tool can also differ in the method of influence on the pipe. According to this criterion, pipelines for metal.plastic are divided into:

- Roller. Equipped with one or more mobile rollers fixed on the C-shaped curved platform. The number of rollers, as a rule, determines the maximum thickness of the pipe with which you can work. The metal.plastic pipe is clamped in the clip, the label of the future cut is combined with the cutting element, after which the tool begins to rotate around the axis of the pipe. With each turn, the cutter approaches the pipe, gradually deepening into its surface and dividing it into two parts. The blade does not press with force on the wall of the pipe, but cuts it out gradually, so the cut turns out to be more even and clean. A small number of burrs can form due to the fact that cutting is carried out with jerks with a slight movement of the part. expensive models with telescopic course are deprived of this lack.

- Guillotine type. Such a tool eliminates the probability of deformation of the cut area due to the uniform application of the load. The blade of the device can fall through the rotation of the handle, or in more expensive models, after pressing the hook of the trigger mechanism. The guillotine option effectively works with pipes with a cross section of up to 100 mm.

- Framing. Act on the principle of scissors. Designed for pipes with a cross section of up to 100 mm. Working element. sharp steel blade. The pipe is placed in a semicircular recess on the tool case. After fixing and applying the label, the handle is closed, and cutting is carried out. Rates are simple in design and affordable. Also suitable for cutting polypropylene products. The main drawback of such tools is the probability of flattening the ends of the pipe (additional processing by the caliber is required) and the inability to guarantee the perfect perpendicular cut of the cut.

- With a clamp latch. Improved model of roller pipeline equipped with special devices for tight fixation of the pipe.

How to choose a pipeline

When choosing a specific pipeline model, you should pay attention to what additional functions can perform the tool. Some models simultaneously with the pipe cut the chamfer, which seriously simplifies the subsequent installation of connecting fittings.

The roller varieties of the tool are often left at the site of the cut of unevenness and roughness, which spoil the appearance of the product and reduce the operational characteristics. A good pipeline will be equipped with an additional nozzle resembling the surface of a small file to remove such defects.

note! To avoid problems with the blade that can swell at the most crucial moment, you should always have a shift at hand.

If the tool is purchased for everyday professional application, it is worth paying special attention to the ergonomics of the device. Each of the options you like must be held in the hand, giving preference to a more convenient model.

Features of cutting metal.plastic pipes. How the cutting of a modern pipe from a metal.plastic base is carried out?

Scissors cutting procedure can be performed with one hand. No special efforts need to be made. This is due to the fact that a gear rake is located on the blades that simplifies the processing process of metal.plastic pipes.

Important! With the help of scissors, metal.plastic pipes are cut with a diameter of up to 40 mm. For larger products, it is better to use pipelines. They are characterized by higher power.

In addition to the scissors, you will not need any special tool for cutting metal.plastics. The procedure is as simple as possible. Even a non.specialist can even cut the pipes.

Only the following actions should be carried out: 1. Pipe marking. 2. Fixing the pipe. 3. Directly cutting procedure.

Important! The cutting process is completely non.current. After it there are no crumbs. Thanks to this, you can immediately start assembling pipes.

Manual and electric scissors for processing metal.plastic pipes

Scissors for cutting can be: 1. Manual. Such models are ideal for cutting small products (pipes with a diameter of up to 30-40 mm). Hand pipelines developed for metal.plastic pipes are activated due to muscular strength. You can use them in any conditions, even in the absence of access to electric networks. Thanks to this, such a cutting tool is popular at construction sites.

Important! If you plan to cut metal.plastic in large volumes, a hand tool will not be enough. In addition, with constant cutting, the operator will simply get tired after a couple of hours. This will reduce the performance of the process.

Electric. Such a tool for working with a metal.plastic pipe is more universal. As a rule, it is used by professionals in various sectors (construction, housing and communal services, etc.). Electric pipelines allow you to reduce not only the efforts of the operator, but also the risks of influencing the quality of the cut of the pipe of the human factor. Such a tool works from the network. The operator is enough to apply the desired marking and fix the part.

The advantages of the instrument include the possibilities for obtaining clear and even cuts.

Best Hacksaw Blade For Cutting PVC Pipe 2022 [Top 6 Picks Reviewed]

Of course, the cost of electric scissors for metal.plastic pipes is quite high, but with constant use, the device will quickly pay for itself.

Advantages of working with polypropylene

The advantage of polypropylene pipes is their ability to withstand minus temperatures and at the same time not to break. This is especially true in country houses, where gas and power supply at times may disappear. That is why the owners of cottages and cottages prefer to use polypropylene pipes in plumbing communications systems.

In turn, the presence of scissors for cutting polypropylene pipes allows you to instantly correct the malfunction arising in the home pipeline. It is enough to simply cut the damaged part of the pipe and replace it with a new. At the same time, all work will take no more than half an hour. But if there are metal pipes, replacing the pipeline section will be carried out at least a few hours.

In general, polypropylene communications are successfully used at temperatures up to sixty degrees. If there is a need to transport fluids up to ninety.five degrees, then reinforced pipes equipped with a thin aluminum shell from the outside are used. It is this shell that prevents sagging and softening of products.

Before welding, the outer shell on reinforced pipes must be cleaned. For this there is a special knife that removes the coating of aluminum exactly to the depth of welding.

Today, some enterprises began the production of products whose reinforcement is made from the inside. In this case, preliminary stripping is not required for welding.

Pipe cutters wholesale from the manufacturer

The company “Masterprof” carries out wholesale and retail trade, and is also a manufacturer of scissors for cutting pipes (pipelines) supplied to private plumbing stores and large DIY store stores. We provide a detailed price list for the entire assortment, have wide opportunities for payment and delivery, as well as provide advice on any issue. Over the years, we established partnerships with many stores and suppliers.

Our experts will help organize their own business and choose the necessary products.

There were questions? Call or write. we will answer. Phone: 7 812 309-53-81 E-mail: Info@MasterProf.SPB.ru address: St. Petersburg, st. ZASTAVSKAYA, 5/1.

Hand.bearing manually when mounting pipes made of metalloplasty

Metal.plastic structures during installation often have to bend. If the bending angle is small, and the length is significant, then this operation can be done manually. However, it is recommended to divide it into several stages, approaches. This is done for the only purpose: to prevent haste to turn into a change in the transverse section of the product or the formation of folds on its concave side, or hopeless deformation. The length of the bending section should be seven times larger than the diameter of the pipe.

The metal.plastic pipe can be bent manually using a spring of a suitable diameter

If there is no special tool at hand, then you can use it for bending:

Using a spring of suitable diameter allows you to avoid deformations when bending the structure. The sand covered from one end (as a kind of spring) will not be deformed when the second end is closed. Uniform heating of a metal.plastic structure on all sides with a soldering lamp or a building hairdryer can be used, combining with other bending methods or as an independent way. After heated, the bend is set by a single impact of the hands.

Method That Surprised 40 Year Old Plumber! Fix Plastic Pipes With Bread

At home, you can use a spring mechanism to flex the metelloplastic pipes. It will be necessary to choose a spring of the desired cross.section and length with one extended end, for the convenience of use. The use scheme is as follows:

- Steel wire is connected to the cross.sectional and length of the spring.

- The pipe is inserted into the pipe (or vice versa).

- The spring is located in such a way that its center coincides with the center of the planned fold.

- Flexion is made, possibly with the use of an emphasis in the form of your own knee.

- The spring is removed by stretching the steel wire attached to it.

Manual pipe bend will be able to bend the pipe with a diameter of not more than 50 mm

Metal.plastic pipes.

Early or a little later, there is a need to replace old pipes with new.The question involuntarily arises: “And from what to make a new pipeline?»Copper, metal.plastic, polypropylene or iron? There are of course options, but they are less common. Personally, from iron, I make wiring extremely rarely. We can say that I practically do not, but there are people who want iron and that’s it. I don’t work with copper. Polypropylene and metal.plastic remains. Let’s start estimate. What is it and how to mount it.

But before we start, I will still explain a little why I do not like to make iron wiring and copper. Iron. heavy delivery and inconvenient in installation. Copper is also not very light, not convenient in installation, but also the pipes turn green if they are in a humid environment. And the most important drawback of copper is the price.

And so first of all, you need to decide on the tool. We will need: a calibrator for metal.plastic (reduce to. m.P.) pipes, scissors on m.P., pipe-beam or turbot spring, ramps, linen and unipak, or fum-tape/Teflon tape.

Almost always, a metal.plastic pipe, it is necessary to shake the metal. For these purposes, there is a transition from a metal pipe to metal.plastic, otherwise it is called. fitting. In order not to collect everything in one porridge, I divided this post into several parts. Based on this, about crimping and pressing fittings, you can read in another section. Now it will be discussed directly, about the metal.plastic pipe itself. How to cut, how to bent, and how to fix it.

Metal.plastic pipe is supplied in bays up to 200 meters. Cm. Photo above. Sold from one meter long. Pipes diameters are different. The most popular sizes in our house are 16, 20 and 32. MP diameter is up to 63mm. Intra.apartment wiring, usually made of 16 and 20 megapixels pipe.

What is a metal.plastic pipe?

MP pipe, consists of a layer of plastic, then an aluminum tube, which is welded with a laser or ultrasound overlap, and another layer of plastic. (Plastic. polyethylene). All three layers are glued together with special glue, the composition of the glue in each manufacturer has its own. Actually the reliability and durability of the pipe depends on it.

The inner layer of plastic, very smooth, which does not allow rust and other craps on the walls of the pipe as on iron pipes.

This is what an iron pipe looks from the inside. Pipe size 120 mm. Apartment risers and wiring are clogged completely. To dig/clean something cunning, useless waste of time. This growth is very solid. I would even say. stone.shaped.

Metal.plastic pipes, very convenient in installation, are easy to bend. Used for cold water supply and hot. You can also make a heating system from them, including warm floors. The pipe can be equally used both on the street and indoors. When used on the street in winter, the pipe should be thoroughly insulated or equipped with an electric port from. Otherwise…

When installing the pipe, you need to take into account the factor of the extension of the pipe. How to do it? And hell knows, probably there is some formula. If you also do not know how to calculate, then leave the pipe with a margin during installation. Never mount it in an eye. Attach the pipe to the wall, you need to be special clips, and not with rigid clamps. The pipe should be able to walk in the places of fastening.

These are the same clips that allow the pipe to move.

First of all, the pipe must be straightened. We step on the edge of the pipe and align it on the floor.

Than cutting? There are special metal.plastic scissors for this. For example, this type:

No comment. The process of pipe segments is visible well. Next, somewhere you have to bent the pipe. Without specially (pipeline) device, bend the pipe carefully, is very difficult, and sometimes unrealistic.

Without a pipeline, the pipe can be bent until a certain point, then. it will break.

At first glance, we can say that it has not broken. But if you straighten it, then the inner aluminum tube will be broken. And such a pipe will not be able to keep for a long time, at least some water pressure. To prevent this from happening, you need a pipe bastard for an MP or a spring of a suitable diameter.

And for the total completeness of the picture, I recommend viewing topics on how to combine fitting with a pm pipe, about crimping fittings, and a little about press fittings.